FOREST PRODUCTS LABORATORY In cooperation with the University of Wisconsi n

advertisement

FOREST PRODUCTS LABORATOR Y

In cooperation with the University of Wisconsi n

MADISON, WISCONSI N

1925 PRIMING COAT TESTS

FOR CERTAIN WOOD S

By F. L. BROWNE

Chemist in Forest Products

Approved Copy File d

December 31, 1925

The objects of the 1925 priming coat tests on ce r

woods have been explained in detail in the Working Plan ,

Project L .6262-4, entitled, "1925 Exposures in Study of th e

inting Characteristics of Different Kinds of Wood," Augus t

1925, a copy of which has been sent to each of the co p

The test panels of 18 species of wood put out i n

4 were all painted in the same manner with the white lea d

the mixed pigment paints respectively . It was realize d

at the method employed would not prove suitable for all th e

woods, but it was thought best to start out from a commo n

* rt

e

basis of treatment in all cases . The inspection in the sprin g

of 1925 indicated that this expectation would be realized i n

the cases of the yellow pines, firs, hemlocks, and larch .

Although in no case had the deterioration of the paint coating gone far enough to make repainting desirable, the evidenc e

seemed sufficiently conclusive to warrant going ahead wit h

further studies of methods of painting these woods more

satisfactorily, especially since the findings are in accor d

with practic el experience with the different woods . Cypres s

was added to the list of woods to receive further study be cause it has been accused of giving difficulty in painting ,

although the 1924 cypress panels were in very good shape .

Table 1 lists the woods used in the new tests, th e

various painting methods adopted, and the distribution of th e

panels to the cooperating stations . One-half of the panels

(Part A), is painted in the same way as the 1924 panels, whil e

the other half (Part B) receives the special treatment unde r

study . In this way a direct comparison of the new metho d

against the old is obtained without danger of differences i n

the wood or the conditions under which the, paints were applie d

disturbing the results .

The special troatments in all case s

are confined to the amount of reduction of the priming coa t

paint with oil and thinner or to the use of special p riming

coats . The second and third coat paints are the same a s

those used in 1924 .

The purpose of the present report is to give in de tail the data concerning the preparation of the paints an d

panels, the application of the paints, and the key to th e

reference numbers on the panels for the 1925 tests .

THE LUMBER USED

Southern yellow pine - The lumber was purchase d

from a lumber yard in Madison .

R816

-2

,stern yellow pine ('s inus ponderosa) - The lumbe r

was taken from the stock contributed for the 1924 tests b y

the western Pine Manufacturers Association (from Ore gon

lumber) and the California White and Sugar Pine Associatio n

(from California lumber) . The California and Oregon pin e

were used indiscriminately because their behavior in the 192 4

tests has been identical, both the painted panels in the vertical and 45° positions (at Madison) and the unpainted panel s

(at Madison) .

Douglas fir (Pseudotsuga taxifolia)

- Most of thi s

lumber was taken from the stock contributed for the 192 4

tests by the West Coast Lumbermens Association . A few board s

were purchased from a Madison lumber yard to fill out th e

amount required .

Western larch (Larix occidentalis) - The Wester n

Pine Manufacturers association contributed this lumber, obtaining it from the J . Neils lumber Company of Libby, Montana .

The material for the 1924 tests came from the same producer .

Western hemlock (Tsuga heterophylla) - The lumbe r

was taken from the stock contributed by the West Coast Lumber men's Association for the 1924 tests .

Eastern hemlock (Tsuga canadensis) - The lumber

was purchased from a Madison lumber yard .

Cypress (Taxodium distichum) - The lumber was purchased from a Madison lumber yard .

M.WING THE P _U ELS

The panels were of the same dimensions and construction as for the 1924 tests with the exception that the "channel rustic" style has been replaced by plain boards with la p

joints because the plain surface has been found more practica l

for testing purposes for several reasons . it is easier an d

quicker to apply the paint to the plain surface and more confidence can be placed in the "spreading rates" determined o n

such panels . A paint coating of more nearly uniform thicknes s

can be applied to the plain surfaces . The channel in the ol d

style siding affords a convenient lodging place for dirt,

es-

pecially on the top boned where it is shaded by the overhanging "drip" . By eliminating a shaper operation, which necessitated taking the material from the shop in the New Soil s

' u.ilding to the shop in the Main Fuilding and bringing i t

Tnlck again, considerable time was saved in manufacturing th e

ninel s .

