Date: October 18, 2005 TO:

advertisement

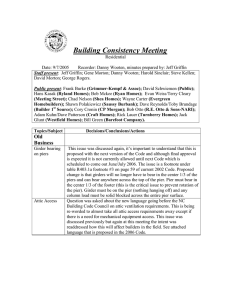

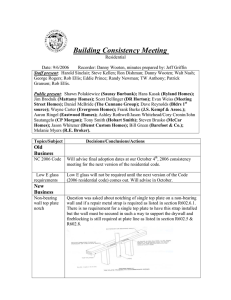

Land Use and Environmental Services Agency Code Enforcement MECKLENBURG COUNTY Memo Date: October 18, 2005 TO: From: all contractors Jim Bartl RE: Code Compliance Report For the last 8 years, the Department has collected data on inspection failures, based on a system of defect codes, which are recorded at the time of inspection. This data is summarized in reports for presentation to the Building Development Commission on a quarterly basis, and subsequent distribution to the industry. Attached is a copy of the most recent Code Compliance Report Data Summary for the period July 1, 2005 to September 30, 2005. This report highlights the most frequent code defects sighted in each of the four inspections trades, Building, Electrical, Mechanical and Plumbing. Since July 1, 2001, detailed contractor code defect data has been available on the Department web site (go to the contractors tool box at www.meckpermit.com). Questions on the data may be directed to the appropriate trade chief or Kathleen Batey (704-336-3545). Prior to July 1, 2002, we also held hard copies of individual contractor defect reports at the Building Development Center front desk for contractor pickup. Given the huge amount of paper involved, and the fact that the vast majority of these reports were not picked up, this service was discontinued. However, Hal Marshal Center Document Control staff will provide assistance to contractors on downloading their reports over the counter or by phone (704-336-3830). Mecklenburg County Code Enforcement Department Building Trades Code Compliance Report Building Inspections Electrical Inspections Mechanical Inspections Plumbing Inspections July 1, 2005 through September 30, 2005 Building Consistency Meeting Residential Date: 7/6/2005 Recorder: Danny Wooten, minutes prepared by: Jeff Griffin Staff present: Jeff Griffin; Gene Morton; Danny Wooten; Ron Dishman; Harold Sinclair; Jacki Templeton; Steve Kellen; David Morton; George Rogers. Public present: Frank Burke (Grimmer-Kempf & Assoc); David Schwiemon (Public); Hans Kasak (Ryland Homes); Daniel Mcbridge (The Cunnane Group); Bob Mckee (Ryan Homes); Evan Weiss/Terry Cleary (Meeting Street); Chad Nelson (Shea Homes); Tony Smith (Hobart Smith); Wayne Carter (Mulvaney Homes); Shawn Polakiewicz (Saussy Burbank); Chris Huzar (DR Horton); Scott Karriker/Robert Gordon (Superior Walls); Charlie Mitchell (P.E.); Dave Reynolds/Toby Brundage (Builder 1st Source). St. Topics/Subject Decisions/Conclusions/Actions Old Business Insulation vapor barrier The NC Building Code Council has approved and New Business New Asst. Chief Introduced new Asst. Chief Building Code Administrator George Rogers. County has 2 asst. chief’s who can be reached at numbers below: George Rogers -704/336-3504 cell#634-0287 Jeff Griffin -704/432-2383 cell#634-8847 Code update Introduce a few new items that are in the works for change (not in effect until 2006 printed addition adoption date). Please note that due to delays in the review of the 2003 IRC the Building Code Council doesn’t expect to meet the Jan 1st Code Change and is schedule to implement on June 1st, 2006 at this time. With this the change in Solar Heat Gain requirements for windows will go into effect. This gives almost a year from now to get the word out that Low E glass will be required for windows with the 2006 Code. Code Compliance Task Force Superior wall systems Due to a rise over the last several years in the overall industry failure rate the Code Compliance Task force has been put back together to look at ways to reduce these rates, through training, notification to a contact person within an organization of their overall ranking/performance; delayed re-inspection or other measures. There were many initiatives that came out of this task force when started up several years ago, one of which was the present day CO program. As this task force works to develop programs or new initiatives we will keep the industry notified as well through the Code Consistency Task Force of any changes that will affect the industry and inspection requirements. Superior walls representative and engineer presented information in regards to their precast foundation walls systems. This wall system is not specifically listed in the Code and is an engineered product. Some