Machine Tool Technology

advertisement

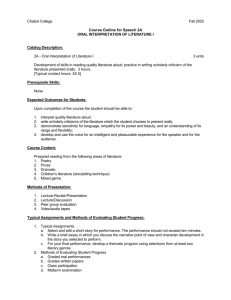

Chabot College Fall 2010 Course Outline for Machine Tool Technology 60A MACHINE TOOL TECHNOLOGY I Catalog Description: 60A – Machine Tool Technology I (May be repeated 3 times) 4 units Introduction to machine tool operations relating to precision measuring tools, layout methods, screw threads, benchwork, drill presses, bandsaws, optical and manual inspection techniques, basic lathe and vertical milling operations, and evaluation of manufacturing job opportunities. Emphasis on safe and correct use of hand and machine tools. 2 hours lecture, 6 hours laboratory. [Typical contact hours: lecture 35, laboratory 105] Prerequisite Skills: None Expected Outcome for Students: Upon completion of the course, the student should be able to: 1. properly use precision measuring tools, such as the vernier caliper, vernier height gauge, dial test indicator, and various types of micrometers, also optical / video measuring machines; 2. perform common bench operations, such as filing, sawing, deburring and hand threading; 3. set up and perform basic drill press, bandsaw, lathe and vertical milling machine operations; 4. make precision layouts on the surface plate using precision layout tools, such as the vernier height gauge, angle plates, parallels, and V-blocks; 5. apply basic mathematical formulas for calculating correct speeds, feeds, and data required for precision part layout; 6. evaluate a blueprint to make a manufacturing plan to produce the desired machine part; 7. safely setup and operate a manual lathe to make a 60 Degree threaded shaft; 8. safely setup and operate a manual milling machine to make a prismatic part manufactured within the part drawing tolerances and geometrically shaped part; 9. offhand grind a High Speed Steel Toolbit to a tolerance of +/- 1 degree for each of the tool’s six major cutting or clearance angles as described in the Machine Tool Laboratory Manual; 10. measure the parts manufactured and evaluate whether the piece part is acceptable to the print tolerance, geometries and published machining standards like ANSI Y14.5M. Course Content (Lecture): 1. Precision measuring tools, standards, micrometers, calipers height gages, precision pins 2. Identity of benchworking tools such as the combination square set, trammel points, center / prick punches, wrenches and hammers 3. Layout methods, blueprint interpretation and part layout techniques 4. Screw threads types, styles and dimension standards 5. Drill presses, includes chuck and tapered drills and speeds and power feeds 6. Explanation and examples of bandsaw operations, including safely setting speeds and welding new blades 7. Basic lathe operations, including turning, facing, drilling, tool and machine setup & beginning operations, 8. Basic vertical milling machine operations, speeds and feeds, identifying parts components and accessories, setup clamping and indicating methods and techniques 9. Evaluate and inspect parts produced in class and prepare Laboratory Inspection Reports 10. Manufacturing / fabrication Job opportunities, specialties and trends Chabot College Course Outline for Machine Tool Technology 60A, Page 2 Fall 2010 Course Content (Laboratory): 1. Typical Techniques a. Set tool Height and angles b. Set chuck parameters indicate to .001” TIR c. Face Cut the parts to Blueprint specifications d. Turn each of the steps of the “Step Turn Project” to +/- .001” per Blueprint e. Cut the 45 Degree Chamfer X 1/16” by compound Rest Setup and Operations, Inspect to published tolerances f. Set Milling Machine to Proper cutting parameters g. Cut the ID Slot ¼” X .020 Deep 1.00” Long h. Edge finding and indicating part stock and vices i. Create part plans from engineering drawings; have your instructor signoff j. Inspect parts produced and write a Laboratory Report on machining successes and failures analyzing why problems were encountered and what remedies where developed and implemented for remediation of the scrap part 2. Safety a. Safe operation of the Lathe / Milling Machines and Grinders, including all tools used to cut form or inspect the project parts b. Develop safe skills and habits while following posted machining procedures Methods of Presentation: 1. Lecture, informal with student questions encouraged 2. PowerPoint presentations, videos, safety and application movies, and overhead transparencies 3. Hands-on Demonstrations and interactive participation while in lecture 4. Field Trips / on-site manufacturing visits Assignments and Methods of Evaluating Student Progress: 1. Typical Assignments a. Homework: 1-2 worksheets each week on the material covered in the texts and in lecture. Example: Sketch the C-Clamp project, draw in the tool and cutting locations, and calculate their X - Y coordinate positions. b. Laboratory assignment: Manufacture a complete C-Clamp project and all 6 of the detail parts of the C-Clamp Assembly to published blueprint standards and practices. Verify the thread sizes to a class 3A published in the Machinery Handbook. Maximum Pitch Diameter .3344” and Minimum .3311” Minimum. Inspect the other parts on the Video measuring machine and recreate a “first article” inspection report. Did the part pass inspection? Why? 2. Methods of Evaluating Student Progress a. Homework b. Quizzes c. Written laboratory inspection report on each part project d. Fabricated parts checked to be accurate size and shape e. Midterm examinations f. Final examination Chabot College Course Outline for Machine Tool Technology 60A, Page 3 Fall 2010 Textbook(s) (Typical): Machine and CNC Technology, Fitzpatrick, Career Education; 2004* *Rationale: This book more completely covers the subject matter taught in Chabot's Machine Tool Technology program than any other text book we have found. The new edition is due out in the first quarter of 2010. We will adopt that edition if, after review, we feel it continues to meet our needs. Operations Manual for Machine Tool Technology, Clifford Oliver, Chabot Bookstore* *Rationale: This book was written by a former Chabot College Machine Tool instructor and is an exact match for the projects, equipment, and operations that are taught in Chabot's Machine Tool Program. Machinist Ready Reference, Weingartner, Prakken Pubn; 2007 Special Student Materials: 1. 2. 3. 4. 5. 6. Machine shop approved safety goggles Sharp EL-531W scientific calculator Plastic circle template, 6” rule, protractor, compass USB drive – 1gb minimum Combination or keyed padlock Students are encouraged to purchase tools, a list given by the instructor, to use in class as a start to entering the work world, but are not required to do so. Revised: 9/25/09 Ashley Long / Mike Absher