AS Unit 1 Topic 7

advertisement

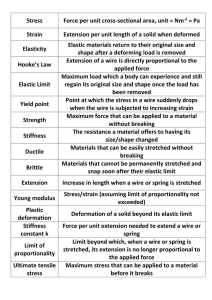

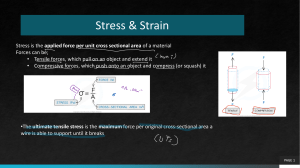

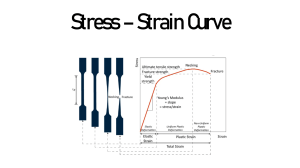

Edexcel AS Physics Unit 1 : Chapter 7: Solid Materials Prepared By: Shakil Raiman 7.1 Elastic Deformation A material undergoing elastic deformation will return to its original dimensions when the deforming force is removed. Example: Spring, Steel wire etc. 7.2 Plastic Deformation A material undergoing plastic deformation will not return to its original dimensions or remain deformed when the deforming force is removed. Example: modelling clay 7.3 Elastic and Plastic Deformation Some material can behave in an elastic or plastic manner depending on the nature of the deforming force. A thin steel sheet will deform elastically when small forces are applied to it, but the huge forces of a hydraulic press will mould the sheet into car panels. 7.4 Properties of Solid Materials Hardness: Hardness is a surface phenomenon. The harder the material, the more difficult it is to indent or scratch the surface. Diamond is hardest which has a rating 10. Stiffness: A stiff material exhibits very small deformations even when subjected to large force. Steel etc. 7.4 Properties of Solid Materials Strength: An object is strong if it can withstand a large force before it breaks. Steel is strong but cotton is weak. Malleability: A malleable material can be hammered out into thin sheets. Gold 7.4 Properties of Solid Materials Ductility: Ductile materials can be drawn into wires. copper 7.5 Stress Stress (tensile/compressive stress) is defined as force per unit cross-sectional area. force stress cross _ sec tional _ area F A Unit: Pa (Pascal) 7.6 Strain Strain is defined as extension per unit original length. extension strain original _ length l l Unit: no unit 7.7 Young’s Modulus Young modulus is defined as the ratio of tensile or compressive stress to strain. stress Young _ mod ulus strain Fl E Al Unit: Pa (Pascal) 7.8 Hooke’s Law Hooke’s law states that, upto a given load, the extension of a spring (or wire) is directly proportional to the force applied to the spring (or wire) F kx where K represents the stiffness or spring constant 7.9 Elastic Potential Energy or Elastic Strain Energy The elastic potential energy or elastic strain energy is the ability of a deformed material to do work as it regains its original dimensions. W Fave x 1 W Fmax x 2 7.10-1: Stress-Strain Graph 7.10-2: Stress-Strain Graph O-A represents the Hooke’s Law region. Strain is proportional to stress up to this point. The Young modulus of material can be found directly by taking the gradient in this section. B is the elastic limit. If the stress is removed below this value, the wire returns to its original state. 7.10-3: Stress-Strain Graph C is the yield stress. For stresses greater than this, the material will become ductile and deform plastically. D is the maximum stress that a material can endure. It is called ultimate tensile strength (UTS). E or F is the breaking point. After E the wire starts narrowing. 7.10-4: Stress-Strain Graph 7.10-5: Stress-Strain Graph 7.10-6: Stress-Strain of Rubber The hysteresis loop for stressstrain graph represents the energy per unit volume transferred to internal energy during loadunload cycle. Thank You All Wish you all very good luck and excellent result.