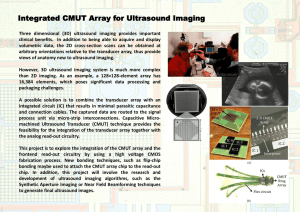

A Column-Row-Parallel ASIC Architecture for 3D Kailiang Chen

advertisement