Journal of Materials Science and Engineering B 1 (2011) 200-205

advertisement

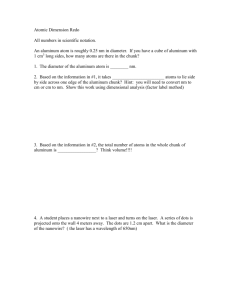

Journal of Materials Science and Engineering B 1 (2011) 200-205 Formerly part of Journal of Materials Science and Engineering, ISSN 1934-8959 Microhardness Evaluation of Pure Aluminum Substrate after Laser Surface Alloying with Iron and Copper Yusef Ab. Alwafi, Noriah Bidin, Rosli bin Hussin, Muhammad Shakhawat Hussain and Dwi Gustiono Department of Physics, Faculty of Science, Universiti Teknologi Malaysia (UTM), Skudai 81310, Johor, Malaysia Received: January 12, 2011 / Accepted: January 29, 2011 / Published: July 25, 2011. Abstract: A low level energy of Q-switched Nd-YAG laser was used to produce thin layers of Fe-Cu alloy on pure aluminum substrates. Two-step laser deposition (2SLD) method was employed. Pure aluminum substrates were pre-coated by a mixture of Fe and Cu powder (with the rate 1:2) using a suitable binder and then irradiated by partially overlapped laser pulses. Different parameters were conducted in order to obtain the suitable treatment condition. X-ray diffractometer (XRD), glow discharge spectrometer (GDS), optical microscope and microhardness tester were used to analyze the treated surfaces. According to XRD results, copper-iron phase (Cu9.9Fe0.1) was formed. GDS analysis showed that the weight percentage of Fe is higher than that of Cu within the modified layer. The average micro hardness of the modified surface was found to be four times higher than that of untreated surface. Key words: Laser alloyed, Fe-Cu powder, microhardness, laser plasma. 1. Introduction Among the various materials, aluminum has attracted the attention of many researchers because of its unique properties. Aluminum is the world’s most abundant metal and the third most common element comprising 8% of the earth’s crust. Aluminum has excellent technological properties; it can be easily rolled, forged, drawn and extruded practically to any required complicated shape [1]. However, its hardness, wear resistance and mechanical properties are poor in comparison to steel but such properties can be substantially improved by alloying and heat treating. One feature of aluminum is its ability to form many intermetallic phases with most common elements, such as Fe, Ni, Co, Cr, Ti, or Cu. The nickel and iron aluminides intermetallics, in particular, have received the most attention in recent studies [2-7]. The alloying process can be done by several techniques but laser surface alloying is considered to be the most effective technique for surface modification. The most important Corresponding author: Noriah Bidin, professor, research field: laser technology. E-mail: Noriah@utm.my. advantage of laser surface modification processes is the possibility of modifying the properties and composition within a thin surface layer without affecting the properties of the bulk material. In the present paper, the Fe-Cu laser alloyed on aluminum substrate is reported by using low energy laser. The microstructure analysis and microhardness of the modified surface is the subject of discussion. 2. Experimental Details The main purpose of this study was to increase the surface hardness of aluminum using a low power laser. Pure aluminum plate was used as a substrate. The plate was cut into small pieces; each piece has a surface area of about 2 cm2. These pieces were chemically cleaned and then coated by a mixture of Fe and Cu with the ratio 1:2 respectively using suitable glue. A Q-switched HY200 Nd: YAG laser manufactured by LUMONIC was employed as a source of energy. The laser was operated in repetitive mode. The pulse duration of laser is 10 nanosecond with variable output energy of within 10-100 mJ per pulse. Fig. 1 shows a schematic diagram of the experimental set-up. The laser beam was focused Microhardness Evaluation of Pure Aluminum Substrate after Laser Surface Alloying with Iron and Copper Trigger unit Power supply and cooling system 201 CCD video camera Filter He-Ne laser Nd:YAG laser Laser surface alloyed material Plasma formation Photodetector Translation stage Powermeter Fig. 1 Experimental set-up. using a convex lens with focal length of 30 cm. The power density at the focal point was estimated to be as 5 × 1015 W/m2. The energetic source at the focal point can be visualized by the appearance of optical breakdown and the plasma formation. The temperature of the plasma region is almost 1 eV (each eV is equivalent with 11,600 K) [8]. The plasma can expands in the free surface within 300 to 500 μs depend on the energy delivered at the focal point [9]. In this case the quench rate induced by plasma was estimated to be as 20 × 106-40 × 106 K/s. In order to avoid direct photodisruption, the samples were exposed at defocused distances. Experiments were carried out with different defocused distances to determine the suitable position of the samples with respect to the focal point. The precision location and the plasma formation were visualized and recorded by a charge couple device (CCD) video camera. A Helium-Neon (He-Ne) laser of 633 nm (red color) was also coaxial with Nd:YAG laser to guide the invisible light targeted on the specimen. After laser alloying process, all the treated samples were analyzed for evaluating the surface properties. Glow discharge spectrometer (GDS) was used to obtain a quantitative analysis of the alloyed layer. A Reichert Polyvar 2 Met optical microscope was utilized to evaluate the microstructure. The strength of modified surface was measured by means of HMV-2 Shimadzo microhardness tester. At least, 10 indents were made on each sample. The average of the indentations was calculated to find the hardness for each individual sample. The composition of the treated surface was also analyzed by using X-ray diffraction (XRD). In this work, two-step laser deposition (2SLD) method was used. Mixture of Fe and Cu powder was pre-placed on pure aluminum substrates. The thickness of mixture layer was about 0.8 mm. The alloying process was carried out in free space. 