NO EMISSIONS FROM KRAFT PULP MILLS

advertisement

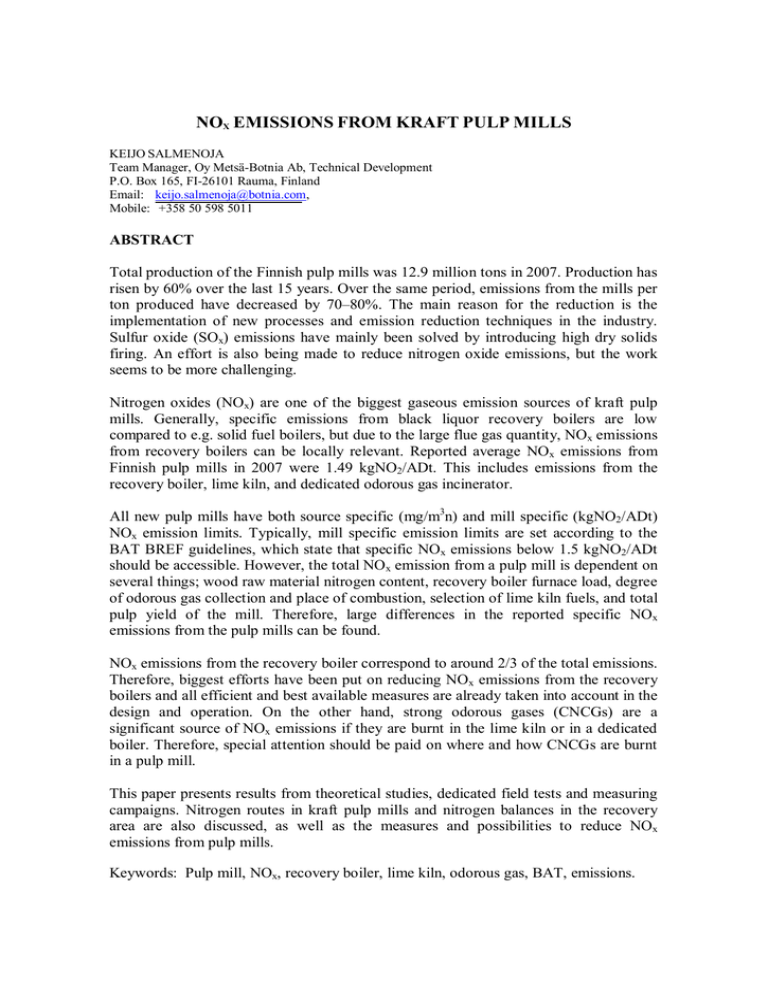

NOX EMISSIONS FROM KRAFT PULP MILLS KEIJO SALMENOJA Team Manager, Oy Metsä-Botnia Ab, Technical Development P.O. Box 165, FI-26101 Rauma, Finland Email: keijo.salmenoja@botnia.com, Mobile: +358 50 598 5011 ABSTRACT Total production of the Finnish pulp mills was 12.9 million tons in 2007. Production has risen by 60% over the last 15 years. Over the same period, emissions from the mills per ton produced have decreased by 70–80%. The main reason for the reduction is the implementation of new processes and emission reduction techniques in the industry. Sulfur oxide (SOx) emissions have mainly been solved by introducing high dry solids firing. An effort is also being made to reduce nitrogen oxide emissions, but the work seems to be more challenging. Nitrogen oxides (NOx) are one of the biggest gaseous emission sources of kraft pulp mills. Generally, specific emissions from black liquor recovery boilers are low compared to e.g. solid fuel boilers, but due to the large flue gas quantity, NOx emissions from recovery boilers can be locally relevant. Reported average NOx emissions from Finnish pulp mills in 2007 were 1.49 kgNO2/ADt. This includes emissions from the recovery boiler, lime kiln, and dedicated odorous gas incinerator. All new pulp mills have both source specific (mg/m3n) and mill specific (kgNO2/ADt) NOx emission limits. Typically, mill specific emission limits are set according to the BAT BREF guidelines, which state that specific NOx emissions below 1.5 kgNO2/ADt should be accessible. However, the total NOx emission from a pulp mill is dependent on several things; wood raw material nitrogen content, recovery boiler furnace load, degree of odorous gas collection and place of combustion, selection of lime kiln fuels, and total pulp yield of the mill. Therefore, large differences in the reported specific NOx emissions from the pulp mills can be found. NOx emissions from the recovery boiler correspond to around 2/3 of the total emissions. Therefore, biggest efforts have been put on reducing NOx emissions from the recovery boilers and all efficient and best available measures are already taken into account in the design and operation. On the other hand, strong odorous gases (CNCGs) are a significant source of NOx emissions if they are burnt in the lime kiln or in a dedicated boiler. Therefore, special attention should be paid on where and how CNCGs are burnt in a pulp mill. This paper presents results from theoretical studies, dedicated field tests and measuring campaigns. Nitrogen routes in kraft pulp mills and nitrogen balances in the recovery area are also discussed, as well as the measures and possibilities to reduce NOx emissions from pulp mills. Keywords: Pulp mill, NOx, recovery boiler, lime kiln, odorous gas, BAT, emissions. INTRODUCTION The control of emissions from European pulp mills and the development of emissions regulations are guided by the IPPC BREF document, which specifies, among others, the best available techniques (BAT) guidelines, for limiting nitrogen oxide emissions from pulp mills (European Commission, 2001). The document sets the range for nitrogen oxide emissions at 1.0-1.5 kgNO2/ADt, when a pulp mill is using a suitable combination of best available techniques. The figures include emissions from recovery boilers, lime kilns and odorous gas boilers, but not emissions from auxiliary or bark boilers. The total production of pulp in Finland was 12.9 million tons in 2007, from which Metsä-Botnia's share was ca. 2.5 million tons. The share of chemical pulp of the total production was 7.7 million tons. Production of chemical pulp has risen by 35% over the last 15 