Chabot College Fall 2010 – Numerical Control Operator

advertisement

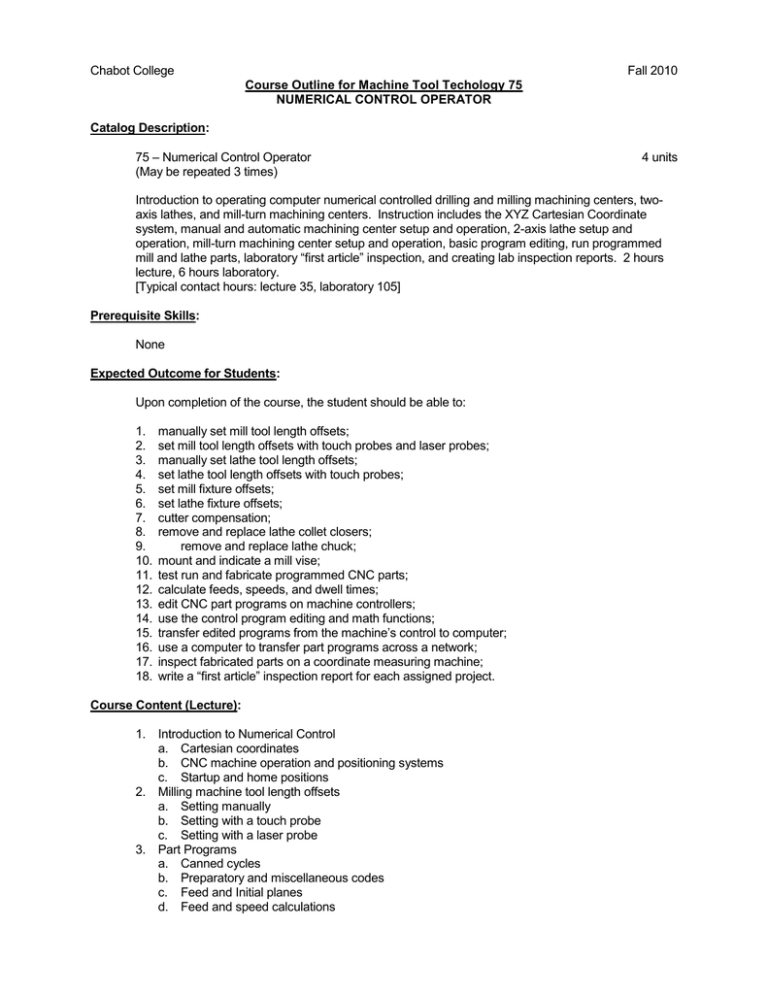

Chabot College Fall 2010 Course Outline for Machine Tool Techology 75 NUMERICAL CONTROL OPERATOR Catalog Description: 75 – Numerical Control Operator (May be repeated 3 times) 4 units Introduction to operating computer numerical controlled drilling and milling machining centers, twoaxis lathes, and mill-turn machining centers. Instruction includes the XYZ Cartesian Coordinate system, manual and automatic machining center setup and operation, 2-axis lathe setup and operation, mill-turn machining center setup and operation, basic program editing, run programmed mill and lathe parts, laboratory “first article” inspection, and creating lab inspection reports. 2 hours lecture, 6 hours laboratory. [Typical contact hours: lecture 35, laboratory 105] Prerequisite Skills: None Expected Outcome for Students: Upon completion of the course, the student should be able to: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. manually set mill tool length offsets; set mill tool length offsets with touch probes and laser probes; manually set lathe tool length offsets; set lathe tool length offsets with touch probes; set mill fixture offsets; set lathe fixture offsets; cutter compensation; remove and replace lathe collet closers; remove and replace lathe chuck; mount and indicate a mill vise; test run and fabricate programmed CNC parts; calculate feeds, speeds, and dwell times; edit CNC part programs on machine controllers; use the control program editing and math functions; transfer edited programs from the machine’s control to computer; use a computer to transfer part programs across a network; inspect fabricated parts on a coordinate measuring machine; write a “first article” inspection report for each assigned project. Course Content (Lecture): 1. Introduction to Numerical Control a. Cartesian coordinates b. CNC machine operation and positioning systems c. Startup and home positions 2. Milling machine tool length offsets a. Setting manually b. Setting with a touch probe c. Setting with a laser probe 3. Part Programs a. Canned cycles b. Preparatory and miscellaneous codes c. Feed and Initial planes d. Feed and speed calculations Chabot College Course Outline for Machine Tool Technology 75, Page 2 Fall 2010 4. Loading, testing, and running milling machine programs 5. Milling machine fixture offsets a. Data input using G10 6. Mounting milling machine work holding devices a. Mill vise b. Vacuum fixtures c. Modular tooling 7. Introduction to the Coordinate Measuring machine a. First article inspection b. Lab inspection reports 8. Milling machine Manual Data Input – MDI operation 9. Incremental and Absolute programming 10. Program editing a. Machine control math functions b. Machine control programming and editing functions 11. Introduction to conversational milling machine programming 12. Introduction to contouring a. Cutter diameter compensation