3. Results and Discussion A typical plasma formation induced by focusing the Q-switched Nd:YAG laser is shown in Fig. 2. The laser beam direction was from the right to the left of the figure. The target material was located at the left hand side of the picture. The image was captured via a high speed photographic system. As shown in Fig. 2, the plasma formation was observed attached to the target. Although in the reality the target was placed at a defocused distance of 5 mm away from the focal point. However, the plasma touching the target is relatively in large area. This means the power density is not that strong to damage the surface, but potentially enough to alloy the mixture into the aluminum base. In addition, the surface is also subjected to a thermal shock wave induced associated with the optical breakdown. It is 202 Microhardness Evaluation of Pure Aluminum Substrate after Laser Surface Alloying with Iron and Copper Fig. 2 The plume of plasma formation at defocus point. Table 1 Physical properties of tested materials. Properties Melting temperature (°C) Boiling temperature (°C) Thermal conductivity (Wm-1·K-1) Specific heat (Jg-1·K-1) Thermal diffusivity (cm2·sec-1) Mass density (g·cm-3) Aluminum 660.2 2480 237 0.900 0.7 2.7 Copper 1083 2595 401 0.386 0.9 8.9 Iron 1536 2861 80.2 0.451 0.12 7.8 better to note that the plasma temperature (11,000 K) is much higher than the melting and boiling points of each element deposited on the aluminum surface (Table 1). Since the short lifetime of the plasma (within nanosecond to microsecond region), the cooling period or the quench process is fast enough to control further heat dissipation in the bulk of aluminum base. However in the plasma region the heat transfer is enough to melt the metals mixture as well as the aluminum within a skin depth layer appropriate with transient time of plasma existence. As a result the alloy process stops immediately and forms a skin depth layer of Fe-Cu-Al on the aluminum base. (a) Fig. 3 shows the typical microstructure of the laser Fe-Cu alloyed surface. Fig. 3a shows the aluminum based before expose to laser pulse for comparison purposes. The thermal skin depth effect on cross section of modified surface can be seen clearly in Fig. 3b. Since pure aluminum was used, the solidified surface became irregular after heat treatment. The white portion on the top surface in Fig. 3b indicates the solidified region. The laser alloyed surface of the same specimen was further quantified based on the Glow Discharge Spectroscopy (GDS) analysis. The result obtained from GDS analysis is shown in Fig. 4. GDS analysis showed that Fe atoms have diffused into the Al base to a depth down to 22 µm. Meanwhile the Cu atoms have penetrated less (12 μm) into the Al bulk. On the other hand, Al atoms have diffused up and appeared on the upper portion of the alloyed layer. The weight percentage of Fe (55%) available on the laser surface alloyed almost 5 times greater than the Cu atoms (10%). It is better to remember that the initial composition of mixture Cu was twice greater than Fe. Why iron atoms are more than cu on the surface layer and why they diffused further down from the alloyed surface? In order to explain this phenomenon, we have to investigate their thermal properties. According to Table 1, iron has very low thermal conductivity (80 Wm-1·K-1) in contrast with high conductivity of copper (401 Wm-1·K-1). This means that iron quenched 5 times faster than Cu. That is why (b) Fig. 3 Optical micrograph of polished cross section of: (a)- untreated aluminum surface and, (b)-the alloyed surface of Fe-Cu on Aluminum substrate (magnification X50). Microhardness Evaluation of Pure Aluminum Substrate after Laser Surface Alloying with Iron and Copper 203 Cu Fig. 4 The weight percentage versus the depth within the modified surface obtained by GDS analysis. the weight percentage of Fe is 5 times greater than that of Cu from the GDS result. Why Fe can be found deeper than Cu? This can be described base on the mobility each of the atom. However, the diffusion of Fe and Cu atom are almost the same trends. Their weight percentage are decreasing with depth. In contrast, Al has shown entirely different profile with the other two previous elements. Instead of decreasing, the weight percentage of Al was increasing with the depth as shown in Fig. 4. Initially, the amount of Al component is less than Fe because the surface has been covered by coating layer. As mentioned earlier the direction of weight percentage is different, instead going down for Fe and Cu atoms, the Al atoms move upwards. It is not surprise for the Al to achieve 