Quality Management Standards

advertisement

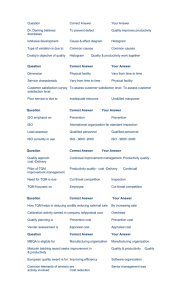

Quality Management Standards 1 THE ISO 9000 FAMILY ISO 9000: 2005 • Identifies the fundamentals and vocabulary for Quality Management Systems (QMS) ISO 9001:2008 • Specifies requirements for a QMS where capability to provide product that meets customer and regulatory requirements needs to be demonstrated ISO 9004:2009 • Provides guidance on QMS that contributes to the satisfaction of customers and other interested parties 2 ISO 9000 : 2008 Eight quality management principles 1. 2. 3. 4. 5. 6. 7. 8. Customer focus Leadership Involvement of people Process approach System approach to management Continual improvement Factual approach to decision making Mutually beneficial supplier relationships 3 ISO 9001:2008 CONTINUAL IMPROVEMENT OF THE QUALITY MANAGEMENT SYSTEM Management responsibility Customers Clause 5 Customers Measurement, Resource Clause 6 Clause 8 analysis and management improvement Satisfaction Clause 7 Requirements Input Product realization Value adding activities Information flow Product Output PROCESS REQUIREMENTS With What? (Materials / Equipment) Inputs How Many? (Measurement / Controls) Objectives and Targets Business Process Process Linkages WHO? Special Skills? / Competence? Outputs How? (Methods/Procedures) 5 Source: AIAG ISO/TS 16949:2002 Implementation Guide SCOPE OF STANDARD 1. Scope General Application 2. Normative reference 3. Terms and definition e.g., Supplier Organization Customer 6 QUALITY MANAGEMENT SYSTEM REQUIREMENTS 4.1 General requirements Document, implement, maintain and continually improve Identify and determine sequence and interaction of processes Determine criteria and methods needed Ensure availability of resources Monitor, measure and analyze processes Implement actions to achieve planned results 7 QUALITY MANAGEMENT SYSTEM REQUIREMENTS 4.2 Documentation requirements Management system documentation Quality Manual Control of documents Control of records 8 MANAGEMENT RESPONSIBILITY 5.1 Management commitment 5.2 Customer focus 5.3 Quality policy Must be documented Must be used for setting objectives 5.4 Planning Document objectives- Must be Measurable Quality management system planning 9 MANAGEMENT RESPONSIBILITY 5.5 Responsibility, authority and communication Responsibility and authority Management representative Internal communication 10 MANAGEMENT RESPONSIBILITY 5.6 Management Review General Review input Review output 11 RESOURCE MANAGEMENT 6.1 Provision of resources 6.2 Human resources General Competence, awareness and training 6.3 Infrastructure 6.4 Work environment 12 PRODUCT REALIZATION 7.1 Planning of product realization 7.2 Customer-related processes Determination of requirements related to the product Review of requirements related to the product Customer communication 13 PRODUCT REALIZATION 7.3 Design and development Planning, inputs, outputs, systematic reviews, verification and validation, control of changes 7.4 Purchasing Supplier evaluation and selection Relevant purchasing information Verification of purchased product - receiving, source 14 PRODUCT REALIZATION 7.5 Production and service provision Controlled conditions including product characteristics, work instructions (as necessary), suitable equipment, monitoring and measuring devices, monitoring and measurement, and release, delivery and post- delivery activities Validation of processes when no other method Identification and traceability of product and it’s status Care of customer property Preservation of product Includes constituent parts 15 PRODUCT REALIZATION 7.6 Control of monitoring and measuring devices Calibrated or verified where necessary Adjusted and re-adjusted as necessary Identified to enable calibration status Safeguarded from invalid adjustment Protected from damage and deterioration 16 MEASUREMENT, ANALYSIS, AND IMPROVEMENT 8.1 General 8.2 Monitoring and measurement Customer satisfaction Internal audit Monitoring and measurement of processes Monitoring and measurement of product 17 MEASUREMENT, ANALYSIS, AND IMPROVEMENT 8.3 Control of nonconforming product 8.4 Analysis of data 8.5 Improvement Continual improvement Corrective action Preventive action 18 ISO 9001:2008 A Structured Approach to Quality Management 19 Documented Systems 20 QUALITY SYSTEM DOCUMENTATION STRUCTURE 1st Level Quality Manual 2nd Level Procedures 3rd Level Work Instructions Machine instructions Computer inputs Detailed work instructions Policy and Objectives What the company wishes to achieve How the company implements its policy Structured to reflect process flow of events 4th Level Detailed instructions How to complete a job or task Technical Data International standards Computer operating manuals DetailedDiaco product specifications Inc. asahi515874@comcast.net 505 780-3185 21 TQM • TOTAL QUALITY MANAGEMENT TQM Total quality management is a systemic approach to productivity improvement using qualitative and quantitative methods and involving all stakeholders to continuously improve the quality of all products and services. TQM • IS THE SET OF MANAGEMENT PROCESSES AND SYSTEMS THAT CREATE DELIGHTED CUSTOMERS THROUGH EMPOWERED EMPLOYEES, LEADING TO HIGHER REVENUES & LOWER COST THE JURAN INSTITUTE, Inc. TQM • It is the process of individual & organizational development the purpose of which is to increase the level of satisfaction of all the stakeholders PIKE, R J BARNES WHY TQM? B/C IT IS FOR BENEFIT OF ALL STAKEHOLDERS • INTERNAL SATKEHOLDER • EXTERNAL STAKEHOLDER COMPONENTS OF TQM 1. 2. 3. 4. PRICE REDUCTION CUSTOMER SATISFACTION INVOLVEMENT OF EVERYONE CONTINUOUS QUALITY IMPROVEMENT 5. LEADERSHIP PRICE REDUCTION • COST AN ESSENTIAL ELEMENT OF TQM • CROSBY PHILOSPHY QUALITY IS FREE QLTY IS THE RIGHT OF CUSTOMER Who determines quality? THE CUSTOMER If the customer does not perceive you as offering quality service you are not. INVOLVEMENT OF EVERYONE CONTINUOUS IMPROVEMENT • Improve each and everyday - Do not focus on problems, focus on improvements. • IF YOU’RE NOT PART OF THE SOLUTION, YOU’RE PART OF THE PROBLEM. CONTINUOUS IMPROVEMENT • Customers are not interested in excuses, they’re interested in results. • Be proactive - because if you don’t someone else will. • Ishikawa Says The organization which does not make a change in the 06 months is a dead organizations LEADERSHIP • NO EFFORT FOR QUALITY IMPROVEMENT CAN SUCCEED WITHOUT COMMITMENT OF TOP MANAGEMENT LEADERSHIP A NATION WITHOUT LEADERSHIP IS THE HERD OF SWINE EINSTEIN