Thursday Night Operations Management

advertisement

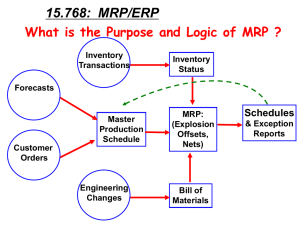

Thursday Night Operations Management Class 7 Chapter 14 Resource Planning Enterprise Resource Planning (ERP) Organizes and manages a company’s business processes by sharing information across functional areas Connects with supply-chain and customer management applications Largest ERP provider SAP ERP Modules ERP’s Central Database Finance & Accounting Sales & Marketing ERP Data Repository Human Resources Production & Materials Management ERP Implementation First step is to analyze business processes Which processes have the biggest impact on customer relations? Which process would benefit the most from integration? Which processes should be standardized? Customer Relationship Management (CRM) Plans and executes business processes that involve customer interaction Changes focus from managing products to managing customers Point-of-sale data is analyzed for patterns used to predict future behavior Supply Chain Management Supply chain planning Supply chain execution Supplier relationships Distinctions between ERP and SCM are becoming increasingly blurred ERP and MRP MRP (material requirements planning) was the precursor to ERP Primarily a production planning and control system MRP evolved to MRP II (manufacturing resource planning) ERP and ERP II continue to extend the links through all business processes Material Requirements Planning Computerized inventory control & production planning system Schedules component items when they are needed - no earlier and no later When to Use MRP Dependent and discrete items Complex products Job shop production Assemble-to-order environments Material Requirements Planning Product structure file Master production schedule Material requirements planning Item master file Planned order releases Work orders Purchase orders Rescheduling notices Master Production Schedule Drives MRP process with a schedule of finished products Quantities represent production not demand Quantities may consist of a combination of customer orders & demand forecasts Quantities represent what needs to be produced, not what can be produced Basic MRP Processes 1. Exploding the bill of material 2. Netting out inventory 3. Lot sizing 4. Time-phasing requirements MRP Outputs Planned orders Work orders Purchase orders Changes to previous plans or existing schedules Action notices Rescheduling notices Capacity Terms Load profile Compares released and planned orders with work center capacity Capacity Productive capability; includes utilization and efficiency Utilization % of available working time spent working More Capacity Terms Efficiency – how well the machine or worker performs compared to a standard output Load The standard hours of work assigned to a facility Load percent The ratio of load to capacity Load % = (load/capacity)x100% Capacity Requirements Planning MRP planned order releases Routing file Capacity requirements planning Load profile for each machine center Open orders file Hours of capacity Initial Load Profile 120 – 110 – 100 – 90 – 80 – 70 – 60 – 50 – 40 – 30 – 20 – 10 – 0– Normal capacity 1 2 3 4 Time (weeks) 5 6 Remedies for Underloads 1. Acquire more work 2. Pull work ahead that is scheduled for later time periods 3. Reduce normal capacity Remedies for Overloads 1. Eliminate unnecessary requirements 2. Reroute jobs to alternative machines or work centers 3. Split lots between two or more machines 4. Increase normal capacity 5. Subcontract 6. Increase the efficiency of the operation 7. Push work back to later time periods 8. Revise master schedule Hours of capacity Initial Load Profile 120 – 110 – 100 – 90 – 80 – 70 – 60 – 50 – 40 – 30 – 20 – 10 – 0– Normal capacity 1 2 3 4 Time (weeks) 5 6 Hours of capacity Adjusted Load Profile 120 – 110 – 100 – 90 – 80 – 70 – 60 – 50 – 40 – 30 – 20 – 10 – 0– Pull ahead Overtime 1 2 Work an extra shift 3 Push back Push back 4 Time (weeks) Normal capacity 5 6 Manufacturing Resource Planning (MRP II) Customer orders Aggregate production plan Forecast No Feasible? Yes Master production schedule Material requirements planning Capacity requirements planning No Feasible? Feedback Yes Purchase orders Work orders Inventory Shop floor control Manufacture Chapter 16 Scheduling Scheduling Specifies when labor, equipment, facilities are needed to produce a product or provide a service Last stage of planning before production occurs Scheduling by Process Type Process Industry Linear programming EOQ with noninstantaneous replenishment Mass Production Assembly line balancing Project Project -scheduling techniques (PERT, CPM) Objectives in Scheduling Meet customer due dates Minimize job lateness Minimize response time Minimize completion time Minimize time in the system Minimize overtime Maximize machine or labor utilization Minimize idle time Minimize work-in-process inventory Efficiency Shop Floor Control Scheduling and monitoring day to day production of a job 1. Loading - Check availability of material, machines & labor 2. Sequencing - Release work orders to shop & issue dispatch lists for individual machines 3. Monitoring - Maintain progress reports on each job until it is complete Loading Allocate work to machines (resources) Perform work on most efficient resources Use assignment method of linear programming to determine allocation Sequencing Prioritize jobs assigned to a resource If no order specified use first-come first-served (FCFS) Many other sequencing rules exist Each attempts to achieve to an objective Sequencing Rules FCFS - first-come, first-served LCFS - last come, first served DDATE - earliest due date CUSTPR - highest customer priority SETUP - similar required setups SLACK - smallest slack CR - critical ratio SPT - shortest processing time LPT - longest processing time Critical Ratio Rule CR considers both time and work remaining CR = time remaining work remaining = due date - today’s date remaining processing time If CR > 1, job ahead of schedule If CR < 1, job behind schedule If CR = 1, job on schedule Sequencing Jobs Through Many Machines/Processes Facility is dynamic, new jobs added Develop global sequencing rules First-in-system, first-served (FISFS) