Magnetic Phase Formation in Self-Assembled Epitaxial BiFeO[subscript 3]–MgO and BiFeO[subscript

advertisement

![Magnetic Phase Formation in Self-Assembled Epitaxial BiFeO[subscript 3]–MgO and BiFeO[subscript](http://s2.studylib.net/store/data/012705780_1-9b2bd524965079e3241c9fd54ac0dd7e-768x994.png)

Magnetic Phase Formation in Self-Assembled Epitaxial

BiFeO[subscript 3]–MgO and BiFeO[subscript

3]–MgAl[subscript 2]O[subscript 4] Nanocomposite Films

The MIT Faculty has made this article openly available. Please share

how this access benefits you. Your story matters.

Citation

Kim, Dong Hun, XueYin Sun, Tae Cheol Kim, Yun Jae Eun,

Taeho Lee, Sung Gyun Jeong, and Caroline A. Ross. “Magnetic

Phase Formation in Self-Assembled Epitaxial BiFeO[subscript

3]–MgO and BiFeO[subscript 3]–MgAl[subscript 2]O[subscript 4]

Nanocomposite Films Grown by Combinatorial Pulsed Laser

Deposition.” ACS Applied Materials & Interfaces 8, no. 4

(February 3, 2016): 2673–2679. © 2016 American Chemical

Society

As Published

http://dx.doi.org/10.1021/acsami.5b10676

Publisher

American Chemical Society (ACS)

Version

Final published version

Accessed

Fri May 27 02:40:54 EDT 2016

Citable Link

http://hdl.handle.net/1721.1/102191

Terms of Use

Article is made available in accordance with the publisher's policy

and may be subject to US copyright law. Please refer to the

publisher's site for terms of use.

Detailed Terms

This is an open access article published under an ACS AuthorChoice License, which permits

copying and redistribution of the article or any adaptations for non-commercial purposes.

Research Article

www.acsami.org

Magnetic Phase Formation in Self-Assembled Epitaxial BiFeO3−MgO

and BiFeO3−MgAl2O4 Nanocomposite Films Grown by Combinatorial

Pulsed Laser Deposition

Dong Hun Kim,†,‡ XueYin Sun,†,§ Tae Cheol Kim,‡ Yun Jae Eun,‡ Taeho Lee,‡ Sung Gyun Jeong,‡

and Caroline A. Ross*,†

†

Department of Materials Science and Engineering, Massachusetts Institute of Technology, Cambridge, Massachusetts 02139, United

States

‡

Department of Materials Science and Engineering, Myongji University, Yongin 120-728, Republic of Korea

§

School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, People’s Republic of China

S Supporting Information

*

ABSTRACT: Self-assembled epitaxial BiFeO3−MgO and

BiFeO3−MgAl2O4 nanocomposite thin films were grown on

SrTiO3 substrates by pulsed laser deposition. A two-phase

columnar structure was observed for BiFeO3−MgO codeposition within a small window of growth parameters, in which

the pillars consisted of a magnetic spinel phase (Mg,Fe)3O4

within a BiFeO3 matrix, similar to the growth of BiFeO3−

MgFe2O4 nanocomposites reported elsewhere. Further, growth

of a nanocomposite with BiFeO 3 −(CoFe 2 O 4 /MgO/

MgFe2O4), in which the minority phase was grown from

three different targets, gave spinel pillars with a uniform

(Mg,Fe,Co)3O4 composition due to interdiffusion during

growth, with a bifurcated shape from the merger of neighboring pillars. BiFeO3−MgAl2O4 did not form a well-defined vertical

nanocomposite in spite of having lower lattice mismatch, but instead formed a two-phase film with in which the spinel phase

contained Fe. These results illustrate the redistribution of Fe between the oxide phases during oxide codeposition to form a

ferrimagnetic phase from antiferromagnetic or nonmagnetic targets.

KEYWORDS: thin film oxide, epitaxy, spinel, perovskite, multiferroic, combinatorial pulsed laser deposition,

self-assembled oxide nanocomposite, BiFeO3

■

INTRODUCTION

affects the magnetic and ferroelectric properties dramatically

and leads to magnetoelectric coupling.6,14−16

Interdiffusion between spinel and perovskite phases has been

reported to be small,12,13 but significant interdiffusion can occur

within spinel pillars during deposition, leading to a homogeneous pillar composition even if the composition of the arriving

flux was changed partway through growth.17 We showed

previously that interdiffusion in spinel pillars was prevented by

growing a diffusion barrier such as BFO partway through the

film, producing a film consisting of two separated layers of

spinel pillars with different compositions.17

In this paper, we report on the growth of nanocomposites

made by combinatorial pulsed laser codeposition of MgO or

MgAl2O4 (MAO) and a perovskite BFO, with a focus on

examining interdiffusion between the two phases during

growth, and the deposition conditions that determine which

Self-assembled nanocomposite thin films are columnar

structures comprising two (or more) codeposited crystalline

phases grown epitaxially on a single crystal substrate, and

exhibit a remarkable range of functional properties, which can

include high-temperature superconductivity, colossal magnetoresistance, ferroelectricity, magnetism, and multiferroicity.1−4

