The catalytic hydrogenation of certain aliphatic amines by Robert A Currie

advertisement

The catalytic hydrogenation of certain aliphatic amines

by Robert A Currie

A THESIS Submitted to the Graduate Faculty in partial fulfillment of the requirements for the degree

of Master of Science in Chemical Engineering

Montana State University

© Copyright by Robert A Currie (1960)

Abstract:

The effects of pressure> temperature, and space velocity on the hydrodenitrogenation of certain

aliphatic amines were studied. The feed concentration and hydrogen rate were held constant for all

runs. The compounds studied were n-butyl amine, octyl amine, iso-butyl amine, sec-butyl amine, and

tert-butyl amine. An increase of temperature caused a corresponding increase in the conversion of the

nitrogen compound. An increase in pressure also caused an increase in the nitrogen conversion.

By comparing n-butyl amine to octyl amine, it was evident that the lower molecular weight amine

denitrogenated more readily. Similarly, the isomers of butyl amine denitrogenated in the order n-butyl

amine, iso-butyl amine, sec-butyl amine and tert-butyl amine, with the ease-of denitrogenation

increasing respectively. The product formed from n-butyl amine is a mixture of iso-butane and

n-butane. Sec-butyl amine forms essentially n-butane, while iso- and tert-butyl amine form essentially

iso-butane at high conversions. THE

.CATALYTIC HYDROGENATION

•OF

CERTAIN

ALIPHATIC AMINES

by

ROBERT A. ,CURRIE

O

A THESIS

Submitted to the Graduate Faculty

in

p a r t i a l •f u l f i l l m e n t •of t h e 'requirements

f o r .the degree of

Master:

of Science in Chemical Engineering

at

.Montana State College

Approved:

Head, Major Departm^p

Jean, Graduate Division

Bozeman,. Montana

J u n e ,.i960

'

J

i!.;

fyl'

I A

f

r;:ii;■

M i

1 s'

r,/Pkc

'(Vf-^

•2TABLE OP CONTENTS

page

Abstract

..........................................................

3

I

Introduction .................................................

4

II

Experimental Considerations

9

A.

B.

C.

D.

E.

...............................

Introduction .............................................

9

Materials.................................................... 10

E q u ipment.................................................... 11

Operating Procedures ....................................

13

Analytical Procedures...................................... 16

III

Discussion of Methods of Data A n a l y s i s .................... 17

IV

Discussion of R e s u l t s ........................................... 22

A.

B.

C.

D.

Effect

Effect

Effect

Effect

of

of

of

of

Tenperature......................................

P r e s s u r e ......................................

Molecular Weight

...........................

Structure on Hydrogenation of Butyl Amine

.

24

25

2$

26

V

C o n c l u s i o n .................................................... 32

VI

A c k n o w l e d g e m e n t s ............................................... 33

VII

Literature Cited .............................................

34

VIII A p p e n d i x ........................................................ 35

145253

-3ABSTR AC T

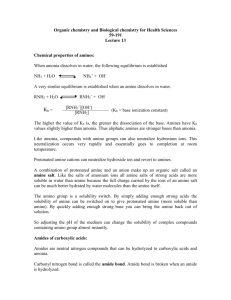

• The effects of pressure, temperature, and space velocity on the

hydrodenitrogenation of certain aliphatic amines were studied.

The feed

concentration and hydrogen rate were held constant for all runs.

The.com­

pounds studied were n^butyl amine, octyl a m i n e , .iso-butyl ■amine., secbutyl--amine, a n d .tert-butyl amine.

i

An increase of temperature caused a corresponding increase in the

conversion of the nitrogen compound.

An increase in pressure also caused

an increase in the nitrogen conversion.

By comparing n-butyl amine to octyl amine,.it was evident that the

lower molecular weight amine denitrogenated more readily.

Similarly,..the

isomers of butyl amine denitrogenated in the order n-butyl amine s isobutyl amine, .■sec-butyl amine and tert-butyl amine., with the ease of deni.trogenation increasing respectively. ' The product formed from n-butyl

amine is a mixture of iso-butane and h -butane. Sec-butyl amine forms

essentially n - b u t a n e , while iso- and tert-butyl amine form essentially

iso-butane at high conversions.

-4—

I.INTRODUCTION.

When .a nation's industrial picture is changing rapidly* new.proc­

esses and products.must.he.introduced at a corresponding rate.

But

with each new or improved p r o c e s s ^ more demands are placed •on each inter.?mediateosiepp:-.-uThesedeman'ds may be quite, diversified,, but .one of the

largest demands falls on the- specifications.and requirements of an inter­

mediate used.

This rapidly.changing industrial picture applies directly

to-most chemical, and petroleum industries..

With any.industrial changes or.new growths ..new.markets are created.

To -supply, these .markets larger.and different sources or raw materials

and intermediates are needed.

Often new sources -of these materials

must be used,, which may. .require the .use. of inferior grades.

This imme­

diately, presents the problem-of upgrading the materials to meet the

required specifications.

Demands to. improve any product present;'new

problems' that must.be- met .and h a n d l e d ,

If the information needed-to '

obtain a ,complete knowledge.of the problem is not available.,.then it

may.be necessary.to- conduct studies to obtain this information.

In recent years, one problem has arisen that exemplifies this

demand.

This problem.concerns, itself with the efficient removal of

nitrogen-containing compounds from the petroleum.distillates■of which

t h e y sarepa .part.

Since 1953 the Esso Research and Engineering Company has sponsored

a research project at Montana State College.

Not only was this study

I

-5conducted here.* ,but also- In their, own research laboratories.

The

purpose of the.project was to study.the removal of sulfur by hydro­

desulfurization which also included in-cycle catalyst.deactivation

studies

(6 , ,g.jt-ll, l 6) .

Recently,, however, ..the study has been

carried to the level where it is no.longer desirable to continue .

this..type of,work -at the present time.

Since 195$ and.the .com­

pletion of Mahughts thesis., attention has been focused on hydrode<-.

nitrogenation.

Because of •previous experience, with desulfurization.,

and the similarities between this and denitrogenation* this new

..study, was conducted in much the same way. as desulfurization.

In an effort, to understand .better a.small portion of the.:over-■

■all .problemj,,. this study, was conducted on Qnly,one type of nitrogen

-compound..

The type of nitrogen compound .used.in this study was

limited.,to/ aliphatic.amines... h o w e v e r ,. this- type o f .compound makes

up a.part -of the total nitrogen content of' many commercial..petro^

•Ieum feedstocks . ■T h e 'e£E'gx$ts up on hydrogenation, of stiCh..variables

as pressure.,., temperature*..space-velocity J,. and-structure, of the.

amines, were studied^ and their correlations to hydrogenation were

■examined.

The feedstock used in this study- was blended.to -resemble -some

o f .the ,characteristics of a commercial, feed.

However3..only, one

type, of nitrogen compound of known concentration was introduced

into.the feed.

This-.made it.possible to understand better the

-6behavior of this compound to hydrogenation.

Commercial feeds may contain several types of nitrogen coim­

pounds .. Some of the more common compounds encountered are as

follows:

I.