information was discussed related to the installation of this system. The building inspector should expect to receive on site at a foundation inspection a foundation plan and the complete installation book. It is very important that this installation guide book be followed when using this system and will be required to on site at both the foundation and frame check. Smoke detector location CO detectors Cementitious siding Laundry room gas appliances (make up air) As discussed in previously. The electrical inspectors are no longer looking at location of smoke detectors since no longer a requirement under the NEC. Building has requirements as listed in section R317. With this the building inspectors are looking at placement and recent issue that came up and was discussed was a ceiling installation. When a house has a room that is wired or setup for a ceiling fan, but not installed, there should be some consideration as to the permanent placement of these detectors as if the fans had been installed. Example given was that detector was required by installation instructions to be 3’ from a ceiling fan. Largest ceiling fan usually installed might have a 52” blade; this means that from the box without a fan installed, the smoke detector should be about 6’ away. Installation instructions on a specific tested detector must be followed. Carbon monoxide detectors are required to be in every home according to the County’s Health Department ordinance. Building inspectors should still be leaving stickers as to the requirement but this is a notification service only-Health Department enforces ordinance. Questions continue to be asked related to 2 areas and the use of this type siding product. Felt paper or housewrap is required behind siding and aluminum flashing cannot be in contact with this type of siding product. Flashing code reference R703.8. Question asked about make up air for Laundry room areas where dryer & gas water heaters are located. This would be covered by the Mechanical code only issue related to building would be if outside air was brought into this space then this area would need to have thermal separation. Separation requirement would be to insulate these interior walls, a door with weatherstrip and if located on the second floor then the floor system between levels under this area would need to be insulated. Next meeting is on August 3rd Woods room 1st floor at 8:00am, 700 N. Tryon Building Consistency Meeting Residential Date: 8/3/2005 Recorder: Danny Wooten, minutes prepared by: Jeff Griffin Staff present: Jeff Griffin; Gene Morton; George Rogers; Danny Wooten; Ron Dishman; Harold Sinclair; David Morton; Steve Kellen; George Rogers; Eric Brown. Public present: Frank Burke (Grimmer-Kempf & Assoc); David Schwiemon (Public); Daniel Mcbridge (The Cunnane Group); Bob Mckee (Ryan Homes); Chad Nelson (Shea Homes); Tony Smith (Hobart Smith); Shawn Polakiewicz (Saussy Burbank); Dave Reynolds/Toby Brundage (Builder 1st Source); Steve Corriher (CPCC); Mike Mcgee/Doc Mcgee/Michael Watkins (Mcgee Brothers); Bill Green (Barefoot Co.); Stu Jelenick (BRI); Bob Otto (NARI-representative); Adam Kuhn/Dave Patterson (Craft Homes). Topics/Subject Decisions/Conclusions/Actions Old Business Insulation vapor barrier The NC Building Code Council has approved the removal of the interior vapor barrier in most of the State. This code change can now be accepted in Mecklenburg County which will no longer require the installation of a paper face product or 4 mil poly coverage on wall cavities. New Business Code Update Final enforcement date for the next residential Code change is scheduled for June 1st, 2006. With this the requirement for Low E glazing will be required (SHGC). • NC Code Commentary-work will begin on developing a Code Commentary (State residential Ad Hoc Committee) that • • • explains/illustrates many sections of the code to help with interpretations and Code intent. Work will begin in October on the 1st NC version of a commentary and hope to have out with the Code change next year. Deck Code appendix M-Cantilever section of the code has been changed as far as item #9. There is a new cantilever section in chapter 5 of the Code that will allow for 2x8 and other lengths of cantilevered floor systems. This will also be allowed to be used when building decks. Table 602.10.5- Committee moved to keep this table as it relates to a single wall line the same as is currently