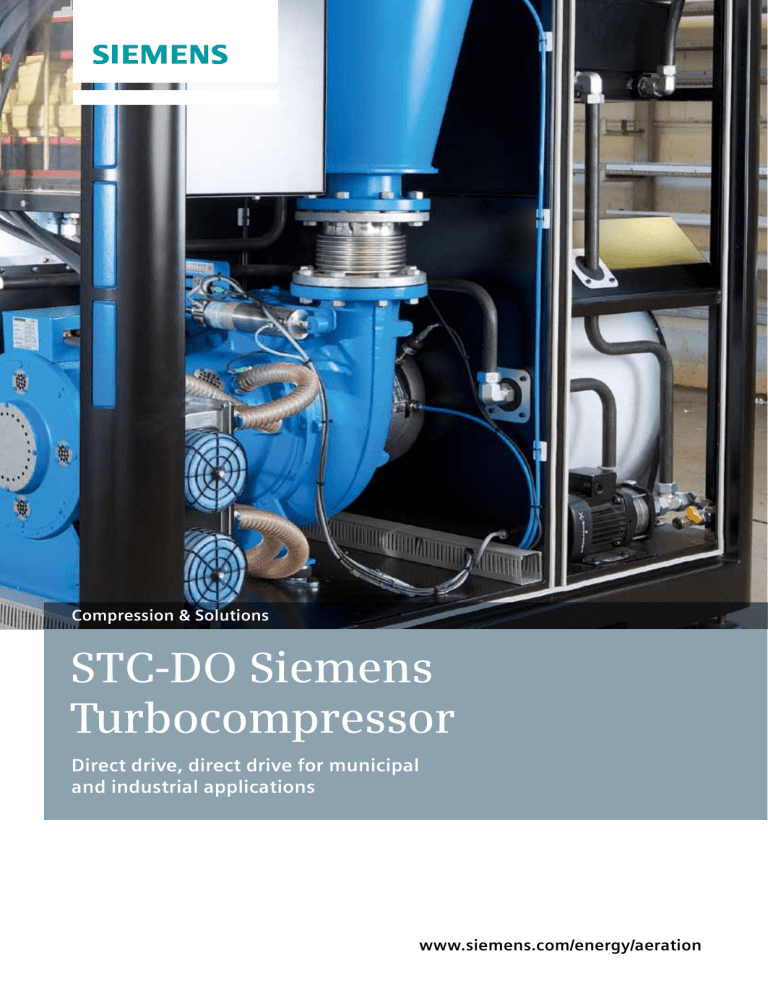

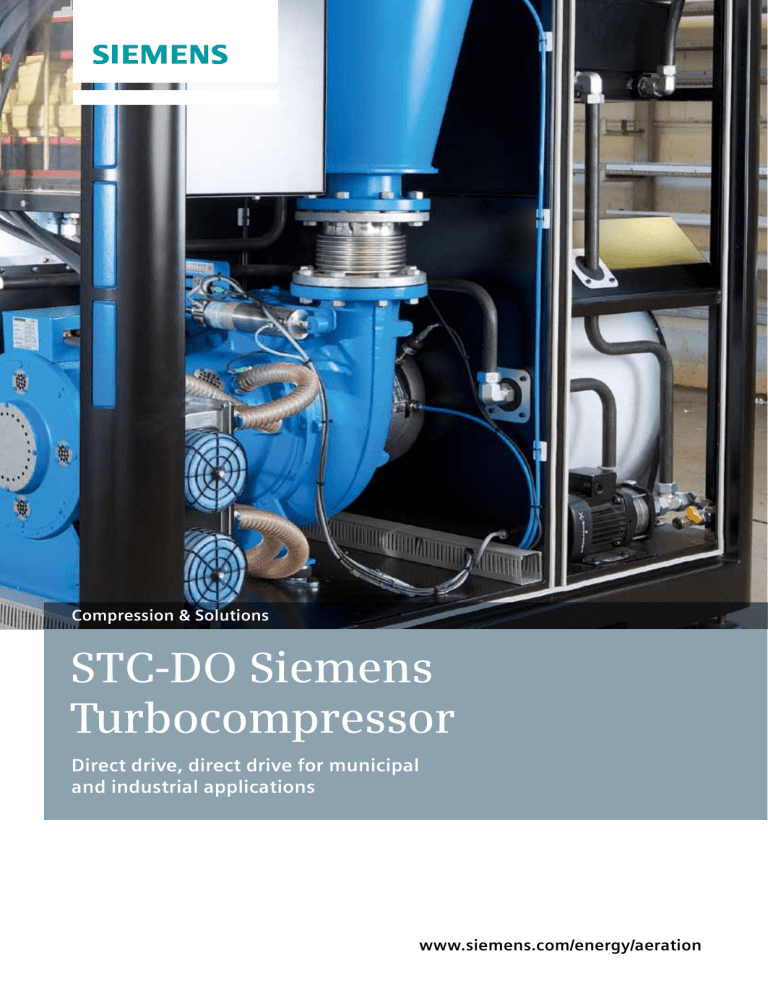

Compression & Solutions

STC-DO Siemens

Turbocompressor

Direct drive, direct drive for municipal

and industrial applications

www.siemens.com/energy/aeration

2

Highest efficiency at

High Speed

The Siemens STC-DO unit is the highest efficiency direct

driven centrifugal compressor available today that utilizes

a high-speed motor with the impeller mounted directly on

the motor shaft.