Most of the self-assembled nanocomposites reported to date

consist of pairs of oxides such as a perovskite (e.g., BiFeO3,

BFO) and a spinel (e.g., CoFe2O4, CFO), grown on single

crystalline substrates such as (001)-oriented SrTiO3 (STO). A

common morphology is for one phase to grow as pillars within

the other,5−8 such as spinel pillars in a perovskite matrix, with

both phases epitaxial with the substrate. There are also reports

of epitaxial nanocomposite thin films which incorporate other

oxide crystal structures such as MgO or ZnO.9−11 Elastic

interactions through the interfaces between the two phases are

very important in determining the properties of the nanocomposite. For example, strain transfer at the vertical interface

between piezoelectric BiFeO3 and magnetostrictive CoFe2O4

© 2016 American Chemical Society

Received: November 7, 2015

Accepted: January 11, 2016

Published: January 11, 2016

2673

DOI: 10.1021/acsami.5b10676

ACS Appl. Mater. Interfaces 2016, 8, 2673−2679

Research Article

ACS Applied Materials & Interfaces

Figure 1. (a, b, and c) Top view SEM images of BFO−MgO nanocomposites on (001) STO substrate fabricated by combinatorial PLD. BFO

content increases from left to right. (d, e, and f) SEM of etched BFO−MgO nanocomposites corresponding to panels a, b and c, respectively. (g, h

and i) XRD patterns of unetched and etched BFO−MgO nanocomposites grown by combinatorial PLD corresponding to panels a, b and c,

respectively.

process for CFO and MFO was reported elsewhere.17 A Bi-rich

Bi1.2FeO3 target was prepared by Plasmaterials, CA.

BFO−MgO and BFO−MAO nanocomposite films were deposited

by combinatorial pulsed laser deposition (CPLD) using a KrF excimer

laser (λ = 248 nm) on SrTiO3 (001) substrates (STO, abulk,STO = 3.905

Å) at 5 mTorr of oxygen pressure. The substrate temperature during

deposition was fixed at 650 °C, which is the optimal condition in our

chamber to make stoichiometric BiFeO3 from the Bi-rich target.

Nanocomposite thin films contained excess Bi at low deposition

temperatures,24 whereas the volume fraction of BiFeO3 was reduced at

higher deposition temperatures (>700 °C) due to Bi volatility. The

laser frequency was 10 Hz and the fluence at the target was 2.6 J/cm2.

CPLD was used to produce a set of samples with a range of

composition by alternately ablating two different targets to produce a

submonolayer film of tapered thickness from each target, as described

elsewhere.17,25,26 The five 5 mm by 5 mm STO substrates were placed

in a row with 18 mm offset between the center of the plume of

evaporated material and the substrate rotation axis, and the targetsubstrate distance was 7 cm. The films were made using cycles

phase forms. MgO is commonly used as a tunnel barrier

material for magnetic tunnel junctions.18,19 MAO has received

attention as an alternative barrier material,20,21 and an 8 nm

thick MAO layer served as a diffusion barrier preventing Ti

migration from an STO substrate into a CFO film.22 MgO and

MAO layers are quite well lattice matched to CoFe2O4 or

MgFe2O4, suggesting their possible utility as diffusion barriers

to be incorporated within nanocomposite films. CFO/MFO

nanocomposites have been reported previously.23

■

EXPERIMENTAL SECTION

MgO, MgAl2O4 (MAO, the eponymous spinel), CoFe2O4 (CFO,

cobalt ferrite), and MgFe2O4 (MFO, magnesium ferrite) targets were

prepared by a conventional oxide sintering method. The lattice

parameters of the final targets from X-ray diffraction (XRD) were aMgO

= 4.213 ± 0.002 Å and aMgAl2O4 = 8.081 ± 0.003 Å, which are close to

the bulk lattice parameters of abulk,MgO = 4.213 Å (JCPDS # 04-0829)

and abulk,MgAl2O4 = 8.083 Å (JCPDS # 21-1151). The target preparation

2674

DOI: 10.1021/acsami.5b10676

ACS Appl. Mater. Interfaces 2016, 8, 2673−2679

Research Article

ACS Applied Materials & Interfaces

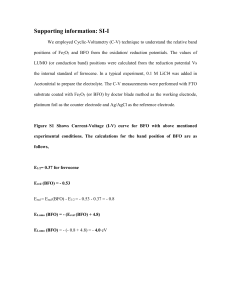

Figure 2. (a) Top view SEM (b) θ-2θ XRD pattern of BFO−MgO nanocomposite grown at optimal deposition conditions. (c) In-plane and out-ofplane hysteresis loops of nanocomposite measured by VSM. (d) TEM image and elemental mapping of released pillars on a copper grid.

parameter of 4.209 ± 0.002 Å (Figure 1g), which is close to

that of bulk MgO. An alternative interpretation is that the

pillars consist of a spinel phase, MgxFe3−xO4 (MxFO) formed

by incorporating Fe from the arriving flux. This is plausible

because the lattice parameter of MgFe2O4 (MFO) is 8.375 Å,

making its (004) peak nearly coincident with that of MgO

(002). Peaks from (00l) pseudocubic BFO were not observed,

and instead a peak at 2θ = 32.1° corresponds to bismuth oxide

Bi2O3 or to BFO (011) that was removed by etching, Figure 1d.