H

R - C H

NH 2

Amlnes

Quinoline

Isoqulnollne

Pyridine

Pyrrole

H

6 . Figurations undetermined

Porphyrins

A feedstock may contain many more types of nitrogen com­

pounds than these.

Also, each type of compound may have more than

one possible arrangement of atoms In its structure.

As an example,

quinoline differs from isoquinoline In only the placement of the

nitrogen atom in the heterocyclic ring.

Since many compounds are

present in most feedstocks, numerous reactions may occur simul­

taneously.

as f o l l o w s :

Some of the problems encountered in hydrogenation are

-71-

Does the ^pfesenoe of different nitrogen compounds cause

an interaction ttia-t would affect the hydrogenation?

.2,

Does the presence ,of c m p o p n d s other than nitrogen-con­

taining ,compounds affect hydrogenation?

3..

What affect- does the- carrier h a y e on. hydrogenation?

-4.

What part of the reaction is rate controlling?

5-.

What,physical conditions arid limits'

-6 .

How do variables like pressure and. temperature affect the

ape present?

hydrogenation?

In most cases before a study like this is. conducted, there,

must first-he sufficient interest to merit such an investigation.

Reasons leading up to the.desire to remove nitrogen compounds are

numerous and diversified,,

-gome of the more.obvious reasons are as

follows:

1.,

When, nitrogen-containing compounds c o m e into -contact with,

sensitive catalysts^ the catalysts are easily poisoned

and quickly lose their efficiency.

Some processes in -

which this may occur are catalytic cracking., hydrogen

.platforming,, and alkylation (I,.

' 2..

10).,

Nitrogen compounds are- partially responsible for extensive

gum formation.,

TMs- formation is Caused, by their ability

to accelerate the oxidation of numerous unsaturated

compounds

(1,

5.)..

3.

Removal .of nitrogen compounds to produce .a product that

is competitive with those from other sources.

The re­

moval of nitrogen compounds from, shale ail to upgrade its

.quality would be, an example,

The catalytic hydrogenation

of crude shale ail has been studied by the Chemical

Engineering Department at Montana State College since

1954

.4.

(2 , 5 j- 7) v

Nitrogen compounds are.often the source,of objectionable

odors

(15)..

5 . Nitrogen impurities Can hinder various chemical processes

The purpose and. reasons f o r this st.udy have been previously

stated.

The information obtained f r o m this study is of funda­

mental nature and should be of value in solving the broader

p r o b l e m of upgrading -commercial feedstocks,

-9

II EXPERIMENTAL .CONSIDERATIONS

A.

Introduction

C a r r i er :

In order to- p r e p a re a feedstock that contained the

desired, amount of nitrogen as amines> it was necessary to use a

hydrocarbon carrier that simulated commercial feedstock charac^

teristics.

It was necessary to choose a carrier that in barrel

lots was reasonably"' p r i ced* .that would blend readily with various

low molecular weight amines* and not affect the hydrogenation

process itself.

The hydrocarbon carrier .chosen was normal h e p t a n e », which has

a boiling point of

98„5°C a n d a density of 0,6838 gm/cc (4),

The

•normal heptane was purchased in barrel lots from the Phillips

Petroleum Company,

Process Conditions:

The operating conditions chosen for this

study were orginally selected, with the assistance of the Esso

Research and Engineering Company.

After a few- exploratory runs

were conducted* the -conditions were modified, to prevent total

nitrogen conversion and. also to be more compatible with the limi­

tations of the equipment involved, and the analytical techniques

used.

The following .conditions .were finally selected:

Pressure — 10.0

$00 psig.

Temperature - 62$°?

725°]?.

Hydrogen flow rate -■ $00 SCE/bbl.

Nitrogen concentration - 1,6$ N by wt.

Space velocity - 10 — 100 gm/gm p er hour.

-tIOCatalyst -• CoMo-; 1 0 - 100 grains „

Amines .used: n-batyl amine

tent-butyl amine

sec-butyl amine

iso—butyl amine

n-octyl amine

B.

Materials

Feedstock:

The various amines u s e d in this study were com­

mercial grade reagents purchased f r o m Eastman Organic Chemicals.

The desired amine was blended with n-heptane to produce approxi­

mat e l y lfo by weight nitrogen,..

space velocities

Since each, run consisted, of four

(IO jl- 2 0 4 0 „. 100) * it w a s .nodessary to Jblend about

15 liters' of feed p e r run..

This quantity of feed was sufficient to

r u n the unit until the .nitrogen conversion reached a constant level

and samples obtained.

Catalyst a n d .catalyst s u p p ort:

Hydrodesulfurization w°rk con­

ducted previously at Montana. State College in. conjunction with, the

Esso Research and Engineering .Company j[-9>. 11) Used a cobaltmolybdenum catalyst..

Erom previous experience of hydfodenitro-

genation and from the similar characteristics between, desulfuri­

zation .and denitrOgenatIonj the Halco-Esso cobalt-molybdenum 1/16inch extruded catalyst was used..

This catalyst is a mixture of

cobalt and molybdenum, oxides on an al u m i n a .support.

T h e catalyst b e d was supported in the reactor on the top and

bottom by

1/ 8 -inch alundum pellets which were obtained from the

Morton Company.

The alundum pellets were also used to dilute the

-ll-.

catalyst and. thereby produce a larger catalyst zone.

The catalyst

was diluted j? parts pellets to I part catalyst by yolpme.

The cata­

lyst dilution made it possible to use a larger portion of the r e ­

ac t o r which aided .in. the control of reactor conditions.

Hydrogen Treat G a s The hydrogen treat gas was supplied in.

h i g h press u r e .cylinders by H R Oxygen .and Supply.,. Billingsjc Montana.

The h y d r o g e n was first passed through a "Peoxp" to remove trace

quantities of oxygen,.

A palladium, catalyst in the 'tBeoxo" unit

catalytic ally combined the oxygen with hydrogen to form water.,

The

water was then removed b y passing the hydrogen through a drying

,unit which was p a c k e d with "Drierite".

C»

Equipment

Elow D i a g r a m :

A schematic flow .diagram of the catalytic

hydrogenation unit is shown, in Figure I.

The feed is pumped to

the top of the reactor where it enters along .with the purified

hydrogen.

Together the f e e d and hydrogen pass down through the

preheater, catalyst^ and after-heat zone.

The vapors are.con­

densed first in a counter current water condenser while still

under reactor pressure..

After passing through the reactor pres­

sure regulator^ the gas a n d liquid products ar e then passed

through a cooling .coil .contained in a n ice b a t h .

The liquid p r o ­

duct is collected in .a flask while the gaseous product is vented

to the atmosphere.

-12EqiiilBment Specifications :

seamless,^ schedule

length.

The reactor was made frqm I -Inch O D j

8 O j stainless steel .pipe,f;and .was 30 Inches In

The bottom -of the reactor was silver welded to a flanged

union to permit easy access to the Inside,of the reactor.

The top

,of the reactor was permanently, connected to a .high pressure cross.

A thermowell enters the reactor through the top of the cr o s s . •The

feed, and hydrogen enter the r e a c t o r .through one side of the., cross

while the.other is used as a. safety device to vent the reactor to

the atmosphere.

A 1 5 0 0 psi rupture disk was used for this purpose.

