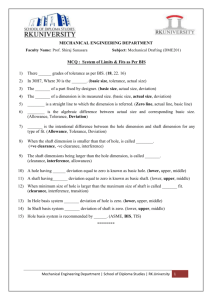

Definition of Limit, Fit and Tolerance: The extreme permissible values of a dimension are known as limits. The degree of tightness or looseness between two mating parts that are intended to act together is known as the fit of the parts. The character of the fit depends upon the use of the parts. Thus, the fit between members that move or rotate relative to each other, such as a shaft rotating in a bearing, is considerably different from the fit that is designed to prevent any relative motion between two parts, such as a wheel attached to an axle'. Tolerance on the other hand is the total amount that a specific dimension is permitted to vary. It is the difference between the maximum and the minimum limits for the dimension. The extreme permissible values of dimensions of a mating part are known as limit. Due to the inevitable inaccuracy of manufacturing methods, a part cannot be made precisely to a given dimension, the difference between maximum and minimum limits of size is the tolerance. When two parts are to be assembled, the relation resulting from the difference between their sizes before assembly is called a fit. HOLE SHAFT Max Hole size – Basic Size = Upper Deviation Max shaft size – Basic Size = Upper Deviation Min Hole size – Basic Size = Lower Deviation Min shaft size – Basic Size = Lower Deviation CLEARANCE FIT Maximum shaft dimension < Minimum hole dimension Condition of looseness or tightness between two mating parts being assembled together INTERFERANCE FIT Maximum Hole size < Minimum Shaft size TRANSITION FIT Obtained by overlapping of tolerance zones of shaft and hole Does not guarantee neither clearance nor interference fit To obtain different types of fits, it is general practice to vary tolerance zone of one of the mating parts HOLE BASED SYSTEMSize of hole is kept constant, shaft size is varied to get different fits. SHAFT BASED SYSTEMSize of shaft is kept constant, hole size is varied to get different fits. Allowance: Allowance is calculated as the difference between the maximum shaft size and minimum hole size is known as allowance. It is a amount of designed (intentional) deviation between two mating parts of dimensions in a fit. In a clearance fit it is have a minimum clearance and is positive allowance. In an interference fit it is have a maximum interference and is negative allowance. Allowance is the difference between the dimensions of hole and shaft. The selection of letter freezes one limit of hole / shaft (how much away from Basic size) Representation of Tolerance 1) Letter Symbol Basic Size 45 E8/e7 One can have different possible combinations; eg. 45H6g7, 45H8r6, 45E5p7 E.S. – upper deviation E.I. – lower deviation H : lower deviation of hole is zero h : upper deviation of shaft is zero Representation of Tolerance 2) Number or Grade IT01, IT0, IT1,….IT16 Tolerance Grade defines range of dimensions (dimensional variation) There are manufacturing constraints on tolerance grade chosen D =√ (D1×D2 (Geometrical mean diameter) Standard or fundamental tolerance unit Tolerance Grade IT5 IT6 IT7 IT8 IT9 IT10 IT11 IT12 IT13 IT14 IT15 7i 10i 16i 25i 40i 64i 100i 160i 250i 400i 640i or Zone Tolerance Magnitude Tolerance Magnitude RANGE or Distribution IN A GIVEN TOLERANCE GRADE Upper and lower deviations Tolerance on Components Example 3. A medium force fit on a 75 mm shaft requires a hole tolerance and shaft tolerance each equal to 0.225 mm and a maximum interference of 0.0375 mm. Determine the proper hole and shaft dimension with the basis hole standard. Minimum diameter (lower limit) of hole: Dmin = 75 mm Maximum diameter (higher limit) of hole: Dmax = 75 +0.225 = 75.225 mm Minimum diameter (lower limit) of shaft: dmin = Dmax + maximum interference dmin = 75.225 + 0.0375 = 75.2625 mm Maximum diameter (higher limit) of shaft: dmax = dmin + tolerance = 75.2625 + .225 = 75.4875 mm H8-f7 f7 = 59.97- 0.030 = 59.94 mm Example 5. In a limit system, the following limits are specified to give a clearance fit between a shaft and a hole: Determine:(a)basic size (b) shaft and hole tolerance (c) the maximum and minimum clearance (a) Basic Size: 30 mm (b) Shaft tolerance: Tolerance = upper limit – lower limit = -0.005 – (-0.018) = 0.013 mm Hole Tolerance = 0.02 mm (c) Shaft Limit: High limit (dmax) = 30-0.005 = 29.995 mm Low Limit(dmin) = 30-0.018 = 29.982 mm Hole Limit: High Limit (Dmax) = 30+0.02 = 30.02 mm Low Limit (dmin) = 30 mm (d) Maximum Clearance = Dmax- dmin = 30.02 – 29.982 = 0.038 mm Minimum Clearance = Dmin – dmax = 30 – 29.995 = 0.005 mm Example 6. A hole and shaft have a basic size of 25 mm, and are to have a clearance fit with a maximum clearance of 0.02 mm and a minimum clearance of 0.01 mm. The hole tolerance is to be 1.5 times the shaft tolerance. Determine: limit for both hole and shaft (a) using a hole basis system (b) using a shaft basis system.