Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report for April

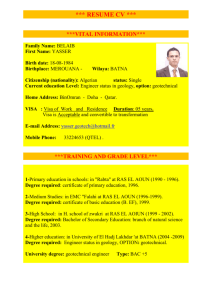

advertisement

Interpretive Geotechnical Report for Clifton Garage Investigation April 2015 Geotechnical REF: JG0012/2015/04/2565 Paarl Mountain Slip Geotechnical Investigation Interpretive Geotechnical Report SMEC REPORT QUALITY ASSURANCE ISSUE DATA Report Title: Interpretive Report for Clifton Garage Geotechnical Investigation Client: City of Cape Town Metropolitan Municipality Project Name: Clifton Garage Geotechnical Investigation Report Number: JG0012/2015/04/2565 Revision Number Final v.01 Revision History: 2015-03-20 2015-04-16 Issued to Report Status Date Draft Interpretive Report Final Interpretive Report Written by Reviewed/Approved by Name Ryan Freese Pr. Sci. Nat. MSc (Engineering & Environmental Geology) Professional Geologist Fernando Pequenino Pr. Eng. BEng Hons (geotechnical) Section Manager Written by: 2015/04/16 Signed Date 2015/04/16 Signed Date Approved by: SMEC | SOUTH AFRICA | GEOTECHNICAL Neil Eybers Institution City of Cape Town Metropolitan Municipality Paarl Mountain Slip Geotechnical Investigation Interpretive Geotechnical Report TABLE OF CONTENTS Page No 1. INTRODUCTION AND TERMS OF REFERENCE ......................................................... 1 1.1 1.2 1.3 1.4 1.5 Scope ..................................................................................................................................................... 1 Terms of Appointment........................................................................................................................... 1 Aims and Methodology .......................................................................................................................... 1 Information Sources .............................................................................................................................. 2 Limitations of Assessment ..................................................................................................................... 2 2. LOCATION AND SITE DESCRIPTION ........................................................................ 3 3. GEOLOGY .............................................................................................................. 4 4. SITE INVESTIGATION ............................................................................................. 5 4.1 4.2 4.3 4.4 4.5 4.6 Test Pits .................................................................................................................................................. 5 Rotary Core Boreholes ........................................................................................................................... 5 Electrical Resistivity Survey ..................................................................... Error! Bookmark not defined. Laboratory Testing ................................................................................................................................. 6 Electrical Resistivity Survey .................................................................................................................... 8 Borehole Pump Tests ............................................................................................................................. 9 5. GENERAL ASSESSMENT OF THE GEOTECHNICAL CONDITIONS ............................... 9 5.1 5.2 5.3 Engineering and Geological Ground Units ............................................................................................. 9 5.1.1 Fill Soils .................................................................................. Error! Bookmark not defined. 5.1.2 Residual Granitic Soils ......................................................................................................... 10 5.1.3 Granite Bedrock .................................................................................................................. 11 Groundwater ....................................................................................................................................... 11 Expansive, Dispersive and Collapsible Soils ......................................................................................... 12 6. GEOTECHNICAL ANALYSIS ................................................................................... 13 6.1 6.2 Bulk Earthworks ................................................................................................................................... 13 6.1.1 Excavation Conditions ......................................................................................................... 13 6.1.2 Geotechnical Analysis Parameters ...................................................................................... 14 Foundation Conditions ........................................................................................................................ 15 7. CONCLUSIONS AND RECCOMENDATIONS ........................................................... 15 8. REFERENCES ........................................................................................................ 17 9. CLOSING .............................................................................................................. 17 SMEC | SOUTH AFRICA | GEOTECHNICAL Paarl Mountain Slip Geotechnical Investigation Interpretive Geotechnical Report APPENDIX A: SITE PLANS APPENDIX B: TEST PIT PROFILES AND PHOTOGRAPHS APPENDIX C: BOREHOLE LOGS AND PHOTOGRAPHS APPENDIX D: DRILLER’S LOGS APPENDIX E: LABORATORY TEST RESULTS APPENDIX F: ELECTRICAL RESISTIVITY SURVEY RESULTS APPENDIX G: BOREHOLE PUMP TEST RESULTS APPENDIX H: SITE CROSS‐SECTIONS SMEC | SOUTH AFRICA | GEOTECHNICAL Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report 1. INTRODUCTION AND TERMS OF REFERENCE 1.1 Scope This interpretive report presents the findings of a geotechnical investigation for the proposed Clifton Garage “Redevelopment Precinct”. The proposed project is approximately 3000m² in extent consisting of a 3 level underground parking facility, a retail facility, together with shops and a restaurant. The investigation was carried out in accordance with the scope of work provided by the client, to determine whether the development is feasible and to obtain the relevant ground parameters for use in design of the development. Particular emphasis has been placed on assessing the stability of the proposed cut on the eastern side of the development and producing ground parameters for the design of stabilisation methods for this cut. 1.2 Terms of Appointment SMEC South Africa was initially appointed to undertake the geotechnical investigation on the 11th of December 2014 according to the SMEC quote Q818. A site walk over took place on the 21st of January 2015; at the meeting a number of issues became apparent in terms of access to the majority of the site. As such the scope of the investigation was amended and an extension to the contract was compiled to include the amended scope. SMEC South Africa was appointed under the variation order on the 27th February 2015. 1.3 Aims and Methodology The following methodology was adopted to realise the aims of the study: Desktop study including the review of available geological, topographical and hydrological maps, site plans, plans of the proposed development and reports and literature for the proposed infrastructure on underlying geology. (Stage 1) Undertaking of a geotechnical investigation fieldwork. o Excavation of test pits across the site, to profile the surficial soils and take representative soil samples. (Stage 2) o Drilling of rotary core boreholes to profile materials to beneath the proposed development and sample materials at depth. (Stage 3) o Electrical resistivity to provide a wider indication of underlying conditions to depth between borehole positions. Analysis and reporting of the results obtained during the desktop study and investigation, with regard to the bearing capacity of the founding horizons, anticipated settlement, excavatibility, depth of ground water and cut slope stability. (Stage 4) SMEC | SOUTH AFRICA | GEOTECHNICAL 1 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report 1.4 Information Sources The following information sources were consulted and made available; 1.5 Topographical Map, Sheet 3318CD at a scale of 1 : 50 000. Geological Map, Sheet 3318CD Cape Town at a scale of 1 : 50 000. Published technical references (listed in Section 8 of this report). Unnamed aerial plan of proposed development (contained in Appendix A). Unnamed cross-section of proposed development (contained in Appendix A). Limitations of Assessment The investigation comprised testing at a limited number of positions and is not likely to reveal the detail of the conditions that will become evident during construction. It is thus imperative that a Competent Person inspects all excavations to ensure that conditions