The r e a c t o r wras wrapped-with five, ceramic-beaded nichrome

heating co i l s .

The heating coils were covered with approximately

1-1/2 inches .of .magnesia, insulation.

A thermowell extended .down through the center of the reactor,

to the .flanged, ,union at the bottom.

A 3/l6^inch OD stainless

steel.tube-y sealed at the lower end,^ .was u s e d for the thermowell.,

.Inside the thermowell were placed fiye lron^constantau thermo­

couples which measured the temperature at various leyels through

the reactor.

A diagram of the location -of heating coils.* thermo­

couples^. •and catalyst aone are shown in Figure.2.

Accessory equipment was also utilized i n the hydrogenation

unit as f o l lows: .A HIlls-McCanna high pressure proportioning

.pump with a l/ 8-inch piston;, a Brooks armored, high pressure roto.meter with 3/52-inch b a l l 5 a drove back pressure regulator) five

-13110 volt Powers tats ;j a 100Q ml glass feed reseryoir with a.

50 ml

graduated burette attached through a side arm* a Leeds and

Worthrup. indicating potentlffimdter,* four Marshalltown. 200.0 psi test

g a u g e s ; a Qohor Deoxp P u r ifier 5.a Matheson hydrogen regulator.

'

The tubing used,on the,unit was type 304- stainless steely 1 /8-,inch.

OD tubing.

Various', types of yalyes used on the .unit are -as follows:

Hoke- on-off yalv.e; Hoke turn-to-open needle .yalye j .Hoke micro,

adjusting needle valve used for hydrogen metering..

D.-

Operating Procedures

Reactor Preparation.:

Once the reactor is. dismantled from the

•system it i s .cleaneduand dried before recharging.

The reactor is

inverted to expose the annular space between the reactor wall and

the thermowell.

The alundum. pellets were first charged into the

reactor to a selected depth,.of the reactor.

This forms the- feed preheat section

The,catalyst that had been diluted with pellets

was then, charged, into the reactor and, p a c k e d Jpy tapping.

The

length of the .catalyst ,zone was kept as .uniform ,as possible for

each run.

The reactor was then filled to .about one inch below

the flange with more .catalyst support...

A .stainless steel coil

Vfas then secured.on the- bottom, of the reactor to hold .the catalyst

and catalyst support in place when it was turned up into its n o r ­

m a l position.

The reactor was then coupled into its position in

-14the system..

The feed and gas line> the thermocouple leads,,, and the Power­

'stat cords were then connected, to the reactor.

Qnce the reactor,

was pressurized,, the unit >ras checked for l e a k s ,

After the reactor was brought to a temperature of 288"0, a

gas mixture of

5$ hydrogen sulfide and. 95$ hydrogen was passed,

over the.catalyst for a period of 24 hours at a reactor pressure

of 250 psig.

This procedure was used for catalyst hydrodenitro-

genation run s t a r t s .

Reactor Operation.:- Before the actual run was started, the

reactor was changed from, the break-in temperature to the desired

temperature fo,r that particular run.

Once the pump was started

it was necessary to adjust the pumping ,rate to the ..desired, rate.

This was done by a micro,-adjustor on the pump that changed the

stroke length of the piston.

The space velocity was set to the

desired .value by .measuring the volumetric oil feed, r a t e .

As the

f e e d and hydrogen entered the reactor it was necessary to adjust

the preheat Powerstat to heat the incoming feed to reactor tem­

perature.

The temperatures through the reactor were recorded,

and the Powerstats were continually adjusted to maintain the

desired constant temperaturet

The product passed out of the

reactor and the liquid w a s collected in a flask until a product

sample was taken.

-.15gampllng,:

Before a .prodtiet sample was taken,,, it was necessary

to wait for the reactor to line pat .and. thereby produce a. reasonably

•constant c.onversiqn.

quinoline that from,

Ryffel

(13). fo.und In his. investigation of

6 to 8 hours of line-out time was sufficient to

insure a constant conversion,

After sufficient line out time,, a

sample’ of about 50 cc was taken in a 500 ml flask.

This sample

was followed by another sample at approximately I hour l a f e r .

In

most cases both samples were analyzed and. the average of the two

conversions was used.

Since- the various amines are. in vapor phase

while in the reactor, it was necessary to be sure that all of the

amines that had not Jpeen converted to ammonia were.condensed and

collected in the product s a m p l e .

To, insure this^ the liquid p r o ­

duct .and, the gas product were passed, through,,an additional con­

denser after passing through the Grove regulator.

This condenser

was a.stainless steel.coil that was maintained in a n ice b a t h .

At the beginning of the study^ the additional condenser was

not used.

In Figure 3> two runs of identical conditions are

plotted^ except during ,one of the runs, the additional.condenser

was employed..

,It pan be seen that the. ice-bath h a d considerable -

effect on fully recovering the unreacted amines from, the gas

product stream.

Additional procedures were employed in, .an

effort to .determine if there was a n appreciable loss of amines

from the product due to carry oyer but this could, not b e fully

—1.6determlned.

E.

Analytical Procedures

The nitrogen, content of each product sample was determined ,by

the standard Kjeldahl method (8).

For each run it was necessary to

determine the nitrogen content of the feed, as well as the nitrogen

content of the various samples.

Each determination was run in

duplicate to insure accuracy,, and the average of the two trials was

used.

Samples f r o m the runs which studied, the effect of hydrogena­

tion of the isomers of n-butyl amine were further analyzed with a

vaporphase chromatography u n i t .

The use of this unit ,made it

possible to examine the .various intermediates and products formed

upon hydrogenation.

This work was accomplished with a n Aerograph

Model A-IlO-C gas chromatograph in conjunction with a BrownHoneyweil .Model 14,5 x.

57 I H V

recorder.

—3-7’

III DISCUSSION OP METHODS OP DATA ANALYSIS

The rate of a chemical reaction, is expressed, quantitatively

as the mass or ,moles of a product produced, or reactant consumed^

per unit time

(14).

The rate of reaction can also be termed the

velocity or speed of a specific reaction.

Since the mass or

moles of a product or reactant are usually expressed as a concen­

tration,; the rate of reaction is.dependent upon the change of

concentration with time.

If the rate is based on the .change of concentration (C) of

the reactant with time

(t)> the rate of reaction (r) can be exp.

pressed as:

since the concentration of the reactant is decreasing.

"The law of mass action .states that the rate of a chemi

cal .reaction is proportional to the product of the 'active

masses' of the reactants involved. Since the activity of

a substance in a mixture is frequently difficult to obtain,

concentrations are usually used to replace the active mass

terms.

Por example, in the reaction

A + B —> R + S

we can express the rate as

r = --

s kC% 8%

where r is the rate, C a and C^ are the Concentration of the

respective reactants A and B and a, b, and k are constants.

The constant k in the above equation is termed the 'specific

reaction rate c o n s t a n t ', or simply the 'rate.constant'.

In

, rrgineral, its .units depend upon those employed for the con-

—18 —

centrallon arid upon the order .of reaction.

The order of

reaction Is defined as the sxtoi of the' exponents a and. h.