The near-bulk lattice parameter of the MgO or MxFO indicates

that it is not coherent with the matrix, and the matrix did not

form the usual cube-on-cube BFO/STO (001).

In contrast, the sample in Figure 1b showed peaks from both

MgO (002) or MxFO (004) and BFO pseudocubic (00l),

Figure 1h. The pillar phase was under out-of-plane compressive

strain (c = 4.187 Å) compared to the sample of Figure 1(a) due

to epitaxy at the vertical interface with BFO. There were two

overlapping peaks near 2θ = 45° from the rhombohedral BFO

matrix corresponding to c = 4.065 Å and c = 3.995 Å

(compared to bulk pseudocubic abulk,BFO = 3.965 Å). This is

consistent with the SEM image in Figure 1b that indicates two

populations of BFO, the material surrounding the dense pillars,

and larger BFO regions that cover part of the surface.

In the film with the most BFO, Figure 1c, the diameter and

fraction of the pillar phase was much lower. From the X-ray

data, Figure 1i, the pillar phase peak could not be distinguished

due to its small volume fraction. The major peaks were from

rhombohedral BFO grown epitaxially on the STO with out-ofplane lattice parameter of 4.087 Å. A smaller peak from

tetragonal BFO also occurs around 39°, similar to what was

seen in low-temperature-deposited BFO−CFO nanocomposites.24 The lattice mismatch between the pillar phase and the

matrix may help stabilize the tetragonal BFO phase.

consisting of 500 laser pulses of BFO followed by 200 pulses of MgO

or MAO, repeated to build up the desired film thickness.

The phases present in each film were investigated by XRD

(PANalytical X’Pert Pro). Top view images of the surface morphology

were obtained from scanning electron microscopy (SEM, Helios

Nanolab 600). To observe the vertical growth of the nanostructured

composites, some samples were etched with 10% dilute hydrochloric

acid (HCl) to remove the BFO and reveal the pillars. Composition

analysis was carried out using energy dispersive spectroscopy (EDS) in

a high resolution transmission electron microscopy (HR-TEM, JEOL

JEM 2010F) instrument. Pillars from the nanocomposite were freed by

removing the BFO matrix then gathered on a copper mesh coated with

a carbon film using a syringe after dispersing them in isopropyl alcohol.

In-plane and out-of-plane magnetic hysteresis loops were measured

using vibrating sample magnetometry (VSM, ADE model 1660) at a

magnetic field of −10 to +10 kOe at room temperature. The

magnetization was calculated for the whole volume of the film instead

of normalizing for the volume of the pillar phase.

■

RESULTS AND DISCUSSION

Figure 1a−c shows top view SEM images of the BFO−MgO

series, which had thicknesses of 80 to 120 nm. As the BFO

content increases, the density and areal coverage of the ∼20−

40 nm diameter rectangular islands both decrease. Figure 1d−f

shows the corresponding top view SEM images after removing

the matrix phase in hydrochloric acid for 2 min.27 The inset in

Figure 1f is a 45° tilted image of the nanocomposite after 1 min

etch that shows free-standing pillars supported by the

remaining matrix. These images show that the BFO−MgO

codeposition produces a columnar nanocomposite of islands or

pillars in a Bi-rich matrix. Films were grown up to 200 nm

thickness and demonstrated columnar structures.

For the MgO-rich sample of Figure 1a, the XRD peak at 2θ =

43.0° corresponds to MgO(002) with an out-of-plane lattice

2675

DOI: 10.1021/acsami.5b10676

ACS Appl. Mater. Interfaces 2016, 8, 2673−2679

Research Article

ACS Applied Materials & Interfaces

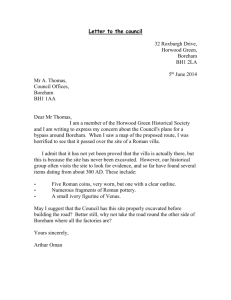

Figure 3. Top view SEM image of (a) as-deposited BFO−(MFO/MgO/CFO) nanocomposite. (b) XRD pattern of BFO−(CFO/BFO/MFO)

trilayer nanocomposite. (c) etched nanopillars after removing BFO. (d) TEM image and elemental mapping of etched trilayer pillar. (e) In-plane and

out-of-plane hysteresis loops of trilayer pillar nanocomposite measured at room temperature.

phases on the substrate, although some additional peaks were

detected.

