Section 3: Food Science

advertisement

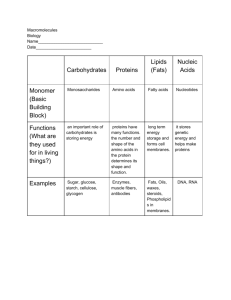

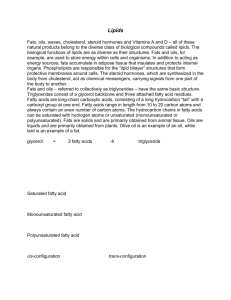

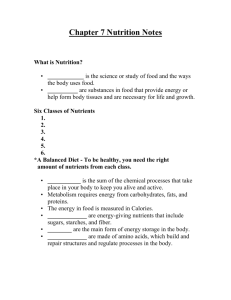

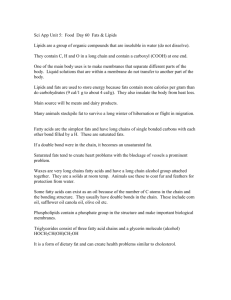

SECTION 3: FOOD SCIENCE Section 3: Food Science Resource management Content Elaboration Food science: the chemical structure of the main nutrients The chemical structure of: carbohydrates (sugar, starch and non-starch polysaccharides) – monosaccharide, disaccharides and polysaccharides fats and oils – fatty acids and glycerol; unsaturated, saturated, poly unsaturated; essential fatty acids; trans and cis fatty acids proteins – amino acids Carbohydrates Carbohydrates are found in all plants, and are produced during the process of photosynthesis. Carbohydrates are compounds of carbon, hydrogen and oxygen in the ratio of C n :H 2n :O n . They can be divided into three main categories according to the size of the molecule, namely: monosaccharides disaccharides polysaccharides. Monosaccharides These are the simplest carbohydrate molecule s, with the general formula of C 6 H 12 O 6 . HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 1 SECTION 3: FOOD SCIENCE Their basic structure can be shown as: Glucose, fructose and galactose are the basic monosaccharides. They have the same chemical formula but differ in the way they are arranged. The chemical names of all sugars have the ending ‘ose’. Glucose is found in grapes, sweet fruits and honey. Fructose is found in sweet fruits and honey. Galactose is not found in food but is produced when lactose, a disaccharide, is broken down during digestion. Monosaccharides are white crystalline solids that dissolve in water to give clear, colourless solutions. Disaccharides (double sugars) These sugars are formed when two monosaccharide molecules join toget her with the elimination of one molecule of water, for example sucrose is built from one molecule of glucose and one molecule of fructose. Disaccharides have the general formula C 12 H 22 O 11 . Disaccharides, like monosaccharides, are white crystalline solids that dissolve in water to give colourless solutions. The following table shows the monosaccharides that make up each disaccharide. Disaccharide Monosaccharides sucrose = glucose + fructose lactose = glucose + galactose maltose = glucose + glucose 2 HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE Polysaccharides (complex carbohydrates) Polysaccharides are enormous molecules made up of one or several types of monosaccharide units (usually glucose) that are joined together, with the elimination of one water molecule at each link. They have the gene ral formula (C 6 H 10 O 5 ) n where n represents a large number and can be over 1000. Polysaccharides can be further divided into two groups: starch, which the body can use – acids in the stomach break down starch into monosaccharides and uses them as a source of energy non-starch polysaccharides, which the body cannot digest. Starch Starch is made up of glucose units joined together. It is a white solid, not sweet, and it will not dissolve in water. Starch molecules are formed in roughly spherical granules. Starch actually consists of two different polymers of a glucose unit: amylose and amylopectin. Amylose starches are very long, straight chains of glucose units while amylopectin is very large, highly branched polymer. Some waxy starches, like rice and maize, contain largely amylopectin. Non-starch polysaccharides Non-starch polysaccharides (NSP) are the most complex of all the carbohydrates. They are so complicated that humans are unable to digest them as the acids in our stomach cannot break the links be tween the glucose units. They can be further divided into: cellulose pectin. Cellulose Cellulose is one of the most common NSP and is always very large, with several thousand glucose units joined together in chain -like molecules. Bundles of these chains lying side by side are then linked together to give cellulose fibres. Pectin Pectin is the name given to a mixture of NSP found in fruits and some roots. It is responsible for the formation of gels in jam manufacture. Pectins have a flexible backbone made up of a chain of monosaccharide units. This is then divided into sections classified as either smooth (no monosaccharide units attached) or hairy (other monosaccharide units attached). The smooth sections of pectins can join together, forming gels. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 3 SECTION 3: FOOD SCIENCE Fats and oils Like carbohydrates, fats and oils are compounds of carbon, hydrogen and oxygen. Fatty acids and glycerol Fats and oils are similar chemically, both belonging to the chemical group of triglycerides. Triglyceride molecules consist of one molec ule of glycerol with three molecules of fatty acids, as shown below. G L Y C E R O L Fatty acid Fatty acid Fatty acid Glycerol (also known as glycerin) is depicted as follows, with three carbon atoms and their associated hydroxyl groups (OH): H 2 COH H 2 COH H 2 COH Fatty acids differ in many ways, a main difference being chain length. Fatty acids can be categorised as follows: saturated, where the carbon atoms have all the hydrogen atoms that will combine with them 4 HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE unsaturated, where some of the hydrogen atoms are missing from some of the carbon atoms. Degrees