The lumber was all thoroughly dry before manufacture, of the panels was started. Accurate record of the moisture content of the wood was not kept because a study carrie d

out last year indicates strongly that the moisture held b y

the wood does not affect the painting materially until

a

region of very much higher moisture content than we were concerned it is attained .

"Drips" and "moldingswere made for use in separating the individual panels when attached to the fence in th e

same manner as for the 1924 studios .

The backs of all panels and the "drips" and "moldings" all received one coat of black paint . The paint was

applied by brush to the panels and "moldings", but by moan s

of the spray gun to the "drips" .

The end grain edges of th e

p anels received one heavy brush coat of aluminum powder i n

shellac to minimize absorption of moisture and end-checking .

PAINT MATERIAL S

The second and third coat paints, consisting o f

straight white lead and of 60-30-10 paint, were made up i n

accordance with the same formulas used for the 1924

tests .

The materials employed were as follows :

Raw linseedoil - This vias purchased loca2 .1y from

Mautz Brothers Co :_pany .

,knalysis shoved :

Specific gravity 15°/15°

Acid. number

Iodine number (Hanus)

Saponification nu: [7 er

0 .9334

6 .3 8

178 . 1

191 . 3

Boiled linseedoil was drawn from the laboratory

stores .

Turpentine - was obtained from the laborator y

stores .

Gum spirits were employed .

Liquid drier - Pratt and Lambert's liquid paint

drier was purchased from a local paint store .

Analysis gave :

Specific gravity 25°'15°

Lead (as Pb )

Manganese (as Mn .)

0 .8713

2 .82

0 .39 5

Cobalt and zinc

0 .00 0

Calcium (as Ca .)

0 .34 5

White lead paste,- 92 per cent "Dutch Boy", basi c

carbonate white lead ground in eight per cent raw linseed oi l

by the St . Louis Lead and Oil Company was purchased locally .

Red lead paste - 93 per cent "Dutch Boy" red lea d

ground in seven per cent raw linseed oil by the Nationa l

Lead Company was purchased locally.

Zinc oxide - XX "Black oxide" was donated by th e

New Jersey Zinc Company . The dry pigment was ground to a

paste with asbestine for use in making all paints excep t

priming coat No . 21 . For this a quantity of XX black zin c

oxide ground in 18 per cent raw linseed oil was contribute d

by the New Jersey Zinc Company .

Asbestine was drawn from the laboratory stores .

Aluminumpowder - "Standard varnish" polished alumi-

num powder made by the Aluminum Company of America, was used .

Zincdust was donated by the New Jersey Zinc Company .

PREPARATION OF THE PAINT S

Third coat white lead pain t

The formula used is as follows :

Paste white lead

Raw linseed oil

Turpentine

Liquid drier

R816

100 pound s

3 .5 gallons

1 pin t

1 pint

- 6

The oil, turpentine, and drier were mixed and then incorporated with the paste white lead, adding the liquid to th e

paste at first in small portions, and mixing thoroughly be fore adding succeeding portions .

The paint was finall y

strained .

The paint was found to weigh 19 ..5 pounds (8,86 5

grams) per gallon .

Second coat white lea d

The formula used is as follows :

Paste white lead

Raw linseed oil

Turpentine

t,iquid drier

100 pounds

1 .5 gallons

1 .5 gallon s

1 pin t

The paint was found to we ig ht 21 .0 pounds T9,530 grams) pe r

gallon .

Third coat 60-30-10 pain t

The formula used is as follows :

A paste was prepared having the composition :

Zinc oxide

Asbestine

Raw linseed oil

50% (by weight )

16-243%

33-1/3%

The paste was passed through a laboratory paint mill thre e

times and when tested by spreading on a glass plate with a

steel spatula showed a satisfactory "grind" with complete absence of agglomorates perceptible to the eye .

The paint was then made up as follows :

Paste white lead

41 .5' (by weight )

Paste zinc oxide - asbestine 38 .3%

Raw linseed oil

16 .3 =

Turpentine

1 .8%

Liquid drier

1 .8%

The two pastes were mixed in one container and the liquid ingredients in another . The liquids were then incorporate d

with the mixed pastes, adding them at first in small increments, then in lar g er portions . The paint was finally strained .

The resulting paint has the following composition :

Pigment

White lead

Zinc oxide

Asbestine

Vehicle

Raw linseed oil

Turpentine

Liquid drier

64%

36 %

60 %

30 %

10 %

(by weight )

90%

5%

The paint was found to weigh 16 .5 pounds (7,470 grams) pe r

gallon .