The in-plane and out-of-plane magnetic hysteresis loops

show soft, isotropic magnetic behavior with a saturation

magnetization of 20 emu cm−3 averaged over the volume of

the entire film. We propose that these nanopillars consist of

magnesium ferrite spinel, MxFO. MFO has the spinel structure

and shows a soft magnetic behavior28−30 with bulk saturation

magnetic moment of 130 emu/cm3,29 and the bulk lattice

parameter is 8.375 Å (JCPDS #00-017-0464), close to that of

the pillar peak in Figure 2b that corresponds to out-of-plane

spinel lattice parameter of 8.374 ± 0.004 Å. The volume

fraction of the pillar phase estimated from the area in the top

view SEM image is 18 ± 4% which implies a saturation moment

for the pillars of 117 ± 26 emu cm−3, close to that of bulk

MFO. The low magnetic anisotropy of MFO pillars is a result

of the low magnetostriction and low magnetic moment, which

produce low magnetoelastic and shape anisotropies, respectively.

Further evidence that the pillars are spinel not MgO comes

from their morphology. The pillar shape resembles those of

CFO−BFO nanocomposites. The rectangular prismatic shape

and top surface faceted structure with four tilted (111) planes is

characteristic of spinel pillars in a perovskite matrix, originating

from the lowest surface energy {111} planes of spinel.6 In

contrast, simulation results show that the lowest surface energy

planes of MgO are {100} planes.31

STEM-EDS elemental mapping also supports the identification of MxFO pillars. The top left image in Figure 2d shows

Unexpectedly, the BFO−MgO nanocomposites showed a

magnetic signal measured with VSM at room temperature

(Figure S1), though single phase BFO films deposited at the

same conditions did not show a magnetic moment (Figure S2).

The saturation magnetic moments were 17, 30, and 15 emu

cm−3 for the samples of Figure 1a,b,c respectively, calculated

over the volume of the film, i.e., not normalized to the pillar

volume fraction. The magnetic hysteresis loops were isotropic

with low coercivity (<100 Oe). This supports the idea that a

ferrimagnetic spinel is present because neither MgO nor BFO

has a magnetic signal when grown at this deposition condition

(Figure S2), BFO being a canted antiferromagnet. The

magnetic signal did not disappear on etching by HCl so is

attributed to the pillar phase (Figure S3). To investigate this

further, a BFO−MgO nanocomposite was made by alternating

ablation of MgO and BFO targets at the optimal ratio obtained

from combinatorial PLD. 100 and 250 pulses were incident on

the MgO and BFO targets respectively, repeated 200 times to

make a 60 nm thick film. In Figure 2a, rectangular nanopillars

can be seen with their edges aligned along the ⟨110⟩ directions

of STO substrate. This nanocomposite showed XRD peaks

corresponding to MgO (002) or MxFO (004), and BFO (002)

near 2θ = 45° with out-of-plane lattice parameter of 4.187 ±

0.002 for the pillars and 4.099 ± 0.003 Å for the BFO. These

values are closer to each other compared with those of the

nanocomposites grown by CPLD. The pillar phase was in outof-plane compression and the BFO in out-of-plane tension. φ

scans shown in Figure S4 demonstrated 4-fold symmetry of

BFO and spinel phases indicating epitaxial growth of both

2676

DOI: 10.1021/acsami.5b10676

ACS Appl. Mater. Interfaces 2016, 8, 2673−2679

Research Article

ACS Applied Materials & Interfaces

Figure 4. (a, b, and c) Top-view SEM image of BFO−MgAl2O4 nanocomposites grown by CPLD with increasing BFO content. (d, e, and f)

Corresponding etched films. (g, h, and i) Magnetic hysteresis loops of the BFO−MAO nanocomposites measured by VSM at room temperature.

We now discuss a “triple-layer” nanocomposite consisting of

CFO/MgO/MFO in a BFO matrix, designated BFO−(CFO/

MgO/MFO), which was fabricated to investigate the effects of

inserting an MgO layer within a spinel pillar. We have already

shown in nanocomposite BFO−(CFO/BFO/MFO), where

layers of CFO and MFO pillars were separated by a thin BFO

layer, that any direct contact between the CFO and MFO

pillars led to interdiffusion producing (Co1−xMgx)Fe2O4 pillars

of uniform composition.17 Therefore, it was interesting to see

whether MgO could fulfill the function of a diffusion barrier in

a spinel pillar.

First, a magnetically hard BFO−CFO nanocomposite was

grown on a STO (001) substrate, then 20 nm thick BFO−

MgO was grown, and finally a soft magnetic BFO−MFO

nanocomposite layer was grown. Samples were made in a single

run in the same chamber equipped with four targets without

breaking vacuum. Figure 3a shows the top view SEM image of

the BFO−(CFO/BFO/MFO) trilayer nanocomposite. The

XRD pattern shows BFO and a single peak for spinel and/or

MgO, Figure 3b.

the TEM images of agglomerated nanoparticles collected on a

TEM grid after etching in HCl solution, and the other panels in

Figure 2d show Mg, Fe, and O mapping of the same area. The

composition analysis reveals that there is no detectable Bi, but

Fe is present throughout the pillars. The small pillar size

compared to the beam size precluded an accurate measurement

of Mg:Fe ratio.