of unsaturation differ depending on the number of missing hydrogens. The ratio of saturated and unsaturated fatty acids has a major impact on whether a substance is a fat or an oil, as shown below. Fat Oil Solid at room temperature Liquid at room temperature Longer fatty acid chain Shorter fatty acid chain Chains are more saturated Chains are less saturated Higher melting point Lower melting point Saturated, monounsaturated and polyunsaturated fatty acids Each fatty acid is made up of a chain of carbon atoms with a methyl group at one end and an acid group at the other. Each carbon atom in between has either one hydrogen atom attached (monounsaturated) or two hydrogen atoms attached (saturated), as shown below: monounsaturated H H C saturated O C C H H H Methyl Carbon group group C H Acid group OH H H H H O C C C C H H H Methyl Carbon group group OH H Acid group If there is more than one double bond in a fatty acid it is known as a polyunsaturated fatty acid. These fatty acids will have a longer carbon chain. They easily combine with oxygen in the air to become rancid. It is the acid group from each fatty acid that is able to combine with the glycerol to form a triglyceride. All triglycerides (fats and oils) contain a mixture of both saturated and unsaturated fatty acids. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 5 SECTION 3: FOOD SCIENCE Fats and oils can be described as saturated or unsaturated according to the proportion of fatty acids present, for example butter is described as a saturated fat because it has more saturated fatty acids than unsaturated fatty acids. Most vegetable oils are described as unsaturated fats because they have more mono- or polyunsaturated fatty acids. Saturated fats are solid at room temperature and tend to be from animal sources whilst most unsaturated fats are liquid at room temperature and are usually from vegetable sources. Essential fatty acids The body can make the fatty acids it needs except for th e following two: alpha-linolenic (n-3), also called omega-3 linoleic acid (n-6), also called omega-6. These are known as the essential fatty acids as they must be supplied by the diet. They are easily identified due to the unique positioning of the doub le bond. Linoleic acid has a double bond three carbon atoms from the methyl end of the carbon chain. Alpha-linolenic has a double bond six carbon atoms from the methyl end of the carbon chain. Cis and trans fatty acids Cis and trans refer to the arrangement of the hydrogen atoms in unsaturated fatty acid molecules. In the cis arrangement the hydrogen atoms are on the same side of the double carbon bond and in the trans arrangement the hydrogen atoms are on opposides of the double carbon bond, as shown below: cis form trans form H H H H H H C C C C C C H H H H C C H H During the processing of oils to make margarine, trans fatty acids are formed. This means that instead of being on the same side of the molecule , the hydrogen atoms next to the double bond are on the opposite sides. The cis and trans arrangement is important as trans fatty acids appear to behave in the body in the same way as saturated fatty acids. 6 HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE Proteins Chemically, proteins differ from carbohydrates and fats as they always contain nitrogen. They are composed of carbon, hydrogen, oxygen, nitrogen and sometimes sulphur and phosphorous. As a result proteins are much more complex substances than carbohydrates and fats. Proteins are made up of simple substances known as amino acids. Amino acids are chemical compounds with at least one amino acid (- NH 2 ) and at least one acidic group ( - COOH) attached to the same carbon atom, as illustrated below. H O C C H N OH H R The rest of the amino acid is represented by R. R is different for every amino acid. There are about 20 different amino acids commonly found in plant and animal proteins. This gives each amino acid its individuality , as seen in the table below: ** ** ** ** Name Alanine Aspartic acid Glutamic acid Glycine Isoleucine Leucine Lysine Phenylalanine Abbreviation Ala Asp Glu Gly Ile Leu Lys Phe R structure CH 3 CH 2 –COOH CH 2 –COOH H CH(CH 3 )–C 2 H 5 CH 2 –CH(CH 3 ) 2 –CH 2 –CH 2 –CH 2 –CH 2 –NH 2 –CH 2 – ** ** Serine Valine Ser Val (benzene ring) –CH 2 –OH –CH(CH 3 ) 2 **An essential amino acid. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 7 SECTION 3: FOOD SCIENCE The amino group of one amino acid can link with the acid group of another amino acid to form a chain of amino acids. The link is called a peptide bond. When two amino acids are joined together a dipeptide is formed. When many amino acids join together a polypeptide is formed , as detailed below. The primary structure of proteins is determined by the peptide bonding. Each protein has its own specific number and sequence of amino acids. The chains of amino acids making up protein are also held together by further levels of structural organisation (bonding): secondary, tertiary and quaternary. The final shape of the molecule is important as it often determines t he function of the protein. Any errors in the primary structure can result in faulty proteins being formed. Each species, including humans, has its own characteristic proteins. The proteins of human muscle are very different from those of beef muscle. Indispensable (essential) and dispensable (non-essential) amino acids Plants can build their own protein from the carbon dioxide they obtain from the air, and from water and mineral substances containing nitrogen from the soil. Animals, including humans, are unable to make proteins and therefore depend entirely on proteins already made up in plants or animals. When we digest protein foods our digestive juices break up the protein back into different amino acids. These amino acids are then circulated in the blood. Each cell of the body chooses the amino acid it requires for growth and repair, with any surplus being used for energy. 