CM_GlassFurnace_060329 - Ozone Transport Commission

advertisement

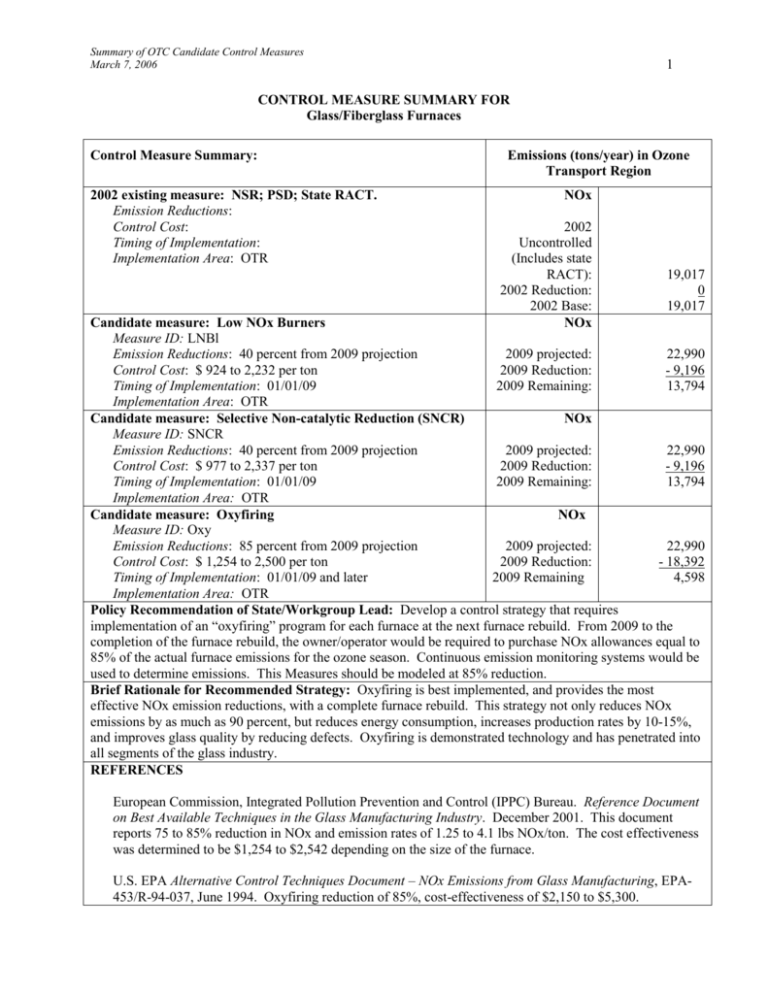

Summary of OTC Candidate Control Measures March 7, 2006 1 CONTROL MEASURE SUMMARY FOR Glass/Fiberglass Furnaces Control Measure Summary: 2002 existing measure: NSR; PSD; State RACT. Emission Reductions: Control Cost: Timing of Implementation: Implementation Area: OTR Emissions (tons/year) in Ozone Transport Region NOx 2002 Uncontrolled (Includes state RACT): 2002 Reduction: 2002 Base: NOx 19,017 0 19,017 Candidate measure: Low NOx Burners Measure ID: LNBl Emission Reductions: 40 percent from 2009 projection 2009 projected: 22,990 Control Cost: $ 924 to 2,232 per ton 2009 Reduction: - 9,196 Timing of Implementation: 01/01/09 2009 Remaining: 13,794 Implementation Area: OTR Candidate measure: Selective Non-catalytic Reduction (SNCR) NOx Measure ID: SNCR Emission Reductions: 40 percent from 2009 projection 2009 projected: 22,990 Control Cost: $ 977 to 2,337 per ton 2009 Reduction: - 9,196 Timing of Implementation: 01/01/09 2009 Remaining: 13,794 Implementation Area: OTR Candidate measure: Oxyfiring NOx Measure ID: Oxy Emission Reductions: 85 percent from 2009 projection 2009 projected: 22,990 Control Cost: $ 1,254 to 2,500 per ton 2009 Reduction: - 18,392 Timing of Implementation: 01/01/09 and later 2009 Remaining 4,598 Implementation Area: OTR Policy Recommendation of State/Workgroup Lead: Develop a control strategy that requires implementation of an “oxyfiring” program for each furnace at the next furnace rebuild. From 2009 to the completion of the furnace rebuild, the owner/operator would be required to purchase NOx allowances equal to 85% of the actual furnace emissions for the ozone season. Continuous emission monitoring systems would be used to determine emissions. This Measures should be modeled at 85% reduction. Brief Rationale for Recommended Strategy: Oxyfiring is best implemented, and provides the most effective NOx emission reductions, with a complete furnace rebuild. This strategy not only reduces NOx emissions by as much as 90 percent, but reduces energy consumption, increases production rates by 10-15%, and improves glass quality by reducing defects. Oxyfiring is demonstrated technology and has penetrated into all segments of the glass industry. REFERENCES European Commission, Integrated Pollution Prevention and Control (IPPC) Bureau. Reference Document on Best Available Techniques in the Glass Manufacturing Industry. December 2001. This document reports 75 to 85% reduction in NOx and emission rates of 1.25 to 4.1 lbs NOx/ton. The cost effectiveness was determined to be $1,254 to $2,542 depending on the size of the furnace. U.S. EPA Alternative Control Techniques Document – NOx Emissions from Glass Manufacturing, EPA453/R-94-037, June 1994. Oxyfiring reduction of 85%, cost-effectiveness of $2,150 to $5,300.