Highlights

Dual PointTM control

Our highly experienced aerodynamicists combined our

unique Dual PointTM control technology with an optimized air path and impeller design using the latest

design software. This allows the highest efficiency

throughout the widest turndown range in the industry.

Siemens single stage direct drive unit (STC-DO) is a stateof-the-art design, specifically tailored to the unique environmental and process needs of the aeration market.

Turndown range down to 35%

Fields of application

Wastewater treatment of:

» Municipal sewage

» Industrial sewage

Low noise level with no pressure pulsation

High-quality components are integrated into a standardized, easily accessible enclosure for reduced

footprint

The only real plug and play machine with fully

enclosed components, easy to install and operate

100% oil free

Low maintenance cost

Electrical filters as standard

Fermentation

» Yeast production

» Enzyme production

» Similar biological processes

Flow and pressure range

1,000 to 13,000 m³/h

Differential pressure up to 1.1 bar

Single stage direct drive centrifugal core compressor with Synchronous permanent magnet motor and airfoil bearings (STC-DO)

3

Single point speed control design

Head (%)

120

100

80

Speed 1

Speed 2

Turndown

Speed x

40

60

100

Performance curve

Design point

More efficient

Surge lines

Operational line

Less efficient

Capacity (%)

With Single point speed control, the design point has to be chosen at a considerably higher pressure level which would not be required under normal operating conditions. The design is a trade

off between turndown capability and efficiency.

Dual PointTM speed control

Head (%)

120

100

80

Diffusor

Position 1

Diffusor

Position x

Diffusor

Position 2

Turndown

40

60

100

Performance curve

Design point

More efficient

Surge lines

Operational line

Less efficient

Capacity (%)

With a Dual PointTM speed control the design point can be aligned with required operational conditions,

allowing the blower to work in its highest isentropic efficiency area with the widest regulation range

(up to 35%).

4

Efficiency by control

Dual PointTM control

The unique Dual PointTM control process allows to independently regulate the flow and head of the compressor,

giving superior efficiency at design and especially off

design conditions. The control management system operates automa­tically and simultaneously the position of the

variable diffuser vanes as well as the Variable Frequency

Drive (VFD).

The compressor flow function is managed through the

­diffuser vanes, or discharge control vanes, which increase

or decrease the airflow path exiting the impeller wheel,

allowing a step-less turndown range from 100 % to 40 %

or less with almost no efficiency loss. The compressor

head function is controlled by changing the impeller rotational speed through the Variable Frequency Drive (VFD).

The control methodology maintains the isentropic efficiency at its maximum relative value across a wider range

of flow, water depth, and temperature conditions.

Variable Diffuser System

The variable diffuser system controls the flow by adjusting

the angle of the diffuser vanes, which are positioned radially around the impeller.

The vanes are flow-optimized non-symmetrical airfoils,

allowing adjustment of the nozzle area, while still maintaining an excellent efficiency throughout the entire operational range of the compressor.

Variable Frequency Driver (VFD)

The VFD is designed to deliver the required power with

the minimum vibration and electrical noise. The VFD controls impeller speed to obtain highest efficiency even

when the compressor is working under off-design conditions (low temperature and/or pressure).

The VFD System

Siemens offers true plug and play including all required

electrical filters as standard.

The VFD package includes:

VFD drive

Input choke, reduces the input effective current

EMC filter, reduces the interference caused by

­variable speed drives

Sinus filter, reduces the effect of eddy-current

losses in PM rotors

This system enables a longer lifetime, higher efficiency

and reliability.

5

Efficiency by design

An Integrated Solution

Impeller

The core of the compressor is the impel-ler, which is

machined from a solid forged piece of high-grade aluminum alloy and is statically and dynamically balanced.

Integrated Package

All components are integrated into a standardized, easily accessible enclosure, resulting in a reduced footprint

solution and true plug and play. The enclosure includes

the inlet filter, inlet silencer, compressor/motor unit,

­variable frequency drive (VFD), discharge cone/silencer,

blow-off valve, cooling system, instrumentation and

local control panel (LCP).

Siemens provides different impeller sizes for the STC-DO

model for customization to client requirements in terms

of flow and ambiant conditions.

Permanent Magnet Synchronous Motor (PMSM)

The electrical motor is a synchronous (permanent magnet) type, with permanent magnet and carbonfiber

sleeves mounted on the steel shaft. The motor is specially designed for high speed operation (speed range

from 13,000 rpm to 41,000 rpm). All components are

rated for continuous duty at the specified conditions.

