Chabot College Fall 2010 – Production Practices

advertisement

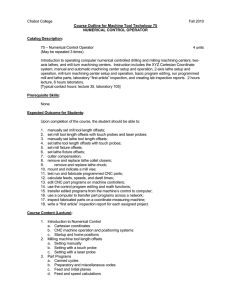

Chabot College Fall 2010 Course Outline for Machine Tool Technology 65 PRODUCTION PRACTICES Catalog Description: 65 – Production Practices (May be repeated 3 times) 4 units Introduction to design and fabrication of production-type tooling such as jigs, fixtures, and gauges as applied in industry. Emphasis on tool design practices, fabrication techniques, set-up procedures, and inspection of production parts. Prerequisite: Machine Tool Technology 60B (completed with a grade of “C” or higher). 2 hours lecture, 6 hours laboratory. [Typical contact hours: lecture 35, laboratory 105] Prerequisite Skills: Before entering the course, the student should be able to: 1. properly use precision measuring tools, such as the Bore Micrometers, Large Vernier calipers, dial height gauge, .0001” dial test indicator, and various types of micrometers, also optical / video measuring machines; 2. perform advanced bench operations, such as draw filing, contour sawing and geometric die head threading; 3. set up and perform advanced drill press, lathe and vertical milling machine operations; 4. machine to a precision layout on the surface grinders using precision tools, such as the vernier protractor, parallels, and Angle and Gage Blocks; 5. apply intermediate mathematical formulas for calculating correct pitch, leads, and gearcutting data required for precision part manufacture; 6. evaluate a blueprint to make a manufacturing plan to produce the desired machine part; 7. safely setup and operate a Hardinge lathe to make a 60 Degree threaded shaft with no thread relief; 8. safely setup and operate a manual milling machine to make a prismatic part (like the 1-2-3 Block Set) manufactured within the part drawing tolerances and geometrically shaped part; 9. heat Treat the 1-2-3 Blocks and Precision Grind all external surfaces to within the +/- .0002” Tolerance Zone per ANSI Y14.5M; 10. offhand grind a High Speed Steel Roughing and Threading Toolbit to a tolerance of +/- 1/2 degree for each of the tool’s six major cutting or clearance angles as described in the Machine Tool Laboratory Manual; 11. measure the Gears manufactured and evaluate whether the gear is acceptable to the print tolerances published, all geometries and published Gear Machining Standards like ANSI Y14.5M. Expected Outcome for Students: Upon completion of the course, the student should be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. design basic production tools; fabricate basic production tools; select and correctly apply standard jig and fixture components; apply mathematical formulae to solve tooling-related problems; set up production tools on standard and numerically controlled machine tools for production machining operations; select proper measuring tools for inspecting production workpieces; operate and program procedures and events for the Prototrak dual mode lathe; perform setups and inspections using the video measuring machine; select the proper speeds and feeds for use with carbide and carbide insert tooling; align parts using a four jaw adjustable chuck in a lathe; tram the milling machine head with a trammel gauge to .001” TIR; Chabot College Course Outline for Machine Tool Technology 65, Page 2 Fall 2010 12. setup and grind workpieces flat and parallel within .001" with a vertical spindle grinder; 13. operate and program procedures for the Makino dual mode milling machine; 14. properly disassemble and assemble production jigs and fixtures from engineering drawings. Course Content (Lecture): 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. Design requirements for production tooling Types of production tooling Standard tooling components Setting up production tooling Inspection of production parts Drill bushings, types and styles and installation Tooling components list, pricing and cost analysis Sine bar setup and evaluation Angular interpolation Process planning for production Production cost analysis and unit cost determination of time lines Selection of fixture plate materials and heat treatment / preparation Beginning tooling ball setup and calculation Course Content (Laboratory): 1. Techniques a. Set tool lengths b. Set fixture offsets c. Edge finding and indicating part center lines for fixtures d. Create program / procedures from engineering drawings for the Makino dual mode CNC mill e. Proof program using precision measuring accessories on the machine tool f. Generating large radii using the head tilt method g. Trammel Gauge usage demonstration h. High speed steel production roughing tool demonstration and application of the “5 minute tool” i. Contour lathe programming with the Prototrak lathe j. Extracting production data from Solidworks files k. Precision grinding of production tooling and components l. Using the sine bar on the lathe to set accurate compound rest angles “short taper” applications m. Acme thread example and multiple start thread applications of the “higby cut” n. Universal horizontal milling machine indicating, setup, production fixtures 2. Safety a. Safe operation of the Dual Mode CNC machining centers b. Safe production practices in the team working environment Methods of Presentation: 1. Lecture, informal with student questions encouraged 2. PowerPoint presentations, videos, industry relevant movies, and model examples of large and specialized tooling and machines 3. Hands-on demonstrations Chabot College Course Outline for Machine Tool Technology 65, Page 3 Fall 2010 Assignments and Methods of Evaluating Student Progress: 1. Typical Assignments a. Homework: 1-2 worksheets each week on the material covered in the text, in lecture and laboratory Example: Sketch the outer contour of the Trammel Gauge Project, draw in the tool tangency locations, radii and calculate their Cartesian coordinate positions from datum locators. Write a program using the Makino mill to machine all radii for the Trammel Gauge Project. b. Laboratory assignment: Setup the mill table stop base for production of ten base pieces to mill the .750” radius with a .75” 4 flute high speed steel end mill. Use the milling machine and rotary table and fixture. Test run each tool operation checking for accuracy and proper tool cutting rotation and feed direction. Only mill utilizing conventional milling. Inspect the part on the Video / Coordinate measuring machine and create a “first article” inspection report. Did the part pass inspection? If not, why? What remediation would correct the problem, if any? 2. Methods of Evaluating Student Progress a. Homework b. Quizzes c. Written laboratory inspection report on each part project d. Fabricated parts checked to be accurate size and shape e. Midterm manipulative and written examinations f. Final examination, written and manipulative Textbook(s) (Typical): Fundamentals of Tool Design, Society of Manufacturing Engineers, 2003* *Rationale: Tool design theory and techniques have not changed much in the past 10 years. This book, from the Society of Mechanical Engineers, is still the best resource on the market to date. Special Student Materials: 1. 2. 3. 4. 5. Machine shop approved safety goggles Sharp EL-531W scientific calculator USB drive – 1gb minimum Combination or keyed padlock Appropriate laboratory attire Revised: 9/28/09 Ashley Long / Mike Absher