8 HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE The human body, however, is able to make some amino acids for itself by transferring the amino group of an amino acid to another molecule. This is known as transamination. Because of this, many amino acids are known as dispensable (non-essential) amino acids as the human body can make them from other amino acids that it gets, for example glycine can become alanine. Examples of dispensable amino acids are: alanine arginine aspartic acid asparagine cysteine cystine glutamic acid clutamine glycine hydroxyproline proline serine tryosine It is not possible to get every amino acid like this, so some must be supplied by the diet. These are known as indispensable (essential) amino acids. Examples of indispensable amino acids are: isoleucine leucine lysine methionine phenylalanine threonine trytophan valine Histidine and arganine are essential for infants since their requireme nt for these is greater than their ability to synthesis them during their period of rapid growth. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 9 SECTION 3: FOOD SCIENCE Resource management Content Elaboration Food Science The properties of food and their uses – carbohydrates: solubility, inversion and crystallisation, caramelisation, gelatinisation, retrogradation of starch and pectin gel formation Properties of carbohydrates Starches and sugars are of plant origin and serve a variety of roles in food production due to their properties. 1. Solubility Starches are not readily soluble in cold water. Starches are soluble in hot water and form pastes and gels. Manufacturers use the solubility of starches to improve the texture and viscosity of foods. When a suspension of starch in water is heated, the water penetrates the outer layers of the starch granules and the granules begin to swell. The starch granules break up and the contents disperse throughout the water. The starch/water mixture becomes more viscous , ie it thickens and forms a paste which, on cooling, forms a gel. This property is used by manufacturers to make sauces. Because of their viscosity, starch pastes are used to thicken foods and starch gels, which can be modified by sugar or acid, are used in puddings. In recent years, natural starches have been modified by physical and chemical means and as a result the range of uses of starch as a food ingredient by a manufacturer has increased. Food items which require the minimum of heating to achieve the desired viscosity are now 10 HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE available, for example instant puddings that do not require cooking. Pre-gelatinised starches are used in some manufactured foods. These are cooked in water, ie gelatinised, and then dried. These are used in instant desserts. 2. Inversion and crystallisation Invert sugar is related to sucrose. Sucrose is a disaccharide that goes through a process of hydrolysis to form monosaccharides. Hydrolysis is the chemical breakdown of a molecule, by combination with water, producing smaller molecules. The hydrolysis of sucrose is also known as the inversion of sucrose and the product, a mixture of glucose and fructose, is called invert sugar. Inversion may be brought about either by heating sucrose with an acid or by adding the enzyme invertase. Invert sugar is used in the production of jam, boiled sweets and some other sugar confections. A small quantity of invert sugar, added to a hot sucrose solution, will help reduce the likelihood of crystallisation when the mixture is cooled. Invert sugar can prevent or help control the degree of sucros e crystallisation. Glucose and fructose crystallise more slowly than sucrose, so when some invert sugar is added to the mixture, the amount of sucrose that could rapidly crystallise is reduced. This is important during the cooling of syrups, when most of the crystals are formed, and during later storage where crystals precipitate and grow in size. Manufacturers substitute some invert sugar to slow down the crystallisation process during storage to ensure the product is acceptable to the consumer. A mixture of sucrose and invert sugar has greater solubility in water than sucrose on its own – increased solubility means less crystallisation. Invert sugar also encourages the formation of small crystals , which are essential in some products – the finished product will be smoother, eg fudge making, fondant making and soft mints. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 11 SECTION 3: FOOD SCIENCE Invert sugar will also prevent more chewy candies from drying out and becoming too brittle. 