Building Consistency Meeting

advertisement

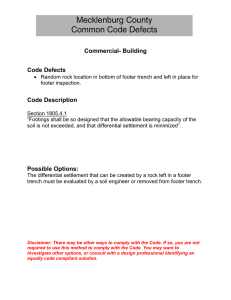

Building Consistency Meeting Residential Date: 9/7/2005 Recorder: Danny Wooten, minutes prepared by: Jeff Griffin Staff present: Jeff Griffin; Gene Morton; Danny Wooten; Harold Sinclair; Steve Kellen; David Morton; George Rogers. Public present: Frank Burke (Grimmer-Kempf & Assoc); David Schwiemon (Public); Hans Kasak (Ryland Homes); Bob Mckee (Ryan Homes); Evan Weiss/Terry Cleary (Meeting Street); Chad Nelson (Shea Homes); Wayne Carter (Evergreen Homebuilders); Shawn Polakiewicz (Saussy Burbank); Dave Reynolds/Toby Brundage (Builder 1st Source); Cory Cronin (CP Morgan); Bob Otto (R.E. Otto & Sons-NARI); Adam Kuhn/Dave Patterson (Craft Homes); Rick Lauer (Turnberry Homes); Jack Glunt (Westfield Homes); Bill Green (Barefoot Company). Topics/Subject Decisions/Conclusions/Actions Old Business Girder bearing on piers Attic Access This issue was discussed again, it’s important to understand that this is proposed with the next version of the Code and although final approval is expected it is not currently allowed until next Code which is scheduled to come out June/July 2006. The issue is a footnote under table R403.1a footnote #3 on page 59 of current 2002 Code. Proposed change is that girders will no longer have to bear in the center 1/3 of the piers and can bear anywhere across the top of the pier. Pier must bear in the center 1/3 of the footer (this is the critical issue to prevent rotation of the pier). Girder must be on the pier (nothing hanging off) and any column load must be solid blocked across the entire pier surface. Question was asked about the new language going before the NC Building Code Council on attic ventilation requirements. This is being re-worded to almost take all attic access requirements away except if there is a need for mechanical equipment access. This issue was discussed previously but again at this meeting the intent was readdressed how this will affect builders in the field. See attached language that is proposed in the 2006 Code. New Business Vapor Barrier installation Last month issue was discussed that a code change has already been approved that will no longer require a vapor barrier on exterior walls in most of NC. Although a vapor barrier is no longer required if one is used and installed it will not be prohibited but must meet mfg requirements to install correctly. Batts with paper face towards the exterior walls will not be acceptable. Issue came up behind a fireplace area where all the paper faced Batts were installed backwards. Non-vented attics Petition for non-vented conditioned attic assemblies has been approved by the NC Building Code Council and rules committee. Attached to the minutes is a copy of the petition and Code language approved. If requested by a contractor this application can be approved at this time based upon new Code language. Also attached is a section of a letter submitted to the BCC restating the language of the Code and an on line website for additional information, you’ll note that currently 2 shingle manufacturers have approved installation with their product. Bay area roof venting Question raised about if there is any change to the bay area option discussed several months ago for that small attic ventilation. The nonvented attic space listed above is an option for foam applied directly to roof deck and doesn’t affect the previously discuss venting allowance for small bays that have fiberglass insulation batts with full vapor barrier on the ceiling (to reduce vent requirement) and continuous soffit venting only. The 2006 Code will allow this also but will not require in the language if it passes BCC the vapor barrier. Questioned asked about the use of structural fiberboard. This continues to be an issue that comes up due to rising cost of OSB/plywood. Method #4 as listed in section R602.10.3 for braced wall panels. So this would be allowed and is not an alternate. Table R602.10.3 reads almost the same as method #3 (plywood corners). 1 story house would have to have 1 piece at each corner and every 25’ on center and not less than 16% of the wall line. In a 2 story and above there is more % of the wall required to have structural fiberboard. Builder can us but must design per this table on page 118 of the 2002 NC Residential Code. Structural fiberboard Engineered Issue keeps coming up in the field in regards to engineered designs and footers or Slabs if a County inspector needs to inspect. It is a requirement that all engineered slabs or footers such as caissons or pile’s be inspected by this Department and documented. The following is required for each inspection. Caisson footer- The hole for the caisson footer doesn’t need to be viewed prior to concrete pour and can be filled to base of footer trench prior to County inspection/review of footer layout. This doesn’t have to be pre-poured and can be poured with the footer or mono slab after the footer inspection. An engineer’s plan must be on site for footer inspection and all trenches dug, steel tied and in place, and all caisson positions verified per engineers design sheet. Footer will be turned down without a penalty if all is per design, pending a final engineers letter on installation sign off including the layout. This needs to be ready by next inspection. Inspector will document caisson footer and engineer of record. Pile footers- Similar procedure as with caisson footers. Wood piles can be driven and when inspector arrives on site a pile placement plan along with footer plan should be provided, trenches cleaned out and all steel in place. Footer will be turned down without a penalty (if no other issue are noted) pending engineer’s final approval report that includes a pile report (location and depth of each pile). This should be provided by next inspection. Inspector will document pile footer and engineer of record. Engineered slab- (waffle slab, post tension, etc..) Slab must be completely ready and all required steel in place. An engineers design must be provide for review by field inspector prior to any concrete placement. Engineered slab will be turned down without penalty (if no other issues noted) pending final engineers letter on design and sign off on installation. Engineer’s letter should be supplied by frame inspection. Inspector will document type of slab construction and engineer of record. Next meeting is on October 5th Ed Woods room 1st floor at 8:00am, 700 N. Tryon St.