years. Over the same period, emissions from the mills have decreased by 70– 80% (Finnish Forest Industries, 2008). The most significant reduction in chemical pulp production has been obtained in sulfur dioxide (SOx) emissions, mainly due to the introduction of high dry solids firing in the 1980s. An effort is also being made to reduce nitrogen oxide (NOx) emissions, but the work seems to be extremely challenging. The forest industry sector contributes some 10% of Finland’s total nitrogen oxide emissions. All new pulp mills have both source specific (mg/m3n) and mill specific (kgNO2/ADt) NOx emission limits. Typically, mill specific emission limits are set according to the BAT guidelines. Figure 1 shows the annual average NOx emissions from Finnish pulp mills in 2007. As can be seen from Figure 1, reported NOx emissions varied from 0.5 up to 2.2 kgNO2/ADt. Only 40% of the Finnish mills reported emissions lower than 1.5 kgNO2/ADt. Reported average NOx emissions from Finnish pulp mills in 2007 were 1.49 kgNO2/ADt. Specifying and comparing emissions from pulp mills as kgNO2/ADt contains, therefore, a strong effect of the pulping yield. 2.50 kg NO2/ADt 2.00 1.50 1.00 0.50 0.00 0 1000 2000 3000 4000 5000 6000 7000 8000 9000 Cumulative Production (1000 ADt/a) Figure 1: Annual average NOx emissions from Finnish pulp mills in 2007 (Finnish Forest Industries, 2008. NOx emissions from the recovery boiler correspond to around 2/3 of the total emissions from the mill (Salmenoja et al., 2007). Typical NOx emission from a recovery boiler furnace is around 200 mgNO2/m3 n (Vakkilainen, 2005), which corresponds to ca. 1.5 kgNO2/ADt. Therefore, biggest efforts have been put on reducing NOx emissions from recovery boilers. However, the total NOx emission from a pulp mill is dependent on several things; wood raw material nitrogen content, recovery boiler furnace load, degree of odorous gas collection and place of combustion, and the selection of lime kiln fuels. If the measures to reduce NOx emissions are only aimed at the recovery boiler, the results may be slender. Therefore, all the relevant factors should be taken into account. The large variation (1.7 kgNO2/ADt) in reported NOx emission numbers also implies that there are differences in the treatment of nitrogen containing streams in the mill, as well as in the measuring and reporting procedures. The purpose of this paper is to give an overview of the formation of NOx emissions at kraft pulp mills and possibilities to reduce the emissions. The review is based on theoretical studies, dedicated field tests, and numerous mill-scale follow-up studies. FORMATION OF NOx EMISSIONS FROM KRAFT PULP MILLS The formation of nitrogen oxide emissions from pulp mills is significantly more complicated than was perceived before. Detailed studies on the formation of nitrogen oxides in the burning of black liquor began in the 1990s. However, a complete picture of the cycle of nitrogen compounds at pulp mills has only been clarified relatively recently (Kymäläinen, 2001). In particular, the sodium cyanate (NaOCN) forming in the recovery boiler smelt and the ammonia (NH3) generated through it in the chemical recovery cycle are new key factors, the importance of which has only been understood in the last few years. Nitrogen is mainly introduced into the mill with wood chips, but other nitrogen sources are also available, including defoamers, anti-scaling agents, chelating agents, etc. Their contribution has been considered to be negligible, but they may, however, have an impact on the black liquor nitrogen content in the future. The recycling of fiberline filtrates back to the recovery cycle in a mill with a high degree of closure may increase the nitrogen content of