at variance with those predicted do not occur and to undertake an interpretation of the facts supplied in this report to apply to on-site conditions as exposed during development of the site. It is possible that certain indications of ground contamination or ground water levels were latent or otherwise not visible. Our opinions can only be based on what was visible at the time the visit was conducted. This report has been prepared for the exclusive use of the client, with specific application to the proposed project. SMEC | SOUTH AFRICA | GEOTECHNICAL 2 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report 2. LOCATION AND SITE DESCRIPTION The site is situated to the west of Victoria Road (M6) in the Clifton suburb of Cape Town. The northern part of the site consists of single storey parking garages with interstitial paved areas, the majority of the site consists of bowls greens built on a cut-fill platform. The area has an approximate gradient of 1V:7H and lies on the side slope of Lions Head Mountain, approximately 150m from the Atlantic Ocean coastline. The site generally drains towards the west. It ranges from 20-30m above mean sea level, and the proposed development will cover an area of approximately 3000m². According to the 1:1 500 000 Map Veld Types of South Africa (Acocks, 1975) the site falls within the coastal fynbos veld type. Cape Town receives annual rainfall of 475mm. The Weinert’s climatic N-value for the Clifton area is approximately 3.5, this implies that chemical decomposition is the dominant mode of weathering and accounts for the deep weathering profile observed during the investigation. With the exception of the northern and southern areas, the vast majority of the site is inaccessible to any vehicles or plant. The site location is at approximate co-ordinates S33.942953°and E18.375319°, indicated on Diagram 2.1 below. THE SITE Diagram 2.1: Site locality map SMEC | SOUTH AFRICA | GEOTECHNICAL 3 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report 3. GEOLOGY The geological map of Cape Town (Sheet 3318CD, scale 1:50 000) indicates the site is underlain by porphyritic and biotitic granite, with some fine grained and hybrid variants, the granite is also intruded by multiple dolerite dykes in the area. The rock forms part of the Cape Peninsula Pluton, of the Cape Granite Suite, which was formed by a number of large magmatic intrusions into the Malmesbury Group sedimentary rocks. The granitic rock is Namibian Aged dated to 600±20Ma. Outcropping granite bedrock is visible close to the site, up slope from Victoria Road. The soils on site are almost exclusively derived from the granite bedrock and predominantly comprise of silty sands to gravelly sands. In most cases the transition from hard bedrock to residual soil is virtually immediate, with very little weathered rock present between. Large granite boulders (up to 6m³) were observed in the area, and where generally upslope of the site. Figure 3.1: Geological Map 3318 Cape Town, site shaded in blue. Site Symbol N-Cc Stratigraphy Lithology Cape Peninsula Pluton, Mainly porphyritic and biotitic Granite with fine to Cape Granite Suite medium grained and hybridic variants SMEC | SOUTH AFRICA | GEOTECHNICAL 4 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report 4. SITE INVESTIGATION The testing positions for the investigation are indicated in Figure 4.1. 4.1 Test Pits A total of 4 test pits (CTP1-4) were excavated across the site on the 22nd of January 2015. The test pits were excavated by hand to depths of 1.20-1.40m, refusal was not experienced in any of the test pits. Heavy excavating machinery was not used to excavate the trial pits due to access constraints over the majority of the site. The materials in the test pits were profiled, photographed and representative samples retrieved for laboratory testing. The test pit profiles and photographs are attached in Appendix B. 4.2 Rotary Core Boreholes Six rotary core boreholes, CBH1-6 were drilled on the 2nd to 16th March 2015 to depths of 9.90-15.27m by Fairbrother Geotechnical Engineering cc, a specialist geotechnical drilling contractor, using a HD300 DTH drill rig (CBH1 and 2), a dismantle-able LH75 drill rig (CBH3 and 4) and a HC6000 drill rig (CBH5 and 6). The conditions at CBH3 and 4 are believed to be most critical as this is where the cut for the development will be deepest and where water seepage in the adjacent existing retaining wall was observed. The boreholes were drilled vertically, SPT’s (Standard Penetration Tests) were undertaken in unconsolidated materials and Shelby tube samples were recovered at selected positions where the consistency of the soils allowed for driving of the tube. The borehole cores were profiled by our Engineering Geologists. The borehole logs (with SPT results) and core photographs are attached in Appendix C. The driller’s logs are attached in Appendix D. SMEC | SOUTH AFRICA | GEOTECHNICAL 5 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report Figure 4.1: Site layout plan indicating testing positions. Legend CTP= test pit CBH = borehole 4.3 Laboratory Testing Laboratory tests were scheduled to confirm the on-site investigation and establish shear strength parameters for the soils. Testing was undertaken by The University of Cape Town Geotechnical Laboratory and our associated SANAS-accredited laboratory Soillab Western Cape (Pty) Ltd. Tests were undertaken on representative disturbed and undisturbed samples collected from site. The foundation indicator, consolidated undrained triaxial and rock test results are summarised in Tables 4.1-4.3. SMEC | SOUTH AFRICA | GEOTECHNICAL 6 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report Table 4.1: Indicator results (sieve analysis, hydrometer and Atterberg Limits). Test Depth Position (m) Origin CTP1 0.7-1.3 Fill, derived from residual granite CTP4 0.741.28 Residual Granite CBH2 5.0-6.0 Residual Granite CBH3 5.507.50 Residual Granite CBH4 5.505.90 Residual Granite CBH6 3.0-4.5 Residual Granite CBH6 7.0-7.95 Residual Granite Clay Silt Sand Gravel LS % % % PI % Pot. Uni. Exp Clas. 10.6 6 64 20 0.2 NP Low SP 11.8 17 46 25 9 18 Low SC 7.2 17 40 36 5 12 Low SC 3.9 11 49 37 5 10 Low SCSM 55 12 N/A 8.1 N/A SM 33 6 19 64 11 5 10 Low SCSM 2.9 18 62 17 4 9 Low SCSM LS= Linear Shrinkage PI= Plasticity Index Pot. Exp.=Potential Expansiveness Uni. Clas.=Unified Soil Classification Table 4.2: Triaxial results (CU). Testing Depth Position (m) CBH4 5.50-5.90 Material φ’ (°) Sample Type Silty Sand φ’ = Effective Angle of Internal Friction c’ (kPa) Shelby Tube 30 Undisturbed c’ = Effective Cohesion 26.4 Table 4.3: Rock sample testing. Test Hardness Description Average Is(50) Conservatively Assessed Mean UCS (MPa) RQD (%) Failure Mode Granite Point Load Very hard rock 3.5 82.4 94 N/A 9.40-9.80 Granite Point Load Very hard rock 3.1 73.0 100 N/A BH3 11.0-11.30 Granite Hard rock N/A 29.7 78 Sliding Shear Failure BH3 11.0011.30 Granite Hard rock 1.2 28.3 78 N/A Test Positi on Depth of Test (m) Rock Type BH1 5.85-6.10 BH3 UCS Point Load SMEC | SOUTH AFRICA | GEOTECHNICAL 7 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report Table 4.3: Rock sample testing. Test Positi on Depth of Test (m) Rock Type BH5 8.65-9.00 Granite BH5 8.65-9.00 Granite Test Hardness Description Average Is(50) Conservatively Assessed Mean UCS (MPa) RQD (%) Failure Mode Point Load Very hard rock 5.3 124.8 100 N/A Very hard rock N/A 118.7 100 Sliding Shear Failure UCS Uniaxial compressive strength calculated from point load Is(50). Based on the point load data and UCS test results an average correlation of UCS=23.55*Is(50) was calculated this was used for the correlation. 