The pillar structure and the magnetic hysteresis of the BFO−

MgO nanocomposite are similar to those of BFO−MFO

nanocomposites reported previously.23 The spinel phase forms

in the BFO−MgO nanocomposite because MFO is thermodynamically stable,32 and MFO has also been observed to form at

the interface between an MgO substrate and an iron oxide thin

film.33 However, other nanocomposites containing MgO have

been grown, such as (La0.7Ca0.3MnO3)−MgO,34 CoFe2O4−

MgO,11 and ZnO−MgO.35 This suggests that the low stability

of BFO contributes to the formation of MxFO in the BFO−

MgO codeposition. Formation of MxFO would leave excess Bi,

but Bi or Bi2O3 peaks were not detected by XRD except in the

sample of Figure 1a, and it is likely that excess Bi is lost from

the film due to its volatility.

2677

DOI: 10.1021/acsami.5b10676

ACS Appl. Mater. Interfaces 2016, 8, 2673−2679

Research Article

ACS Applied Materials & Interfaces

of spinel, which may indicate a lower Fe content in the spinel

made at lower BFO fraction counteracting the higher volume

fraction to give similar average magnetization. The films

showed magnetic anisotropy, in comparison with the isotropic

behavior of the BFO−MgO (Figure S1). This is assumed to

originate from the different morphology, composition and/or

magnetostriction and lattice strain of the (Mg, Al, Fe)3O4 spinel

phase in the BFO−MAO nanocomposites compared to the

MxFO in the BFO−MgO nanocomposites.

In the plane view, faceted rectangular pillars line up along the

[110] directions of the STO substrate resembling Figure 2a.

However, after etching in HCl solution for 3 min (Figure 3c),

the nanopillars are seen to grow from two or three roots

connected by a wider midsection. The roots correspond to the

BFO−CFO growth, the midsection to BFO−MgO, and the top

to BFO−MFO. The BFO−MgO layer is assumed to grow as

BFO−MxFO as discussed above, resulting in a higher pillar

volume fraction that caused the small CFO pillars to expand

and merge. Then growth of the top CFO−MFO layer leads to

narrowing of the pillars. The growth sequence suggests that the

pillars should consist of three chemically different layers, but

compositional analysis with EDS mapping shows a uniform

cation distribution throughout the whole pillar to produce a

spinel phase of (Co1−yMgy)Fe2O4 (Figure 3d). This exhibited

magnetic hysteresis loops with intermediate magnetic behavior

between that of hard magnetic CFO and soft magnetic MFO

(Figure 3e),17 in which both shape and magnetoelastic

anisotropy promote an out-of-plane easy axis. The anisotropy

was lower than that of a BFO−CFO nanocomposite.

Therefore, growing a layer of BFO−MgO did not provide an

effective diffusion barrier within the spinel pillars due to the

formation of MxFO instead of MgO from the arriving Mg flux.

In the all-spinel pillar, cation interdiffusion took place as seen in

bilayer spinel pillars.17

We finally describe the growth of nanocomposites made

from BFO−MAO. Figure 4a,b,c shows top-view SEM images of

100 nm thick BFO−MAO nanocomposites grown by CPLD

using BFO and MAO targets and Figure 4d,e,f shows their

SEM images after etching. MAO did not form well-defined

pillars as seen in the BFO−CFO or BFO−MFO cases,17,23,31

even though the lattice mismatch between BFO (2abulk,BFO =

7.930 Å) and MAO (abulk,MAO = 8.083 Å) is smaller than in

BFO−CFO or BFO−MFO.

The MAO-rich nanocomposite (Figure 4a) showed micrometer-sized islands that had facets along STO {100}. XRD

patterns, Figure S5a, clearly showed one film peak corresponding to MAO (004) whose lattice parameter was 8.098 ± 0.004

Å, but no BFO or Bi2O3 peak. The etching had little effect on

the morphology indicating that BFO or Bi2O3 were not present

at the top surface.

As the BFO content increased, Figure 4b, the numbers of

islands increased, and etching removed some of the island

material to produce an irregular surface. XRD showed two

phases corresponding to MAO (8.088 ± 0.004 Å) and BFO

(3.947 ± 0.004 and 3.975 ± 0.002 Å), Figure S5b. In Figure 4c

with greater BFO content, BFO covered most of the surface

and small diameter pillars were present, revealed by etching.

The XRD pattern displayed BFO peaks that had out-of-plane

lattice parameters of 4.027 ± 0.003 and 3.952 ± 0.004 Å, Figure

S5c. In both samples of Figure 4b,c, the BFO peaks (Figures

S5b,c) did not disappear on etching suggesting interdiffusion

may have led to a more etch-resistant matrix phase.