Reactions orders m a y h a v e values of 0, I* 2^

or some

fractional value.. This derivation of the rate equation

based.upon the law of mass action is theoretically■valid

only for homogeneous systems. However* it has been found

that data f r o m heterogeneous systems can also, be correlated,

quite -well in many cases.

This is particularly true when

one of the reactants.is present in large excess,

In. a heterogeneous catalytic reaction^ a factor must

also be included in the .rate equation to account for the

preparation^ composition^, and. physical properties of the

catalyst.

Thus for the overall reaction of

Quinoline + Hydrogen — $=■Hydrocarbons + Ammonia

the rate could, be expressed a s ; s

1=--aF=kM cS.

where k is the rate constant> z is the catalyst factor* and

C a n d C are the concentrations of quinoline and hydrogen*

respectively.

This is* of course* assuming constant tem­

perature a n d pressure,." (13)

The above equation for this particular study would be replaced

by the reaction:

Amines + Hydrogen -— > Hydrocarbons + Ammonia

■

If a large concentration of hydrogen is used*, the change in con­

centration.of hydrogen is negligible-and therefore the concentration

is assumed to be constant.

For any one given catalyst^ the factor

z is a constant and .can be combined with the rate .constant

f o r m a new constant R 2 .

to

Since the product from the reaction is

analyzed for nitrogen,* and, the nitrogen concentration of the feed

is also, knovjn^ it is advisable to base -the change of concentration

-+19'.

in the reaction on the concentration of the nltfogen rather than

the particular nitrogen compound.

This changes.the above rate

equation to the .new form:

Since the amount of nitrogen remaining in the sample, is

analyzed the-diff erence between the. initial .concentration (A) a n d

the amount converted (x), is determined.

then be substituted, for

This quality. (A~x) can

In, equation (I,)..

Also^ the symbol (.'O) is

u s e d to represent time by common convention.,.

r = -^

Equation (I) becomes:

= .Ka(A-Tx).11

(2 )

Since the actual .contact time is virtually impossible to.

determine^ some proportional measure of contact time must b e used.

The term ,space velocity is used and it is based. Upon, the yolume or

weight of reaching mass per unit v o l u m e .or weight of catalyst p e r

unit time.

Since ,both the feed and catalyst are measured, in, the

same units.,, space velocity has the unit of reciprocal time.

By

using the reciprocal of space velocity? this quantity can be subr

Stitufced

for the actual contact time in the above e q u a t i o n F o r

this study, the space velocity was determined by the weight of feed

in ,grams to the yreight of the catalyst in grams per hour.

If equation (2) is rearranged and integrated from. x. = .0 to

x = x

and Q = 0 to & = Q, the following is truer

(3)

-2.0Where O is also replaced by l / S y

The order of ,the reaction, is then equal to the'exponent

equation, (3) -

(n) in

In. arriving at this- equation^ it, was assumed the

hy d r o g e n concentration was a constant,; therefore^, ,the order .of, the

reaction is termed, "pseudo order".

T o r experimental .methods of determining order of reaction^ the

different orders are usually assumed,until one is found, which agrees

with the experimental -data. , T h e •agreement between the order of

'

reaction tested and. the data is. ,usually tested, visually unt i l the

.data looks as though it fits quite well.

If additional assurance

is needed.* statistical methods can. b e u s e d to further verify the

exactness of the res,ttlts,

.Under any condition^ however* the d a t a

points should n o t s h o w ..a .definite Upward o r .downward trend j (3')

-In. this, study the following, orders were -assumed -and tested,;

n = I.* 3/2.* 2.

f o r the .case of n = I

P

O

. ,fe

.A-X

=

'

-%A.

Sy

which integrates to give ln( V a -x :). = K e/S^,

A plot, of I n ( V A 7X). ys

l/Sy would, then, yield, a straight line with a .slope .of ,Kg. and an'

intercept of zero,.

To study reaction, orders of 3/2 a n d .2* the f o l l owing.should

be plotted and the results examined to determine if the .data yields

a. .straight Ihie.;

n = 3/2

Plot

2 / (A-X-J1^ 2VS l / S y

Intercept u 2 / A ^

— 21—

n = 2

Plot

I / (A-x)

vs

Intercept - l/A

1/SV

This.discussion..is. IarSeiI, on the assumption that the reaction isAmines + Hyirogen —

Hydrocarbons •+ Ammonia.

Pnom the ,analysis

obtained Ir pm. the. chromatograph., it was .evident that no .intermedi­

ates tha/k .contained nitrogen were lprmed.,

.I t .is-.,reasonable to

assume that the nitrogen compounds were .entirely converted to

ammonia or else remained in the s a m p l e .as the original nitrogen

compound.

—22—

IY DISCUSSION. OF RESULTS

The data from -this study were first examined .in. the m a n n e r .out­

lined previously.

Two hydrogenation runs were selected for the

■study of possible, reaction rate's.

The two runs chosen for this

analysis were selected on the basis that they best represented.the

charaoteristies of all t h e .

■data,,,'and because these runs were con­

ducted with some of the operating conditions similar to each of the

other.runs.

The operating conditions along w i t h 'the initial feed concentra­

tion changed with each run.

Since this information is only used- in

analyzing the dafa^ it is not generally referred to in this report.

These data.are given in Table II.

Also, the data.contained in

Tables III,.IV, V,.and VI, are the data.used for.constructing

,Figures 4 through 10.

Figure 4

is a plot of In A / (Ar-X) vs reciprocal space Velocity.

Since the data do not even resemble a, straight line through the

origin for either.run.,, it is assumed t h e .reaction cafe between

n - b u t y l :amine and hydrogen 'under the giveh conditions is not first

order. .Similarly,.-Figures 5 and 6 are plots to determine if the

reaction is- second order, or 3/2. order, respectively.

In "Figure 5,,

l / (A-x) i s . p l o t t e d ,vs reciprocal space velocity with the- intercept

equdl to l/A.

In this figure, ..the run conducted at 2^0 psig

I

reactor pressure comes closer to .fitting.a straight l i n e , but is

StiXl not accupEtte enough to assume a second..order reaction.

Figure

6 indicates clearly that the reaction rate is not of the order 3/ 2 .

F r o m the ,basis of this analysis,, it is assumed that the.reaction

rate is not of -common o r d e r .

This does not •eliminate the possi­

bility of an empirical equation that could express the reaction rate

for hydrogenation of n— butyl -amine.

It is- possible that the reaction

is controlled by some particular-step which .must first occur before

the-actual hydrogenation reaction, is completed.

For example., if it

is first.necessary.to form a carbonium ion from the amine before

the reaction can occur., then this rearrangement would conceivably b e

the controlling.step in the reaction. -The .possibilities of -actually

forming carbonium.ions, in such a reaction are -discussed later.

Since .more -extensive -studies were, not conducted into possible reac­

tion c o n t r o l l i n g ^steps., an oyerall reaction rate expression cannot

be determined.

In an effort to compare the.results of these runs ^.a common

basis was chosen for the analysis of all the-data.

The method

chosen was t o 'h a n d l e .the data in a,manner-similar to that f o r a first

order.reaction.

This- method was chosen f o r two reasons.

