THE EFFECT OF ULTRAVIOLET LIGHT A THESIS

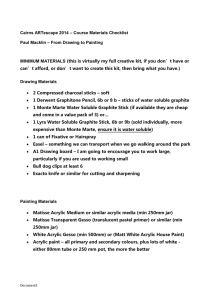

advertisement