The nanocomposites all showed magnetic phases with inplane easy axis even though the spinel unit cell parameters were

characteristic of nonmagnetic MAO rather than MxFO. We

presume the magnetism originates from a partly substituted

(Mg, Al, Fe)3O4 spinel phase. Consequently, the excess Mg or

Al is present in the perovskite phase, yielding for example

Bi(Fe,Al)O3 with higher etch resistance than BFO. (The end

member BiAlO3 can form a perovskite structure.36) The

averaged saturation magnetization for the three samples was

similar, 20−25 emu cm−3 despite the different volume fractions

■

CONCLUSION

In summary, self-assembled two-phase nanocomposite films

were made by codeposition of BFO−MgO and BFO−MAO

and phase formation was investigated. The BFO−MgO formed

a nanocomposite consisting of spinel MxFO pillars in a BFO

matrix within a very small window of deposition parameters,

with little or no rocksalt MgO. The pillars contributed a

magnetic signal consistent with the volume fraction and the

saturation magnetization of MFO. A multilayer nanocomposite,

BFO−(CFO/MgO/MFO), showed related behavior in which

the pillars had a spinel structure throughout, with interdiffusion

leading to a uniform composition of (Co,Mg,Fe)3O4. The

pillars had interesting bifurcated structures due to the merger of

smaller pillars into larger ones, and the magnetic properties

were intermediate between those of magnetically hard CFO

and soft MFO pillars. In contrast, codeposition of BFO with an

aluminum spinel, MAO, in which there is a lower lattice

mismatch between the pure bulk phases, grew as a two-phase

film but did not produce clearly defined crystallographic pillars

under the deposition conditions used here. Fe incorporation in

the MAO led to a magnetic moment, and incorporation of Al

or Mg into the BFO matrix increased its etch resistance. These

results show that intermixing of the arriving flux from two

targets leads to formation of phases not present in the targets,

and in particular the growth of Fe-containing spinel phases

leads to magnetic properties in nanocomposites made from

nonferromagnetic targets.

■

ASSOCIATED CONTENT

S Supporting Information

*

The Supporting Information is available free of charge on the

ACS Publications website at DOI: 10.1021/acsami.5b10676.

Magnetic hysteresis data of BFO−MgO and BFO, and Xray diffraction data of BFO−MgO and BFO−MAO

samples (PDF).

■

AUTHOR INFORMATION

Corresponding Author

*C. A. Ross. E-mail: caross@mit.edu.

Notes

The authors declare no competing financial interest.

■

ACKNOWLEDGMENTS

This work was supported by the 2015 Research Fund of

Myongji University and by FAME, a STARnet Center of the

Semiconductor Research Corporation funded by DARPA and

MARCO. It was also supported by the National Research

Foundation of Korea (NRF) grant funded by the Korean

government (Ministry of Science, ICT & Future Planning)

(No. 2015R1C1A1A01051656).

2678

DOI: 10.1021/acsami.5b10676

ACS Appl. Mater. Interfaces 2016, 8, 2673−2679

Research Article

ACS Applied Materials & Interfaces

■

(19) Ikeda, S.; Miura, K.; Yamamoto, H.; Mizunuma, K.; Gan, H. D.;

Endo, M.; Kanai, S.; Hayakawa, J.; Matsukura, F.; Ohno, H. A

Perpendicular-Anisotropy CoFeB−MgO Magnetic Tunnel Junction.

Nat. Mater. 2010, 9, 721−724.

(20) Chapline, M. G.; Wang, S. X. Room-Temperature Spin Filtering

in a CoFe2O4/MgAl2O4/Fe3O4 Magnetic Tunnel Barrier. Phys. Rev. B:

Condens. Matter Mater. Phys. 2006, 74, 014418.

(21) Sukegawa, H.; Miura, Y.; Muramoto, S.; Mitani, S.; Niizeki, T.;

Ohkubo, T.; Abe, K.; Shirai; Inomata, K.; Hono, K. Enhanced Tunnel

Magnetoresistance in a Spinel Oxide Barrier with Cation-Site Disorder.

Phys. Rev. B: Condens. Matter Mater. Phys. 2012, 86, 184401.

(22) Rebled, J. M.; Foerster, M.; Estradé, S.; Rigato, F.; Kanamadi,

C.; Sánchez, F.; Peiró, F.; Fontcuberta, J. Ti Diffusion in (001)

SrTiO3−CoFe2O4 Epitaxial Heterostructures: Blocking Role of a

MgAl2O4 Buffer. Phys. Chem. Chem. Phys. 2013, 15, 18274−18280.

(23) Kim, D. H.; Aimon, N. M.; Ross, C. A. Self-Assembled Growth

and Magnetic Properties of a BiFeO3-MgFe2O4 Nanocomposite

Prepared by Pulsed Laser Deposition. J. Appl. Phys. 2013, 113, 17B510.

(24) Kim, D. H.; Aimon, N. M.; Ross, C. A. Pillar Shape Modulation

in Epitaxial BiFeO3−CoFe2O4 Vertical Nanocomposite Films. APL

Mater. 2014, 2, 081101.

