High availability for the Sandreuth

biomass heat and power plant, thanks to

state-of-the-art Siemens solutions

Reference – Siemens Power & Process Automation (SPPA)

Instrumentation, Controls & Electrical

SPPA-E3000 Electrical Solutions

SPPA-T3000 Control System

are employed in the new biomass heat and

power plant in Sandreuth, with the aim of

attaining optimum availability.

The Result

■ High availability thanks to

reliable, cutting-edge

instrumentation, controls

and electrical engineering

supplied from a single

source

■ Operation of the biomass

heating power plant via

on-site workstations and

in parallel with the control

room of the existing power

plant

■ Significant savings in

auxiliary power

consumption achieved

by use of frequency

converters on drives

The Plant

Fall 2011 saw the commissioning of a new

biomass heating power plant at the power plant

facility in Nuremberg-Sandreuth, already the

site of a modern combined-cycle power plant.

This new plant, belonging to N-ERGIE Aktiengesellschaft, achieves a thermal output of

14 MW and an electrical output of 6 MW

through the combustion of natural residual

forest wood. This means that 10,000 households

can be supplied with electricity and 7,000

households with district heating. An overall

efficiency of more than 85 % is attained through

the use of combined heat and power.

The Task

For N-ERGIE, the construction of the biomass

heating power plant marked a further milestone

in its development into a green energy supplier.

The objectives of the project included the generation of 35 million kWh of green electricity per

annum and the integration of the plant into the

existing infrastructure of the power plant complex.

To meet these requirements, the new plant

needed a state-of-the-art instrumentation,

controls and electrical engineering solution.

Our Solution

Siemens supplied the complete electrical and

I&C package for the biomass plant in Sandreuth.

It was possible to realize the complete electrical

scope for the new-build power plant with the

portfolio of SPPA-E3000. The auxiliary supply

transformer employed ensures reliable distribution

for the plant’s own electrical requirements and

significant additional savings can be realized

through the use of frequency converters.

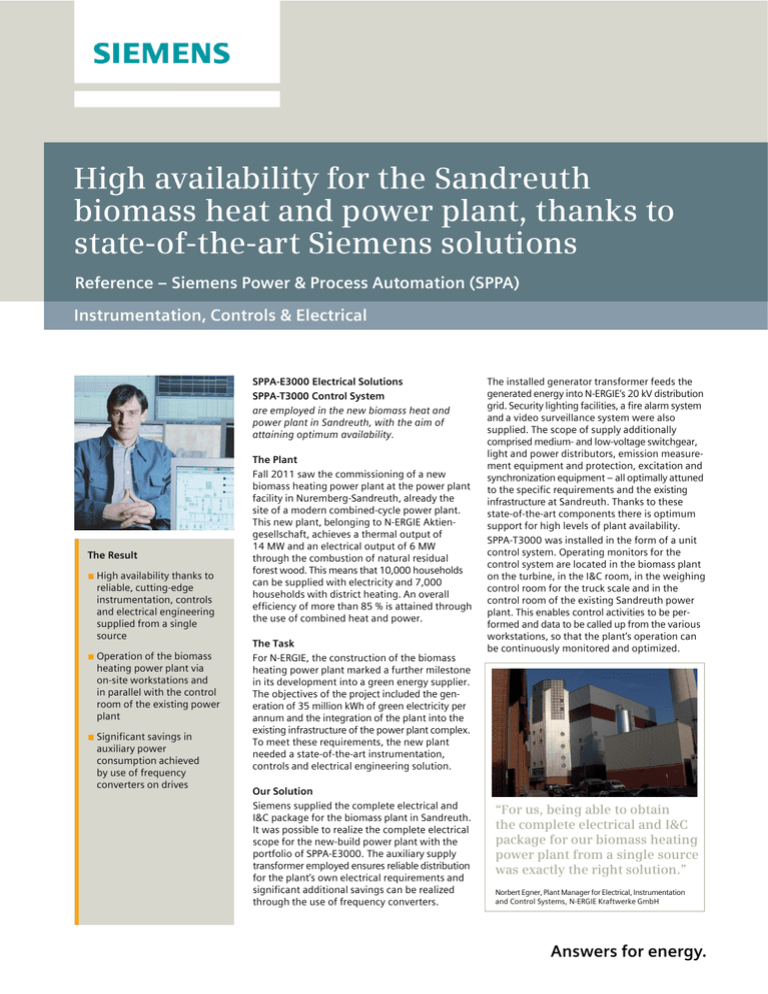

The installed generator transformer feeds the

generated energy into N-ERGIE‘s 20 kV distribution

grid. Security lighting facilities, a fire alarm system

and a video surveillance system were also

supplied. The scope of supply additionally

comprised medium- and low-voltage switchgear,

light and power distributors, emission measurement equipment and protection, excitation and

synchronization equipment – all optimally attuned

to the specific requirements and the existing

infrastructure at Sandreuth. Thanks to these

state-of-the-art components there is optimum

support for high levels of plant availability.

SPPA-T3000 was installed in the form of a unit

control system. Operating monitors for the

control system are located in the biomass plant

on the turbine, in the I&C room, in the weighing

control room for the truck scale and in the

control room of the existing Sandreuth power

plant. This enables control activities to be performed and data to be called up from the various

workstations, so that the plant‘s operation can

be continuously monitored and optimized.

“For us, being able to obtain

the complete electrical and I&C

package for our biomass heating

power plant from a single source

was exactly the right solution.”

Norbert Egner, Plant Manager for Electrical, Instrumentation

and Control Systems, N-ERGIE Kraftwerke GmbH

Answers for energy.

Published by and copyright © 2013:

Siemens AG, Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information contact

sppa-e3000.energy@siemens.com

www.siemens.com/energy/sppa-e3000

Siemens Energy, Inc.

Instrumentation, Controls, & Electrical

1345 Ridgeland Parkway, Suite 116

Alpharetta, GA 30004, USA

SPPA_FR_Sandreuth-E3-T3_e_V1-0

order-no. E50001-G230-A355-X-4A00

Printed in Germany

Dispo 05401, c4bs-Nr. 7465

Printed on elementary chlorine-free

bleached paper.

Unrestricted

AL:N ECCN:N

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.