used. New version of the Code had language that if you could not get your bracing like at garage lugs then you could use this table only if you completely sheathed the entire house with OSB/plywood. Currently it looked at as only that braced wall line has to be all plywood/OSB. Appendix P cantilevers has been deleted completely in 2006 Code. Closed crawl spaces Closed crawl spaces are currently being installed and are permitted now; see Code changes on DOI website for the September 2004 building Code council minutes. The issue that has recently come up is that this is being installed way too early. A sealed crawl space cannot have walls and floor covered before the foundation inspection has passed. It also is not practical to have the floor covered until after frame due to the likelihood that liner will trap moisture under the house (house not dried in) and that trades may damage liner. Foundations that are covered over, meaning poly and foam on walls, prior to foundation inspection will be turned down. CPCC Code change training Discussed efforts to put together a 1/2 day training class on just dealing with the Code changes in the 2006 NC Code. Intent is to have something available to builders through CPCC that can be taught on campus or at builder’s offices and be ready by March of 2006. Will let builders know once this course has been set up. Question raised about porch suspended slabs and if inspection is required. General rule is if space under the slab can be seen at a later time like at final with crawl access then not generally required. If suspended slab well area cannot be seen then it should be checked prior to concrete placement. This question was asked as a follow up to the effective date of any Code change and the issue date of the permit applies to the code being enforced at that time. Question presented to mechanical and they will require 13 SEER system on any permits issued after January 1, 2006. Suspended slab porch inspections Mechanical system requirement 13SEER Next meeting is on September 7th Woods room 1st floor at 8:00am, 700 N. Tryon St. Building Consistency Meeting Residential Date: 9/7/2005 Recorder: Danny Wooten, minutes prepared by: Jeff Griffin Staff present: Jeff Griffin; Gene Morton; Danny Wooten; Harold Sinclair; Steve Kellen; David Morton; George Rogers. Public present: Frank Burke (Grimmer-Kempf & Assoc); David Schwiemon (Public); Hans Kasak (Ryland Homes); Bob Mckee (Ryan Homes); Evan Weiss/Terry Cleary (Meeting Street); Chad Nelson (Shea Homes); Wayne Carter (Evergreen Homebuilders); Shawn Polakiewicz (Saussy Burbank); Dave Reynolds/Toby Brundage (Builder 1st Source); Cory Cronin (CP Morgan); Bob Otto (R.E. Otto & Sons-NARI); Adam Kuhn/Dave Patterson (Craft Homes); Rick Lauer (Turnberry Homes); Jack Glunt (Westfield Homes); Bill Green (Barefoot Company). Topics/Subject Decisions/Conclusions/Actions Old Business Girder bearing on piers Attic Access This issue was discussed again, it’s important to understand that this is proposed with the next version of the Code and although final approval is expected it is not currently allowed until next Code which is scheduled to come out June/July 2006. The issue is a footnote under table R403.1a footnote #3 on page 59 of current 2002 Code. Proposed change is that girders will no longer have to bear in the center 1/3 of the piers and can bear anywhere across the top of the pier. Pier must bear in the center 1/3 of the footer (this is the critical issue to prevent rotation of the pier). Girder must be on the pier (nothing hanging off) and any column load must be solid blocked across the entire pier surface. Question was asked about the new language going before the NC Building Code Council on attic ventilation requirements. This is being re-worded to almost take all attic access requirements away except if there is a need for mechanical equipment access. This issue was discussed previously but again at this meeting the intent was readdressed how this will affect builders in the field. See attached language that is proposed in the 2006 Code. New Business Vapor Barrier installation Last month issue was discussed that a code change has already been approved that will no longer require a vapor barrier on exterior walls in most of NC. Although a vapor barrier is no longer required if one is used and installed it will not be prohibited but must meet mfg requirements to install