(25) Kim, D. H.; Bi, L.; Aimon, N. M.; Jiang, P.; Dionne, G. F.; Ross,

C. A. Combinatorial Pulsed Laser Deposition of Fe, Cr, Mn, and NiSubstituted SrTiO3 Films on Si Substrates. ACS Comb. Sci. 2012, 14,

179−190.

(26) Sun, X. Y.; Zhang, C.; Aimon, N. M.; Goto, T.; Onbasli, M.;

Kim, D. H.; Choi, H. K.; Ross, C. A. Combinatorial Pulsed Laser

Deposition of Magnetic and Magnetooptical Sr(GaxTiyFe0.34−0.40)O3−δ

Perovskite Films. ACS Comb. Sci. 2014, 16, 640−646.

(27) Kim, D. H.; Aimon, N. M.; Sun, X.; Kornblum, L.; Walker, F. J.;

Ahn, C. H.; Ross, C. A. Integration of Self-Assembled Epitaxial

BiFeO3−CoFe2O4 Multiferroic Nanocomposites on Silicon Substrates.

Adv. Funct. Mater. 2014, 24, 5889−5896.

(28) Wells, D. M.; Cheng, J.; Ellis, D. E.; Wessels, B. W. Local

Electronic and Magnetic Structure of Mixed Ferrite Multilayer

Materials. Phys. Rev. B: Condens. Matter Mater. Phys. 2010, 81, 174422.

(29) Morrish, A. H. The Physical Principle of Magnetism; Wiley-IEEE:

New York, 2001; p 507.

(30) Cheng, J.; Lazarov, V. K.; Sterbinsky, G. E.; Wessels, B. W.

Synthesis, Structural and Magnetic Properties of Epitaxial MgFe2O4

Thin Films by Molecular Beam Epitaxy. J. Vac. Sci. Technol., B:

Microelectron. Nanometer Struct.−Process., Meas., Phenom. 2009, 27,

148−151.

(31) Watson, G. W.; Kelsey, E. T.; de Leeuw, N. H.; Harris, D. J.;

Parker, S. C. Atomistic Simulation of Dislocations, Surfaces and

Interfaces in MgO. J. Chem. Soc., Faraday Trans. 1996, 92, 433−438.

(32) Rao, Y. K. Stoichiometry and Thermodynamics of Metallurgical

Processes; Cambridge University Press: Cambridge, 1985; p 135.

(33) Zimnol, M.; Graff, A.; Sieber, H.; Senz, S.; Schmidt, S.; Mattheis,

R.; Hesse, D. Structure and Morphology of MgFe2O4 Epitaxial Films

Formed by Solid State Reactions on MgO(100) Surfaces. Solid State

Ionics 1997, 101, 667−672.

(34) Moshnyaga, V.; Damaschke, B.; Shapoval, O.; Belenchuk, A.;

Faupel, J.; Lebedev, O. I.; Verbeeck, J.; van Tendeloo, G.; Mücksch,

M.; Tsurkan, V.; Tidecks, R.; Samwer, K. Structural Phase Transition

at the Percolation Threshold in Epitaxial (La0.7Ca0.3MnO3)1−x:(MgO)x

Nanocomposite Films. Nat. Mater. 2003, 2, 247−252.

(35) Das, S.; Chakrabarti, S.; Chaudhuri, S. Optical transmission and

photoluminescence studies of ZnO−MgO nanocomposite thin films. J.

Phys. D: Appl. Phys. 2005, 38, 4021−4026.

(36) Belik, A. A.; Wuernisha, T.; Kamiyama, T.; Mori, K.; Maie, M.;

Nagai, T.; Matsui, Y.; Takayama-Muromachi, E. High-Pressure

Synthesis, Crystal Structures, and Properties of Perovskite-like

BiAlO3 and Pyroxene-like BiGaO3. Chem. Mater. 2006, 18, 133−139.

REFERENCES

(1) Zheng, H.; Wang, J.; Lofland, S. E.; Ma, Z.; Mohaddes-Ardabili,

L.; Zhao, T.; Salamanca-Riba, L.; Shinda, S. R.; Ogale, S. B.; Bai, F.;

Viehland, D.; Jia, Y.; Schlom, D. G.; Wuttig, M.; Roytburd, A.;

Ramesh, R. Multiferroic BaTiO3-CoFe2O4 Nanostructures. Science

2004, 303, 661−663.

(2) Ma, J.; Hu, J.; Li, Z.; Nan, C. W. Recent Progress in Multiferroic

Magnetoelectric Composites: from Bulk to Thin Films. Adv. Mater.

2011, 23, 1062−1087.

(3) Yan, L.; Yang, Y.; Wang, Z.; Xing, Z.; Li, J.; Viehland, D. Review

of Magnetoelectric Perovskite−Spinel Self-Assembled Nano-Composite Thin Films. J. Mater. Sci. 2009, 44, 5080−5094.

(4) MacManus-Driscoll, J. L. Self-Assembled Heteroepitaxial Oxide

Nanocomposite Thin Film Structures: Designing Interface-Induced

Functionality in Electronic Materials. Adv. Funct. Mater. 2010, 20,

2035−2045.