4.4 Electrical Resistivity Survey The Electrical Resistivity (ER) survey was undertaken by a specialist geophysics contractor, Engineering and Exploration Geophysical Services (E&EGS), on the 30th and 31st March 2015, and consisted of 6 ER traverses undertaken in the median between the bowls greens at Glen Country Club. Due to the differential weathering which is a result of the texture and chemistry of granite rock, literature and experience show that, granitic profiles are prone to a number of geotechnical hazards, namely granite corestones and variable depth to bedrock. Corestones and variable bedrock depth can lead to excavation difficulties/uncertainties and the corestones are well documented in causing slope stability problems, particularly in the Clifton area. These geotechnical features are easily misinterpreted or not identified using the point information gathered from boreholes and test pits, therefore geophysics was undertaken to delineate conditions between borehole positions. The borehole logs were used to calibrate the geophysical data. ER was chosen as the preferred method of investigation as this method gives a good indication of corestone formation and bedrock depth. Furthermore this method of was favoured as the least intrusive to the adjacent bowling greens and country club. Another concern was the proximity of Victoria Road and resultant traffic which would cause excessive noise for other geophysical techniques. As was anticipated, on this geology, the ER results show a good contrast between low resistivity materials interpreted as soils and high resistivity material interpreted as rock. The traverses indicate that continuous bedrock is found at depths as shallow as 5m towards the north and west of the site. Soils are found to much greater depth in the south and east of the site grading into bedrock at depths in excess of 15m depth in places, with resistive pinnacles of rock rising to shallow depths (up to approximately 5m below egl). Multiple resistive blocks are found throughout the soil horizons, indicating the presence of corestones. These results SMEC | SOUTH AFRICA | GEOTECHNICAL 8 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report indicate the residual soil horizon has abundant granitic corestones and that the depth to bedrock is highly variable. The full ER results and report are attached as Appendix F. 4.5 Borehole Pump Tests Due to the depth of the proposed excavations for the development and the observation of heavy seepage through an existing retaining structure on site, borehole pump tests were undertaken to give an indication of the problem. Two pump tests were undertaken, one each at BH3 and BH4. Constant head pumping tests were undertaken, it was specified that these be undertaken at a head of approximately 8m below egl (the envisaged maximum depth of the development) in order to give an indication of the amount of seepage into the excavation. In 7 hours the test at BH3 was carried out, with the initial ground water level of 4.56m pumped to a depth of approximately 9m below egl. The inflow into the borehole at this depth was measured to be approximately 2.08x10-5 m³/second. The ground water level in BH3 recovered to a depth of 5.12m in 3 hours after pumping was terminated. In 6 hours the test at BH4 was only able to pump from the initial ground water level of 3.65m down to approximately 5.5m depth, before the capacity of the pump was exceeded. The measured inflow into the borehole, at this depth was 1.36x10-5 m³/second. The ground water level in BH4 recovered to a depth of 3.66m in 4 hours after pumping was terminated. These tests were carried out in permeable standpipe piezometers with an internal diameters of 60mm. During both tests the ground water levels in the surrounding boreholes were measured, but these levels were unaffected by the tests. 5. GENERAL ASSESSMENT OF THE GEOTECHNICAL CONDITIONS An assessment of the geotechnical conditions, based on the test pits, boreholes, laboratory results, on-site observations, DCP and SPT test results, is provided in Sections 5.1 to 5.4. Three cross-sections indicating the materials and ground water level underlying the site are attached as Appendix H. It must be noted that the cross-sections are largely based on extrapolated and interpolated point information, and levels were estimated from observation, no survey of the site was undertaken. 5.1 Engineering and Geological Ground Units The material underlying the site consisted of broadly similar soil horizons over bedrock, despite this the thickness of these horizons and depth to bedrock varied greatly across the site; which is to be expected in a granitic profile. From egl the typical soil profile consisted of fill soils of variable thickness (and in some places non-existent), underlain by thick layers of residual granitic soils overlying un-weathered granite rock. SMEC | SOUTH AFRICA | GEOTECHNICAL 9 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report 5.1.1 Fill Soils As anticipated the manmade platform (the bowls greens) which dominated the site consisted of deep fill soils at its western extent where it had been built up. These soils were found to from surface to depths of 3.0-4.6m. At positions on the eastern (cut section) of the platform these soils were generally thin to non-existent. The fill soils consisted of pinholed, silty sand, which appeared to be derived from residual granitic soils and occasionally residual sandstone materials. The fill soils contained abundant granitic and sandstone cobbles and occasional corestones. The fill is anticipated to exhibit low expansion. This material was observed to have a loose to medium dense consistency. Laboratory testing indicates the fill material classifies as SP (poorly graded Sand) (USCS BS 1377, 1990). This material was generally found to have SPT values in the order of 5-20, with a conservative average of approximately 10. Based on these values the soil is anticipated to be cohesion-less and have an estimated angle of friction of 28-32. 5.1.2 Residual Granitic Soils The residual granitic soils were generally found below the fill layer on the western border of the site and from surface or below very thin topsoil layer on the eastern extent of the site. These soils were found to depths of between 3.5-13.2m below egl. and consisted of gravelly sands with locally high silt and clay horizons. Although core stone boulders were anticipated in the horizon, none were intersected during drilling but are clearly distinguished on the ER survey. The finer portion of the soil was made up of variably weathered, kaolinized plagioclase (kaolin), whilst the coarser fraction predominantly of weathered quartz mineral grains. It must be noted that due to the high gravel content of these soils, SPT results are thought to be an over estimation of actual conditions. SPT testing indicates variable SPT values for this material, with the values generally increasing with depth. SPT values at depths of less than 5m where generally in the region of 10-20 indicating a medium dense consistency, a conservative SPT value for this layer is 10. SPT values at depths greater than 5m where generally in the region of 20-60 indicating a dense to very dense consistency, a conservative SPT value for this layer is 25. These soils classify as SC to SM (clayey to silty Sand) and are anticipated to exhibit varying cohesion with a conservative estimate of 10kPa an estimated angle of friction of approximately 28-32 at depths of less than 5m and approximately 30-34 at depths in excess of 5.0m. This correlates well with the triaxial test result on the residual soil at a depth of 5.5-5.9m (CBH4), tested to have an angle of friction of 30 and a cohesion of SMEC | SOUTH AFRICA | GEOTECHNICAL 10 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report 26.4kPa. The angle of friction and cohesion of the intact residual soil may be slightly higher than that of disturbed residual material due to the relict granitic grain structure observed, but it is difficult to quantify the degree to which this will increase the shear strength. 5.1.3 Granite Bedrock The granite bedrock observed varied greatly in depths and was found from 3.5-13.2m below egl. There was also almost no weathering zone between the overlying residual soils and unweathered granite bedrock. The bedrock was porphyritic very coarse grained rock with abundant accessory biotite. The rock mass, was slightly fractured to unfractured, the orientations of the few joints observed varied between horizontal and 60-70º. Joint condition varied, with closed joints to joint fill of 100mm, the wider joints were filled with gravel and sands and appeared to have been heavily weathered by water seepage. Uniaxial Compressive Strength (UCS) and point load testing indicates that slightly weathered granite has a UCS of approximately 15-50MPa and the unweathered granite 50-120MPa. These rocks are anticipated to have shear strength parameters far in excess of the overlying soils. The stability of any rock face excavated for the development, must be assessed by a geotechnical specialist once excavated to determine the orientation of the jointing of the rock mass in relation to the cut. It is anticipated that the rock mass will provide a stable cut face if exposed in the excavation. 