822(.41 FOREST PRODUCTS LABORATORY

advertisement

822( .41

ib 64

U. S. Department of Agriculture, Forest Service

FOREST PRODUCTS LABORATORY

In cooperation with the University of Wisconsin

MADISON, WISCONSI N

THE CONIFER LEAF OIL INDUSTRY

By A . W . SCHORGER

Chemist in Forest Products

Published in

AMERICAN LUMBERMAN

April 29, 1916

THE CONIFER LEAF OIL INDUSTRYBy

A . W . Schorge r

Chemist in Forest Product s

The production of oils from the leaves or needle s

of various conifers is a small but fairly old industry i n

the United States . According to the best estimates obtainabl e

the value of the oils produced annually from this sourc e

amounts to approximately $50,000 . The leaves of only a fe w

species of conifers are regularly distilled for their oils ,

since it is only for these oils that a steady demand ha s

been created . The principal species employed are the blac k

spruce (Picea mariana, Hill .), white spruce (Picea canadensis ,

Mill .), eastern hemlock (Tsuga canadensis, Linn .), red junipe r

(Juniperus virginiana, Linn .), and arborvitae (Thuj a

occidentalis, Linn .) . The oils of white spruce, black spruce ,

and hemlock are very similar in composition . No attemp t

appears to be made to keep the leaves of the latter specie s

separate, and for practical purposes a distinction betwee n

them seems unnecessary . The annual consumption of spruc e

and hemlock oil is estimated at 40,000 to 50,000 pounds .

It is quoted at 45 to 60 cents a pound . The leaf oil of th e

red juniper is used largely in insecticides, the annual consumption being 15,000 to 20,000 pounds . The prices of th e

oils from the various native conifers are approximately th e

sane as that given above . The oil of Pinus picea imported

from Europe is sold at about $4 per pound but the annua l

demand is below 50 pounds .

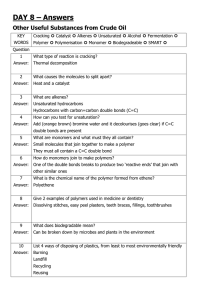

Yields of Oil from Various Specie s

The oil is found in longitudinal ducts runnin g

through the needles . The number and size of the oil duct s

vary greatly with the different species, and on these factor s

the yield of oil is largely dependent . The number of oi l

ducts may vary from one to ten . Naturally the species containing numerous ducts of large size will give the larges t

-Published in American Lumberman, April 29, 1916 .

R272

-1-

yield of oil . This assumption has been verified in the various species examined . The longleaf pine needle contain s

five large oil ducts, the average yield of oil being 0 .42

per cent, while the lodgepole pine needle contains two oi l

ducts, the average yield of oil being only 0 .16 per cent .

In all cases the yields are given in per cent of the weigh t

of the green leaves .

The approximate yields and principal constituent s

of the various species are given in the table presented o n

the following page .

Properties, Composition and Use s

As a general rule, the oils have a pleasant odo r

resembling the fragrance of coniferous forests . Occasionall y

the freshly distilled oils have a disagreeable odor tha t

frequently improves with age .

The oils are composed mainly of terpenes, terpen e

alcohols and their esters, and sesquiterpenes .

(See table . )

Among the terpenes pinene and limonene are ordinarily present .

The attractive odor of the oils is due mainly to borneol an d

its acetic ester . In general, the more highly prized oil s

contain large amounts of borneol, both free and combined .

Spruce and hemlock oil contain 35 to 50 per cent of thes e

constituents . The popular Siberian needle oil, of whic h

5,000 to 10,000 pounds are imported, contains from 29 t o

39 per cent bornyl acetate . Among the sesquiterpenes cadinen e

occurs most commonly . Thujone .is a characteristic constituen t

of thuja oil from Thuja plicata and Thuja occidentalis .

It is difficult to obtain direct information on th e

purposes for which the various oils are employed . A larg e

amount of correspondence addressed to manufacturers purporte d

to use these oils in their products afforded very little information . Information on the uses to which the oils are put

was obtained mainly from dealers and distillers of the oil .

The spruce and hemlock oils are extensively employe d

as a perfume in greases and shoe blackenings . They are als o

used in considerable quantities in liniments and othe r

medicinal preparations .