(5) Li, J.; Levin, I.; Slutsker, J.; Provenzano, V.; Schenck, R. K.;

Ramesh, R.; Ouyang, J.; Roytburd, A. L. Self-Assembled Multiferroic

Nanostructures in the CoFe2O4 -PbTiO3 System. Appl. Phys. Lett.

2005, 87, 072909.

(6) Zheng, H.; Zhan, Q.; Zavaliche, F.; Sherburne, M.; Straub, F.;

Cruz, M. P.; Chen, L.-Q.; Dahmen, U.; Ramesh, R. Controlling SelfAssembled Perovskite−Spinel Nanostructures. Nano Lett. 2006, 6,

1401−1407.

(7) Zhan, Q.; Yu, R.; Crane, S. P.; Zheng, H.; Kisielowski, C.;

Ramesh, R. Structure and Interface Chemistry of Perovskite-Spinel

Nanocomposite Thin Films. Appl. Phys. Lett. 2006, 89, 172902.

(8) Aimon, N. M.; Kim, D. H.; Choi, H. K.; Ross, C. A. Deposition of

Epitaxial BiFeO3/CoFe2O4 Nanocomposites on (001) SrTiO3 by

Combinatorial Pulsed Laser Deposition. Appl. Phys. Lett. 2012, 100,

092901.

(9) Zhang, W.; Chen, A.; Khatkhatay, F.; Tsai, C.-F.; Su, Q.; Jiao, L.;

Zhang, Z.; Wang, H. Integration of Self-Assembled Vertically Aligned

Nanocomposite (La0.7Sr0.3MnO3)1−x:(ZnO)x Thin Films on Silicon

Substrates. ACS Appl. Mater. Interfaces 2013, 5, 3995−3999.

(10) Khatkhatay, F.; Chen, A.; Lee, J. H.; Zhang, W.; Abdel-Raziq,

H.; Wang, H. Ferroelectric Properties of Vertically Aligned Nanostructured BaTiO3−CeO2 Thin Films and Their Integration on

Silicon. ACS Appl. Mater. Interfaces 2013, 5, 12541−12547.

(11) Barber, S. M.; Lin, Q.; Zou, G.; Haberkorn, N.; Baily, S. A.;

Wang, H.; Bi, Z.; Yang, H.; Deng, S.; Hawley, M. E.; Civale, L.; Bauer,

E.; McCleskey, T. M.; Burrell, A. K.; Jia, Q.; Luo, H. Magnetic

Properties of Self-Assembled Epitaxial Nanocomposite CoFe2O4:SrTiO3 and CoFe2O4:MgO Films. J. Phys. Chem. C 2011,

115, 25338−25342.

(12) Zheng, H.; Straub, F.; Zhan, Q.; Yang, P. L.; Hsieh, W.-K.;

Zavaliche, F.; Chu, Y.-H.; Dahmen, U.; Ramesh, R. Self-Assembled

Growth of BiFeO3-CoFe2O4 Nanostructures. Adv. Mater. 2006, 18,

2747−2752.

(13) Dix, N.; Muralidharan, R.; Warot-Fonrose, B.; Varela, M.;

Sánchez, F.; Fontcuberta, J. Critical Limitations in the Fabrication of

Biferroic BiFeO3−CoFe2O4 Columnar Nanocomposites Due to

Bismuth Loss. Chem. Mater. 2009, 21, 1375−1380.

(14) Comes, R.; Liu, H.; Khokhlov, M.; Kasica, R.; Lu, J.; Wolf, S. A.

Directed Self-Assembly of Epitaxial CoFe2O4−BiFeO3 Multiferroic

Nanocomposites. Nano Lett. 2012, 12, 2367−2373.

(15) Zavaliche, F.; Zhao, T.; Zheng, H.; Straub, F.; Cruz, M. P.; Yang,

P.-L.; Hao, D.; Ramesh, R. Electrically Assisted Magnetic Recording in

Multiferroic Nanostructures. Nano Lett. 2007, 7, 1586−1590.

(16) Aimon, N. M.; Kim, D. H.; Sun, X.; Ross, C. A. Multiferroic

Behavior of Templated BiFeO3−CoFe2O4 Self-Assembled Nanocomposites. ACS Appl. Mater. Interfaces 2015, 7, 2263−2268.

(17) Kim, D. H.; Aimon, N. M.; Sun, X.; Ross, C. A. Compositionally

Modulated Magnetic Epitaxial Spinel/Perovskite Nanocomposite Thin

Films. Adv. Funct. Mater. 2014, 24, 2334−2342.

(18) Yuasa, S.; Nagahama, T.; Fukushima, A.; Suzuki, Y.; Ando, K.

Giant Room-Temperature Magnetoresistance in Single-Crystal Fe/

MgO/Fe Magnetic Tunnel Junctions. Nat. Mater. 2004, 3, 868−871.

2679

DOI: 10.1021/acsami.5b10676

ACS Appl. Mater. Interfaces 2016, 8, 2673−2679