5.2 Groundwater Ground water strikes were recorded in all boreholes, and standpipe piezometers were installed in every borehole. The level of the ground water was measured 24 hours after the completion of drilling, and was found to vary between positions from 2.25-6.41m below egl. Upon inspection of the existing retaining wall on the western side of the platform on site, large quantities of seepage were observed (during the dry summer) from 2m below platform level, as shown in Figure 5.1. Upon enquiry about the seepage problem at the Glen Country Club house, they acknowledged seepage came through the wall constantly to the point that a sump pump was installed in the basement of the country club basement to pump the water elsewhere. Pump testing of the boreholes on site indicates that the heavy ground water flow can be anticipated into excavations on site, flow rates measured equate to a permeability of approximately 0.1 to 0.001 cm/seconds for the residual granites. It also appears that heavier seepage runs through the central portion of the site (around CBH3 and CBH4). Limited tests have been undertaken and these have been done in the dry summer months, so it is important to note that these tests have not quantified the extent of the problem, but rather identified it. The seepage will need to be managed during construction and depending on SMEC | SOUTH AFRICA | GEOTECHNICAL 11 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report chosen design, a suitable management option must be put in place to deal with this seepage in the long term. All excavations in soil below the depth of seepage must be battered back to a safe gradient or the excavation sidewall must be stabilised to the satisfaction of the resident engineer. Figure 5.1: Seepage observed through existing retaining wall. 5.3 Expansive, Dispersive and Collapsible Soils The laboratory results received indicate that the soils are not expansive or dispersive. Observation of the soils at the approximate founding depth of the development are intact and therefore not considered to be collapsible, furthermore the pre-loading of these soils by the overlying material should mitigate any collapse behaviour at this depth. SMEC | SOUTH AFRICA | GEOTECHNICAL 12 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report 6. GEOTECHNICAL ANALYSIS 6.1 Bulk Earthworks 6.1.1 Excavation Conditions According to SANS 1200D, soft excavation conditions are anticipated beneath the site, to depths ranging from 3.5-13.2m, underlain immediately by hard rock excavation conditions. Beneath the centre of the site where the deepest excavations (approximately 8.0m) are anticipated, boreholes indicate soft conditions to in excess of 8.0m. It should be noted that the depth of bedrock varied greatly over short distances and as such, hard rock excavation should be anticipated within the cut, particularly towards the north and west of the site where bedrock was shallower (3.5m at CBH1). Large core stone boulders were observed at surface in the area surrounding the site, some small boulders were observed in the fill materials and material interpreted as large corestones were identified in the ER survey. Some boulder class A or B excavation conditions are anticipated. Based on assessment of the site, and the depth of the proposed cut (maximum 8m) an estimate of approximately 80% of the excavation conditions are anticipated to be soft, 10% boulder class A or B and 10% hard excavation conditions. Due to the very hard, unweathered, unfractured nature of the bedrock, blasting should be included in the Bill of Quantities for approximately 10% of the excavations undertaken, blasting may also be required for large corestones in the profile. The excavation conditions are described in Table 6.1: Table 6.1: Excavation class description as per SANS 1200D Excavation Class Description Soft Excavation in material that can be efficiently removed by a back-acting excavator of flywheel power approximately 0.10 kW per millimetre of tined-bucket width, without the use of pneumatic tools such as paving breakers Intermediate Excavation in material that requires a back-acting excavator of flywheel power exceeding 0.10 kW per millimetre of tinedbucket width or the use of pneumatic tools before removal by equipment equivalent to that specified for soft excavation. Hard Hard rock excavation shall be excavation in material (excluding boulder excavation) that cannot be efficiently removed without blasting or wedging and splitting. SMEC | SOUTH AFRICA | GEOTECHNICAL 13 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report Table 6.1: Excavation class description as per SANS 1200D Excavation Class Description Boulder (excavation class A) Excavation in material containing more than 40% by volume of boulders of size in the range of 0.03 – 20m3, in a matrix of soft or smaller boulders. Boulder (excavation class B) Excavation in material containing 10-40% by volume of boulders of size in the range of 0.03 - 20m3, in a matrix of soft or smaller boulders. 6.1.2 Geotechnical Analysis Parameters The large excavation and particularly the cut proposed on the eastern side of the development provides an inherent slope stability risk, this risk must be mitigated by excavating the slope at a shallow angle or more likely by using lateral support methods. Based on the findings of the geotechnical investigation, the profile through which the cut will be excavated will consist predominantly of residual granitic soils. Therefore the shear strength parameters of this material are the critical geotechnical design parameters for this structure. In areas where there is sufficient space to batter back the cut slopes, above the ground water level, these slopes should not exceed a gradient of 1V:1H in short term and:1V:2H in the long term. The slopes should not exceed a height of 8m and if in excess, a benched slope must be constructed with individual bench heights of less than 2m. Where space does not permit a shallow angle cut slope, lateral support techniques must be employed. The design of the lateral support should be undertaken by a suitably qualified Geotechnical Engineer according to the Code of Practice for Lateral Support and Surface Excavations and taking into account the geotechnical conditions (particularly the heavy seepage conditions reported). The shear strength design parameters provided in Table 6.2. can be used as a guideline. Table 6.2: Estimated shear strength parameters Material Estimated Effective Cohesion c'(kPa) Estimated Effective Angle of Friction Φ' (degrees) Fill 0 30 Residual Granite at depths <5.0m 10 30 Residual Granite at depths <5.0m 10 32 Corestones are anticipated to be present within the profile. Based on observation of boulders at surface in the surrounding area, it is anticipated these boulders may be in excess of 5m in SMEC | SOUTH AFRICA | GEOTECHNICAL 14 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report diameter. Furthermore literature identifies the problematic conditions caused by granite corestones in the Clifton area (Brink, 1979). Due to the highly generally erodible and permeable residual granite soils, high water flow and resultant erosion may lead to slope instability. It will be possible to remove smaller corestones, whilst larger corestones will have to be incorporated into the lateral support design. If piles are to be used for the lateral support it must be noted that piling techniques capable of penetrating large corestones may be required. 6.2 Foundation Conditions The foundation loads of the basement parking complex are anticipated to be substantial, as such the founding conditions were assessed at the anticipated depth of the proposed foundation. It is envisaged that the foundations will be placed at a depth of approximately 48m below egl. SPT values at these depths generally indicate dense to very dense residual granitic soils, the Estimated Allowable Safe Bearing Pressures (EASBP’s) correlated from SPT testing at these depths indicate bearing pressures in the order of 200-400kPa. An exception is the relatively loose conditions tested at BH5 up to a depth of approximately 6m, where SPT testing indicates EASBP’s of approximately 100kPa. It should also be noted that corestones at or close to the founding depth may lead to variable founding conditions. Thus although spread foundations could be feasible over parts of the site, very low bearing capacities have been recorded elsewhere. Furthermore, the ground water seepage may be very high making the casting and cleaning of foundation bases in soils problematic. Pile foundations, end bearing on bedrock are thus recommended over parts of the site. It should be noted that corestones underlying the site may cause difficulties in terms of piling and should be noted when selecting the method/s of piling used. The foundation loads of the structure were unknown at the time this report was compiled. 