black liquor significantly (Telkkinen, 1997). Raw wood material contains organic nitrogen compounds as natural constituents, typically 0.05-0.50% of dry matter (Martius, 1992, Nichols et al., 1993, Verveka et al., 1993, Kymäläinen, 2001). In normal cooking, nitrogen compounds in the wood dissolve more or less completely in the alkaline cooking liquor and are transferred as part of the black liquor to the evaporation plant and further to the recovery boiler. Black liquors from wood species typically contain 0.05-0.50% of nitrogen in dry solids. This suggests that the nitrogen in wood could account for all the nitrogen present in black liquors. Hardwood black liquors typically contain more nitrogen than softwood liquors (Kymäläinen, 2001), which was also confirmed in this study. Measured average black liquor nitrogen contents for softwood and hardwood black liquors were 0.06% and 0.09%, respectively. NOx formation in the black liquor recovery boiler furnace NOx emissions from the black liquor recovery boiler furnace can originate either from fuel-NO or thermal-NO formation. However, thermal-NO formation i.e. the nitrogen oxide (NO) originating in nitrogen from the air, have shown not to play any role in normal black liquor combustion (Vakkilainen et al., 2005). On the other hand, black liquor nitrogen or fuel nitrogen is the dominant source for NOx emissions from a recovery boiler furnace (Nichols, et al., 1993, Iisa et al., 1998). Nitrogen is released either as ammonia during the pyrolysis of black liquor droplets or as NO during the char oxidation. Some nitrogen can also be released in molecular form (N2) during the oxidation stage in oxygen-lean conditions. According to a recent study (Brink et al., 2008) droplet size has a considerable effect on the NOx emissions from the recovery boiler furnace. Smaller droplet sizes promote higher NOx emissions. Black liquor dry solids content, however, seems not to have significant effect on the NOx emissions from the recovery boiler furnace (Vakkilainen, 2005). The conversion of black liquor nitrogen into NOx in the furnace varies from boiler to boiler, but on the average around a third of the nitrogen in the black liquor is oxidized into NOx (Kymäläinen, 2001). However, conversions lower than 15% have been reported (Saviharju et al., 2007), but these extremely low NOx conversions were achieved in special conditions. Figure 2 presents measured and calculated conversions to NOx during normal operation. Measured conversions are based on nitrogen balance measurement campaigns at five kraft pulp mills (Salmenoja et al., 2007). Calculated conversions are based on year 2007 mill statistics, which correspond to the normal operation at the mills. Conversion to NOx (%) 50.0 Measured 45.0 Calculated 40.0 35.0 30.0 25.0 20.0 15.0 10.0 5.0 0.0 Mill A Mill B Mill C Mill D Mill E hardwood Mill E softwood Figure 2: Measured and calculated conversions to NOx in recovery boiler furnaces. Measured values represent one day averages during the campaigns. Calculated values are based on 2007 mill statistics. As can be seen from Figure 2, measured and calculated conversions are close to each other. Average measured and calculated conversions are 35% and 37 %, respectively. The average conversions agree very well with the 33% rule of thumb. This data suggests that it seems hard to achieve lower than 30% conversion to NOx in the recovery boiler furnace in normal operation conditions. However, high carbon monoxide (CO) concentration seems to favor low NOx emissions from the furnace (Saviharju et al., 2007). Thus, allowing higher CO levels in the flue gases, lower conversions to NOx and consequently lower NOx emissions can be obtained. Effect of recovery boiler