Since this

work was carried on in conjunction with the Esso Research .and Engi­

neering Company.,.the data were analyzed in the form of a first order

reaction so that both groups used the -same- .method .of data analysis.

Secondly* it- has been shown that the rate- of reaction for the

Jaydrogenation of quinoline under somewhat similar operating -condi­

tions -was of first order (13 ).

A,

Effpet Pff temperature,:

The .effect of -temperature.-on

hydrodenitrogenation between the temperatures, of

shown in Fig u r e Th

625-to 7250B1 is

■Fop a ..plot of In ^/(A-x) ys reciprocal, space

Velocity,.. the.;Uurves. should ,have an intercept .of z e r o .

This condi­

tion is true -both from integrating the reaction rate equation and

froni the.fact that at an infinite space velocity,*-the conversion

would b e - z e r o ,

At h i g h space v e l o c i t i e s , .it became increasingly more, diffi­

cult to.maintain -constant.temperature.through the catalyst zone. .

At a. space velocity, of 100.* .the -upper part of the ..catalyst zone

was not maintained at the -desired temperature.

This happened

because it became impossible for the-preheat zone to supply suffi­

cient' heat to bring.such.a.large volume.of feed.up to reactor

temperature.

F o r .this, reason the .data obtained at a space velocity

of 100 were.not included in this .temperature stu d y ^

The -data for

space velocities of 40.or less were obtained at constant tempera­

ture conditions.

■From Figure tJf it is,evident that an increase in temperature

of 5Q°F through- the-reactor w a s .sufficient to increase the conver­

sion considerably.

As -an example., the -data obtained at a space

velocity of .20.can be.used to compare the amount of nitrogen

-25■removed, for each temperature.

At ..this, space, velocity the..-catalyst

zone could h e maintained-at constant temperature, .but yet the .-con.Version was not high en °ugh to create-possible lnacccuracies in the

nitrogen content determination.

At this.space velocity.the ,percent

of nitrogen r e m o v e d .ah .the, temperatures of

respectively-were 66., S 75*2^,. and @0.0#.

•over, this temperature, range -an increase of

625, 675., and 7? 5 0F

This, indicates.that

50°F.-created- a.corres­

ponding increase -of approximately 6, 6^ .in the total, a m o u n t .of

nitrogen removed.

B.

Effect of p r e s s u r e;

The.effect of pressure, on hydrode-

.nitrogenation f or. n-butyl amine .between the .pressures of IOQ and

500 psig is. shown .in'Figure 8..

Figure 8 is a.plot,of In. A/(A-x)

vs.reciprocal s p a c e .veloc i t y .

As the ,pressure increased., ,the conversion increased rapidly.

For a pressure .of 100 psig., a. s p a r e .velocity, of 10 gave a .conver­

sion of -approximately

65^.

At a. pressure of ^OO psig.., .the-space

velocity, was increased to 100 and still gave a conversion higher

than at a space, velocity, of 10 for a reactor pressure of 100 psig..

T h e .conversion at a..pressure, of 5PP psig.and a space velocity, of

100 was 65.8$,, while -a space velocity of 100 at 100 psig had -a

conversion.of 5 5 -.SfL

Three runs were compared i n ‘Figure 8-.

with a n-butyl.amine feed.

All runs were ,made

The,pressures were 100,■250,. and 500

^-26—

psig.

Again ,a. space velocity, cxf 20 was -chosen for a cpmpapison

between conversions,

The conversions f or pressures of 100^-250,

and 500 p s Ig ,were $1.?#, 80.0#, and 95-.2^ respectively.

space velocity of

At a

10 ,and-a pressure.of 500 pslg».there was essen­

tially. complete.conversion.

C.

Effe c t ,of molecular weight:

,As a- comparison for molecu­

lar weight both n-butyl smine a n d .n -octyl amine were studied.

N o r m a l .octyl amine was hydrogenated at pressures of

p s i g ,and a temperature of

plotted In Figure 9-

100 and 500

7250F « The results of these runs are

Also^ in Figure

•amine are .plotted for a comparison.

9 ,similar runs with n-butyl

At pressures of both 500 and

IOO psigj the conversion is hig h er f o r .n-butyl amine than for

.H-OCtyl amine.

toward'

As the .molecular.weight, increases ^ this trpnd

more stable- compounds would probably continue for. other

saturated aliphatic amines

The product from the n-octyl amine study was examined for

ppssible intermediate, compounds.

By-use of the .chromatograph it

was possible to determine that the n-octyl amine was not cracked

to form lower .molecular weight hydrocarbons .

dent that the •carrier, -n-heptane* underwent

Also.,.it- was evi­

very, little .cracking

or change of composition.

D.

Figure

. Effect of structure on .the .hydrogenation of butyl a m i n e s ;

10 shows the effect of hydrogenation on the,various isomers

-27of butyl a m i n e . .F r o m the Figure It is evident that the ease of

denltrogenating the Isomers decreases from tert-butyl amine.* secbutyl amine* Iso-butyl amine.., to ,n-butyl amine In that order.

a ■comparison between, the conversions , ..a^space velocity of

As

100 for

tert-butyl. amine gave much higher conversions than did a space

velocity of

10 for n-butyl amine.

In an effort to justify this occurrence*, various possible reac­

tion mechanisms were studied.

The possible intermediates were

examined by use of a vapor-phase chromatograph.

It was proposed

that the reaction occurred after the amine first went through a

rearrangement to form a. carbonium-ion.,

A carbonium ion. is a.group

of carbon atoms such that the carbonium. ion carbon has only.six

electrons i n its valence shell (12).

As an example of a carbonium

i o n * ■isOtbutyl amine can. f o r m the ion:

.H3C

i.

CH 3 - 0+

i

H 3C

■This ion .can then react with a hydrogen ion from the catalyst to

form the hydrocarbon isobutane.

The identification of the reaction products and intermediates

was accomplished, by using the method., of yapor-phase chromatography.

A vapor-phase chromatograph works essentially as a highly efficient

distillation column., ..However., it allows the analysis of very small

samples in a.matter of minutes.

The sample under investigation is

.-28in je eted into the iinit and is carried.,by a stream of helium into the

packed column where it is selectively absorbed on .the substrate..

■The absorption properties of each compound determine their

respective retention times in the column.

The stream of gas

emerging, f r p m the column passes through a sensing .element which

measures its thermal..conductivity and compares it to a.standard

(helium) .

This change i n thermal conductivity is shown -on .a

continuous chart recorder-.as a series, of peaks ? one for each com­

po u n d .as it emerges f r o m the column.

.Thus by identifying each

peak by. comparing it to peaks created f p o m k n o w n compounds ,■ it is

possible to determine the various intermediates.or products formed

in a reaction (13).

Samples studied by this method were:

1.

.n-butyl ,amine .under high conversion.

2 . iS'Q'-butyl amine under h i g h conversion.

3 . sec - b u t y l .amine under high conversion.

4. • t e r t - b u t y l .amine .under ,high conyers i o n .

3 . .Urrbutyl pmine under -low. conversion.

6.. iso-butyl-amine ..under low. conversion.

7 . sec- b u t y l -Umine Under l o w .conversion..

8 . tert-butyl-amine under low.conversion.

9 . iso-butyl amine with acid.wash.