R272

-2-

H

0

a)

I~

Fi

0

O

i

c

rl a)

q F-l

N 'd

l~c

i

q H

H

ci

o

. ~

H

te a )

a)

a)

O

0

a)

ci a)

a) ci

+3 a)

a)

0

d) cis~ a)

ci •r1 •H ic

a)

p, a)

s

a)

ci

a)

•H

Pi

I

H

'-

O

Q)

co a)+)+'ci

a)a) , A cd cd ci

4-)

cdacia)o

a) F

Cd cd a)

F-4

o

a) a)

-

O

O

a)

cd

a)

cd

a)

a)

0

a)

H

^ 0 ci O a) O

O

.1~

0 a) •H

ci

cd +' rl rt H O

rl

H

O

a)

ci

a)

a) a) FI Fi t~ F+

•P -P O O a) a) • H Q)

0

H

,0

H

H

a)

O cd 4-3

P4

d F-t • (J)

a)

O C ] a) 0 0

a) '

P.1

ci ' ci a) a) H a) W F+ 0rl a) H

•H E

~`' Q) Q) a) a) cl fi o ci 'd

o

o

cd cd ci c

ci a) l~ a) lM

a) a) a) o a )

U 1 Q )

p a) O a) a) ci 0 a ] a) a) H

-H

g O ~-~ •r•I

I~: I

o •H a)

id

+

. . d e--I r-f

"r g

g00

H I

H >~ 'd 4 rJ •H •H Fi •H r-I r-i •H F4 •H H U) '."^. '+•,-1 •r-i •rl O •rip •H ''d •H

Fi I

ri rl P., o P., o

P, Pi n, • r-) a • P+ cd

p, cd P-i cd p p, o

r-i I U 1

P4

I

I

O

o I 1 ,0 I a) a) I ,0 I A F-i Fa F-I 1 1 i

9

..

..

'o

.

C)

6

~'

wa

I~'

PI MI

00

00

0 141

0150

N- 01

d1

I` r1 ~f)

ti

lfl

LO Oti O O Ell M

q

1 50 50 5o N- Lfl ti r--H H N N O N fO

so

rr1 5o

o

▪ +~ ! 50 t50 50 50 50 5o

01

4-i •H I

+' 44' +) 01+' •

•

•H 1

O O O O O O cd cd cd cd • cd

O

O

U cd

I

I

1

1

I

I

I

O

I

01

Imot50

I

a) F-1 1

N

f~- 0 LC10I f'-- 01 z " O 50 H I Lcl Lf1

t50

bD

I

H

N

ImoH

I`H

01\O

N

N

P

a

l

li-4

50

Lcl

LCl

t`

P,

U)

1

0 tO '60 f`\O LC\lD \O ti

f`

LcI N N N 50 H 1Y1~D 50

01150 l5q 60 60 t50 )50 50 t50 t50

01010101150 010150 '60

HI

a1

o

0

ri

r4 •H

a) O

•H

4-1

q

E

I

1

I

I

1

00 0

00 O . 00 00 O . 00

c tom-

0000

r-irirlZ

• . . .

0

00 00 00 00 00 00 00 00 00 00 00 00 0

N- 5001 O N\LC l rl

N

OO

ONri H

. .

.

H

0000

•▪

•

q-4

.H

PC

cd

r•, i • ^ 4-D

Cd' Fi, . F-1

,O

O

cd .-p o rl

-H ~; .•i . . O

C

0 (A U

•H O •r.4 c; -4-)

•

F.

a s a)

• vv ci

w o p.

.1-4

Q) (D 5a,

•H Pi Q, cd

a)

a

a) .H

P4 PA

R272

H

-P

O

*

H

'2

Q)

a

c

i

0 Pi

•

Cdd

+)

O cd

•

0

*

F-1

0

cf.)

* *

cd • $D O 'd

CQ p. C

d

,- a

a)

dD

(D

a) 14'4

p,

H

a) p, O

•c

•HH ra) -A-04

F-i

F-1

o F-1 4-1

Fi a •H

•H

4-1 v

cA

Cd

Q) a) CH a)