b. Climb and conventional milling 13. Programming with DXF files 14. Introduction to lathe programs a. Tool nose radius compensation b. Canned cycles c. Preparatory and miscellaneous codes 15. Introduction to two axis and mill-turn lathes a. Cartesian coordinates b. Lathe tooling and accessories c. Carbide insert tooling 16. Lathe tool length offsets a. Setting manually b. Setting with a touch probe c. Setting lathe fixture offsets 17. Sub spindle operation 18. Machining center simulator functions and operation Course Content (Laboratory): 1. Techniques: a. Set milling machine tool length offsets manually and with probing systems b. Set milling machine fixture offsets c. Edge find parts and fixtures manually and with CNC control routines d. Indicating parts and fixtures e. Skew machine axes using a touch probe f. Proof programs on machine tool simulators g. Test run programs h. Fabricate programmed parts i. Set lathe tool length offsets manually and with probing systems j. Set lathe fixture offsets k. Create a conversational program l. Edit part programs in the CNC mill controller m. Inspect parts with a coordinate measuring machine n. Inspect parts with manual inspection tools 2. Safety: a. Safe operation of the CNC machining centers b. Safe program proofing procedure Chabot College Course Outline for Machine Tool Technology 75, Page 3 Fall 2010 Methods of Presentation: 1. Lecture, informal with student questions encouraged 2. Powerpoint presentations, videos, instructor created movies, and overhead transparencies 3. Demonstrations Assignments and Methods of Evaluating Student Progress: 1. Typical Assignments a. Homework: 1-2 worksheets each week on the material covered in the texts and in lecture. Examples: Calculate the depths, feeds, speeds, and dwell to spot drill, drill, and tap a series of 1/4-20 UNC - 2B holes.. Write a step by step procedure for mounting and indicating a mill vise. Have it approved by your instructor. b. Laboratory assignment: Using your step by step procedure for mounting and indicating a mill vise, properly install and indicate a Kurt mill vise on the Haas machining center. 2. Methods of Evaluating Student Progress a. Homework b. Quizzes c. Written lab inspection report on each part project d. Fabricated parts checked to be accurate size and shape e. Midterm examinations f. Final examination Textbook(s) (Typical): Haas VF2 Mill Programming Manual* Haas SL-20 Lathe Programming Manual* *Rationale: Both textbooks are programming manuals for specific equipment in Chabot's Machine Tool Technology lab. They are the standard for all operations and programming functions for our equipment. Special Student Materials: 1. 2. 3. 4. 5. 6. Machine shop approved safety goggles Sharp EL-531W scientific calculator Plastic circle template, 6” rule, protractor, compass, three inch 30-60° and 45° triangle USB drive – 1gb minimum Headphones – 1/8” stereo jack Combination or keyed padlock Revised: 9/29/09 Ashley Long/Mike Absher