3. Caramelisation When sugars are heated they caramelise. Although caramelisation occurs most readily in the absence of water, sugar solutions (syrups) will caramelise if heated strongly enough. Caramelisation occurs when sugar is heated to a temperature above its melting point. It turns brown and has a toffee flavour. When sprinkled over the top of a crème brûlée the sugar gives a toffee flavour and adds crunch. If the sugar is heated for too long it becomes black in appearance and has a bitter flavour. Sugar toppings on cakes and pastries can be caramelised to give an attractive appearance and good flavour. Caramel can be added to ice creams and mousses. 4. Gelatinisation Gelatinisation results when a suspension of starch in water is heated . The water penetrates the outer layer of the starch granules and the granules begin to swell. This occurs as the temperature rises from 60C to 80C. The granules may swell to five times their original size. As the size of the granules increases the mixture becomes viscous. At about 80C the starch granules break up and the contents are dispersed throughout the water and as a result the mixture becomes more viscous, ie thickens and forms a sol. On cooling, if the proportion of starch to water is sufficiently great, the starch molecules form a network with the water enclosed in its meshes , producing a gel. The entire process is known as gelatinisation of starch and is very important in food production. The texture of the food is a gel rather than a fluid, which means it is easier to transport and eat. Starches take up water and produce viscous pastes and gels , giving the desired texture to foodstuffs, eg macaroni and cheese. In food production, gelatinisation is responsible for the thickening of sauces, soups and gravies by the addition of flour or cornflour. 12 HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE Gelatinisation is also important in baked goods, for example bread and other flour goods, where it contributes to the desired crumb structure and texture of the product. Storage behaviour and the rate of digestion are also affected by the gelatinisation of starch. Starch is a mixture of two different polysaccharides: (a) amylose – this molecule consists of between 50 and 500 glucose units joined in a straight chain. Amylose -containing starches gel best but are less stable than high amylopectin starches. (b) amylopectin – this molecule consists of up to 100,000 glucose units joined in a branched-chain structure. The strength of a starch gel depends on a number of factors , including: (a) the proportion of starch and water present – the more starch the stronger the gel (b) the proportion of amylose in the starch – amylose aids gelling because the molecules form a network in which water is trapped. High-amylose starches are used where a rigid gel is needed. Amylopectin molecules are larger but are more compact and therefore do not hold water as well. High amylopectin starches (ie waxy starches) gel only at high concentrations. (c) the presence of sugar – sugar competes with the starch for water and therefore reduces gel strength (d) the presence of acid – acid hydrolyses starch and reduces gel strength, forming a viscous paste. This happens in lemon meringue pie filling. The extent of starch gelatinisation in baked goods strongly affects product properties, including storage behaviour and the rate of digestion. In some baked products, many starch granules remain u ngelatinised due to the high proportion of fat and the low proportion of water. In other products, like white bread, which has a high moisture content, about 96% of the wheat granules are gelatinised. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 13 SECTION 3: FOOD SCIENCE Waxy maize starch produces a clear cohesive paste, which may be desired by manufacturers depending on the use. Potato starch is used in extruded cereals and snack food products and in dry mixes for soups and cakes. Rice starch produces opaque gels useful for baby food. Potato and tapioca starches have wea k intermolecular bonding and swell greatly to give high viscosity pastes, but because the highly swollen granules break easily, the viscosity quickly decreases with only moderate shear (shaking or whipping). 5. Retrogradation of starch Both pastes and gels can revert or retrograde back to the insoluble form on freezing or ageing, causing changes in food texture that would be unacceptable to the consumer. Although amylose-containing starches gel best they are less stable than amylopectin starches because the amylose molecules tend to unwind and the gel becomes opaque and like a pulpy sponge. This change is called retrogradation and occurs particularly when foods are frozen and then thawed. High amylopectin starches, eg waxy corn starch, should be used by manufacturers when preparing foods for a freeze/thaw process. Chemically modified starches are widely used in frozen manufactured foods as they do not retrograde easily and so the texture of the product does not change. 6. Pectin gel formation Pectin is a complex mixture of polysaccharides found in many fruits and in some vegetables – apples and the peel of citrus fruits are particularly rich in pectin. Pectin is important as a gelling agent, especially in jam making. During jam making, the molecules of pectin form a threedimensional network (which is the framework of the gel) with the water, sugar and solid matter from the fruit. Pectin forms a gel when sugar and acid are added and this is the basis of jelly manufacture. 