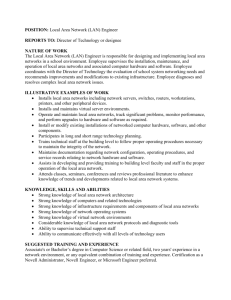

Eric Erickson Objective

advertisement

Eric Erickson eric.erickson@kla-tencor.com Objective I am looking for a position that utilizes my engineering and leadership skills to develop industry-leading products. Professional Profile: I am an experienced results oriented systems engineer and project manager who has worked in the semiconductor equipment and aerospace industries. I am an excellent problem solver who received the Manned Space Flight Safety Award for my work analyzing empirical crack growth and initiation on Space Shuttle hardware. I have presented technical information numerous times to senior company and customer management. I am a proven leader who has managed engineers and technicians in a new product development environment. I have led several successful project teams. As a system engineer I have extensive hands on experience troubleshooting beta and alpha level semiconductor equipment. I have spent a significant amount of time in customer fabs, around the world, supporting beta testing. I have been involved in all phases of product creation: initial concept review, detail drawings, assembly, installation, first test and semiconductor process development. My cradle to grave experience has taught me what needs to be done to run a successful project. I have also authored scores of hardware failure reports, on space shuttle main engine hardware. I quickly acquire new skills. I became a chemical vapor deposition (CVD) process expert for shallow trench isolation (STI) and BPSG films and lead successful customer technology demonstrations. I know that my unique blend of experience and skills will make me a valuable addition to your organization. Experience KLA-Tencor Project Manager (Feb 2004 to Present) Managed the wafer handling system (EFEM) for key KLA division Drastically reduced warrantee and service costs o Exceeded corporate goals Presented to executive staff on the progress of the program Managed supplier relationship while transitioning from external to internal supplier Successfully converted division from external to internal supplier Resulted in 10k cost savings/per tool Supported installation of Beta shipment in Japan Successfully managed testing program for Phoenix 1.3 product Evaluated mini-environment ionizer testing requirements methodologies Reduced cycle time from two days to two hours. Headway Technologies Facility Engineer (Oct 2003 to Feb 2004) Responsible for equipment and personnel moves in support of 12 million dollar fab expansion Dawn-VME Mechanical Engineer (Jul 2003 to Oct 2003) Responsible for mechanical packaging of VME computer hardware Eric Erickson eric.erickson@kla-tencor.com Provide low cost high quality mechanical enclosure solutions Olympus-ITA Senior Systems Engineer (July 2002 to Jan 2003) Installed, tested and qualified beta level micro inspection equipment Evaluated macro wafer inspection system – Determined fitness for the semiconductor equipment market Provided unique hardware solutions that enabled customers to more effectively use their microscope system Solved vibration problem that was preventing production use of the defect detection system ASML(1996 to July 2002) System Engineering Manager (1999 to Jul 2002) Managed a team of engineers and technicians during hardware and process development of CVD system Successfully directed development lab activities – Ensured that daily tasks matched long range goals of the project Managed in a cross functional environment - Lab team made up of several groups that were not direct reports CVD process expert – BPSG and NSG Played key role in several successful technology demonstrations Developed and demonstrated successful 300mm BPSG process for Korean DRAM manufacturer Supported beta site in Taiwan with a multi-discipline team Developed and performed hardware maintenance procedures Led team in debugging a new motion control system – uncovered numerous mechanical and electrical short comings with the design System Engineer (1998 to 1999) Managed the build of several beta and alpha CVD systems Required coordination with design engineering, purchasing, manufacturing and hands on assembly Led system installation – required coordination with facilities contractors Verified systems were mechanically and electrically ready for the introduction of process chemicals (toxic) Worked as a process engineer to develop BPSG and NSG processes Eric Erickson eric.erickson@kla-tencor.com Design Engineer (1996 to 1998) Designed vacuum system for cluster tool transport module Solved conveyor system wafer movement problem by designing custom rollers Successfully beta tested design at two different customer locations – US and Japan Directed the installation and testing of hydrofluoric acid etch tester Responsible for direction of junior engineer and technician Produced source control document for transport module vendor Conducted first article inspection at customer site Worked on several customer special designs Rockwell International Turbomachinery Development Engineer (1989 to 1996) Received Manned Space Flight Safety Award for work determining crack initiation and growth characteristics of critical shuttle hardware Played a significant role in investigation of rocket engine failure – work sited in final report (RSS8595-45) Conducted numerous hardware failure assessments – determined failure cause, corrective action and impact of flight safety Coordinated with multiple engineering disciplines – stress, materials, hydrodynamics, quality, etc. Presented results to senior company and NASA management Responsible for all fuel turbomachinery hardware and performance issues at test site A1 – Test site located 2000 miles from factory Evaluated rocket engine performance data and post test inspection reports to ensure hardware safety Senior material review board member – Responsible for disposition of out of spec. hardware conditions Turbine blade expert – inspected turbine blades for defects and determined if they should be reused Critical responsibility – a turbine blade failure would result in loss of launch vehicle and crew Education: BSME from California State University Fresno 1989 GPA 3.19 Awards: Manned Space Flight Safety Award (presented by Astronaut Kevin Chilton), Directors Award for Technical Achievement, Deans List, (4 Semesters) Software: AutoCAD 2002, Microsoft Office