furnace load Furnace temperature affects the combustion chemistry, reaction kinetics, and retention time in the lower furnace. Although, the formation of fuel-NO is relatively insensitive to temperature in the range 800-1000 °C (Nichols et al., 1993), decreasing the lower furnace temperature seems to decrease NOx emissions (Vakkilainen, 2005). A low load means lower furnace temperature, which in turn enables better combustion control in the furnace. Thus, furnace temperature has also an effect on the recovery boiler NO x emissions. However, reducing NOx by lowering the furnace temperature is problematic, since SO2 emissions will increase and reduction degree will decrease. Several factors contribute to the temperature in the lower furnace including primary and secondary air temperatures, black liquor dry solids content, heating value of black liquor, and dry solids load to the furnace. Generally, recovery boilers are operated at constant air temperatures, black liquor dry solids content and heating value. Thus, the only factor that affects the lower furnace temperature in normal operation is the dry solids load, in other words the heat load into the furnace. The higher the dry solids load, the higher the lower furnace temperature. Figure 3 shows furnace load (tds/d) and relative NOx emissions from a recovery boiler during a two-year period. The load figures are collected from the boiler control (DCS) system and NOx emission values are based on on-line analyzers. According to Figure 3, NOx emissions from this recovery boiler appear to follow rather nicely the changes in the dry solids load to the boiler. The average dry solids load during the two-year period was close to 3000 tds/d, which is around 90% of the design load. Average NOx emission from the recovery boiler during 2006-2007 was equivalent to ca. 1.4 kgNO2/ADt. 1.20 4 500 1.00 3 500 0.80 3 000 2 500 0.60 2 000 0.40 1 500 1 000 0.20 Relative NO x Emission Furnace Load (tds/d) 4 000 500 0 0.00 2006-2007 Figure 3: Relative NOx emissions (line) and furnace load (bar) during 2006-2007 from a recovery boiler in normal operation. NOx emissions calculated according to the measurements by on-line analyzers. Effect of NCGs A significant fraction of the organic nitrogen in the black liquor is transferred into the recovery boiler smelt as NaOCN. The cyanate nitrogen in the smelt passes into the green liquor through the dissolving tank along with the smelt’s other salts. In the green liquor, alkaline hydrolysis gradually transforms cyanate nitrogen into NH3 (DeMartini et al., 2004). The ammonia formed in the green liquor and in the white liquor partially evaporates into dilute gases (DNCGs). However, most of the ammonia continues as part of the white liquor back to the cooking. From the cooking, the ammonia passes into the black liquor together with the organic nitrogen compounds of the wood. The ammonia is separated from the liquor in the evaporation plant, passing into concentrated gases (CNCGs) and methanol. The ammonia in CNCGs ends up – depending on the mill’s processing operations – in the recovery boiler, lime kiln, or in a dedicated incinerator. Total emissions of nitrogen compounds from a pulp mill are, therefore, dependent on how the ammonia containing flows, generated in the chemical recovery cycle, are treated. At old mills where the treatment of DNCGs is deficient, most of the ammonia vapors generated in the production of white liquor escapes into the atmosphere as ammonia emissions with other DNCGs. In the latest processes, DNCGs are collected efficiently and combusted either in the recovery boiler, lime kiln or dedicated incinerator. Depending on the particular case, these ammonia containing streams may increase the total