Second coat mixed paint

Two and one-half pints of turpentine were added t o

one gallon of third coat mixed paint . The resulting pain t

was found to weigh 12 .3 pounds (6,536 grams) per gallon .

Priming coat No . l

This paint having the same formula used for the 192 4

tests, was used on the left hand half of nearly all the whit e

lead panels to serve as "controls" .

The formula follows :

Paste white lead

Raw linseed oil

Turpentine

Drier

100 pounds

4 gallon s

2 gallon s

1 pin t

This paint was found to weigh 16 .5 pounds (7,50 0

grams) per gallon .

Priming coat No . 2

White lead paint containing less oil and more tur :ntine than No . 1 :

Paste white lead

Raw linseed oil

Turpentine

Liquid drier

100 pound s

2 gallons

4 gallons

1 pint

The weight per gallon was found to be 16 .3 pound s

(7,390 grams) .

Priming coat No . 3

White lead paint with oil and thinner proportion s

intermediate between Nos . 1 aad 2:

Paste white lead

Raw linseed oil

Turpentine

Liquid drier

100

3

3

I

pound s

gallon s

gallons

pint

The weight per gallon was found to be 16 .1 pounds

(7,295 grams) .

Priming coat No .4

White lead paint having benzol in place of turpentine as thinner :

Paste white lead.

Raw linseed oil

Benzol

Liquid drier

100

2

4

1

pound s

gallons

gallon s

pint

The weight per gallon was found to be 16 .0 pounds

(7,275 grams) .

Priming coat No .5

Red lead - white lead paint :

Paste red lead

Paste white lead.

Ra,:7 linseed oil

Turpentine

Liquid drier

40 pound s

60 pounds

1-3/4 gallons

1-3/4 gallons

1 pin t

The red lead and white lead pastes were mixe d

first and the mixture of liquids incorporated in successiv e

portions, the first portions being small . The paint was the n

strained .

The weight per gallon was found to be 21 .1 pounds

(9,570. grams) .

Priming coat No .6

Red lead -,

white

lead paint :

Paste red load

P 2.ste white lead.

Raw linseed oil

'fie'rpentine

Liquid drier

40

60

4

2

1

pound s

pound s

gallon s

gallon s

pint

The weight per gallon was found to be 16 .6 pounds

(7,550 grams) .

Primingcolt No .7

White lead paint containing zinc dust :

40 pounds of zinc dust were added to 100 pound s

of priming coat No . 1 just before application .

The weight per gallon was found to be 20 .7 pound s

(9,403 grams) .

Priming coat No .8

White lead paint containing aluminum powder :

Two p ounds of aluminum powder were added pe r

nine g allons of priming coat paint No . 1 jus t

before application (9 gallons of paint result from 100 pounds of piste white lead) .

The weight per gallon was practically identical wit h

that for priming coat No . 1 .

Priming coat No . 1 1

This priming coat 60-30-10 paint, having the san e

formula used for the 1924 tests, was prepared by addin g

1-1 /4 pint raw linseed oil and one quart of turpentine t o

one gallon of third coat 60-30-10 paint .

The weight per gallon was found to be 13 .8 pound s

(6,305 grams) .

It z■r :~,s used on the left-hand half of nearly al l

panels with the 60-30-10 paint to serve as "control" .

Primin g coat No . 1 2

60-30-10 paint containin g less oil and. more turpentine than No . 11 :

one g allon of third coat 60-30-10 paint wa s

added five -Pints of turpentine .

he weight per gallon was found to be 12 .5 pounds

696 grams) .

Priming coat No . 1 3

0-30-10 paint having a reduction intermediat e

between No .

and 12 :

To one gallon of third coat 60-30-10 pain t

was added three pints of turpentine .

e weight per gallon was found to be 13 .4 pounds

,123 grams) .

Primin g coat No . 14

60-30-10 paint containing benzol as thinner :

To one gal! lon of third coat 60-30-10 pain t

was added five pints of benzol .

he weight per gallon was found to bp 12 .5 pound s

grams) .

'Priming coat No . 1 5

ead 60-30-10 paint was prepared as follows :

Paste red lead

27 .7% (by weight )

,Paste white lead

14 .1 %

-Paste zinc. oxide - asbestine 38 .8 %

5 .0%

'Raw linseed oil

13 .4%

Turpentine

Liquid drier

1 .0%

he three pastes were mixed and then the mixe d

liquids were incorporated, adding them in increments, th e

first pore

4s

being small

he paint was then trained .