7. CONCLUSIONS AND RECOMENDATIONS This interpretive report covers the findings and test results received for a geotechnical investigation for the proposed Clifton Garage “Redevelopment Precinct”, consisting of a 3 level basement parking garage, associated retail developments and an approximately 8m retaining structure. The objective of the investigation is to determine the viability of the project, provide geotechnical design parameters and recommendations of the design of lateral retaining structures and foundations for the development. Although the site has a number of geotechnical constraints, particularly heavy ground seepage, which will result in cost implications, the development is considered viable as long as the recommendations given in this report are followed. SMEC | SOUTH AFRICA | GEOTECHNICAL 15 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report The geotechnical investigation of the site indicates that the site is underlain by granite bedrock of the Cape Peninsula Pluton making up part of the Cape Granite Suite. The site profile consists of layers of loose to medium dense fill derived from residual granite, underlain by deep residual granite, medium dense to very dense sands, grading suddenly into very hard rock, unweathered, unfractured granite bedrock. Geotechnical conditions affecting the proposed development are: The depth to bedrock varies across the site, with shallower bedrock towards the northern and western parts of the site. Heavy ground water seepage is anticipated below depths of approximately 2.0m. The hydrostatic pressures and flow must be considered in the geotechnical and structural design and the construction contractor must make provision to manage the heavy seepage. The following excavation class quantities are anticipated for the earthworks on site to a depth of 8m (the current assumed Surface Bed level): Soft Excavation: 80% Boulder Class A or B: 10 % Hard Excavation: 10% The majority of the envisaged cut will be within the residual granitic soils, with the estimated design shear strength parameters provided in Table 6.2. The anticipated founding medium, at depths of 4-8m below egl., are anticipated to have EASBP’s in the order 200-400kPa based on SPT test results, with the exception of the south west corner of the site were EASBP’s of approximately 100kPa are anticipated. It is envisaged that foundations would comprise a combination of spread foundations where bedrock is relatively shallow on rock and end bearing pile foundations socketed onto rock. Although not intersected in the boreholes, the ER survey of the site indicates large granitic corestones underlie the site within the residual soil horizon. These corestones may lead to slope instability and require specialised piling equipment if this is undertaken on site. The retaining structure and foundations of the proposed development must be designed by a qualified and registered Geotechnical Engineer, in line with national guidelines and best practice. We trust that this report will be found to be complete and adequate for your consideration. Should further elaboration be required for any portion of this project, we would be pleased to provide assistance. SMEC | SOUTH AFRICA | GEOTECHNICAL 16 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report 8. REFERENCES Brink, A.B.A. (1979), Engineering Geology of Southern Africa, Volume 2. Building Publications, Pretoria. Johnson, M.R., Anhausser, C.R., Thomas, R.J. (1996) The Geology of South Africa. The Geological Society of South Africa and the Council for Geoscience. SANS 633:2012 Soil profiling and rotary percussion borehole logging on dolomite land in Southern Africa for engineering purposes. Weinert, H. H., (1964), Basic igneous rocks in road construction, Research Report 218, CSIR, Pretoria. 9. CLOSING We trust that this report will assist you in the design and construction of the proposed project. SMEC South Africa appreciate the opportunity of providing our services on this project and look forward to working with you on future projects. Should you have any questions, please do not hesitate to contact us. Respectfully submitted, SMEC South Africa (Pty) Ltd SMEC | SOUTH AFRICA | GEOTECHNICAL 17 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report APPENDIX A: SITE PLANS SMEC | SOUTH AFRICA | GEOTECHNICAL APPENDIX A Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report APPENDIX B: TEST PIT PROFILES AND PHOTOGRAPHS SMEC | SOUTH AFRICA | GEOTECHNICAL APPENDIX B TRIAL PIT LOG HOLE NO: CTP1 Depth CLIENT: CCTMPM PROJECT: CLIFTON GARAGE PROJECT NO: JG0012 SITE: GLEN COUNTRY CLUB, CLIFTON X COORD: E18,375378 Y COORD: S33,942963 ELEVATION: PAGE 1 of 1 Dynamic Probe Light Equivalent SPT-N Description 0.00 0.0 10 20 30 40 Ground Surface Loose, slightly silty SAND Slightly moist, dark brown, speckled white, pinholed, imported. Topsoil. 0.35 Soft sandy SILT with some clay Moist, brown, mottled black and orange, intact. Abundant micas. Fill derived from residual granite. 0.5 0.70 Medium dense, very silty SAND Moist, white, mottled orange, black and grey, intact, imported. Abundant micas. Fill derived from residual granite. 1.0 1.30 Termination: time constraint End of Log 1.5 2.0 2.5 3.0 NOTES 1: 1* MOD/CRB sample at 0.7-1.3m. 2: Slight seepage at 1.0m. 3: Old burried wall inside of pit. 4: No side wall collapse SMEC South Africa MACHINE: By hand DIAM: Test pit FILE REF: Template: SMEC TP04 Consulting Engineers DATE PROFILED: 22/01/2015 PROFILED BY: R.FREESE South Africa Prof Reg: 400051/14 CHECKED BY: E.ODENDAAL Prof Reg: 4400445/11 +27 (0)12 481 3800 www.smec.com Test pit 1 profile. Test pit 1 spoil. TRIAL PIT LOG HOLE NO: CTP2 Depth CLIENT: CCTMPM PROJECT: CLIFTON GARAGE PROJECT NO: JG0012 SITE: GLEN COUNTRY CLUB, CLIFTON X COORD: E18,375057 Y COORD: S33,943225 ELEVATION: PAGE 1 of 1 Dynamic Probe Light Equivalent SPT-N Description 0.00 0.0 0.20 10 20 30 40 Ground Surface Loose, slightly silty SAND Slightly moist, dark brown, speckled white, pinholed, imported. Topsoil. Medium dense sandy BOULDERS with some silt Red brown, blotched white, imported. Fill derived from residual sandstone. 0.5 0.70 Medium dense, very silty SAND Moist, beige, speckled white, intact, imported. Abundant micas. Fill derived from residual granite. Abundant granitic cobbles. 1.0 1.20 Termination: time constraint End of Log 1.5 2.0 2.5 3.0 NOTES 1: 1* FI sample at 0.7-1.2m. 2: No seepage. 3: Broken pipe in test pit. 4: No side wall collapse. SMEC South Africa MACHINE: By hand DIAM: Test pit FILE REF: Template: SMEC TP04 Consulting Engineers DATE PROFILED: 22/01/2015 PROFILED BY: R.FREESE South Africa Prof Reg: 400051/14 CHECKED BY: E.ODENDAAL Prof Reg: 4400445/11 +27 (0)12 481 3800 www.smec.com Test pit 2 profile. Test pit 2 spoil. TRIAL PIT LOG HOLE NO: CTP3 Depth CLIENT: CCTMPM PROJECT: CLIFTON GARAGE PROJECT NO: JG0012 SITE: GLEN COUNTRY CLUB, CLIFTON X COORD: E18,375669 Y COORD: S33,943662 ELEVATION: PAGE 1 of 1 Dynamic Probe Light Equivalent SPT-N Description 0.00 0.0 10 20 30 40 Ground Surface Slightly silty SAND and occasional cobbles Dry, dark brown, speckled white and orange, pinholed, imported. Fill. 0.40 Medium dense, slightly clayey SAND with some cobbles Moist, grey brown to orange, mottled red, intact. Fill. With some granitic cobbles. 0.5 1.00 1.0 Soft, slightly sandy SILT and occasional gravel Moist, white, mottled red, intact. Fill derived from residual granite. 1.40 Termination: seepage at 1.4m 1.5 End of Log 2.0 2.5 3.0 NOTES 1: 1* FI sample at 0.4-1.0m and 1.0-1.4m. 2: Seepage at 0.7m. 3: Broken pipe in test pit. 4: No sidewall collapse. SMEC South Africa MACHINE: By hand DIAM: Test pit FILE REF: Template: SMEC TP04 Consulting Engineers DATE PROFILED: 22/01/2015 PROFILED BY: R.FREESE South Africa Prof Reg: 400051/14 CHECKED BY: E.ODENDAAL Prof Reg: 4400445/11 +27 (0)12 481 3800 www.smec.com Test pit 3 profile. Test pit 3 spoil. TRIAL PIT LOG HOLE NO: CTP4 Depth CLIENT: CCTMPM PROJECT: CLIFTON GARAGE PROJECT NO: JG0012 SITE: GLEN COUNTRY CLUB, CLIFTON X COORD: E18,375213 Y COORD: S33,943823 ELEVATION: PAGE 1 of 1 Dynamic Probe Light Equivalent SPT-N Description 0.00 0.0 0.30 0.50 0.5 0.80 10 20 30 40 Ground Surface Medium dense, sandy GRAVEL with occasional cobbles Dry, beige, blotched white, intact, imported, crushed granite rock fill. Abundant quartzite gravel to cobbles and micas. Medium dense, slightly silty SAND and occasional gravel Dry, beige, speckled white, intact, imported, fill. Fill derived from residual granite and hillwash. Abudant micas, sandstone gravel and boulders. Loose, slightly silty SAND Slighty moist, white, speckled yellow, intact, imported, fill. Fill. Medium dense to dense, slightly gravelly SAND with some cobbles Slighty moist, grey brown, speckled orange, black and white, intact. Residual granite. 1.0 1.30 Termination: dense residual granite End of Log 1.5 2.0 2.5 3.0 NOTES 1: 1* FI sample at 0.74-1.28m. 2: Minor seepage at base of pit, 1.3m.. 3: No side wall collapse. 4: SMEC South Africa MACHINE: By hand DIAM: Test pit FILE REF: Template: SMEC TP04 Consulting Engineers DATE PROFILED: 22/01/2015 PROFILED BY: R.FREESE South Africa Prof Reg: 400051/14 CHECKED BY: E.ODENDAAL Prof Reg: 4400445/11 +27 (0)12 481 3800 www.smec.com Test pit 4 profile. Test pit 4 spoil. Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report APPENDIX C: BOREHOLE LOGS AND PHOTOGRAPHS SMEC | SOUTH AFRICA | GEOTECHNICAL APPENDIX C BOREHOLE LOG 0 W A S S P T W A S S P T 61 31 Depth (m) Legend Sample Water No. of fract. SPT- N value RQD % Core size % Mat. recov. % Core recov. CLIENT: CCTMPM PROJECT: CLIFTON GARAGE GEOTECH PROJECT NO: JG0012 CLIENT NO: SITE: GLEN COUNTRY CLUB, CLIFTON KILOMETRE: 0.0 H 1 100 90 97 100 100 Ground Surface Clayey, gravelly SAND Moist, light brown, blotched white, grey mottled yellow. Residual granitic grain structure. 