14 HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE The correct proportion of sugar is needed in jam to assist gel formation, usually about 65%. Pectin will not form a satisfactory gel until the pH of the mixture is 3–3.5 (acidic). In jams made from fruit with a low pectin content, such as strawberries, the addition of an acid, eg lemon j uice, lowers pH and aids setting. Unripe fruit contains more acid and pectin, whilst over-ripe fruit contains pectin that has been converted into a form that is unable to form a gel. Pectin in colloidal solutions contributes viscosity to tomato paste and stabilises the fine particles in orange juice , preventing them from settling out. Pectin is also added to foods to act as a thickener and stabiliser. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 15 SECTION 3: FOOD SCIENCE Resource management Content Elaboration Food Science The properties of food and their uses – fats and oils: melting characteristics plasticity related to creaming and shortening properties hydrogenation of oils smoke point related to uses as a cooking medium colloidal systems emulsifying agent and stabilisers hydrolytic and oxidative rancidity Properties of fats and oils Fats and oils, also known as lipids, are composed of two basic parts: glyceride and fatty acids. A fat is solid at room temperature, while an oil is a liquid. 1. Melting characteristics Fats melt when heated. Since fats are a mixt ure of triglycerides they do not have a distinct melting point but melt over a range of temperatures. Most fats melt at a temperature of between 30 and 40C. The more saturated the fat, the higher the melting point. The more unsaturated the fat, the lower the melting point. 2. Plasticity related to creaming and shortening properties Substances that have the property of plasticity will change their shape when pressure is applied to them, but will remain in their final shape when the pressure is removed. They do not return to their original shape. Fats do not melt immediately but over a range of temperatures. This property is called plasticity. 16 HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE Fats are plastic at certain temperatures, ie they are soft and can be spread. Plasticity is due to the mix of triglycerides, each of which has its own melting point. This means that at a given temperature some of the fat will be liquid and some will be in the form of a solid with very fine crystals. Fats containing smaller crystals, which are produced by rapid cooling of the fat during manufacture, will be more plastic. Some fats have been formulated to have low melting points so that the product can be spread straight from the fridge , eg soft margarines. The range of temperatures over which a fat shows plastic behaviour is known as the plastic range of the fat. A mixture of triglycerides with a large range of melting points will form a fat with a wide plastic range. This type of fat is better for certain purposes , eg creaming and spreading. Most animal fats have a narrow plastic range and are hard and difficult to spread, eg butter straight from the fridge. Shortenings used in bakery production should have as wide a range of plasticity as possible, which means that the melting behaviour should remain constant over a specified temperature range so that the fat can be easily manipulated without melting at room temperature (24–42C). Plastic fats will coat flour particles readily. Shortenings (semi-solid fats) give a ‘short’ or tender quality to baked products as well as enhancing the aeration of leavened (raised) products such as cakes to give a good flavour and texture to the product. Shortenings will prevent toughness in products such as pastry by surrounding the starch granules and protein molecules and thus breaking up the structure. Fat also prevents contact between the protein in the flour and water in the dough, restricting the formation of gluten so that the gluten formed is in short lengths and not long elastic strands , eg bread. Shortenings in products such as doughnuts change or modify the gluten protein of flour. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 17 SECTION 3: FOOD SCIENCE When making rich cakes, fat and sugar are beaten or creamed together. This process incorporates small air bubbles in the mixture, forming a foam and lightening the product. In icings and fillings, fats help to form very small air bubbles when creamed or beaten and thus creates a light, fluffy structure. 3. Hydrogenation This involves the addition of hydrogen to unsaturated fatty acids , which changes oil to fat. Partial hydrogenation of fa ts and oils is used in the manufacture of margarine and shortenings. The addition of hydrogen is only partial as not all the possible hydrogens are added. During processing, the most unsaturated fatty acid chains are selected for hydrogenation. This means that not all partially hydrogenated oils will be that same. Food manufacturers use fats and oils that have been altered by hydrogenation by adding hydrogen atoms to the double bonds in monounsaturated and polyunsaturated fatty acids in order to increase the degree of saturation of the fatty acids in the oil and as a result increase the melting point of the fat. A polyunsaturated oil, which is liquid, can be changed to a fat that is solid at room temperature by hydrogenation. Hydrogenation of oils is used by manufacturers to produce a fat consistency and texture appropriate to the food product being produced. Hydrogenation gives stability to fats and oils that would otherwise be unstable and so manufacturers can use fats and oils that they otherwise could not. The process of hydrogenation creates trans fatty acids , which behave biologically like saturated fats and as a result are a major contributor to heart disease. Many manufacturers are removing trans fats from their products, which is a good health selling point for consumers. 