Overall Equipment Effectiveness (OEE) and its Application in Pharma/Biopharma Manufacturing

advertisement

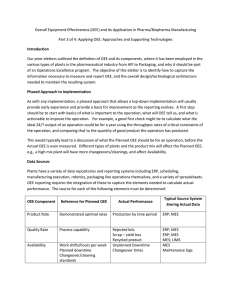

Overall Equipment Effectiveness (OEE) and its Application in Pharma/Biopharma Manufacturing Part 1 of 4 – OEE Basic Philosophy and Definitions Introduction Overall Equipment Effectiveness (OEE) has been applied in many industries over many decades and has its origins in the Total Preventive Maintenance (TPM) philosophy adopted and adapted in postwar Japan and specifically by Toyota. In recent years it has begun to find acceptance as a useful performance measure in the pharmaceutical industry despite initial reluctance (to be explored in a future E-Letter). We can now definitely state that it should be a key element of any Operational Excellence and Lean program to help drive ongoing improvement. Regardless of where OEE has been deployed, one thing all industries have in common in relation to OEE is lively discussion of how it should be defined! Should unplanned working time be excluded? What about preventive maintenance? Or line changeovers? Since OEE is such an important and visible key performance indicator it is important to reach cross-company agreement on how it will be applied in your business. Levels of OEE performance are highly variable and it important to set expectations accordingly. A continuous processing plant in oil or chemicals will often have OEE rates in the high 90%s. A multiproduct sterile pharmaceutical packaging line will often be less than 10%. It is therefore important to recognize the target levels achievable for the equipment on which you are focused. Defining OEE There are two broad approaches to defining OEE which we may consider. The formula for OEE is the same regardless of the approach we take, the arguments center on how the individual elements of OEE themselves are defined, particularly “Availability.” OEE% = PR% x QR% x Av% Where PR = Product Rate (sometimes called Efficiency) and is usually defined as the average output from the asset being measured divided by the maximum demonstrated output from that equipment. The time period over which the output is measured is important and will often be “one week.” Product Rate will be affected by on-line problems which cause the line to stop intermittently or to run slower than optimal. An understanding of PR will help drive line improvement initiatives. QR = Quality Rate (sometimes called Yield) and is defined as the quantity of good product made divided by total volume. Therefore any rework, recycling or rejects will negatively impact QR. In most pharma operations GMP ensures QR is usually 98%+. Availability (sometimes called Utilization) is the time producing product divided by total time. It is the definition of total time that causes concern to many people. For the highest level view of OEE total time equals 8,760 hours in a non-Leap Year and using this gives the measure of absolute effectiveness of using your assets. It is a measure the Finance people will be interested in and over time it is in the interest of Operations Management to also consider this version. However, it is often outside the control of operations managers in the short-term to influence product mix and demand volumes and therefore we find many operations working at less than 24x7 capacity. In this case we may choose to redefine Availability to reflect unplanned working time such as weekends and nights. This version of OEE is often called Planned Equipment Effectiveness (PEE). We recommend using both approaches; the purest form of OEE based on 8,760 should be reviewed at least annually by plant managers to observe the strategic direction of their operations and as input to longer-term planning and the Planned version is one that can be used line-side on a daily basis. The Definition of OEE and PEE are summarized in the following table: In subsequent E-Letters we will explore practical aspects of deploying OEE in the pharma industry. To Follow: Part 2 OEE State of the Art in the Pharma Industry Part 3 Applying OEE; approaches and supporting technologies Part 4 Experience of implementing OEE – Identifying and overcoming barriers