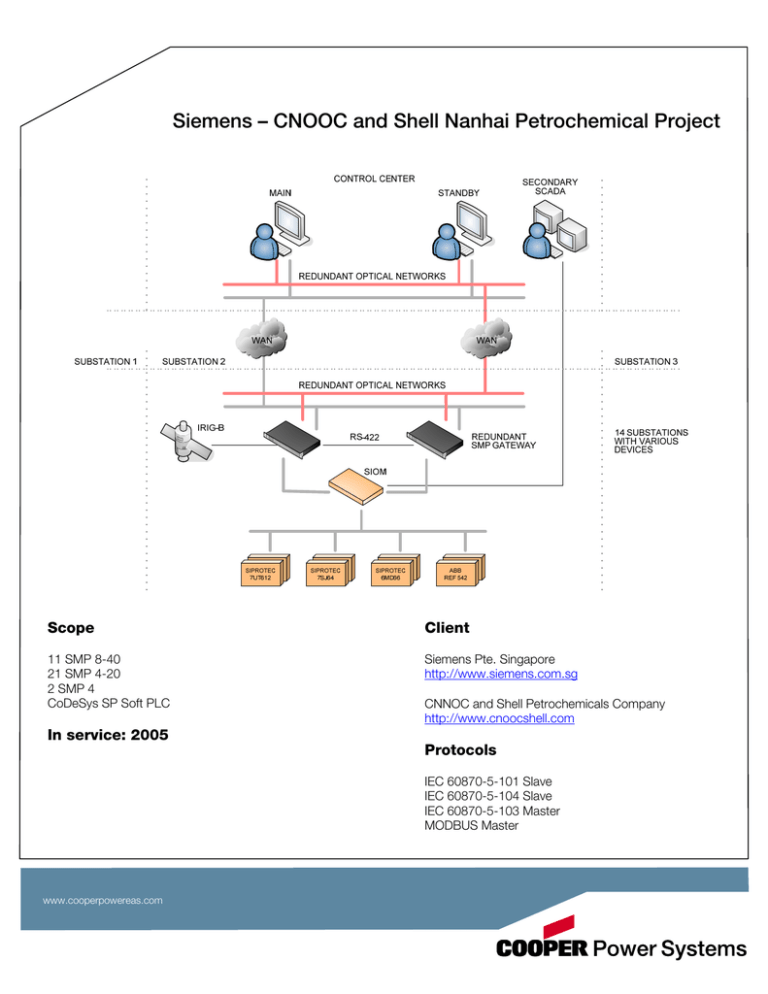

Siemens – CNOOC and Shell Nanhai Petrochemical Project

Scope

Client

11 SMP 8-40

21 SMP 4-20

2 SMP 4

CoDeSys SP Soft PLC

Siemens Pte. Singapore

http://www.siemens.com.sg

CNNOC and Shell Petrochemicals Company

http://www.cnoocshell.com

In service: 2005

Protocols

IEC 60870-5-101 Slave

IEC 60870-5-104 Slave

IEC 60870-5-103 Master

MODBUS Master

www.cooperpowereas.com

The Solution

The Challenge

China National Offshore Oil Corporation (CNOOC) and

Shell Petrochemicals Company Limited (CSPC) are

building and operating a $4.3 billion USD

petrochemicals complex in Daya Bay, Huizhou

Municipality, Guangdong Province, China. It is the

largest capital investment for a Sino-foreign joint

venture project to date in the People's Republic of

China.

The Plant will be an integrated chemical complex

including steam and electricity generation, storage and

handling, shipping facilities, as well as effluent treatment

and environmental protection facilities. Many of the

production facilities are world scale, and all are

designed to international standards.

The design and construction of the power transmission

and distribution system for the plant was awarded to

Siemens Pte Ltd, the representative company of

Siemens AG in Singapore. Siemens AG (NYSE:SI),

headquartered in Munich, is a leading global electronics

and engineering company. It employs some 430,000

people in over 193 countries, and reported worldwide

sales of more than $75 billion in fiscal year 2004

(10/01/03 – 09/30/04).

To ensure continuous fail-safe operation of the power

production and distribution system, Siemens Pte

required a field-proven solution capable of integrating

the various IEDs and protection relays.

Quebec City

730 Commerciale Street, Suite 200

Saint-Jean-Chrysostome, Quebec

Canada G6Z 2C5

Technical Support:

P: +1.418.834.0009

support@cybectec.com

Montreal

1290 St. Denis Street, Suite 300

Montreal, Quebec

Canada H2X 3J7

Sales:

P: +1.514.845.6195

sales@cybectec.com

All Cooper logos and Cooper Power Systems are trademarks of Cooper US, Inc., in the U.S. and other countries.

You are not permitted to use Cooper trademarks without the prior written consent of Cooper US, Inc.

©2009 Cooper US, Inc. All Rights Reserved

B1100-09036 • April 2009 • New Issue

To provide fail-safe operation, Cooper Power Systems

specified a redundant architecture of SMP Gateways.

The SMP gateways are used to integrate the devices in

the substations, perform protocol translation and make

the data available to the control centers.

The Soft PLC option is used to implement sophisticated

power management functions, including the capability

to switch to auxiliary power generators in an orderly

manner in case of external power failure.

The SMP Gateways are configured for hot standby, and

switchover occurs within seconds in case of failure. To

ensure continuous data access, each SMP Gateway is

connected to the control center using dual Ethernet

connections through a fully redundant network.

By using the advanced capabilities of SMP Gateways,

Siemens Pte was able to deliver a sophisticated failsafe control and data acquisition system well within the

allocated project schedule.