4. Smoke point related to uses as a cooking medium Flavour and texture are added to food items when they are cooked by frying. 18 HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE For manufacturers, a cooking oil must be stable under high temperatures and provide moisture during cooking. When a fat or oil is heated to a certain temperature it starts to decompose (break down into fatty acids and glycerol) , producing a blue haze or smoke. Most fats and oils start to smoke at around 200C. The smoke point for lard is 185C and for corn oil is 232C. In general, vegetable oils have higher smoke point s than animal fats. Decomposition of the triglycerides produces small amounts of glycerol and fatty acids. The glycerol further decomposes , producing a compound called acrolein. As this is irreversible, it is advisable when using a fat for deep-fat frying that the frying temperature should be kept below the smoke point to prevent this decomposition. Smoke point is a useful measure when assessing the suitability of a fat or oil for frying purposes. Fats with high smoke points are best for frying. Repeated heating of a fat or oil or the presence of burnt food particles will reduce the smoke point. Repeated heating will also produce oxidative and hydrolytic changes in the fat and give undesirable flavours to the foods cooked in the fat. The temperature of the oil should be maintained at 180C during frying. It is important for manufacturers to maintain the correct temperature to produce an acceptable product. Too low a temperature will result in a greasy product as a result of absorbing a considerable amount of fat. Water in food will contribute to the breakdown of fatty acids , which occurs on heating. Hydrolysis results in an oil of poor quality that has a lower smoking point, darker colour and changed flavour. When oil is heated it will polymerise, which results in the production of a viscous oil that is readily absorbed by foods. This results in a greasy product. The more saturated the oil (solid) the more stable it is to breakdown by oxidation and hydrolysis. In addition, it is less likely to polymerise. Partial hydrogenation makes soya oil more stable. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 19 SECTION 3: FOOD SCIENCE Sunflower and safflower oils have been genetically developed to be used as frying oils. Snacks that are fried and stored prior to eating require a stable oil. If oil is used continually, as in a chip shop, a frying fat must be used that can withstand heavy use. Solid fats are preferable due to their stability through many hours of frying but generally oils are used because of consumer health concerns. The stability of fats and oils is an important consideration in catering, where they may be used for long periods of time. 5. Colloidal systems A colloid is a suspension of particles in a solution – oil and water do not mix: they separate out even after being shaken together vigorously. An emulsifying agent is required to prevent this separation, for example in mayonnaise, egg yolk is used as the emulsifying agent to hold the oil and vinegar together in suspension , forming a colloidal solution and improving the appearance of the mayonnaise. 6. Emulsifying agents and stabilisers The main purposes of emulsifiers and stabilisers are: – emulsifiers are used to make stable emulsions or creamy suspensions from oils and fats and water – stabilisers are used to improve the stability of emulsions and prevent separation of their components. The lecithin in egg yolk is used as an emulsifying agent in mayonnaise. Food manufacturers have to ensure that the choice of fats and oils used in food production can remain stable for the maximum length of time. In low-fat products where a quantity of fat or oil is removed, it must be replaced if the product is to be comparable with the traditional product. Water is often added to replace the fat that has been removed, along with a commercial additive stabiliser to ensure the texture is acceptable and that the oil/fat and water do not separate. 