3 23 100 N/A 3.5 4 85 N/A 5 94 6.2 N/A 7 130 Description 2 H 6 70 X COORD: E18,375133 Y COORD: S33,942151 ELEVATION: PAGE 1 of 1 38 4.5 94 HOLE NO: CBH1 100 100 N/A N/A 8 9 9.9 10 Soft to medium hard rock GRANITE White, mottled orange, black and grey, medium to highly weathered, moderately fractured, coarse grained, massive, Cape Peninsula Pluton, Cape Granite Suite. Fractures 1.Horizontal, rough, sandy gravel fill ~50mm. Medium to hard rock GRANITE White mottled grey, orange and black, medium to slightly weathered, moderately fractured, coarse grained, massive, Cape Peninsula Pluton, Cape Granite Suite. Fractures. 1. Horizontal, rough, sandy gravel fill, closed to 40mm. Soft zone at 6.1-6.2m retrieved as gravel. Hard rock GRANITE White, mottled grey, orange and black, unweathered, unfractured, coarse grained, massive, Cape Peninsula Pluton, Cape Granite Suite. Fractures. 1. ~70deg, rough, no filling , closed. End of Log 11 12 NOTES 1: Core sample at 5.8-6.1 2: 3: 4: CONTRACTOR: FAIRBROTHER GEO ENG MACHINE: HD 300 DTH Drill rig INCLINATION: VERTICAL FILE REF: Template: SMEC BHLP03 DRILLING DATE: 06/03/2015 SMEC South Africa DATE LOGGED: 10/06/2015 Consulting Engineers LOGGED BY: R.FREESE CHECKED BY: E.ODENDAAL South Africa Prof Reg: 400051/14 Prof Reg: 4400445/11 +27 (0)12 481 3800 www.smec.com Borehole1, Box 1 of 2: 0-8.42m Borehole 1, Box 2 of 2: 8.42-9.9m BOREHOLE LOG 0 NXC W A S NXC S P T NXC W A S NWD4 S P T 52 S P T 13 NWD4 W A S NWD4 P T 21 P T 43 S P T 61 NWD4 W A S NWD4 S P T NWD4 W A S NWD4 P T REF P T REF Depth (m) Legend Sample Water No. of fract. SPT- N value RQD % Core size % Mat. recov. % Core recov. CLIENT: CCTMPM PROJECT: CLIFTON GARAGE GEOTECH PROJECT NO: JG0012 CLIENT NO: SITE: GLEN COUNTRY CLUB, CLIFTON KILOMETRE: 0.0 H 41 1 H 2 HOLE NO: CBH2 X COORD: E18,374955 Y COORD: S33,942577 ELEVATION: PAGE 1 of 1 Description Ground Surface Silty SAND Moist, dark brown, mottled red, voided, fill, abundant quartz gravel and concrete cobbles. Hard rock granite at 4.3-4.6m, interpreted as granite boulder. NWD4 58 NWD4 S 3 H 4 4.6 NWD4 105 NWD4 S NWD4 86 NWD4 S H 5 6 6.1 Gravelly, clayey SAND Moist, light brown, blotched white, mottled orange and black, relict granitic grain structure. Residual granite. 7 REF Gravelly, silty SAND Moist, beige, mottled white, grey and orange, intact. Residual granite, abundAnt quartz gravel, some relict structure in places. 8 H 9 NWD4 49 NWD4 S 10 10.4 End of Log 11 12 13 14 15 NOTES 1: 1*FI sample at 5.0-6.0m 2: Water level at 5.8m 3: 4: CONTRACTOR: FAIRBROTHER GEO ENG MACHINE: HD 300 DTH Drill rig INCLINATION: VERTICAL FILE REF: Template: SMEC BHLP03 DRILLING DATE: 06/03/2015 SMEC South Africa DATE LOGGED: 10/03/2015 Consulting Engineers LOGGED BY: R.FREESE CHECKED BY: E. ODENDAAL South Africa Prof Reg: 400051/14 Prof Reg: 4400445/11 +27 (0)12 481 3800 www.smec.com Borehole 2, Box 1 of 1: 0-10.075m BOREHOLE LOG 0 W A S S P T 23 P T 5 P T Depth (m) Legend Sample Water No. of fract. SPT- N value RQD % Core size % Mat. recov. % Core recov. CLIENT: CCTMPM PROJECT: CLIFTON GARAGE GEOTECH PROJECT NO: JG0012 CLIENT NO: SITE: GLEN COUNTRY CLUB, CLIFTON KILOMETRE: 0.0 H HOLE NO: CBH3 X COORD: E18,374955 Y COORD: S33,942947 ELEVATION: PAGE 1 of 2 Description Ground Surface Silty SAND Moist, beige to orange brown, mottled white, black, voided, fill, zones of sandy silt. materials vary in derivation. Beach sand to granitic sandy silt. 1 109 2 S 27 3 S 13 3.5 58 4 S P T 39 22 4.0 Clayey SILT Slightly moist, grey, mottled red, stiff, intact. Fill. Gravelly, silty SAND Moist, grey, blocthed white, mottled orange, black, relict granitic grain strUcture. Residual granite. 5 S P T 44 6 26 7 S P T W A S 43 H 8 NOTES 1: Core samples at 9.4-9.8 and 11.0-11.3 2: 3: 4: CONTRACTOR: FAIRBROTHER GEO ENG MACHINE: LH75 Drill rig INCLINATION: VERTICAL FILE REF: Template: SMEC BHLP03 DRILLING DATE: 06/03/2015 SMEC South Africa DATE LOGGED: 10/03/2015 Consulting Engineers LOGGED BY: R.FREESE CHECKED BY: E.DENDAAL South Africa Prof Reg: 400051/14 Prof Reg: 4400445/11 +27 (0)12 481 3800 www.smec.com BOREHOLE LOG 100 0 N/A 115 100 100 N/A Depth (m) 100 Legend T Sample P Water RQD % S No. of fract. SPT- N value Core size % Mat. recov. % Core recov. CLIENT: CCTMPM PROJECT: CLIFTON GARAGE GEOTECH PROJECT NO: JG0012 CLIENT NO: SITE: GLEN COUNTRY CLUB, CLIFTON KILOMETRE: 100 N/A Hard rock GRANITE Orange to pink, blotched white, unfractured, slightly weathered, coarse grained. 10.3 Very hard rock GRANITE White, mottled grey, orange and black, unweathered, very slightly to slightly fractured, coarse grained. Fractures. 1. 60 deg, round, sandy gravel, 30mm. 10.6 11 67 90 78 11.0 11.8 N/A Hard rock GRANITE Orange to pink, blotched white, very slightly fractured, slightly weathered, coarse grained. Fractures 1. Horizontal, rough, sandy gravel fill, 10-100mm. 13 96 100 N/A 14 Hard rock GRANITE White, mottled grey, orange, black, unweathered, very slightly fractured, coarse grained, massive. Fractures. 1. 60deg, round, sandy gravel fill, 30mm. Sandy GRAVEL Moist, orange brown, speckled white, black, voided. Residual granite. Interpreted as broken granite saprolite. 12 86 Description 9.2 10 6 X COORD: E18,374955 Y COORD: S33,942947 ELEVATION: PAGE 2 of 2 8.8 REF 9 100 HOLE NO: CBH3 14.0 Very hard rock GRANITE White, mottled grey, orange, black, unweathered, very slightly fractured, coarse grained, massive. Fractures. 1. Horizontal, round, sandy gravel fill, 0-50mm. End of Log 15 16 17 NOTES 1: Core samples at 9.4-9.8 and 11.0-11.3 2: 3: 4: CONTRACTOR: FAIRBROTHER GEO ENG MACHINE: LH75 Drill rig INCLINATION: VERTICAL FILE REF: Template: SMEC BHLP03 DRILLING DATE: 06/03/2015 SMEC South Africa DATE LOGGED: 10/03/2015 Consulting Engineers LOGGED BY: R.FREESE CHECKED BY: E.DENDAAL South Africa Prof Reg: 400051/14 Prof Reg: 4400445/11 +27 (0)12 481 3800 www.smec.com Borehole 3, Box 1 of 2: 0-9.8m Borehole 3, Box 2 of 2: 9.80-14.0m BOREHOLE LOG 0 W A S S P T Depth (m) Legend Sample Water No. of fract. SPT- N value RQD % Core size % Mat. recov. % Core recov. CLIENT: CCTMPM PROJECT: CLIFTON GARAGE GEOTECH PROJECT NO: JG0012 CLIENT NO: SITE: GELN COUNTRY CLUB, CLIFTON KILOMETRE: 0.0 H HOLE NO: CBH4 X COORD: E18,375563 Y COORD: S33,943301 ELEVATION: PAGE 1 of 2 Description Ground Surface Gravelly , sandy SAND Moist, beige, speckled white, black and orange, pinholed, clayey sandy silt. Hillwash of granitic origin. 1 7 72 S 2 P T 10 3 3.1 63 S H E L B S P T 13 13 Clayey, gravelly SAND Moist, beige to white, mottled orange, speckled black, intact, relict granitic structure, gravelly silty sand. Residual granite. Sandy silt zones at 5.36.5m. Y 4 80 5 S P T S H E L B Y 6 49 6.7 S P T REF 7 135 Gravelly, silty SAND Moist, light orange to white, mottled red, speckled black, intact, residual granitic granite structure, sandy gravel. Residual granite, 8.5-9.5m zones of sandy silt, believed to constitute granite saprolite close to very soft rock, granitic rock. 8 NOTES 1: No samples. 2: 3: 4: CONTRACTOR: FAIRBROTHER GEO ENG MACHINE: LH 75 Drill rig INCLINATION: VERTICAL FILE REF: Template: SMEC BHLP03 DRILLING DATE: 06/03/2015 SMEC South Africa DATE LOGGED: 10/03/2015 Consulting Engineers LOGGED BY: R.FREESE CHECKED BY: E.ODENDAAL South Africa Prof Reg: 400051/14 Prof Reg: 400445/11 +27 (0)12 481 3800 www.smec.com BOREHOLE LOG Depth (m) Legend Sample Water No. of fract. SPT- N value RQD % Core size % Mat. recov. % Core recov. CLIENT: CCTMPM PROJECT: CLIFTON GARAGE GEOTECH PROJECT NO: JG0012 CLIENT NO: SITE: GELN COUNTRY CLUB, CLIFTON KILOMETRE: HOLE NO: CBH4 X COORD: E18,375563 Y COORD: S33,943301 ELEVATION: PAGE 2 of 2 Description 120 9 10 134 11 149 12 13 108 46 74 13.1 Soft rock, GRANITE White, mottled black, grey, sligthly to unweathered, very slightly to unfractured, granite rock, very hard rock, coarse grained, massive, granite, Cape Peninsula Pluton, Cape Granite Suite. N/A 14 126 100 100 N/A 15 15.3 End of Log 16 NOTES 1: No samples. 2: 3: 4: CONTRACTOR: FAIRBROTHER GEO ENG MACHINE: LH 75 Drill rig INCLINATION: VERTICAL FILE REF: Template: SMEC BHLP03 DRILLING DATE: 06/03/2015 SMEC South Africa DATE LOGGED: 10/03/2015 Consulting Engineers LOGGED BY: R.FREESE CHECKED BY: E.ODENDAAL South Africa Prof Reg: 400051/14 Prof Reg: 400445/11 +27 (0)12 481 3800 www.smec.com Borehole 4, Box 1 of 3: 0-6.50m Borehole 4, Box 2 of 3: 6.5-12.5m Borehole 4, Box 3 of 3: 12.5-15.27m BOREHOLE LOG 0 Depth (m) Legend Sample Water No. of fract. SPT- N value RQD % Core size % Mat. recov. % Core recov. CLIENT: CCTMPM PROJECT: CLIFTON GARAGE GEOTECH PROJECT NO: JG0012 CLIENT NO: SITE: GLEN COUNTRY CLUB, CLIFTON KILOMETRE: 0.0 HOLE NO: CBH5 X COORD: E18,375299 Y COORD: S33,943880 ELEVATION: PAGE 1 of 1 Description Ground Surface Silty SAND Very moist, black to beige, voided. Fill. NWD4 26 1 NWD4 S P T 10 2 NWD4 W A S NWD4 S P T S H E L H 3 3.0 12 B Y 3.7 4 Gravelly, very clayey SAND Very moist, light brown, blotched white, mottled orange and black, relict granitic grain structure. Residual granite. NWD4 43 5 NWD4 S P T S H E L 11 6 B Y 7 NWD4 75 NWD4 S P T N/A 6.3 7.4 REF 100 100 N/A 9 NWD4 99 100 100 N/A 10 Gravelly, very silty SAND Very moist, light brown, blotched white, mottled orange, black, relict granitic grain structure. Residual granite. Silty SAND to GRAVEL Very moist, light orange brown, mottled white and black, relict granitic grain structure. Residual granite, interpreted to be saprolite ripped by drill bit. 8 NWD4 110 Sandy SILT Very moist, beige, mottled grey, intact. Residual granite. 