Management of Production Planning Data

Management of Production

Planning Data

By

Medimi Harita

Mrt Nr:206760

1

Overview

• Introduction

• SAP ERP Systems

• Production Planning Basic data

• Material Master

• Bill of Material (BOM)

• Work Center

• Capacity

• Routing

• Production resoures

• DELMIA

• Conclusions

Introduction

Production planning is nothing but managment of sales,procurement,qulity,maintance, project,human capital,finance and controlling functions of the campany.

• Industries have different information indivitual specialized systems.

• Customized information systems.

• SAP ERP systems plays a critical role.

• CAD is also another Production planning tool used in many industries.

• DELMIA is a digital manufacturing tool to designing and planning

3

SAP ERP

• ERP is an integrated information system

• Can be accessed by many branches of an Industry

• Change made by any user is immediately seen by any other users

• Centralized data base managed system

4

Production planning basic data

routing materials

Work center

Production facillites

PP Basic data

Production resourse capacities

Inspection plans

Bill of material

5

Material master

• Material master team coordinates with the client

• Aggrements for configuration objects (type or quality)

• Material master contains the basic information to manage the material .

• Information is used through various departments.

• Material description and base unit for measure is visible to all departments.

6

MRP

Accouting

Forecasting

Branches

Work

Scheduling

Material master record

Storage

Quality management

7

To set up the attributes of material types, follow the configuration

(Transaction SPRO) menu path Logistics – General Material Master

Basic Settings Material Types Define Attributes of Material Types.

8

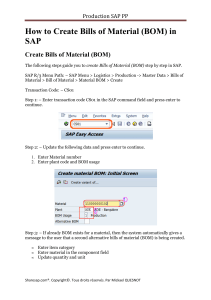

Bill of Material (BOM)

• A bill of material is a complete, formally structured list of the components that make up a product or assembly.

• The list contains the object number of each component, together with the quantity and unit of measure.

• It contains the information about the integrated material management and control.

• It can be divided in to simple, variant and multiple BOMS

9

BOM Usage

• The design department can base their work according to BOM .

• The production BOM includes all the items required from the production and assembly point of view.

• To assemble a product, only items required which are relevant to production.

• The costing BOM describes the product structure and is used to automatically determine the costs of the materials required for a product.

• Items that are not relevant to costing are not included in the costing

BOM.

10

Typical BOM overview Tab

11

Work Center

• Work center is a place where a machine or group of machines, persons or group of persons add value to the production manufacturing process.

• Production and Production costs teams togehter decides number of work centers needed.

• Formulas are defined in Work center those can be used in capacity requirements planning (CRP), Scheduling and costing.

12

Work Center (contd..)

• Standard value key: Standard values are planned values for the excution of an opertion and are maintained in the operation.

• Performance Efficiency rate key=

Individuals actual output/planned averaged output

13

capacity

• Capacity planning enables the use of the production resoures

• Standard Available capacity :

It‘s used for calculating execution time.

• It is indepenant on order

• It has fixed working time

• Unit of Available capacity

• Time

• In any unit it is expressed in numers

14

Routing

Describes

• Various operations involved

• Proper ordering of the individual operations

• Locations of various work centers

• Standard value keys

• Formulas

• Performance keys

15

Production Resource

• Movable machinary

• Each of the resource is assigned for particular application

Production Facility

• Layout

• Design

• Location

16

DELMIA

• Digital manufacturing tool for production planning

• 3DExperience platform

• Provides real time visibility accross manufacturing operations

• Process simulations

17

DELMIA (Contd..)

• Improves the resource management

• Manage operations as a cohesive whole

• Responds faster to un expected events

• Reduce the operational costs

• Continuously improve products and processes

• Maintain 24x7 operations

• Impliment global manaufacturing best practices

18

Conclusions

• Process planning is an integral component of Product life cycle management

• There are various number of tools are existing in market

• SAP –PLM is one of the most sophisticated sytem for the process planning and design

• SAP ERP is integrated information system to interlink among various components in production planning

• DALMIA is more robust and cost effective system where 3D experience and simulaions are possible

19

References

• SAP ERP guide

• Production planning and control with SAP ERP. Javed Aktar,

Galileo press.

• DELMIA user manual

20

Thank you

21