20 HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE 7. Hydrolytic and oxidative rancidity Rancidity is the term used to describe the spoilage of fats and oils – off-flavours develop. Oxidative rancidity occurs as a result of the reaction between unsaturated fats and oxygen from the air, giving rise to an unpleasant, rancid taste. The more unsaturated the fat, the more likely the rancidity is to occur. The rate of oxidative rancidity is accelerated by: – heat/temperature – exposure to light – amount of oxygen present – traces of metal such as copper and iron. Oxidative rancidity can be reduced by: – the presence of antioxidants – eg citric acid, vegetable oils containing natural antioxidants such as vitamin E – packaging materials – keeping well wrapped and in a cool, dark place – adding antioxidants to foods which contain fats. They work by reacting with the ‘free radicals’ which are produced in the first stages of oxidative rancidity. This reaction stops the onset of rancidity. Manufacturers must ensure that the correct amount of antioxidant is used as too high a concentration can actually speed up rancidity. Manufacturers have to make sure that the choice of fats and oils used in the production of a food item can remain stable for a long time – antioxidants may help. Hydrolytic rancidity is caused by enzymes called lipases – these enzymes hydrolyse fats, breaking them down into fatty acids and glycerol. Lipases may occur naturally in fats and oils but they can be inactivated by heat treatment. They may also be produced by micro organisms in fatty foods. The free fatty acids that are produced by this reaction can give fats an unpleasant taste and smell , eg when butter goes rancid. Hydrolytic rancidity has to be considered in the dairy and meat industry. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 21 SECTION 3: FOOD SCIENCE Resource management Content Food Science Elaboration The properties of food and their uses – protein: colloidal systems denaturation gels and gelatine Maillard reaction Properties of protein 1. Colloidal systems A colloid is a suspension of particles in a solution. If a substance such as albumin, the protein in egg white, is mixed with water, it does not dissolve but forms a colloidal dispersion. The molecules of protein do not dissolve and are dispersed throughout the water. Gelatine consists of very large molecules that have a thread-like shape. This shape allows the molecules to trap and hold relatively large amounts of water – this forms a jelly-like solid known as a gel. During gel formation the long molecules link together loosely to form a mesh. This makes the gel stable, ie it sets and forms a colloidal system as the particles are held in suspension in the gel. Manufacturers use gelatine in cold desserts, eg mousse and jellies, and in savoury pies, eg pork pies. Types of colloidal systems are: – – – – – 22 foam – beaten egg white solid foam – meringue, cake emulsion – milk, cream, mayonnaise gel – jelly, baked egg custard sol – egg white. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE 2. Coagulation and denaturation Proteins undergo a process called denaturation. Denaturation involves breaking the cross-linkages that maintain the shape of the protein molecule. Denaturation of protein is usually irreversible as it is impossible to regain the original structure of the protein molecule. As a result of denaturation the properties of protein change – it becomes less soluble and becomes hard and sets. This is known as coagulation. Many proteins are denatured by heat, ie they coagulate. Coagulation results in loss of solubility or change from a fluid (sol) to a more solid state to a formation of a gel, for example egg white begins to coagulate at 60°C; egg yolk begins coagulation at 65/66°C. This coagulation is used extensively in the preparation of many dishes, eg egg custard and sponge cake. The muscle fibre proteins in meat coagulate when heated , resulting in the shrinkage of meat during cooking. As temperature rises, coagulation continues until whole mass is solid – different proteins coagulate at different rates. If the cooking temperature is kept below 100°C coagulation is slow and coagulated protein is not too firm, ie it is more digestible, which is important when cooking meat and products containing eggs. Manufacturers have to take account of thi s when formulating cooking instructions to give consumers good results. If the cooking temperature is above 100°C coagulation is rapid and denatured protein forms a hard solid mass. This is particularly important when stewing/casseroling meat, which will become tough if cooked at too high a temperature and/or for too long. Coagulation is brought about by the following: (a) Action of heat Coagulation of protein is responsible for the thickening effect eggs have in products, eg egg custard, quiche, lemon curd. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 23 SECTION 3: FOOD SCIENCE Coagulation of egg custard produces a gel. The property of coagulation is used by manufacturers when coating Scotch eggs, fish, rissoles, etc, in breadcrumbs. The egg cooks/sets and holds the breadcrumbs in place. Overheating results in protein becoming hard and separate from the liquid in the product, which will then produce a holey, open-textured product. The firmness of the final product or custard will depend on the proportion of ingredients, eg eggs to milk, and the addition of other ingredients, eg the addition of sugar raises the temperature for coagulation and produces a softer texture. (b) Presence of acid When milk sours, the bacteria in the milk ferment lactose, producing lactic acid. The pH of the milk is lowered and this causes the milk protein – caseinogen – to coagulate. The starter culture, used in the manufacture of some milk products, such as yoghurt and cheese, consists of lactose fermenting bacteria. The lactic acid, produced by the bacteria, is responsible for the coagulation or ‘setting’ of the milk and the formation of a curd. (c) Addition of salt During cheesemaking, salt is often added to the curd to increase firmness and also to suppress the growth of micro organisms. Salts are necessary for the coagulation of egg custard mixtures. Salt may be present in milk or can be added. (d) Mechanical action Mechanical action during the whisking of egg white causes a partial coagulation of the protein. The protein molecules unfold and form a network round the air bubbles , stabilising the foam. This property is used by manufacturers when whisking egg white for meringues and soufflés, whole eggs and/or yolks for sponge cakes. 