NOx emissions from the pulp mill. Practical studies have shown that burning NCGs in a recovery boiler does not increase the NOx emissions (Janka and Tamminen, 2003). The increase in NOx emissions can more or less be avoided if the malodorous gases are injected in the correct way and in the right location in the recovery boiler furnace. Effect of lime kiln fuels Experiences has shown that burning oil in a lime kiln produces lower NOx emissions than natural gas, even though oil contains significant quantities of organic nitrogen that is not present in natural gas (Salmenoja et al., 2007). This is because of the higher temperatures with the natural gas flame. This will cause a higher thermal-NO x formation than the burning of oil. Low-NOx burner technology can be applied to lime kilns, but it is still under development and has not been widely utilized in the pulp mills. In most cases burning the NCGs in the lime kiln results in a significant increase in the NOx emissions. Developing low-NOx technology for lime kiln burning, when both NCGs and the main fuel are present, will require additional investments, and currently there are no reliable technical solutions available. The main reason for burning NCGs in the lime kiln are the high heating value and the high sulfur content of the gases. The use of NCGs as lime kiln fuel can replace around 15% of the heavy oil, which means considerable annual fuel savings. Typically, CNCGs contain 3-5 kgS/ADt and those mills that suffer from high sulfidity levels can not burn concentrated gases in the recovery boiler and recycle the sulfur. Therefore, CNCGs are burnt in the lime kiln or in a dedicated incinerator and the sulfur recovered as sodium bisulfite (NaHSO3) with an alkali scrubber. Liquid methanol has a high heating value and therefore some mills use methanol as a lime kiln fuel. Due to the high nitrogen content in methanol, NOx emissions from the lime kiln will also increase during the combustion of methanol. Lime kiln emissions represent around 15% of the total emissions from the mill (Salmenoja et al., 2007) and therefore methanol combustion in lime kiln may have a considerable impact to total NOx emissions. A practical test was carried out in a mill where methanol is used as a lime kiln fuel. Measured nitrogen content in methanol was 2.5%. This is five times higher than the nitrogen content in heavy oil (0.5%) used in the lime kiln. Thus, methanol increased the nitrogen flow into the lime kiln three-fold. When methanol flow was turned on, a rapid increase was also seen in the NOx emissions from the lime kiln. Since most of the NO x in flue gases is in NO form, the alkali scrubber after the lime kiln is not able to handle increased emissions. Therefore, total emissions from the mill will increase. METHODS FOR REDUCING NOx EMISSIONS There are a number of methods under development or undergoing testing that could potentially reduce NO emissions at pulp mills. Some of these are also mentioned in the IPPC document. Existing best available techniques include only combustion or socalled primary measures. Additional air levels above the conventional ones can provide more freedom for managing NOx emissions with combustion technology, and according to the experiences could result in a 10-25 % reduction depending on the original NO emission level (Janka et al., 1998). It has become apparent that NOx reduction techniques based on optimizing air distributions are not efficient if the boiler load is very high, or if boilers are operating overloaded, as is the case at several pulp mills. In addition to this, optimizing the air system will require special furnace wall tube materials that can withstand corrosion in a reducing atmosphere. These