Proper Selection of Compressor Trains

advertisement

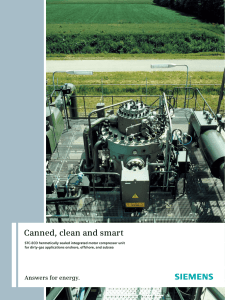

Proper Selection of Compressor Trains Choose the most appropriate compressor train from your high-pressure, oil & gas application from one of the most extensive portfolios in the industry © Siemens AG 2015. All rights reserved. Revenue History of innovation and technology leadership Helping your business grow for over 160 years Outstanding innovation and growth since 1840 With a growing number of world leading technology innovations Siemens and Dresser-Rand always have focused on what is really important: MOS separable compressor Your specific needs for the Oil and Gas market New 38.2MW industrial gas turbine Isothermal turbocompressor with integrated coolers 1st high efficiency model (HGM 500) 1st seal-less turbocompressor with integrated motor 1st biogas engine Foundation of Guascor; first diesel engine 1st integrally geared turbocompressor 10MW standard steam turbine genset 1st gas engine TUPI III world’s highest density CO2 compressor - DATUM 1st turbocompressor New 12MW pre-designed steam turbine; 1st LNG compressor built in China 1st DATUM I ICS 1929 1st stand by, prima stoichiometric engines and mechanical drive engines 1st DATUM 1st Ingersoll-Rand HHE process reciprocating compressor installed 1920s 1st TRENT aero-derivative gas turbine mechanical drive 1948 1966 © Siemens AG 2015. All rights reserved. 1988 1992 2000 2012 LNGomodularized, portable natural gas liquefaction plant 2014 Sales, in logarithmic scale Compact systems Multiple options fit to client/project requirements Conventional compressor STC-ECO (Hermetically sealed, canned, vertical rotor) Canned HS Motor stator Canned AMBs Driver can also be a GT Direct-drive compressor Common Motor/Compressor Rotor DATUM ICS (Hermetically sealed, flexible coupling, int. separator) DATUM C (Hermetically sealed, flexible coupling) © Siemens AG 2015. All rights reserved. Compact Systems Direct-Drive Compressor © Siemens AG 2015. All rights reserved. Compact systems Multiple options fit to client/project requirements Conventional compressor STC-ECO (Hermetically sealed, canned, vertical rotor) Canned HS Motor stator Canned AMBs Driver can also be a GT Direct-Drive compressor Common Motor/Compressor Rotor DATUM ICS (Hermetically sealed, flexible coupling, int. separator) DATUM C (Hermetically sealed, flexible coupling) © Siemens AG 2015. All rights reserved. Compact systems Hermetically sealed compressors © Siemens AG 2015. All rights reserved. One-stop-shop – our customers can choose from different technologies in the full output range • • • • • • Industrial gas turbines Aero derivative gas turbines Steam turbines Electric drives High-speed engines Up to 60 MW Up to 66 MW Up to 250 MW Up to 100 MW Up to 2 MW Efficiency Reliability Flexibility Environmental compatibility Low life cycle costs and ROI1) Access to heavy duty gas turbines >100 MW • • • © Siemens AG 2015. All rights reserved. Most reliable and easily maintained Benchmark for fuel economy and cost savings Highest efficiency and fast-start capabilities • • • • • Highest efficiency Excellent flexibility for complex processes Economical installation and operation Modular design Customized steam path • • • • Compact Low weight High efficient asynchronous/ synchronous and variable speed drives Fit for purpose auxiliaries • • • • High-efficiency, low-emission gas and diesel engines Long service intervals Easy maintenance Low fuel consumption The best compressor portfolio to fit your needs Turbo Reciprocating Engineered integrally geared Gas field and process • Performance Air separation, chemicals Standardized design Air separation Oil and gas upstream, LNG, refining and petrochemicals Gas transport Industry, metallurgy, utilities • Lowest capital expenditure • Sustainable • Field-proven compression for low life cycle costs • Fit for purpose with reliable field-proven design • For highest efficiencies • Highest aerodynamic efficiency • Reliability • Low maintenance • Versatile • For most demanding up-, mid-, and downstream applications • Reliable © Siemens AG 2015. All rights reserved. Single stage • Cost-effective and technologically advanced solution • Cost-efficient • Customized and proven Pipeline • Vertical and horizontal split compressors incl. high pressure applications • Outstanding efficiencies according to your requirements • Efficiency Centrifugal • Efficient • Best efficiencies for highest plant availability • Flexible design to accommodate all expected conditions • Long time uninterrupted operation One-stop-shop Excellent fit – complementary technologies Product portfolio with full power output range MW IGT (Siemens) ADGT (RollsRoyce) 0 20 SGT- SGT100 300 SGT500 SGT- SGT200 400 501 40 SGT-700 SGT-600 Complementary technology strengths 60 SGT-800 Only on-site service possible Good gas fuel flexibility Stable proven DLE systems Main application: Industrial power generation SGT-750 RB211 G62 TRENT 60 RB211 GT61 Light cores and fast core change for service Quality level inherited from aero engines Designed for high number of cycles with high efficiency Main application: Offshore production platforms Expertise and sense of responsibility ensures consistent reliability DLE = Dry Low Emissions: Emissions combustion system to minimize the emissions to atmosphere © Siemens AG 2015. All rights reserved. Your gateway to … a unique portfolio from a single source Large power generation Instrumentation, automation and controls Digitalization Power transmission Power distribution Process solutions Subsea Fossil fueled power plants Automation systems Enterprise technology for oil and gas Efficient, reliable and flexible power transmission Reliable power distribution Solutions for oil & gas and marine Subsea power grid Product lifecycle management provides owner and operators in the oil and gas industry with advanced technology for managing risk and controlling costs on capital projects. High-voltage transmission solutions, switching products and systems as well as power and distribution transformers, as well protection and power control systems. Medium and low voltage products, systems, solutions, and services; assuring safe, reliable and economic distribution of electrical power in industrial grids. Reliable, safe and environmentally friendly answers for electrification, drive systems, process automation, modularization and water management of oil & gas and marine clients. Subsea power, control, sensing and distribution systems, products and services to support electrical power, control, data, hydraulic, optical, monitoring and surveillance applications. Gas fired power plant solutions and products making energy reliable and affordable for the global society, and at the same time profitable for operators. Process and factory automation systems from field instrumentation to enterprise software. With the broadest portfolio and market coverage and with its leading technology, setting industry standards. © Siemens AG 2015. All rights reserved. We are happy to answer your questions! © Siemens AG 2015. All rights reserved.