,-

~~-

c

i

I

•H O a) ,

O

raIZ

a

f=l

* * * * *

•

0

H

to

50

00 00 00 00,00 00 00 0 0

•00M

. . r ..l ^ cd

• <-- r-i O -p

0 Lf l

N

H

cd

• c

i

cd

CA ••H•H cd .~ •H

▪

.H o co

•r• ita Cd •H c •H

• cd ci • - +) H a) iiO

• cia)

cdciP4F-i

N

( -HH ai co '0 Cd c

vcdcd

o

a)

o o ,.g

U d Cd

EH

A

• a) U R

cd p

o

rd

Cci

r~ F1 •H

cd U

a) •H -H O o

cd ,..-I

U 1=4 P,

• rl .i ''a

H .._.~ Cd ,O

o F4

•

- , U 0 c

- 'd b

O

Pi

FF-1 a ,

O

C

FF-1

a

•H

i

H

•H 'd H O P+

a)

o t~ .a)

Fr'

to rte, a) O Cd a) a)

U+)H CY]4-'4~ a)

•H

• cd . H

zi

(D r-l .s; ; a) Cd

a) S~

a)

Fi

ar~xm

x

*

HI

Df +

f

Cedar oil from Juniperus virginiana is' employe d

mainly in insecticides . Thuja oil from Thuja occidentali s

is used in insecticides and liniments . Various native and

foreign oils are employed medicinally as inhalations fo r

lung diseases, and as additions to baths and ointments i n

rheumatic afflictions . Various perfumes contain certai n

amounts of needle oils whose value consists in having a

so-called "ozonizing" effect . The oil of Pinus montana

tamed with chloroform is used in quantity as an eibrocation .

Tnt'Europe, especially, the finer neet1B 611 --grit ised .

tensively as perfumes in soaps .

"t

The great ,

ill ed i*'

lli'4 ' r

-small farriers in Ne

ngland during

onths when .'

the farm work is slacat t l~e , ?'~a

In 1912 a c

w4v eng od in the di

')*ton of t

of red ,l t

cata) oij an~~I,~q

>' "' The branches,,

3A4 inch

r

deli* r '` n Seattle in bundle o f

nt, ct price of

50 to $5 .50 per tort,

or). t'

oil content . The material was packed i n

'tom

E and 0

tilled with steam at a pressure of 40 t o

90, pCAi , for 3 - . 5-• ours, the distillation being discontinued when the amount of oil coming over did not excel

10 cubic 'centimeters in 5 minutes .

1

,r -

'The average yield of oil was about 1 per cerit '-th-o weight of the green material . Young trees containe d

largest a lount Qf oil, and the haves= were richest in . .': •

January, , f ebru_a fir, , and , ag.rch . , T .,

a market value of . .

4+0

its a pi)

arcely suffici. _it to cove r

, buf' t *

ths cost of p

tion .

ri'f the oil was

v.

+o '

ITtsu31B.c'

e' is

insel44de ca

-'Mothine . " VIM, art . i

day '

cont

about 35 pc*,

of cedar &I' -End

45 por

t . of

1 ~~ . . bent made .

ating the fine .

gstbund Che1ls of peac 4 pits .

. i: ,tempts:-'hac,n mad®•4 i''OrItious times to utilil e

pine fiz

• .fstiori .of fiber after the oil:been removed by distillation . The most ambitious attemp

in this direction were made by C . A . and O . C . Terrell ,

Grant's Pass, Oreg ., who obtained patents Nos . 675,206 a

_

758,874, Rovering methods and apparatus . The plant, des Zbec

by Erown, utilized leaves systematically picked from On g

2

-Scien

. Amer . 84, 344 (1901) .

8272

-4-

trees of the western yellow pine . The stills consisted o f

wooden tanks with steam connections, and had a daily capacit y

of 2,000 pounds from which 10 pounds of oil were obtained .

After suitable treatment the spent needles produced a long . ,

tough fiber that could be woven into fabrics or made int o

mattresses when mixed with hair .

Forest Service Investigation s

The large amount of lumber cut from coniferou s

woods renders available large quantities of needles and twig s

that at the present time are not only a sheer waste but ar e

frequently the cause of destructive forest fires . If a sufficient market could be created for the oils a great economi c

advance in management would be effected . At present, however ,

the demand and price for oils of this type do not warran t

their manufacture on a large scale .

The leaves of a number of the most important wester n

and southern conifers were distilled to determine the yiel d

and chemical composition of the oil . Samples of these oil s

were sent to various manufacturers for practical tests . The

most promising oils, judged from odor, were those of the long leaf pine and western yellow pine . Unfortunately in nearl y

all the oils and ester content was low and their odors di d

not surpass those of the already firmly established spruc e

and hemlock oils . There appears to be an increasing utilization of conifer leaf oils, and the creation of a demand fo r

new oils, as well as the extension of markets for the commo n

ones, may be anticipated . It is frequently difficult, however ,

to introduce a new oil on the market, even though it may hav e

decided merit .