10.. .tert-butyl-amine with acid wash.

The chromatograms of the above studies are included in Figures

11 and 12.

In these figures* the Various products formed a r e also

identified.

The proposed mechanism for hydrodenitrogenation, of the isomerp

of butyl-amine is essentially that of a car.bonium ion rearrangement.

-29Both n-butyl amine-and iso-butyl amine form the carbonium ion before,

reacting.• The .sec-butyl amine, reacts directly without rearrange­

ment while tert-butyl .amine reacts as a carbonium ion since it is

already in that, form ('12).

Samples f r o m these.runs which had,very high conversions seemed

to uphold this theory.

This assumption is based,on the fact that

the carbonium. ion. must first be.formed before.the reaction can

occur.

Because of this.,,, -some .of the hydrocarbons.produced must

s'

appear in. the product as isobutane.

■E i g u r e .11 shows the. results

of this investigation.

The.difference between the isobutane curve ,and.the n-butane

curve is labeled (A).on Figure.11.

By comparing the s e .c u r v e s •to

the .curves-' produced ,from the product, samples.,.it is. possible to

•distinguish .the :various hydrocarbons -which were formed.

Part

qf Figure 11.shows.the effect of the n-butyl.amine s a mple.

(B)

By

comparison .it is.evident that some isobutane is formed from n-butyl

amine.

Also,, Part

(O) shows that iso-butyl,amine produces essen­

tially iso butane at high .conversions,

Part

(D) indicates that sec-

butyl -amihe-does not ppodp.ee,-any. Isobutane.!,therefore.,,the. carbonium

ion was.probably n o t .formed,before denitrogenation occurred. Finally,

Part

(E) indicates that, tert-butyl.amine,produced isobutane .-upon

■reaction...

This .analysis at high conversions tends to.uphold.the

carbonium ion rearrangement as .a, possible intermediate .step.,in the

-90reaction.

As .-a further check,.■samples from the .same.studies...at low. con^

versions.w e r e .examined.

Part

(A) of Figure 12 indicates that at

l o w e r .conversions.,.n -butyl amine, still, produces, some isohutane .and

Part '(B) indicates, that sec-hutyl-amine still forms, only, n-hufane.

However, iso-butyl .amine.and., tert-hufyl amine indicate that, there

is. some, other intermediate formed.in addition to. the isobutane..

This is sh otm..as Part

('C).and (B) in. Figurp 12.

The .possibility

that these two .compounds form, an intermediate.of n - b u t a p e .is diffi­

c u l t .t o :understand .or explain,.

.In a n e f f o r t .to--determine the.

nature of this intermediate, compound,,, the .samples, were acid-washedbefore b eing .examined..-on-the chromatograph.

acid wash are Part

(E) and

The. s.amples. after­

(F) of Figure 12.* iso-butyl-amine and

tert - b u t y l .amin^.-respectively.

However,., f.rpm-the .Figure.it is

evident that the-acid .-wash did. not remove the intermediates . -If

■ these intermediates had been unsaturated.or-perhaps some a m i n e ,

the -acid-wash sho u l d .h a y e .r e m o v ed,t h e s e .compounds .

Since.the

carrier has been shown to ..not he affected.by. the hydrogenation, ,it

is difficult t.p -determine fully the nature of these intermediates.

The true.mechanism for.these -reactions cannot be fully determined

,.withp.ut.further inves tigation,

The .feed-samples for each-compound were-also examined for

impurities^ but since no impurities.were found, this analysis is

not reported- in the ,appendix.

The.possibility that,.these compounds must, form various inter­

mediates before ..reacting, may be part .-of the-reason'.that. the. reac­

tion rate cou,ld not be.expressed as.some.simple.order.

i "

By assuming such ,a mechanism .for t h e .hydrogenation, it would

then ,be' possible .to explain- ttie-order,in '.which these, compounds'

^enitrogenated,

Using the carbonium ion..mechanism.as an example.,,

the f o l l o w i n g .mny.occur.

If the tert-butyl amine-did not -rearrange

-and.was. alre a d y .in ,-a. form which -caused,-direct .reaction.,,.then .it

would yield.the highest conversions.

If the secondary compound

also did not' BeaMaiager ^hpt -was not in the-some active, state-as

tert-butyl.amine,, then It would ,yield,high.-conversions.but not as

high ..as.tert-butyl a m i n e .

The .iso-butyl amine -would -undergo some,rearrangement^, but

.not as much,as .would -nsbutyl amine.

•This would ,cause.the iso-

butyl amine.to-react faster than the n-b-ptyl.amine.

This, t h e n / .

means that-the-amines.reacted.in-the,order with this.rearrangement

mechanism.

•From. Figure.10, it can be seen Lthat these.compounds

.did -.denitrogenate in this, particular, order.

V ''CONCLUSIONS

The data; from the .hydrqdenitrogenatlon atudy were f i r s t .-examined

for possible pseudo reaction rate.order. .It was determined that

the reaction rate was not of common order.

From the .chromatograph

analysis,:it was evident that n-butyl amine .formed'intermediate

compounds upon hydrogenation.

The formation of intermediates.could

.be.rate controlling, causing the .order .of reaction.rate to be .of

uncommon order.

The effect o f .temperature wfcs.studied on .n-butyl amine.

It

was shown that an increase in temperature increased the total

nitrogen conversion.

At a space .velocity of.20, an increase in

temperature of ^O 0F .increased.the .total conversion by

6+$.

An increase in pressure increased, the total nitrogen conver­

sion considerably.

was

At a space velocity of 100, the conversion

65.8^ at 500 psig.as compared.to a.conversion,of 35.8$ -at 100

Pflg By comparing-.n-butyl amine to n-octyl amine, it was.evident

that the lower molecular- weight compound reacted.to give higher

conversions.

This condition,held fo r pressures.of 100 and 5QQ psig.

The conversions for the isomers of butyl amine decreased in

the order, of tertiary, secondary, iso, and. normal.butyl.amine.

This-order.may fee -accounted.for, by the.various-mechanisms needed

for each compound to denitrogenate.

VI ACKNOWLEDGEMENT

The author would.like.to take this opportunity to. acknow­

ledge and ..thank the Esso -Research, and Engineering .Company that

sponsored this research project and supplied many materials used

throughout the investigation.

He also wishes, to thank the staff

of the-Chemical Engineering .Department for their helpful suggest

tions and criticisms-;.and in particular. Doctor Lloyd. Befg who

directed this research.

He would also like to thunk.Mr.

G. P.

Schreiber^,fellow research worker,,..for his assistance .on this

project.

. V m B I T E R A T U B E .CITED

(1)

Ball,, J. S. ,., et a l -'"Nitrogen Content of Crude -Petroleum11)

I n d .■and E n g r .■C h e m .,.4^:25 (1951)•

(2)

Benson, D. B., B h .D .■ThesIs * Montana State College, (1958).

(5)

•Corrigan, T . E .,■"Chemical E ngineering,Fundamentals", C h e m .

F n g r vj.61 (-1.954),, 62(1955).

(4)

Hodgemun^l C. D.> and H. N- Holmes.,.-"Hand Book ..of Chemistry

and Physicsn j .Chemical -Rubber Publishing , C o Cleveland,

-Ohio (1955).