This g ate

a

paint of the following composition :

64 .6`

Piment

Red lead

White lead

Zinc oxide

Asbestine

Vehicle

35 .4 %

Linseed oil

Turpentine

Liquid drier

40%

20 %

30%

10 %

(by weight )

59 .3%

38 .0%

2 .7%

The weight per gallon was found to be 16 .4 pounds

(7,440 grams) .

Priming coat P'o . 1 7

60-30-10 paint containing zinc dust :

To 100 pounds of priming coat paint No . 11 was

added 50 pounds of zinc dust just befor e

application .

The weight per gallon was found to be 18 .5 pound s

(8,375 grams) .

Primin g coat No . 1 8

60-30-10 paint containing aluminum powder :

To one gallon of priming coat paint No . 11 wa s

added 0 .3 pound aluminum powder .

The weight per gallon was taken as practically the

same as priming coat No . 11 .

Priming coat No . 20

Special aluminum primer :

Aluminum powder

Boiled linseed oil /

Turpentine

25 pounds

6 .5 gallon s

3.8 gallon s

This paint was prepared just before application .

The weight per gallon was found to be 8 .9 pounds (4,050 grams) .

This formula was taken from H . A . Gardner T s Circular 231 of the Scientific Section of the Paint Manufacturer s

Association of the United States, page 235, Paint No . 5, except that no liquid drier was added . For most purposes th e

added drier is needed to make the paint dry sufficientl y

rapidly .

It is believed that the proportion of aluminum pow-

der can be cut down to advantage also .

Priming coat No . 2 1

Special zinc dust - zinc oxide primer :

Paste zinc oxide (181 oil)

Raw linseed oil

Turpentine

Liquid drier

Zinc dust

100 pound s

15-3/4 gallons

4 gallons

1 gallo n

328 pounds

The mixed liquids were added in successive smal l

increments to the paste zinc oxide and the paint strained an d

stored for use . Just before application the zinc dust wa s

stirred in .

The* weight per gallon was found to be 20 .1 pounds

(9,119 grams) .

Paintfor end coating

The end-grain edges of

all

panels were painted wit h

one heavy coat of' a fast drying paint made by adding aluminum powder to 4-1/2-pound. cut white shellac .

The proportio n

of aluminum powder to shellac was not determined quantitatively .

R816

- 14 -

Black paint

Lampblack ground in oil

Raw linseed oil

Spar varnish

Japan drier

P and V M Naphtha

57 .1' (by weight )

17 .1 0

11 .4%

5 .7 %

8 .6%

The lampblack in oil was made by the Enterpris e

Paint Company and purchased locally through Mautz Brothers .

The proportion of pigment to oil is not stated . The spar

varnish used was Pittsburgh Plate Glass Company's "Waterspar "

all-purpose varnish . Brown Japan drier was made by th e

Pittsburgh Plate Glass Company .

The addition of the spar varnish makes a blac k

paint which dries over night and seems to be very satisfactory .

APPLICATION OF THE PAINT S

For several reasons the painting was all done a t

Madison before shipping the panels to the cooperators . I n

the first place some paint experts feel that it is more desirable to have all of the painting done by the same painter s

than to have the coatings dry at the same geographical locations at which the exposures are made . The experience wit h

the 1924 tests has led us to the conclusion that more uniform

paint coatings are applied by the technically trained men en gaged in paint testing than by many journeymen painters . I t

should be remembered also that when the painting is done i n

the field, let us say at Palmerton, Pa ., the coatings do no t

dry under weather conditions especially characteristic o f

Palmerton, but under a set of conditions that happen to prevail at the time and usually might just as well be encountere d

R816

- 15 -

at Sayville, Washington, or Madison . Of the locations wher e

tests are being conducted the only stations at which unusua l

conditions are likely to be encountered are Grand Junction ,

Tucson, and Fresno . In arranging the 1924 tests the most difficult point with most of the cooperators proved to be pro 7

ioing for the painting of the panels in the field .

In view

of the fore-going considerations, we felt justified in doing

the painting at Madison .

It may be mentioned also that a

series of panels painted with both types of paint was prepare d

in 1924 and exposed on the Madison fence in which the dryin g

took place, (1) on the test fence, (2)

in a room at 30 pe r

cent relative humidity, (3) in a room at GO per cent relativ e

humidity and (4) in a room at 90 per cent relative humidity .

No difference in the behavior of the paint coatings has bee n

observed as yet .

Each test panel was divided in half by a vertical

line, the left-hand half being designated by "A" and th e

right-hand half by "B" . The parts "A", in nearly every cas e

received priming coat No . 1,

paint) .

(white lead), or No . 11 , (60-30-1 0

These paints have the sane formulas used in the 1924

tests so that half of each panel serves as a "control" agains t

which the behavior of the new priming coat paint can be directly compared . This avoids in large measure any influenc e

of variations in the nature of the wood on the results of the

tests .

R816

Any important influence of the conditions under whic h

- I-6

the drying took place would also be shown by a comparison o f

the "A" parts with corresponding panels in the 1924 tests ,

allowance being made for the year's difference in age of th e

coatings .

The various priming coat paints included in th e

study were applied to the "B" halves of the panels as will be

indicated below .

The second and third coat paints were applied t o

the whole areas of the panels .

The divisions between parts "A" and "B" were marke d

off by lines of black paint applied after the third coat paint

had dried . The reference number of each panel was also painted in black in the upper left hand corner . (The number i s

also stamped in the two end-grain edges of each panel, )

The spreading rates of all coatings wore determine d

by weighing the paint, container, and brush before and afte r

application of the paint, the area of the panels and th e

weights per gallon of the different paints being known .

The priming coat paints were applied out of door s

and the panels placed in a horizontal position, face up, o n

a framework to dry . They were exposed directly to the sun .

The painting began on September 22 and the priming coats wer e

all applied by September 25 . On September 26, rainy weathe r

set in making it necessary to bring all of the panels indoor s

for several days . The ..panels were distributed about the Ne w

Soils Laboratory so that the surfaces were all freely expose d

to the air .

R816

- 17 -

On September 30, the panels were again placed ou t

of doors and exposed to the sunlight . Application of th e

second coat was begun on October 1, out of doors . October 2 ,

proving unsuitable for working outside, the panels wore move d

inside and the second coat applied to the remainder in th e

finishing laboratory, kee p ing the windows wide open so tha t

temperature, humidity, and air circulation wore practicall y

the same as outside . The panels were all taken outside onc e

more and placed face up to the sun for two days .

The third coat paints were all applied indoors o n

October 6 and 7 and the panels distributed about the laboratory to dry .

Finally the panels were inspected for hiding of th e

surface, gloss, spotting, brush marks, and color . A blac k

line was drawn separatin g the "A" and "B" halves of eac h

panel and the reference number painted in the upper left hand corner . The panels were then packed for shipment b y

freight to the cooperators, care being taken to protect th e

painted faces against marring during shipment . Shipment wa s

made on October 16 .

The panels for the Madis on fence were placed i n

position on October 21 . Figure 1 shows the section of th e

fence (to the right of the arrow) while Figure 2 gives a

closer view of some of the panels .

R816

- 18 -

RECORDING THl D IT 1

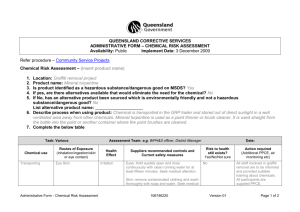

Data on the painting of the panels were recorde d

on the form, a sample of which is given on the next pa ge .

Duplicate records were kept of all panels except those fo r

the Madison fence, one copy to be kept at this laboratory an d

the other to be sent to the cooperator . In the cases of th e

panels for Grand Junction, Tucson, Fresno, and Seattle ,

records were made in triplicate, the third copy to be sen t

to the office of the Forest Service District in which the co operating station is located .

PANEL REFERENCE NITT,TBER S

The Madison fence contains duplicates of all panel s

sent to the different stations . These panels are numbere d

from 201 to 272 . The sane reference number had been used o n

each panel of the same wood with the same type of paint, th e

?p anels for the various testing stations being distinguishe d

letter prefixes .

Thus, there are six panels of souther n

yellow pine painted with priming coat No . 1 on the left han d

or "A" half and priming coat No . 2 on the right hand or "B "

half .

These are numbered respectively M 201, ! 201, S 201 ,

P 201, W 201 and G 201, and each is for a . different exposur e

station .

All panels for a given station are designated by

the same letter as follows :

F Fargo, N . D ., Panels 213 to 224 and 265 to 27 2

C Fresno, Calif ., Panels 213 to 224 and 265 to 27 2

G Gainesville, Fla . , Panels 201 to 212 and 225 to 23 6

GJ Grand Junction, Colo ., Panels 213 to 224 and 249 to 25 6

R816

- 19 -

4

"I

roject.

25

-'ATA SHEET FOR

3 . Kin

5. P r

AT TEST S

2 . Panel No .

4 . Kind of Pain t

ood

6.

Priming Coat, Part B___=

78.

Grain of Wood

_ .

Knots and Defects -,

- --

----------------- Priming Coa t

2nd . Coat

3rd .

Coat

Part A Part B

9.

10.

11.

12.

13.

Date applied .

Hour of day

Temperatur e

Humidit y

Weathe r

14.

Weight of paint, can, an d

brush before application, g .

15. Same after application,

16 . Weight of paint applied

___ _

__ _

17. Weight of paint, g . per gal .

18. Area painted, eq . ft .

19. Spreading rate, sq . ft . per gal .

Appearance when dry :

20. Hiding of surfac e

21. Gloss

22.

23.

Spotting

Brush marks

Remarks :

------------ -

------------- -

------------ -

M Madison, Wis ., Panels 201 to 27 2

Milwaukee, Wis ., Panels 201 to 212 and 225 to 23 6

P Palmerton, '?a . , Panels 201 to 212 and 225 to 23 6

S Sayville, L . I ., N . Y . , Panels 201 to 212 and 237 to 24 8

SL Seattle, Wash ., ? .eels 213 to 224 and 237 to 24 8

T Tucson, Ariz ., Panels 213 to 224 and 237 to 24 8

W Washington, D . C ., Panels 201 to 212 and 257 to 26 4

Tom"

The complete reference number of each panel i s

stamped in each end-grain edge . On the faces of the panels ,

however, the letter prefixes were omitted since they are unnecessary after shipment from MIadison has been made . Th e

letters "A" and "B" were painted on the faces to distinguis h

the "controls" from the new tests .

At the test stations other than Madison, the numSer series is not continuous with the 1924 panels, and ther e

is also a gap in the series of 1925 panels . It simplifie s

reporti n g", however, to use this arrangement whereby the cor responding panels at all stations bear the same number .

Table 1 gives a summary of the priming coats use d

on the different panels and the distribution of the panel s

among the coo2erating stations .

1'LACING PANELS ON ''ELI CE S

The panels will be attached to the fences by th e

cooperators in the same manner followed in 1924 . Zinc-coate d

nails wore sent with each shipment to serve as fastenings .

The panels on the Madison fence have been place d

in numerical order, No .

201 being at the top of the vertical `

umn to which th :; ; arrow points in Fig .

Beneath t in

Reference

Humber

(letter urefix omitted)

201

202

20 3

20 4

205

20 6

20 7

20 8

20 9

210

21 1

212.

:

Speoiee of Wood

:Southern Yellow Pine

. 17n

re of and

and

: 3rd Coat Paint

:

White Lead

"

60-30-10

•

•

We . :

: 1

: 1

: 1

1

:11

:11

:11

:11

:11

:11

-

221miCoat Paint Applied to

p art A

Part 8

`Description

'- seer lio n

:Same as 1924 panels : 2

: 6

8

"

"

:

:20

:

"

:21

" "2

"2

•

7

"

"

"

:12'

.

"

•

:21

"

"

:

"

:18

•

"

:P.O

:

:

•

"

:16

:

"

:17

White Lead

1 :Same as 1924 panels

1

^

1 : " "

"

"

1

"

1

"

•

1

11

:11

•

:11

:11

:11 : " "

"

:11

"

White Lea d

1

1

P.

1

1

8

:11

:11

:12

:11

:11

:18

60-30-10

White Lead

"

: 2

5

: 8

:20

:21

: 7

:12

:2].

:18

:20

:16

:17

:Same as 1924 panels : 2

:

"

6

:More turpentine

: 4

:Same as 1924 panels :20

:

"

:21

:Aluminum-white lead : 7

:Seme as 1924 panels :12

: "

7

7

"

:2.1

:More turpentine

:14

:Same as 1924 panels :20

: " "

"

:15

:Aluminum-60-30-10

:17

1 :Same as 1924 panels : 2

"

1 :

: 5

8

"

1

:20

:21

7

:11 .

"

"

:12

:1].

" "

:21

:11

:18

:11 .

•

:20

:1 1

:15

:17

:1 1

1 : " "

,Vhite Lead

60-30-10

7hite Lead

60-30-10

•

White Lead

60-30-10

`

ffipoaure

Station s

:More turpentine

:Red lead-white lead

.

:Aluminum-white lead

:Special aluminum primer :

:Zino dust-sine oxide

.

;Zino dust-white lead

.

:More turpentine

:Zinc duet-sine oxide

:Aluminum-60-30-1 0

:Special aluminum primer :

:Red lead-60-30-10

:Zino dust-60-30-10

(Madison

(Milwauke e

(Sayville

(Palmerton '

(Washingto n

(Gainesvill e

More turpentin e

:Red lead-white lead

.

:Aluminum-white lead

:Special aluminum primer : (Madiso n

:Zinc dust-zinc oxide

(Fargo

(Seattl e

:Zinc dust-white lead

:More turpentine

(Fresno

:Zino dust-zinc oxide

(Tucso n

(Grand Junctio n

:Aluminum-60-30-10

:Special aluminum primer :

:Red lewd-60-30-10 '

:Zino dust-60-30-1 0

:More turpentin e

:Red lead-white lead

:Benzol thinne r

:Special aluminum primer

:Zino dust-zinc oxide

:Zino dust-white lead

:More turpentine

:Zinc duet-zinc oxide

:Benzol thinner

:Special aluminum primer

Red lead-60-30-1 0

:Zinc duet-60-30-1 0

.

:

.

.

.

(Madison

(Palmerton

(Gainesvill e

(Milwaukee

:

:More turpentine

(Madison

:Red lead-white lead

(Sayville

:Aluminum-white lead

(Seattl e

:Special aluminum primer : (Tucson

:Zinc dust-zinc oxide

:(On the Tucson

Zino dust-white lead

: fence panel s

:More turpentine

: 242,246 .247

: and 248 are

:Zinc duet-zinc oxide

: Western Larch

:Aluminum-60-30-10

:Special aluminum primer : instead of

:Red lead-60-30-10

: Douglas Fir . )

:Zino duet-60-30-1 0

1

1

1

1

:11

:11

:11

:11

:Same as 1924 panels : 2 :More turpentine

.

: 5 :Red lead-white lead

"

"

:

: 8 :Aluminum-white lead

: " "

:20 :Special aluminum primer

:12 :More turpentine

:21 Zino dust-zinc oxide

:

' "

: " "

:18 :Aluminum-60-30-1 0

" "

:20 :Special aluminum primer

: 1

1

1

1

:11

:11

:11

11

:Same as 1924 panels : 3 :More turpentine

:

2

7

2

: 6 :Red lead-white lead

.

: " "

"

"

: 8 :Aluminum-white lea d

:

:20 :Special aluminum primer : (Madiso n

:13 :More turpentine

(Washington

:

:21 :line dust-zinc oxid e

:

:18 :Aluminum-A0-30-1 0

:

•

"

:20 :Special aluminum primer :

1

1

1

:11

:11

:11

:11

:Same as 1924 panels : 3

:

7

2

"

:

6

:

"

"

: 8

:20

:

"

:13

:E1

: " "

..

:

"

:18

:

7

"

:20

:More turpentine

:Red lead-white lead

:Aluminum-white lead

:Special aluminum primer

:More turpentine

Zinc dust-zinc oxide

:Aluminum-60-30-1 0

:Special aluminum primer

.

.

: (Madison

(Grand Junctio n

.

:

.

(Madiso n

: (Farg o

(Fresno

:

:

order are 202, 203, and 204 . It the top of the next column i s

No . 205, etc . It is su gg ested that the same order be employe d

by the cooperators as far as possible, although this is, o f

course, a matter

of

minor im portance . *

INSPECTIONS AND REPORT S

The panels will be inspected by a member of th e

staff of this laboratory at least once a year . It will b e

highly desirable for the cooperators to make inspections a t

shorter intervals and furnish this laboratory with a copy o f

the results .

Progress reports will be prepared and distribute d

to the cooperators as the data obtained justify them .

* On the Tucson fence the 1924 panels were placed facing eas t

instead of south . The 1925 panels should be placed facin g

south .

![[Agency] recognizes the hazards of lead](http://s3.studylib.net/store/data/007301017_1-adfa0391c2b089b3fd379ee34c4ce940-300x300.png)