24 HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE Heating results in further coagulation and the formation of a rigid structure due to the denaturation of the protein, eg in sponge cakes. When whisking, eg egg white, foaming may be promoted by the addition of acid substances (vinegar, cream of tartar) , which lowers the pH value. These substances are used in pavlova to make the foam more stable. Overbeating incorporates too much air and the protein is denatured too much. The protein film around bubbles or air becomes too thin and less elastic. The foam then ‘collapses’, resulting in loss of volume. Addition of salt reduces the stability of the foam and decreases volume. Addition of sugar retards the denaturation of egg white foam. It is better to add sugar after the egg whites have been beaten. Addition of sugar produces a softer foam, eg sponge cakes. High-pressure mechanical shear is generated by vigor ous shaking, kneading or whipping. Protein is denatured because very small air bubbles are incorporated within the mechanical action. In the food industry there are many processes that include high-pressure shear in their operation, for example extrusion, high-speed blending and homogenisation. The greater the rate of shear, the greater the rate of denaturisation. (e) Enzymic coagulation Enzymic coagulation or clotting of milk is used in the production of cheese. The protein, casein, is coagulated by the addition of rennin (or other enzyme). It forms a continuous mass initially and breaks into curds when agitated, ie the gel structure is broken down. 3. Gels and gelatin Gelatin is relatively soluble in cold water, but hydrates readily in warm water. When gelatin is added to cold water the granules swell into particles that can absorb 5–10 times their weight in water. When HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 25 SECTION 3: FOOD SCIENCE the temperature is raised above 40°C the swollen particles form a solution that gels on cooling to its setting point Proteins can be used to produce gels in cold desserts, eg mousse and table jellies, and in savoury pies/aspic jelly. Proteins are used as a gelling agent. Gelatin is produced from the protein collagen (the commercial product is called gelatine) and is used as a stabilising agent for emulsions, eg ice cream. On cooling, gelatin sol (ie protein in water) will set to form a gel . This is semi-rigid but is not coagulated by heat. Unlike egg custard, this type of gel is reversible , ie on heating it will liquefy. If gelatin sol is cooled until viscous but not set it can be beaten into a foam to incorporate air. Gelatine has a degree of elasticity at this stage, and is able to stretch and surround air bubbles. It is used in whipped cream and gelatine desserts. The viscosity of gelatine plays a role in the production of starch moulded confectionery where the working speeds demanded during processing require gelatine with a low viscosity. When used during manufacturers, gelatine gives a melt in the mouth characteristic. It is a useful nutritive component because it is a protein and is free from cholesterol. 4. Maillard reaction (or non-enzymic browning) This reaction is very important in the food manufacturing industry. It occurs when protein and carbohydrates exist together. The amino acid called lysine reacts well to browning. In combination with carbohydrates, the protein reacts, causing non-enzymic browning. Reducing sugars, eg glucose, are the most reactive in the Maillard reaction. This produces desirable changes in flavour, colour and aroma during dry cooking methods such as roasting, baking and grilling, for example consumers expect cold cooked chicken to be a good brown colour. 26 HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 SECTION 3: FOOD SCIENCE This reaction is important for baked goods such as bread, biscuits and cakes; nuts and coffee beans (roasting); flavour in biscuits, breakfast cereals and meat extracts; roasted or grilled meat/poultry. Maillard browning occurs at high temperatures and at pH values of 7 or above. Sometimes non-enzymic browning is not desired by a manufacturer as it is not suitable for the food product. It can be prevented by controlling: – – – – moisture content temperature pH through adding an inhibitor such as sulphur dioxide . Although the reaction is generally considered desirable during cooking, there are two undesirable effects. Firstly, there is some loss of the nutritional value of proteins. Amino acids containing an extra amino group, eg the essential amino acid lysine, are most likely to be involved. Secondly, the reaction can cause discoloration of foods during storage, for example the gradual browning of dried milk powder – undesirable from a manufacturer’s point of view as it would indicate deterioration. HEALTH AND FOOD TECHNOLOGY (AH, HOME ECONOMICS) © Learning and Teaching Scotland 2009 27