(5)

Holecek., -R. J.., M.S. Thesis., ,Montana State College,; (.1955) •

46)

Jacobson, R. L.., -Ph.D. Thesis.,. Montana State Collegef- (I958-) .

(7 )

King, G. A.., M.S. -Thesis;,. Montana State College,. (1955) •

(8 )

Kirkj .P . L. ,• "Kjeldahl .Method for Total Nitrogen"., Analytical

Ch e m . , 22:554(1950).

(9)

Mahugh, R. A. , Ph.D, Thesis^ Montana State . . C o l l e g e (1,960).

(10)

Mills, G. A., et a l . "Chemical,Characteristics of Catalysts.

I. Poisoning.of Cracking,Catalysts by Nitrogen Compounds.and

Potassium Ion." .J. Am. C h e m . Soc ., 7? ^ 5 4 4 (1950) .

(11)

Opprecht, M. K., M.S. Thesis,, Montana State College*

(12)

Royals E . E ., ■"Advanced .Organic Chemistry" , Pr entice-Hall,.

Inc.j New York., (1954) .

(15)

Ryffel,. J. R . f .Ph.D. Thesis* Montana State College,,

.(1.4)

Smithy J. M., "Chemical Engineering Kinetics'!,, McGraw-Hill

Book Co. , New ,York* (1956).

(15 )

United States Bureau,,of Mines,*,Report.of Investigation*,

(1958.) .

(i960).

5044(1951).

(1'6)

Waterman*.-R,. .

vG.,j, Ph.D. Thesis.* Montana State College*. (1958).

APPENDIX

page

Table I

Effect of Ice Bath on Sampling

35

Table .11

Operating .Conditions and Initial Feed

•Concentrations

36

Table III

Data for Test of Reaction Order

37

Table IV

D a t a for Effect of Temperature on Hydrogenation

.38

Table V

D a t a for Effect of Pressure on Hydrogenation

39

Table VI

Effect of Structure on Hydrogenation of Butyl. Amine 40

Figure I

Schematic Flow Diagram .of Hydrogenation Unit

41

Figure 2

Detailed Diagram of Reactor

42

Figure

3

Effect of fee Bath on Sampling

43

Figure

4

Test for

Pseudo First Order Reaction

44

Figure

5

Test for

Pseudo Second Order Reaction

4$

Figure

6

Test for

Pseudo Reaction Order of 3/2

46

Figure 7

'

Effect of Temperature on Hydrogenation

4y

Figure § :.

Effect of Pressure.on Hydrogenation

48

Figure 9

Effect of Pressure on Hydrogenation of

Aminej,.. and Effect of Molecular Weight ojL

Hydrogenation.

nvQctyl

49

Figure 10

Effect of Structure .o n .■Hydrogenation of Butyl Amine 50

Figure 11

Chrdmatogram for High Conversion Samples

Figure 12

Chromatogram for L q w ■Conversion Samples and. Ac,id

Washed. S a m p l e s ’

51

.52

-36table

.I

EFFECT OF- ICE ,BATH ON SAMPLING

Sample

Conversion

A-x

Space

Velocity

Ice

Bath

Sample

.Conversion

A-x

iclce

Space

V e l o c i t y • Bath

Sv

M

.

N- 2,^6

'

.06 0

-IQ

No.

.1262

,2 0

Ho

I

N-IO

'3 5 7

AO

.No-

I

'

,Yes

N —2^f

.2 0 2

20

Yes

N -2 A t 6

.3 8 7

' 40

Yes

■

Unifotim Operating ,Conditionst

Feed.:

Temperature:

.Pressure:.

.Weight.of Catalyst:

10

1% :n>-butyl amine

725'0F

250 psig

,10 g.

— 30’'TABLE II

.OPERATING CONDITIONS.AND.INITIAL FEED CONCENTRATIONS

.Run

Feed

Feed

Cone.

Wt..^N

T e m p .°F

Press.

Ps ig.

Space Velocities

Nr-14

n-butyl amine

0 .9 8 4

675

250

1 0 , 20

N^ l 6

;n-butyl amine

0 .9 7 ;

625

250

N-17

octyl amine

1 .0 5 0

725

500

.-10.,

Nr 18'

n-butyl amine

.1 .0 1 4

725

500

, 1 0 , 2.0, 4 0 ,,1 0 0

N-19

sec-butyl amine

1 .0 2 7

725

290

1 0 , 2 0 , . 4 0 , 100

N-20

iso-butyl amine

1 .0 2 2

725

250

.10., 2 0 , 4 0 ,-1 0 0

NC21

tert-butyl amine

.990

725

250

. 1 0 , - 2 0 , 4 0 , 100

725

100

1 0 , 2 0 , 4 0 ,.1 0 0

100

10.,. 2 0 , 4 0 , 100

■10,20

20j .4 0 , 100

N—22

octyl amine

1 .0 4 0

N-25

n-butyl amine.

.1 .0 4 5

N-24

nObutyl amine

1 .0 0 8

725

250

1 0 , 2 0 , 40

1 .0 0 8

625

250

40

N-24

n-butyl amine

725.

-

Uniform Operating.Conditions:

.Pressure:

.W e i g h t ■of Catalyst:

,Hydrogen -Rate:

250 psj.g

,10 g.

500 SCE of Ha Zbbl .of Feed

''/

TABLE .III

DATA FOR ,TEST OF REACTION ORDER

Sample

Space Velocity

.Sv

l/Sv

Press..

Psig

A-x

A

A-x

In

A.

A-x

N— 23-2

20

.05

100

..505

2.07

:728

N-23-4

10

.10

100

,365

2 .:87

1.054

N —.25— 6

40

.025

100

.605

1.73

N-23-8

100

.01

100

,671

’ 1.56

...443.

N-24-2

•10

,10

250

,108

9.58

2.23 ■

N-24-4

20

.05.

250

,202

4.99

1.61

N— 24-— 6

-40

.025,

2^0

,387

2.61

.96

.548

i

Sample

I

.A-x.

2

.A

.957

'1,955

A-x

1■.- - .

2 ..8l4

2,

I

A

A ,

1:045

N—23-2

1 .98.

N-23-4

- 2.74o

-3..31

N-23-6

1,65

2.57

N^23-"8

1,49

.-2,44

N-24-2

9.27

6.10

.996

N-24-4

4.44

ll_

■It

ri

4,95

N-24-6

3.22

II

n

it

2.59

11

It

11

H

It

it

M

II

11

.Uniform .Operating ,Conditions'

Feed.:

Temperature:.,

.Weight of Catalyst:

.Hydrogen Rate:

lfo .n^buf^l

72§°F.

.10 g.

500 SCF of

amine

H a Z b b l of feed

1.99

■_

.1.008

-3<9—

TABLE .IV

-

.

DATA FOR EFFECT OF TEMPERATURE .ON HYDROGENATION

Sample

Space Velocity

y /v

Tempv0F

A-x

A

A-x

'

In

A.