100% concentration because it is the substrates. In fact Al is a noticeble to have the lowest melting temperature (660 °C) almost two times lower compared to Cu (1,083 °C) or Fe (1,536 °C). Therefore during alloyed, Al was melted earlier and diffused upward, as demonstrated in Fig. 4. Furthermore, due to its small mass density, the conductivity process slow down the Al to achieve its boiling point hence, controlling its transformation into other phases (such as vaporize). But the advantage of this slow heat conduction gives high potential for mixing and creating others compound. The XRD analysis can give us the real composition of element existing under the modified surface. The typical result obtained from this experiment is shown in Fig. 5. As expected from the GDS results, that Fe has formed binary alloyed with Al i.e., AlFe and Al13Fe4. These compositions are in good agreement with the result obtained by other researchers [10]. Although initially Fe:Cu was prepared with a ratio of 1:2, Cu actually did not take part in the alloying process with Al. However, some alloying between Fe and Cu was evident (Cu9.9Fe0.1) in the XRD analysis. It can be obviously seen that Fe (310) has shown the majority line from this XRD analysis beside the Al as a basement. Finally the modified surface was examined by using microhardness test. The typical results obtained from this experiment is presented in Fig. 6. Initially, the hardness of the laser Fe-Cu alloyed surface is found to be linearly increases with the number of pulses irradiating the same area up to 7 pulses. The average hardness within this range is 4.057 HV/pulses. This means the more energy absorbed on the coated surface the more Fe and Cu will be melted and more metastable phases will be formed. As a result, the surface becomes harder than the untreated surface. The hardness of the treated surface is found to be 4 times higher than untreated surface. 204 Microhardness Evaluation of Pure Aluminum Substrate after Laser Surface Alloying with Iron and Copper Al(220) Fe(310) Cu9.9 Fe0.1(400) Al(111) AlFe(110) Al13Fe4 Al(311) Al(331) Fe(110) Fe(211) The XRD analysis of Cu-Fe alloyed by laser on aluminum substrate. Fig. 6 Number of pulses Microhardness of Fe+Cu-coated surfaces treated with different number of pulses. Micro hardness (HV) Fig. 5 However, when the surface was treated more than 7 pulses at the same area, the average microhardness is drastically dropped and remained the same hardness of the aluminum base. It means that irradiating the same area by 7 pulses was enough to melt all the powder material at the surface. But more than that, the coated surface or the alloyed surface was vaporized and destroyed. Consequently the original surface of aluminum base was exposed. As laser surface alloyed treated continue with greater number of pulses, the hardness turn back to be the same as original aluminum base. In fact, it became worse because undergoes surface damage. 4. Conclusions A method to harden a surface was introduced by using a relatively low average of energy laser. This was achieved by focusing a Q-switched Nd: YAG laser. The quenching rate introduced by the laser plasma expansion is the mechanism responsible to alloy the surface. To avoid photodisruption of the surface, the alloying process was carried out at a defocused distance and less number of pulses. The plasma heat treatment was enough to melt and create some new metaphases including copper-iron Cu9.9Fe0.1, aluminum-iron, AlFe and Al13Fe4 phases. These phases were responsible to make the modified surface Microhardness Evaluation of Pure Aluminum Substrate after Laser Surface Alloying with Iron and Copper became harder in comparison to untreated surface. However, the maximum laser alloyed treatment was allowed up to 7 pulses only at the same area. Greater than that limitation, the surface alloyed was destroyed and original surface was exposed for damaging. Acknowledgment The authors gratefully acknowledge to financial support from Malaysia government through Escience fund vote 73989 and UTM through RMC. References [1] [2] [3] H.B. Kamal, M.Sc. Thesis, Physics Department, Al-Fateh University Tripoli, 2001. L. Poire, E. Blank, Laser cladding of copper base alloys onto Al Si7Mg0.3, Journal De Physique IV Switzerland 4 (1994) 81-84. E. Gaffet, J.M. Pelletier, S. Bonnet-Jobez, Precipitation of 205 Cr-rich phases in a Ni-50 Al- 2 Cr (at%) alloy, Acta Metall 37 (1989) 3205-3215. [4] G. Temizel, M. Ozenbas, Intermetallic phase formation at feal film interfaces, Turkish J. Eng. Envi. Sci. 31 (2007) 71. [5] Q. Zeng, I. Baker, Magnetic properties and thermal ordering of mechanically alloyed Fe-40 at% Al, Intermetallics 14 (2006) 396. [6] W. Maziarz, J. Dutkiewicz, J. Senderski, Processing of nanocrystalline FeAIX (X = Ni, Mn) intermetallics using a mechanical alloying and hot pressing techniques, Mater. Sci. 39 (2004) 5425-5429. [7] L. Eleno, K. Frisk, A. Schneider, Assessment of the Fe-Ni-Al system, Intermetallics 14 (2006) 1276. [8] R. Qindeel, Interaction of Q-switched Nd:Yag laser with different target materials, Ph.D. Thesis UTM, 2008. [9] N. Bidin, Studies on laser induced cavitation erosion and mechanism of cavitation damage, PhD thesis, UTM, 1995. [10] S. Pityana, R. Rossouw, Laser alloyed Al-Ni-Fe coating, ICALEO Congress Proceedings, South Africa, 2008, pp. 55-60.