urea

advertisement

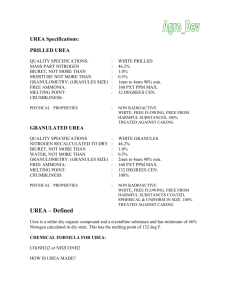

PRODUCTION OF UREA • Urea is a white dry organic compound and a crystalline substance and has minimum of 46% Nitrogen calculated in dry state. M.P: 132 deg C. • Urea is made by reacting carbon dioxide (CO2) with anhydrous ammonia (NH3) under pressure of 208 atm and temperatures of around 176.6 0C. • Water is removed during processing and the molten matter is either converted to prills or into granules. • Urea can be produced as prills, granules, flakes, pellets, crystals and solutions. USES • 1. Urea is highly soluble in water and is therefore also very suitable for use in fertilizer solutions (in combination with ammonium nitrate: UAN) and as animal feed. • 2. For the manufacture of plastics specifically, urea-formaldehyde resin(Plywood adhesiveFevicol) • 3. For the manufacture of various glues (ureaformaldehyde or urea-melamine-formaldehyde). The latter is waterproof and is used for marine plywood • • • • • • • • Specifications for Prilled Urea 46%N: Nitrogen:46.0% min. Moisture:0.3% max. Biuret:1.0% max. Granulation:1 – 4 mm 90-94% min. Melting Point: 132 Degrees Celsius Colour: Pure White Prilled Free Flowing, Treated against caking, 100% free from harmful substances. • • • • • • • • Specifications for Granular Urea 46%N: Nitrogen:46.0% min. Moisture:0.5 % max. Biuret:1.4% max. Granulation:2 – 4 mm 90-94% min. MeltingPoint:132DegreesCelsius Colour: Standard White or Pure. Free Flowing, Treated against caking, 100% free from harmful substances. Market grades • 1. Technical grade: 46% Nitrogen • 2. Fertilizer grade: Coated with Nonhygroscopic dust such as Phosphate rock/Lime stone, containing 40-42% Nitrogen • 3. Liquor: Mixtures of Urea in Ammonia Solution Principle raw materials: 1) CO2 from synthesis gas 2) NH3 • Process description: • 1. Ammonia and CO2 are compressed separately and added to the high pressure autoclave. • 2. The Reactor is water-cooled due to the highly exothermic nature of the reaction. • 3. The Reactor is operated on a continuous basis; A mixture of Urea, Ammonium Carbamate, Water and unreacted NH3+ CO2 results. Process description • This liquid effluent is let down to 27 atms. and fed to a flash-evaporator containing a gas-liquid separator and condenser. • Unreacted NH3, CO2 and H2O as a solution are thus removed and recycled (in case of partial recycle option). • An aqueous solution of carbamate-urea is passed to the atmospheric flash drum, where further decomposition of carbamate takes place. Process description • The off-gases from this step can either be recycled or sent to NH3 processes for making chemical fertilizer. • The 80% aqueous Urea solution can be used as is, or sent to a vacuum evaporator to obtain molten Urea containing less than 1% water. The molten mass is then sprayed into a prillng or granular solidification tower. Process description • To avoid formation of bi-uret in percentages greater than1%, the temp. must be kept just above the Melting Point for processing times of 1-2 sec. in this phase of the operation.