Principles of Distillatio n

The oil is removed from the leaves by the familia r

method of steam distillation, usually at atmospheric pressure .

As the steam passes upward through the needles the oil volatilizes and the mixed vapors pass together into a coolin g

apparatus where condensation takes place y. The condensatio n

products soon separate into a layer of oil and water, owin g

to their immiscibility and difference in specific gravity .

'S' :rig' distillation under pressure is more rapi d

and produces_iwot& *41 than distillation at ordinary pressure .

Then, steam dt dt.inospheWIPkessure is employed a greate r

yield;

obtained if tine n-d*d..es are cut into small pieces .

In this .may the oil ducts are more exposed to the action o f

the steam and more materi-a 'l tan be placed in the still .

Experiments have shown that a still will hold 25 to 50 pe r

cent more material when it is finely cut .

is

The largest yields are obtained from young trees .

In New England c- Oar oil is distilled almost entirely from

small tr,e•es growing- in. aid pas'Gur-es and abandoned fields .

All trrees growing ifs the open contain more oil than thos e

in a normal forest stand . The season of the year also appears to have a considerable effect, the data availabl e

essentially agrAeti g irvVhat the most oil is obtained during the winter amd spring months . The leaves of the wester n

red cedar (Thu12:plica ) were richest in January, February ,

and March ; the leaves oif •incense cedar vvexe r _~ e ice,

February and November than during tie 'llervening summeft -,

4 months .

TheStill and :_Tts 0a01j.on

ThM. exp -rimentaJ, - ,s : • .ll used by the., Forest

~~ c e

,e

4 = Sri•

onstructL i n

n~

+bed

f the - till for holdin g

et 6 in

height by 2 feet 3 inche s

s made of 1 6 B

G . copper . The ends wer e

'1-3/4 inches wide ,

and

the

.

**

he

heating vesse l

1. 1

ty

fla

and

ded w h rings . The cove r

`1

fast :

, linden with malleable iro n

usl in the joints .

In

base of the cylinde r

removable fram e

The exterio r

ed

ss►er .

of

asbestos

in

{

-. .

nsation

of

th

e

yeti• .~r~

~_

rr,► -~

-{'

r was 3 fee t

constructed o f

/2-in h

stop fo r

,' -- - - - e d

t.

1

~ F

-

-~

1-1/2 feet internal diameter, placed in a galvanized iro n

tank 2 feet in diameter by 2-1/2 feet deep . The condense r

was connected to the still with an 8-foot copper pipe, i n

two sections 2 inches in diameter . A 2-gallon aspirato r

bottle, having a brass syphon, served as a receiver .

The material to be distilled was first passed throug h

a feed cutter, the needles and twigs being cut into lengths o f

1/2 to 1 inch . When the chopped material was well packed int o

the still the charge varied from 350 to 500 pounds, dependin g

upon the species . By filling the cylinder ahead of the risin g

column of steam, the needles are decidedly more compressible .

The distillation was continued at the rate of 2-1/2 gallon s

per hour . At the end of 7 to 8 hours the quantity of oil fel l

to 5 to 6 cubic centimeters per hour, and the distillatio n

was then considered complete . The oils are dried and filtere d

through cotton batting or fine muslin, and are then ready fo r

market . Sometimes they are subsequently rectified by dealers .

The small distillers usually employ apparatus constructed partly of wood . The leaves are placed in rectangula r

cr cylindrical wooden tanks while steam is introduced from a

separate generator . The simple apparatus used by a Ne w

England distiller of cedar leaf oil will serve as a type o f

the stills frequently employed . His description is th e

following :

c

A steam-tight box, 3 feet by 4 feet and 3-1/2 fee t

deep, with a boiler plate bottom is set on a rock furnace . Inside of this box is a grating 4 inches abov e

the bottom to hold the cedar up to the top of the grat ing ; a pipe from the top of the box 10 feet long carrie s

off the steam . This steam pipe runs nearly its entir e

length through a trough of water kept cold by runnin g

water . The condensed steam drops into a glass ja r

covered with cloth for a strainer .