10.0 Very hard rock GRANITE White, mottled black, unweathered, unfractured to very slightly fractured, coarse grained, Cape Peninsula Pluton Cape Granite Suite. End of Log 11 12 NOTES 1: Standing water level at 2.25m 2: Core sample at 8.65-9.0m 3: 4: CONTRACTOR: FAIRBROTHER GEO ENG MACHINE: HC 6000 Drill rig INCLINATION: VERTICAL FILE REF: Template: SMEC BHLP03 DRILLING DATE: 06/03/2015 SMEC South Africa DATE LOGGED: 10/03/2015 Consulting Engineers LOGGED BY: R.FREESE CHECKED BY: E.ODENDAAL South Africa Prof Reg: 400051/14 Prof Reg: 4400445/11 +27 (0)12 481 3800 www.smec.com Borehole 5, Box 1 of 2: 0-8.97m Borehole 5, Box 2 of 2: 8.97-10.0m BOREHOLE LOG 0 Depth (m) Legend Sample Water No. of fract. SPT- N value RQD % Core size % Mat. recov. % Core recov. CLIENT: CCTMPM PROJECT: CLIFTON GARAGE GEOTECH PROJECT NO: JG0012 CLIENT NO: SITE: GELN COUNTRY CLUB, CLIFTON KILOMETRE: 0.0 59 1 S P T T Ground Surface Clayey, sandy SILT Moist, beige, blotched red and grey, mottled yellow and black, intact. Residual granite. Clayey, silty SAND Moist, light grey and light brown, blotched white, mottled orange, black, relict granitic grain structure. Residual granite. 3 10 30 S Description 2.3 63 P X COORD: E18,375701 Y COORD: S33,943741 ELEVATION: PAGE 1 of 1 9 2 S HOLE NO: CBH6 4 P T 13 5 61 S P T 6 25 6.8 81 S 7 P T Clayey, silty SAND Moist, light brown, blotched white, mottled orange and black, intact, relict granitic granite structure. Residual granite becoming sandier with depth. 30 8 110 S P 9 T 27 T 55 93 S P 10 10.4 End of Log 11 12 NOTES 1: 1* FI sample at 3.0-4.5 2: 1*FI sample at 7.0-7.95 3: Standard water level at 4.125m 4: CONTRACTOR: FAIRBROTHER GEO ENG MACHINE: HC 6000 Drill rig INCLINATION: VERTICAL FILE REF: Template: SMEC BHLP03 DRILLING DATE: 06/03/2015 SMEC South Africa DATE LOGGED: 10/03/2015 Consulting Engineers LOGGED BY: R.FREESE CHECKED BY: E.ODENDAAL South Africa Prof Reg: 400051/14 Prof Reg: 400445/11 +27 (0)12 481 3800 www.smec.com Borehole 6, Box 1 of 2: 0-7.95m Borehole 6, Box 2 of 2: 7.95-10.45m Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report APPENDIX D: DRILLERS LOGS SMEC | SOUTH AFRICA | GEOTECHNICAL APPENDIX D Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report APPENDIX E: LABORATORY RESULTS SMEC | SOUTH AFRICA | GEOTECHNICAL APPENDIX E ROCKLAB REPORT 2015-SMEC-GEOTECHNICAL-01 CONFIDENTIAL Issued by: ROCKLAB (ROCK MECHANICS & EXCAVATION LABORATORIES) 230 ALBERTUS STREET LA MONTAGNE PRETORIA SOUTH AFRICA TEL: +27 12 481 3894 FAX: +27 12 481 3812 E-MAIL: CHENJ@ROCKLAB.CO.ZA RESULTS OF ROCK PROPERTIES TESTS Sampling Site: Clifton Garage BY DR J. F. CHEN Submitted to: SMEC GEOTECHNICAL 16 MARCH 2015 2 CONTENTS TABLE 1 RESULTS OF UNIAXIAL COMPRESSIVE STRENGTH TESTS TABLE 2 RESULTS OF ROCK POINT LOAD STRENGTH TESTS APPENDIX 1 FAILURE CODES OF ROCK COMPRESSION TESTS TABLE 1 RESULTS OF UNIAXIAL COMPRESSIVE STRENGTH TESTS Client: SMEC Sampling Site: Clifton Garage 2015/3/16 SPECIMEN PARTICULARS Rocklab Specimen No Borehole No 6121UCS-01 UCS-02 Note: SPECIMEN DIMENSIONS Depth From.. To.. m BH 3 BH 5 11.00 - 11.30 8.65 - 9.00 Rock Diameter Height Type mm mm 51.73 51.69 134.8 132.3 All tests were conducted according to the ISRM's Specification. Ratio of Height to diameter 2.6 2.6 SPECIMEN TEST RESULTS Mass Density Failure Load Strength (UCS) Failure Note Code g g/cm³ 732.7 740.2 2.59 2.67 kN 62.5 249.2 MPa 29.7 118.7 XA XA 1 - Sample was weathered. 1 TABLE 2 Client: RESULTS OF POINT LOAD STRENGTH TESTS SMEC SA SPECIMEN ROCKLAB Borehole Specimen No No 6095- PLT-01 PLT-02 PLT-03 PLT-04 Sampling Site: Clifton Garage PARTICULARS Sample Rock depth From.. To.. Type m BH 3 BH 5 BH 3 BH 1 11.00 - 11.30 8.65 - 9.00 9.40 - 9.80 5.85 - 6.10 Core Diameter D Height (mm) (mm) 51.85 51.85 51.85 51.85 51.85 51.85 51.65 51.65 51.65 51.65 51.65 51.65 51.77 51.77 51.77 51.77 51.77 51.77 51.77 51.77 51.77 51.77 52.03 52.03 52.03 52.03 52.03 52.03 52.03 52.03 52.03 52.03 Note: All tests were conducted according to the ISRM's suggested method. 1 - Diametrial loading, 2 - Axial Loading Core 16-03-2015 SPECIMEN TEST RESULTS Failue Equivalent Point Load Load Core Strength IS P Diameter (kN) (mm) (MPa) Corrected Test Code IS(50) (MPa) 27.23 27.95 31.40 6.01 3.65 2.41 2.20 1.06 1.85 51.85 51.85 51.85 42.40 42.96 45.53 2.23 1.36 0.89 1.22 0.57 0.89 2.27 1.38 0.91 1.14 0.54 0.85 1 1 1 2 2 2 26.28 23.73 26.58 21.12 21.73 12.20 4.67 8.75 5.99 51.65 51.65 51.65 41.57 39.50 41.81 7.91 8.14 4.57 2.70 5.60 3.42 8.03 8.26 4.64 2.49 5.04 3.16 1 1 1 2 2 2 27.44 23.79 24.62 24.33 28.23 10.10 13.17 11.55 13.10 8.28 5.50 4.13 2.02 2.10 4.50 51.77 51.77 51.77 51.77 51.77 42.53 39.60 40.28 40.05 43.14 3.77 4.91 4.31 4.89 3.09 3.04 2.63 1.24 1.31 2.42 3.83 4.99 4.38 4.96 3.14 2.82 2.37 1.13 1.18 2.26 1 1 1 1 1 2 2 2 2 2 28.01 26.68 25.33 25.51 25.31 12.01 6.86 7.55 11.71 13.00 4.57 6.21 6.56 4.97 7.02 52.03 52.03 52.03 52.03 52.03 43.08 42.04 40.96 41.11 40.95 4.43 2.53 2.79 4.32 4.80 2.46 3.51 3.91 2.94 4.19 4.51 2.58 2.84 4.40 4.89 2.30 3.25 3.57 2.69 3.83 1 1 1 1 1 2 2 2 2 2 Note APPENDIX 1 CLASSIFICATION OF ROCK SPECIMEN FAILURE MODE INFLUENCED / NOT INFLUENCED BY DISCONTINUITIES DURING COMPRESSION TESTING FAILURE NOT INFLUENCED BY DISCONTINUITIES (INTACT) DESCRIPTION OF SUB CODES TYPE CODE A B X SLIDING SHEAR FAILURE COMPLETE CONE DEVELOPMENT Y SPLITTING BREAKING INTO A LOT OF PIECES FAILURE INFLUENCED BY DISCONTINUITIES DESCRIPTION OF SUB CODES TYPE CODE A B PARTIAL FAILURE ON DISCONTINUITY FAILURE COMPLETELY ON DISCONTINUITY ◦ ◦ 1 AT 0-10 TO AXIS AT 0-10 TO AXIS 2 AT 11-20 TO AXIS ◦ AT 11-20 TO AXIS 3 AT 21-30 TO AXIS ◦ AT 21-30 TO AXIS 4 AT 31-40◦ TO AXIS AT 31-40◦ TO AXIS 5 AT 41-50 TO AXIS ◦ AT 41-50 TO AXIS 6 AT 51-70 TO AXIS ◦ AT 51-70 TO AXIS 7 AT 71-90 TO AXIS ◦ AT 71-90 TO AXIS 0 Multiple Discontinuities Multiple Discontinuities ◦ ◦ ◦ ◦ ◦ Example: Failure Type3B: Failure completely on a discontinuity with an orientation of ◦ ◦ between 21 and 30 to the specimen axis. Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report APPENDIX F: ELECTRICAL RESISTIVITY SURVEY RESULTS SMEC | SOUTH AFRICA | GEOTECHNICAL APPENDIX F ENGINEERING & EXPLORATION GEOPHYSICAL SERVICES CC CK94/10526/23 Geophysical Contractors 170 Jakaranda Street, Doringkloof, Gauteng,0157 012 - 6673369 (tel.) 6675186(fax) E-mail: eegs@iafrica.com 4th April, 2015 SMEC South Africa (Pty) Ltd, P O Box 72927, Lynwood Ridge 0040 Attn: Mr. Ryan Freese Dear Sir, GLEN COUNTRY CLUB RESISTIVITY SURVEY 1. Introduction The methods and results are given here of a geophysical survey carried out in Clifton around the bowling greens of the Glen Country Club. The object of the survey is map changes in bedrock elevation. Several boreholes have been drilled around the club, where an underground garage is planned, but additional information is desired. As the condition of the greens is sensitive to any activity other than bowling, resistivity was chosen as the least intrusive method with which to acquire that information. The country rock is granite and a well-defined electrical contrast between moist overburden and underlying rock was expected. Fieldwork was performed on the 30th and 31st March. Traverses were carried out around the perimeter of the greens and on walkways separating them to obtain six resistivity profiles. 2. Instrumentation, data collection methods and reduction procedure 2.1 Instrumentation An ABEM LS resistivity meter was employed for the work. The ABEM system automates data collection by accessing multiple electrodes through a multicore cable so that several hundred readings reflecting both lateral and vertical changes in resistivity are collected in a reasonable time. The data are stored in the resistivity meter. 2.2 Data collection A Schlumberger-Wenner configuration was used on the two longest perimeter lines, which are 120 metres in length, whilst a dipole-dipole configuration was used for the four 40 metre long cross lines, the latter so that a slightly better exploration depth could be achieved, though at the expense of a higher noise level. The electrode separation was one metre. As the surveyed area is flat, no measurements of elevation differences along the traverses were required. 2.3 Data reduction and presentation Outliers were removed from the apparent resistivity data prior to modelling using Res2Dinv. A common colour scale was chosen for all the models to allow better comparison of the sections. 