Continuous Improvement

advertisement

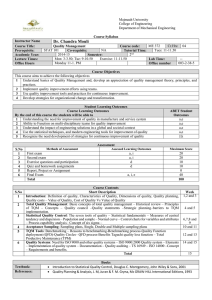

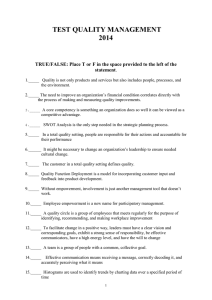

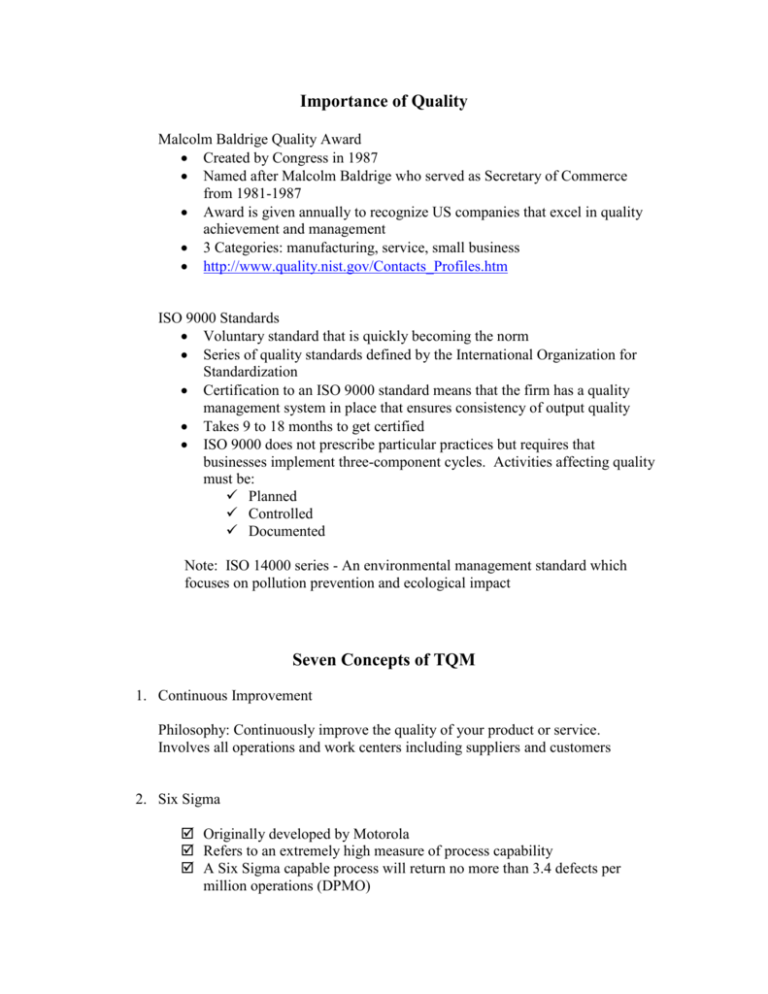

Importance of Quality Malcolm Baldrige Quality Award Created by Congress in 1987 Named after Malcolm Baldrige who served as Secretary of Commerce from 1981-1987 Award is given annually to recognize US companies that excel in quality achievement and management 3 Categories: manufacturing, service, small business http://www.quality.nist.gov/Contacts_Profiles.htm ISO 9000 Standards Voluntary standard that is quickly becoming the norm Series of quality standards defined by the International Organization for Standardization Certification to an ISO 9000 standard means that the firm has a quality management system in place that ensures consistency of output quality Takes 9 to 18 months to get certified ISO 9000 does not prescribe particular practices but requires that businesses implement three-component cycles. Activities affecting quality must be: Planned Controlled Documented Note: ISO 14000 series - An environmental management standard which focuses on pollution prevention and ecological impact Seven Concepts of TQM 1. Continuous Improvement Philosophy: Continuously improve the quality of your product or service. Involves all operations and work centers including suppliers and customers 2. Six Sigma Originally developed by Motorola Refers to an extremely high measure of process capability A Six Sigma capable process will return no more than 3.4 defects per million operations (DPMO) Utilizes a highly structured approach to process improvement Requires the commitment of top management Utilizes corporate sponsors (Champions) Provides extensive training to employees Sets stretch goals 3. Employee Empowerment Getting employees involved in product and process improvements 85% of quality problems are due to process and material Techniques Build communication networks that include employees Develop open, supportive supervisors Move responsibility to employees Build a high-morale organization Create formal team structures Quality Circles Group of employees who meet regularly to solve problems Trained in planning, problem solving, and statistical methods Often led by a facilitator Very effective when done properly 4. Benchmarking The basic premise behind benchmarking is that to deliver quality, you need to compare your business against the “best in class” business and then make changes to your operation so that quality is enhanced. Benchmarking is the process of determining who is the very best, who sets the standard, and what that standard is. 5. Just-in-time (JIT) ‘Pull’ system of production scheduling including supply management Production only when signaled Allows reduced inventory levels Inventory costs money and hides process and material problems Encourages improved process and product quality 6. Taguchi Concepts (aka Robust Design) and others Taguschi Pioneered by Dr. Genichi Taguchi Basic fundamental thinking behind the Robust Design method is to develop products that hold up to adverse conditions (i.e., telephones are designed to be dropped because this commonly happens) If we want to apply this quality principle to service, we should plan for the worst when designing our service. When the adverse condition occurs, we can maintain the quality in our service. Example: if we are going to build a grocery store (typically these stores depend on a high volume of sales to make money), then the facility should be designed for heavy traffic. Shelves should be sturdy, flooring should facilitate the movement of wagons, the layout should promote quick movement through the facility, and shelves should be restocked quickly. To insure quality, we look at the worst case scenario (i.e., a pending hurricane) and plan for it so that quality is maintained during these times. Poka-Yoke (pronounced POH-kah YOH-kay) Also know as failsafing or mistake-proofing Poka-yoke is Japanese for mistake-proofing This approach was developed by Shigeo Shingo, an industrial engineer at Toyota A poka-yoke device is any mechanism that either prevents a mistake from being made or makes the mistake obvious at a glance. He observed that errors occurred, not because employees were incompetent, but because of interruptions in routine or lapses of attention. If we want to apply this quality principle to service, we need to look at where errors occur in service delivery and develop methods that will ensure that these errors do not occur. Example: The french fry scoop at McDonalds measures a consistent serving of potatoes. If the scoop was not used, french fry orders would all look different. Some would be half-full (lead to disgruntled and hungry customers) and some would be bulging over the top (stray fries would fall on the floor and change the aesthetics of cleanliness). Quality Function Deployment (QFD) Developed in Japan and used at Toyota Underlying idea is that customer input is important in product design The process results in a comprehensive matrix called the “house of quality” used to document information, perceptions, and decision. Quality Function Deployment (QFD) uses a set of powerful product development tools originally designed to transfer the concepts of quality control from the manufacturing process into the new product development process. To apply this idea to service, we would seek customer input before establishing a new service. Example: Market surveys 7. Knowledge of TQM tools Deming’s Plan-Do-Check-Act (PDCA) Cycle Plan – select and analyze the problem Histograms Scatter Plots Pareto charts Flowcharts Cause and effect diagrams Control charts Do – implement the solution Check – check the results of the change Act – act to standardize the solution for the long-term