so-called compound tubes would have to be extended from the lower part of the boiler to the highest air level, which would be a significant and expensive alteration in a recovery boiler. Selective non-catalytic reduction (SNCR) Injecting ammonia into hot (ca. 900-1000 °C) flue gases causes a selective non-catalytic reaction, in which nitrogen oxide is converted into N2 by reacting with ammonia or urea ((NH2)2CO). The effectiveness and applicability of SNCR for recovery boilers is still unclear. One problem is changing boiler load which moves the temperature window optimal for the SNCR technique to a different location in the furnace. As a result, the efficiency of the NOx reduction varies. The potential reduction in recovery boilers (low initial NOx level, varying temperature, effect of other components in the gases) is likely to be below 50 %. Selective catalytic reduction (SCR) This process, in which ammonia is injected in a special catalytic reactor into cooled flue gases after the electrostatic precipitator (ESP), is another well-known technology that is commercially in use in power boilers, but has only reached the trial stage in recovery boilers. The problem with this technique is ensuring sufficient flue-gas dust removal before the process in the catalytic reactor and the durability of the catalyst. Optimal temperature window for this process is between 250-350 °C, which means that either hot ESP or extra heat transfer surfaces after the ESP must be used. This means heavy investments in existing boilers. Reductions over 70% can be easily achieved with SCR. In both SNCR and SCR techniques, unreacted ammonia remaining in the flue gases as ammonia emissions is also a factor about which there is still insufficient practical empirical data and which may restrict the effectiveness of these techniques in reducing NO emissions. CONCLUSIONS Nitrogen oxide (NOx) emissions from kraft pulp mills were reviewed. The purpose of the paper is to give an overview of the formation of NOx emissions at kraft pulp mills and possibilities to reduce the emissions. The review is based on theoretical studies, dedicated field tests, and numerous mill-scale follow-up studies. The mills represent Finnish state-of-the-art kraft pulping technology and use the best available techniques (BAT) in pulp production. Different pulping methods and raw materials are used in the mills and several different fuel streams are fed into the recovery boiler and lime kiln. Reported NOx emissions from Finnish pulp mills varied from 0.5 up to 2.2 kgNO2/ADt in 2007. Only 40% of the Finnish mills reported emissions lower than 1.5 kgNO2/ADt, which is the upper limit according to BAT BREF recommendations. Reported average NOx emissions from Finnish pulp mills in 2007 were 1.49 kgNO2/ADt. The large variation (1.7 kgNO2/ADt) in reported NOx emission numbers also implies that there are differences in the treatment of nitrogen containing streams in the mill, as well as in the measuring and reporting procedures. The results in this study show that: • The nitrogen content of the wood raw material largely determines the NO x level of the recovery boiler. The nitrogen content of hardwood is usually significantly higher than that of softwood. • It is hard to achieve lower than 30% conversion to NOx in the recovery boiler furnace in normal operation conditions. Lower conversions can be obtained only in special conditions. • Recovery boiler load has a considerable effect on NOx emissions. Lower furnace load means lower furnace temperature and enables better combustion control. • The way how and where DNCGs and CNCGs are treated is crucial. The high ammonia content in CNCGs must be taken into account when considering the place of combustion