Introduction SAP Material Planning

Introduction SAP Material

Planning

Dr. Djamal Ziani

King Saud University

Organizational Level in Material

Planning

• Client

• Company code

• Plant

• Storage location

Master Data Used

• Material Master

• Bill Of Material (BOM)

• Routings

Material Master

Material Type

• Raw materials

• Operating supplies

• Semi-finished products

• Finished products

Bill of Material (BOM)

• The BOM contains the assemblies or components, to be included in the production of a material.

• Used in MRP, production, procurement and for product costing

Bill of Material (BOM)

• The BOM are single level.

• The items of the BOM can themselves contain further BOM

Bill of Material (BOM)

• Plant: is the plant for which you wish to create or process the BOM. You can assign more than one plant.

• Alternative BOM: For distinguish the different BOM for the same material

• BOM usage: Where you want to use the BOM (production, engineering, costing…)

Routings

• Routings contain the steps that are necessary for production:

– The corresponding operations

– The sequence

– Work center in which these operations are to be executed

– Time elements that are relevant for scheduling the operations

Routings

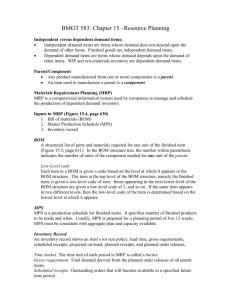

MRP: Material Requirement Planning

• The system calculates the quantity required to continue the sales of the final product without any delays, considering the following resources:

– Stock on hand.

– Receipts: purchase orders, production orders (for the parent item)

• The system then subtracts the following requirements:

– Sales orders

– Forecasts

– Production orders (for the child items)

– A/R reserve invoices

• The system uses the planning policy to make the production/purchase order recommendations. The planning policy is based on:

– Lead time, Minimum amount ,, Time intervals

•

Complete production orders for the parent item, quantities of the child items that comprise the BOM are needed. The system calculates the quantity of the child items, taking the MRP-dependent requirements into account. The system then recommends purchase/ production orders for the child items required for producing the parent item.

MRP: Material Requirement Planning

MRP

MRP-Processing Key

• NEUPL : Regenerative Planning. It will process ALL materials, disregards the fact whether or not planning relevant changes were made to the material.

• For NETCH and NETPL: the system take into consideration only changes that are relevant for planning a material (like sales order entry, purchase order entry, stock release, etc.).

– NETCH : Net Change Planning

– NETPL : Net Change Planning within Planning Horizon. if a change occurs outside the planning horizon (e.g. a sales order is entered 2 months away and your planning horizon is 6 weeks), then the material is not included in MRP even though there is a change.