Document 14649544

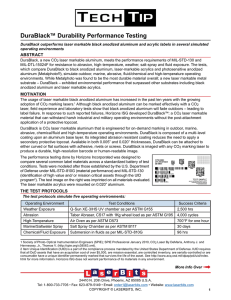

advertisement

Microhardness evaluation of pure aluminum substrate after laser surface alloying with iron and copper Abstract low level energy of Q-switched Nd-YAG laser was used to produce thin layers of Fe-Cu alloy on pure aluminum substrates. Two-step laser deposition (2SLD) method was employed. Pure aluminum substrates were pre-coated by a mixture of Fe and Cu powder (with the rate 1:2) using a suitable binder and then irradiated by partially overlapped laser pulses. Different parameters were conducted in order to obtain the suitable treatment condition. X-ray diffractometer (XRD), glow discharge spectrometer (GDS), optical microscope and microhardness tester were used to analyze the treated surfaces. According to XRD results, copper-iron phase (Cu9.9Fe0.1) was formed. GDS analysis showed that the weight percentage of Fe is higher than that of Cu within the modified layer. The average micro hardness of the modified surface was found to be four times higher than that of untreated surface.