Document 11119281

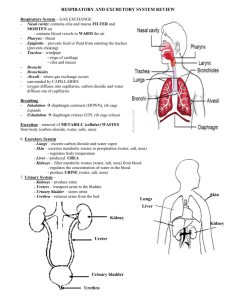

advertisement