A-x

N-24-2

.10

725

.108

9,24

N-24-4

.20

725n

.202

4 .9 9

1.61

6

40

725

.387

2.61

.96

Nr-14-4

20

675

.265

3.71

1.31

N-14-6

10

675

,14-2

6.93

1.93

N - 1 6—2

20

625

.325

3,01

.1.10

N -I6-4

.10

625

.222

4.4

N-24-8.

40

625.

.526

1.92

Uniform Operating.Conditions :■

.Feed:

.Pressure:•

Weight ofCatalyst:Hydrogen R a t e :

Vfo .n-Untyl .amine

250 psig

10 g.

500 SC^ of H 3Zbbl

.

2,23

1.48

.652

TABLE .V

DATA FOR•EFFECT OF PRESSURE .ON HYDROGENATION

Sample

Space

Velocity

v/v

N-23-2 •

N-23--4

N-23-6

N-23^8

N— 24-2

N-24-4

N-24-6

N-18-2

N— l8-4

N- lb- 6

N-18--8

N-22-2

N-22-4

N-22-6

N-22-8

N-17-2

N-17-4

N-I 7-6

N-I 7-8

.20

10

40

100

10

20

40

.20

10

40

100

20'

10

40

100

20

10.

40

100

Press.

Psig

100

.100

.100

100

250

250

,250

30-0

A-x

A

- -A-x

•505

22097

2.#7

1.73

.1,56

9.34

4 .99

2.61

14.7

.365

.605

.671

.108

,202

.387

.069

In

A

A-x

.728

1.054

.548

.443

2 .2 3

M

.11

.96

2.70 ’

' Uniform Operating .Conditions;

.Temperature:

.Weight of Catalyatc

.,Hydrogen R a t e :

n -butyl amine

It

It

' Il

.1 .6,1

500

.complete conversion

500

6.00

.169

1.79

500 ' .347

2,93

1.075

100

1.643

4497

,633

.100

.520

.6o4

2.00

1.00

-747

1.375

.519

100

.8Q2

1.296

.259

500

11.0

2.40

.0956

500

'conversion top high

500

3.80

.1,334

.277

500

..412

2 .55

.936

Feed:

Feed

-1% n-Pptyl -.amine

Vfo n-oetyl amine

7.25°F

IO g.

$00 SCF of Ha/bb.1 of Feed

"

.it

' I!

It

,

n-oetyl amine

11 "

It

It

It

11

M

TABLE .VI

.EFFECT .OF- S T R U C T U R E ,QN HYDROGENATION OF BUTYL AMINE .

Space

Velocity

Feed

It

N-24-6

,11

20

.202

4 .99

-1.61

40

2.61

.96

100

.0)88

2 5.5

3.34-

.20

.0739

13.85

2.63

n

40

.519

3.21

1,167

n

.100

.531

.1.927

.657

.100

,1480

6..94

N-r21--@

tert-butyl amine

N -20-2

iso-butyl, -.amine

N-20-6.

N-20~8

N - 19-8

2.23

9.34

sec-butyl ,amine

Uniform. Operating ,Conditions-:

..Temperature-.

Pressure:

1

.Weight Qf Catalyst:..Hydrqgen. Rahe-

725°F

2 5 0 -psjig

10 g.

56-O UQF of H 2Zhbl

H

N-24-4

Vio-

g

n-butyl amine

A

A-x

iA

A-x

is

N-24-2

In

A-x.

—j

Sample

1.94

-42-

Q K

W O

CO

Eh CO

O CO

Ph U

W Eh

H

FQ

Ph CO

CO Cq

DRIER

ROTOMETER INDICATING

DRIERITE

k

DEOXO UNIT

p w

o ,-q

HYDROGEN

Figure I.

Schematic Flow Diagram of Hydrogenation Unit

-45 -

Thermowell

"Rupture Disk

■Catalyst

Support

■Pipe Wall

■Catalyst Bed

Asbestos Tape

•Nichrome

Heating Coll

■Catalyst

Support

Insulation

"Flanged Union

O " ^ Denote Thermowell Location

Figure 2.

Stainless

Steel Screen

Detailed Diagram of Reactor

-4ty-

0 - U s e of Ice Bath

-Normal Water Condenser

W t . % N in sample

(A-x)

A

Sy Space VelocityFigure 3.

Effect of Ice Bath on Sampling

-4^-

2.5

Z

&

T e m p . 725°F

Feed I % n-butyl amine

O — 250 psig

2.0

Z

/

/

A — 100 psig

f

1 .5

(A/A-x)

z

Z

1 .0

f5'V

Z

, 6°. >

Z

A

A

/

z

Z

.025

.05

.075

.10

l/Sv Reciprocal Space Velocity

Figure 4.

Test for Pseudo First Order Reaction

.125

-46-

O —

250 pslg

— 100 pslg

.025

.05

.075

.10

l/Sv Reciprocal Space Velocity

Figure 5.

Test for Pseudo Second Order Reaction

.125

-4fj-

O

-250 psig

— 100 pslg

.025

.05

.075

.10

V s y Reciprocal Space Velocity

Figure 6.

Test for Pseudo Reaction Order of 3/2

.125

□ — Temp.

O ~Temp.

-Temp.

(A/A-x )

A

l/Sv Reciprocal Space Velocity

Figure ?>.

Effect of Temperature on Hydrogenation

( V a -X)

-4^-

500 psig

100 psig

1/SV Reciprocal Space Velocity

Figure 8.

Effect of Pressure on Hydrogenation

0 — n-butyl Amine

n-octyl Amine

1/SV Reciprocal Space Velocity

Figure 9•

Effect of Pressure on Hydrogenation

of n-octyl A m i n e , and Effect of

Molecular Weight on Hydrogenation

(V A - x )

-$& -

O — n-butyl Amine

A -Iso-butyl Amine

Q -sec-butyl Amine

V - tert-butyl Amine

l/Sy Reciprocal Space Velocity

Figure 10.

Effect of Structure on Hydrogenation

of Butyl Amine

(T)

A iV

<V7> <1

i

(D

(^)

ISe b u T ^ n €.

H

(D

/I Tn -m o -y» I o-

®

I SobuTaI) t

4-

» - bu f a n e

f <•<J

H*

7>-bvTyl

fltn c n <

"sample

©

IS o - bo T y / a Tm,T i«

9

©

Sec - bu7y /

Qmme

§

©

T rtl

6mm e

H

Cf

0

13

*-b

O

4

M

H*

f

O

0

2

5

3

H-

§

M

1H

0>

W

» -

bvT^T* C

- bv T y I

S am p le

S am p le

S tm p le

I

Figure 12.

Chromatogram for Low Conversion Samples and Acid

Washed S amples.

U.1

■'S*

r!

" r

V »

©

^ir

4-

(^ -

>7- bvTy I

(g)-

S e c- Io c ty /

d-miTv# S+Tr*p\e

Am rne Tm*.

/So -

!,aty)

tfy n iT ’ -'

S a m p le

a-jni-pr Sa-mfle

r+>T- bvTy I

^7 771 Iit •#

TerT ' b u ty l

Qyrt noe

ia Tnpl-*

Sample

( actd

uoesbej)

MONTANA STATE UNIVERSITY LIBRARIES

3 1762 1001 3372 5

N i /8

C936c

cop.2

145253

Currie, R . A .

145253