Advantages of the PMSM

Can operate at high speed and frequency, maintaining high efficiency

Low heat generation

Higher overall efficiency compared to an induction

motor.

Compliant Airfoil Bearings

The application of airfoil bearings results in improved

efficiency, thanks to reduced friction, and exceptionally

long life with minimal maintenance since no lubricating oil is required.

6

Easy to install

The enclosure can be fork-lifted and set in place. No

anchoring, or preparation required, simply connect

power and discharge piping, then push the start

button.

Easy to operate

A state-of-the-art, easy intuitive operation control

panel lifts the interfacing to the next level.

Quiet

The sound attenuation is based on years of engineering

knowledge and extensive testing, resulting in a state of

the art acoustic package.

Clean Running

The air is sucked through the air filter to the compressor inlet of which a small part is directed to the enclosure for cooling purpose, whereby the process air and

internals of the enclosure are kept clean and dust free.

Low Maintenance

Airfoil bearing technology eliminates the need for an

oil lubrication system. The air filters are likewise easy to

change. A liquid cooling system for the main crucial

components (motor, VFD) extending their lifespan and

reduce risk of failures.

Complete envelope

Design conditions: 1,013 bar, 80% RH, 20 degree Celsius

1.2

20 30 40 50 60 70

KW KW KW KW KW KW

90

KW

110

KW

130

KW

160

KW

200

KW

max 110

1.1

max 220

STC-DO (5SF-A)

STC-DO (2SF-A)

1.0

STC-DO (1SF-A)

Delta pressure [bar]

0.9

0.8

5-1

5-2

5-3

5-4

5-5

0.7

2-1

2-2

2-3

2-4

0.6

1-1 1-2 1-5

0.5

0.4

0.3

0.2

500

2000

3500

5000

6500

8000

9500

11000

Flow [m /hr]

Flow is defined based on above maximum design conditions

3

Range of application:

STC-DO (1SF-A)

(up to 75 kW motor power)

STC-DO (2SF-A)

(up to 110 kW motor power)

STC-DO (5SF-A)

(up to 200 kW motor power)

Siemens’ comprehensive portfolio provides a full range of applications for Wastewater Treatment

and Fermentation with 3 models and 12 customized impeller types of the compressor STC-DO

­corresponding to customer needs in term of air demand.

Testing

Decades of long experience testing thousands of centrifugal compressors have resulted in extensive know-how.

Combined with an advanced test rig this ensures the highest quality control for our Turbomachinery equipment.

Before leaving the factory each compressor is mechanically and functionally tested in our advanced test rig in

accordance with our Standard Shop Test Specification. The

testrigs are certified every year according to ISO 9001 and

the calibration procedures are conducted at regular intervals in accordance with ASME, ISO and API international

standards. All testing is performed in order to measure

operating data for evaluation of conformity with specified

data. The following will be fulfilled during the rigorous

testing:

Provide sufficient test data over the specified operational range for the quality approval procedure and

­certification before delivery

Provide vibration testing data, which is measured

with an accelerometer, with sampling band width of

10–1,000 Hz and 1,000–10,000 Hz in accordance

with ISO 10816

Ensure accurate, safe, and fast registration of all relevant test data in the shortest possible testing time

and at the lowest possible cost

7

Nulput la consed duisit iustin et loborese

modolob orperostrud et ex esequam est

quam dolorper sed exer sed tat acietsopit

utpatinis alit ipsustrud dolore dolobor sit

eraessequis aut veniat ip et, quissim ip et

iniscincinis alisl dunt vel utat lorer sequi

bla consequam, summod tetu dignismod

tincil ing ex ea acipsustrud molore feum

zzriurer summy nim dolor aut lobore.

Magnis del utpat. Duisis aliquam etumoll

estrud dolorpe ratuerci blamet, su duis it

cipis nit lum veniamet ad delis nonsequi

diam iriure del illum inibh enit ullaore est

irillaorper il utem inim et ipsuscilisi blatag

met veniatum adit irit utpat ero etue et ip

doloreet wis esto er sisl irit alit dino enim

duisi essecte con henis do con vel exe ros

si et ing elendre magnisi.

Published by and copyright © 2012:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens AG

Energy Sector

Oil & Gas Division

Wolfgang-Reuter-Platz

47053 Duisburg, Germany

Siemens Energy Inc.

10730 Telge Road

Houston, Texas 77095, USA

Siemens A/S Turbomachinery Solutions

Allegade 4

3000 Helsingoer, Denmark

For more information, please contact

Phone: +45 49 21 14 00

Fax:

+45 49 21 52 25

E-mail: aeration.energy@siemens.com

Oil & Gas Division

Order No. E50001-G420-A121-V1-4A00

Printed in Germany

Dispo 34806, c4bs 7489 P WS 0312

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document are the property of Siemens

AG, its affiliates, or their respective

owners.

Subject to change without prior

notice. The information in this document contains general descriptions

of the technical options available,

which may not apply in all cases.

The required technical options

should therefore be specified in

the contract.