3. Results The locations of the traverses are shown on figure 1 and the models are presented in figures 2 and 3. The model for ER1 shows a resistive basement, except in the north where it descends below the coverage of the model (figure 2). The basement surface is mostly horizontal, between six to eight metres below ground level with steps separating different levels, but its course is interrupted by two pinnacles. Above basement is a conductor with embedded blocks of higher resistivity. Inland, on ER3, the well-defined basement is absent; instead there are three resistive blocks projecting upward into an otherwise conductive layer (figure 2). As the connecting lines are short, the exploration depth is reduced to about six metres, or about the level of the shallowest depth to basement. Despite the lack of penetration a suggestion of basement is visible on ER2 and ER5, and perhaps at the western end of ER6, but it is absent on ER2 (figure 3). Otherwise, these models are characterised by a conductor encompassing occasional resistive blocks, capped by a surfical resistor of varying thickness. The conductor is expected to be moist sand, the resistive blocks in the conductor perhaps boulders and the surficial resistor dry compact soil. Resistive basement is taken to be rock, an interpretation that agrees with the depth to granite recorded in a draft log for BH3. Rock head appears to get deeper towards the east, that is inland. The pinnacles may be a conglomeration of boulders resting on basement. Yours sincerely, R.W.Day. Pr.Sci.Nat. ER5 E R2 ER3 E R1 BH4 ER4 ER6 BH5 BH6 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report APPENDIX G: BOREHOLE PUMP TEST RESULTS SMEC | SOUTH AFRICA | GEOTECHNICAL APPENDIX G PUMP TEST ON BH4 TIME STARTED: 09H00 WATER LEVEL: 3.650 @08H30 FLOW METER READING:9068 TIME (min) DROP (m) 1 1 1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6 6,5 7 7,5 8 8,5 9 9,5 10 11 12 13 14 15 16 17 18 19 20 22 24 26 28 30 35 40 45 50 55 60 65 3,65 4,85 5,19 5,26 5,22 5,25 5,23 5,23 5,23 5,22 5,20 5,26 5,27 5,35 5,47 5,40 5,33 5,34 5,36 5,42 5,44 5,42 5,45 5,54 5,52 5,49 5,45 5,46 5,48 5,50 5,52 5,54 5,55 5,33 5,35 5,30 5,33 5,45 5,31 5,20 5,24 5,23 5,02 FLOW VOLUME (l) RECOVERY (m) FLOW DIFFERENTIAL(l) Flow Rate l/sec 906,80 4.73 0,00 0,00000 907,2 4.73 0,40 #DIV/0! 908,9 4.46 1,70 #DIV/0! 909,3 4,35 0,40 0,01333 909,6 4,29 0,30 0,01000 910,2 4,25 0,60 0,02000 910,6 4,22 0,40 0,01333 911,1 4,22 0,50 0,01667 911,6 4,10 0,50 0,01667 912,0 4,18 0,40 0,01333 912,8 4,17 0,80 0,02667 913,2 4,17 0,40 0,01333 913,5 4,16 0,30 0,01000 914,1 4,16 0,60 0,02000 914,7 4,16 0,60 0,02000 915,2 4,15 0,50 0,01667 915,4 4,14 0,20 0,00667 915,7 4,14 0,30 0,01000 916,3 4,14 0,60 0,02000 916,8 4,14 0,50 0,01667 917,3 4,14 0,50 0,01667 918,2 4,13 0,90 0,01500 919,2 4,12 1,00 0,01667 920,2 4,11 1,00 0,01667 921,2 4,11 1,00 0,01667 922,2 4,10 1,00 0,01667 923,0 4,10 0,80 0,01333 923,8 4,10 0,80 0,01333 924,8 4,090 1,00 0,01667 925,8 4,085 1,00 0,01667 926,8 4,085 1,00 0,01667 927,7 4,075 0,90 0,00750 929,5 4,065 1,80 0,01500 931,0 4,060 1,50 0,01250 932,8 4,050 1,80 0,01500 934,3 4,040 1,50 0,01250 938,2 4,030 3,90 0,01300 943,4 4,020 5,20 0,01733 946,6 4,015 3,20 0,01067 950,0 4,015 3,40 0,01133 953,4 4,010 3,40 0,01133 956,2 4,005 2,80 0,00933 959,8 4,00 3,60 0,01200 Flow rate m3/sec 0,00E+00 #DIV/0! #DIV/0! 1,33E-05 1,00E-05 2,00E-05 1,33E-05 1,67E-05 1,67E-05 1,33E-05 2,67E-05 1,33E-05 1,00E-05 2,00E-05 2,00E-05 1,67E-05 6,67E-06 1,00E-05 2,00E-05 1,67E-05 1,67E-05 1,50E-05 1,67E-05 1,67E-05 1,67E-05 1,67E-05 1,33E-05 1,33E-05 1,67E-05 1,67E-05 1,67E-05 7,50E-06 1,50E-05 1,25E-05 1,50E-05 1,25E-05 1,30E-05 1,73E-05 1,07E-05 1,13E-05 1,13E-05 9,33E-06 1,20E-05 70 75 80 85 90 95 100 120 140 160 180 210 240 270 300 360 5,23 5,47 5,43 5,44 5,43 5,43 5,43 5,42 5,43 5,43 5,43 5,42 5,43 5,43 5,43 5,43 962,3 966,3 970,3 973,2 976,3 979,2 982,0 992,4 1008,8 1021,3 1033,7 1055,1 1075,3 1096,2 1117,6 1155,0 3,99 3,980 3,980 3,975 3,965 3,965 3,960 3,880 3,880 3,710 3,68 3,68 3,660 2,50 4,00 4,00 2,90 3,10 2,90 2,80 10,40 16,40 12,50 12,40 21,40 20,20 20,90 21,40 37,40 AVG 0,00833 0,01333 0,01333 0,00967 0,01033 0,00967 0,00933 0,00867 0,01367 0,01042 0,01033 0,01189 0,01122 0,01161 0,01189 0,01039 0,01357 8,33E-06 1,33E-05 1,33E-05 9,67E-06 1,03E-05 9,67E-06 9,33E-06 8,67E-06 1,37E-05 1,04E-05 1,03E-05 1,19E-05 1,12E-05 1,16E-05 1,19E-05 1,04E-05 1,36E-05 1,36E-05 PUMP TEST ON BH3 TIME STARTED: 08H00 WATER LEVEL: 4.555 @08H30 FLOW METER READING:1161.6 Litres TIME(min) DROP(m) 1 4,56 1 6,43 1,5 8,40 2 8,55 2,5 8,64 3 8,66 3,5 8,68 4 8,70 4,5 8,72 5 8,73 5,5 8,74 6 8,75 6,5 8,75 7 8,76 7,5 8,77 8 8,78 8,5 8,78 9 8,78 9,5 8,78 10 8,79 110 8,79 12 8,80 13 8,80 14 8,81 15 8,81 16 8,81 17 8,82 18 8,82 19 8,83 20 8,83 22 8,84 24 8,85 26 8,85 28 8,85 30 8,86 35 8,88 40 8,89 45 8,90 50 8,91 55 8,92 60 8,92 65 8,93 FLOW VOLUME FLOW (l) RECOVERY (m) DIFFERENTIAL(l)Flow Rate l/sec 1161,60 8,12 0 #VALUE! 1162,1 8,12 0,50 #DIV/0! 1163,7 6,23 1,60 0,05333 1164,3 6,14 0,60 0,02000 1165,0 6,01 0,70 0,02333 1165,7 5,92 0,70 0,02333 1166,4 5,83 0,70 0,02333 1167,1 5,77 0,70 0,02333 1167,9 5,75 0,80 0,02667 1168,4 5,71 0,50 0,01667 1169,2 5,70 0,80 0,02667 1169,9 5,68 0,70 0,02333 1170,5 5,66 0,60 0,02000 1171,2 5,65 0,70 0,02333 1171,9 5,64 0,70 0,02333 1172,5 5,63 0,60 0,02000 1173,2 5,61 0,70 0,02333 1173,9 5,60 0,70 0,02333 1174,6 5,59 0,70 0,02333 1175,2 5,59 0,60 0,02000 1176,5 5,58 1,30 0,00022 1177,3 5,56 0,80 -0,00014 1177,8 5,45 0,50 0,00833 1179,1 5,43 1,30 0,02167 1180,4 5,52 1,30 0,02167 1181,7 5,51 1,30 0,02167 1183,0 0,55 1,30 0,02167 1184,4 5,49 1,40 0,02333 1185,6 5,48 1,20 0,02000 1186,9 5,48 1,30 0,02167 1189,9 5,46 3,00 0,02500 1192,6 5,44 2,70 0,02250 1195,0 5,44 2,40 0,02000 1197,6 5,43 2,60 0,02167 1200,1 5,42 2,50 0,02083 1206,4 5,40 6,30 0,02100 1212,8 5,37 6,40 0,02133 1219,0 5,35 6,20 0,02067 1225,3 5,33 6,30 0,02100 1231,4 5,32 6,10 0,02033 1237,7 5,31 6,30 0,02100 1247,7 5,30 10,00 0,03333 Flow rate m3/sec #VALUE! #DIV/0! 5,33E-05 2,00E-05 2,33E-05 2,33E-05 2,33E-05 2,33E-05 2,67E-05 1,67E-05 2,67E-05 2,33E-05 2,00E-05 2,33E-05 2,33E-05 2,00E-05 2,33E-05 2,33E-05 2,33E-05 2,00E-05 2,17E-07 -1,36E-07 8,33E-06 2,17E-05 2,17E-05 2,17E-05 2,17E-05 2,33E-05 2,00E-05 2,17E-05 2,50E-05 2,25E-05 2,00E-05 2,17E-05 2,08E-05 2,10E-05 2,13E-05 2,07E-05 2,10E-05 2,03E-05 2,10E-05 3,33E-05 70 75 80 85 90 95 100 120 140 160 180 210 240 270 300 360 420 8,94 8,95 8,96 8,96 8,96 8,97 8,98 8,98 9,00 9,15 9,02 8,67 9,05 9,05 9,05 9,05 9,05 1255,00 1256,1 1262,2 1268,2 1274,3 1280,5 1287,4 1309,0 1333,7 1356,3 1380,0 1414,0 1447,4 1478,5 1513,9 1580,1 1646,5 5,29 5,28 5,28 5,27 5,26 5,24 5,23 5,20 5,18 5,15 5,12 7,30 1,10 6,10 6,00 6,10 6,20 6,90 21,60 24,70 22,60 23,70 34,00 33,40 31,10 35,40 66,20 66,40 AVG 0,02433 0,00367 0,02033 0,02000 0,02033 0,02067 0,02300 0,01800 0,02058 0,01883 0,01975 0,01889 0,01856 0,01728 0,01967 0,01839 0,01844 0,02081 2,43E-05 3,67E-06 2,03E-05 2,00E-05 2,03E-05 2,07E-05 2,30E-05 1,80E-05 2,06E-05 1,88E-05 1,98E-05 1,89E-05 1,86E-05 1,73E-05 1,97E-05 1,84E-05 1,84E-05 2,08E-05 BH4 Pump Test Results Log Time (Minutes) 1 10 100 1000 0,00 Drawdown (meters) 1,00 2,00 3,00 4,00 5,00 6,00 BH3 Pump Test Results Log Time (Minutes) 1 0,00 Drawdown (meters) 1,00 2,00 3,00 4,00 5,00 6,00 7,00 8,00 9,00 10,00 10 100 1000 Clifton Garage Geotechnical Investigation Interpretive Geotechnical Report APPENDIX H: SITE CROSS-SECTIONS SMEC | SOUTH AFRICA | GEOTECHNICAL APPENDIX H LEGEND GEOLOGICAL UNIT FILL / HILLWASH RESIDUAL GRANITE GRANITIC ROCK GROUND WATER LEVEL CLIENT No. REVISIONS DATE DRG SIZE SCALE A3 NTS DESIGNED 267 Kent Avenue, Randburg P.O. Box 1462, Pinegowrie, South Africa, 2123 Website: //www.smec.com Tel. (011) 369-0600 Fax (011) 886-4589 DATE DRAWN PROJECT PROJECT NO PHASE DISCIPLINE STAGE CHECKED Pequenino DRAWING DISCRIPTION DRAWN CHECKED DRAWING NUMBER DOC TYPE TYPE LEVEL NUMBER L/O REVISION LEGEND GEOLOGICAL UNIT FILL / HILLWASH RESIDUAL GRANITE GRANITIC ROCK GROUND WATER LEVEL CLIENT No. REVISIONS DATE DRG SIZE SCALE A3 NTS DESIGNED 267 Kent Avenue, Randburg P.O. Box 1462, Pinegowrie, South Africa, 2123 Website: //www.smec.com Tel. (011) 369-0600 Fax (011) 886-4589 DATE DRAWN PROJECT PROJECT NO PHASE DISCIPLINE STAGE CHECKED Pequenino DRAWING DISCRIPTION DRAWN CHECKED DRAWING NUMBER DOC TYPE TYPE LEVEL NUMBER L/O REVISION LEGEND GEOLOGICAL UNIT FILL / HILLWASH RESIDUAL GRANITE GRANITIC ROCK LOCATION OF CROSS SECTIONS CLIENT GROUND WATER LEVEL No. REVISIONS DATE DRG SIZE SCALE A3 NTS DESIGNED 267 Kent Avenue, Randburg P.O. Box 1462, Pinegowrie, South Africa, 2123 Website: //www.smec.com Tel. (011) 369-0600 Fax (011) 886-4589 DATE DRAWN PROJECT PROJECT NO PHASE DISCIPLINE STAGE CHECKED Pequenino DRAWING DISCRIPTION DRAWN CHECKED DRAWING NUMBER DOC TYPE TYPE LEVEL NUMBER L/O REVISION