of these streams. The effort to reduce NOx emissions from Finnish pulp mills is continuing, but the work seems to be extremely challenging. The formation of nitrogen oxide emissions from pulp mills is significantly more complicated than was perceived before. However, recent studies have shed light to the possibilities to reduce NOx emissions especially from the recovery boiler. Latest measurements have also revealed that at softwood kraft pulp mills, which are operated at full load and have a complete odorous gas collection system, reduction of total NOx emissions below 1.5 kg/ADt is impossible even by using the BAT processes. REFERENCES BRINK, A., ENGBLOM, M, HUPA, M. (2008). Nitrogen Oxide Emission Formation in a Black Liquor Boiler. Tappi Journal. Vol. 7, No 11, November, pp. 28-32. DEMARTINI, N., FORSSÉN, M., MURZIN, D.Y., HUPA, M. (2004). The fate of nitrogen in the chemical recovery process in a kraft pulp mill: Part V: Kinetics of ammonia formation from cyanate in industrial green liquor. Journal of Pulp and Paper Science 30(12), pp. 329-334. EUROPEAN COMMISSION, EUROPEAN INTEGRATED POLLUTION PREVENTION AND CONTROL BUREAU (2001). Integrated pollution prevention and control (IPPC). Reference document on best available techniques (BAT) in the pulp and paper industry, December, 475 p. http://eippcb.jrc.es/pages/FActivities.htm FINNISH FOREST INDUSTRIES (2008). Forest industry’s environmental statistics for 2007. June, 19 p. http://www.forestindustries.fi FORSSÉN, M., HUPA, M., HELLSTRÖM, P. (1999). Liquor-to-Liquor Differences in Combustion and Gasification Processes: Nitrogen Oxide Formation Tendency. Tappi Journal. Vol. 82, No 3, March, pp. 221 - 227. IISA, K. JING, Q., CONN, J., ROMPHO, N., TANGPANYAPINIT, V., PIANPUCKTR, R. (1998). Model for NO Formation in Recovery Boilers. Proc. of the 1998 International Chemical Recovery Conference, June 1-4, Tampa, Florida, USA, pp. 763-776. JANKA, K., RUOHOLA, T., SIISKONEN, P. AND TAMMINEN, A. (1998). A Comparison of Recovery Boiler Field Experiments Using Various NOx Reduction Methods. Tappi Journal. Vol. 81, No 12, pp. 137-141. JANKA, K., TAMMINEN, A. (2003). Recovery Boiler Furnace as Concentrated NCG Incinerator. Tappi Journal. Vol. 2, No 2, February, 9 p. KYMÄLÄINEN, M. (2001). Fate of Nitrogen in the Chemical Recovery Cycle of a Kraft Pulp Mill, PhD Thesis, Åbo Akademi University, Turku, Finland. MARTIUS, C. (1992). Density, Humidity, and Nitrogen Content of Dominant Wood Species of Floodplain Forests (várzea) in Amazonia. Holz als Roh- und Werkstoff. Vol. 50, pp. 300-303. NICHOLS, K. M., THOMPSON, L. M., EMPIE, H. J. (1993). A Review of NOx Formation Mechanisms in Recovery Furnaces. Tappi Journal. Vol. 76, No 1, January, pp. 119-124. SALMENOJA, K., FORSSÉN, M., HUPA, M. (2007). Nitrogen Balances in Finnish Kraft Pulp Mills, Proc. of the 2007 International Chemical Recovery Conference, May 29 – June 1, Quebec City, QC, Canada, pp. 583-588. TELKKINEN, U-T. (1997), Typen määrä ja vaikutukset sulfaattisellutehtaan kemikaalikierrossa johdettaessa valkaisun vedet kemikaalien talteenottoon. Lic. Tech. Thesis. Helsinki University of Technology, Espoo, Finland. (In Finnish). VAKKILAINEN, E. IISA, K., PEKKANEN, M. (2005). Nitrogen Oxide Emissions from Recovery Boilers/Pulp Mills – Scandinavian Perspective. Proc. of the 2005 Tappi Engineering, Pulping, Environmental Conference. TAPPI Press, Atlanta, GA, CDROM Version. VAKKILAINEN, E. (2005). Kraft Recovery Boilers – Principles and Practices. SKY ry, Helsinki, Finland. 244 p. VERVEKA, P., NICHOLS, K. M., HORTON, R. R., ADAMS, T. N. (1993). The Form of Nitrogen in Wood and Its Fate During Kraft Pulping. Proceedings of the Tappi 1993 Environmental Conference, Tappi press, pp. 777 – 780.