correctly. Batts with paper face towards the exterior walls will not be acceptable. Issue came up behind a fireplace area where all the paper faced Batts were installed backwards. Non-vented attics Petition for non-vented conditioned attic assemblies has been approved by the NC Building Code Council and rules committee. Attached to the minutes is a copy of the petition and Code language approved. If requested by a contractor this application can be approved at this time based upon new Code language. Also attached is a section of a letter submitted to the BCC restating the language of the Code and an on line website for additional information, you’ll note that currently 2 shingle manufacturers have approved installation with their product. Bay area roof venting Question raised about if there is any change to the bay area option discussed several months ago for that small attic ventilation. The nonvented attic space listed above is an option for foam applied directly to roof deck and doesn’t affect the previously discuss venting allowance for small bays that have fiberglass insulation batts with full vapor barrier on the ceiling (to reduce vent requirement) and continuous soffit venting only. The 2006 Code will allow this also but will not require in the language if it passes BCC the vapor barrier. Questioned asked about the use of structural fiberboard. This continues to be an issue that comes up due to rising cost of OSB/plywood. Method #4 as listed in section R602.10.3 for braced wall panels. So this would be allowed and is not an alternate. Table R602.10.3 reads almost the same as method #3 (plywood corners). 1 story house would have to have 1 piece at each corner and every 25’ on center and not less than 16% of the wall line. In a 2 story and above there is more % of the wall required to have structural fiberboard. Builder can us but must design per this table on page 118 of the 2002 NC Residential Code. Structural fiberboard Engineered Issue keeps coming up in the field in regards to engineered designs and footers or Slabs if a County inspector needs to inspect. It is a requirement that all engineered slabs or footers such as caissons or pile’s be inspected by this Department and documented. The following is required for each inspection. Caisson footer- The hole for the caisson footer doesn’t need to be viewed prior to concrete pour and can be filled to base of footer trench prior to County inspection/review of footer layout. This doesn’t have to be pre-poured and can be poured with the footer or mono slab after the footer inspection. An engineer’s plan must be on site for footer inspection and all trenches dug, steel tied and in place, and all caisson positions verified per engineers design sheet. Footer will be turned down without a penalty if all is per design, pending a final engineers letter on installation sign off including the layout. This needs to be ready by next inspection. Inspector will document caisson footer and engineer of record. Pile footers- Similar procedure as with caisson footers. Wood piles can be driven and when inspector arrives on site a pile placement plan along with footer plan should be provided, trenches cleaned out and all steel in place. Footer will be turned down without a penalty (if no other issue are noted) pending engineer’s final approval report that includes a pile report (location and depth of each pile). This should be provided by next inspection. Inspector will document pile footer and engineer of record. Engineered slab- (waffle slab, post tension, etc..) Slab must be completely ready and all required steel in place. An engineers design must be provide for review by field inspector prior to any concrete placement. Engineered slab will be turned down without penalty (if no other issues noted) pending final engineers letter on design and sign off on installation. Engineer’s letter should be supplied by frame inspection. Inspector will document type of slab construction and engineer of record. Next meeting is on October 5th Ed Woods room 1st floor at 8:00am, 700 N. Tryon St. The Industry Submitted No New Consistency Issues To The Mechanical/Plumbing Consistency Codes Team. FOR A LISTING OF ALL THE MECHANICAL & PLUMBING INTERPRETATIONS, PLEASE CHECK ON THE PATH BELOW: http://www.charmeck.org/NR/rdonlyres/eass7x4zoyltvgrl4elpox5kmufobvbr utcsvsawnck35efykq3skpp2xy5q6xogwsvbnrsti5dvb4ufuxg3pnkb7gd/Mech anicalQA.pdf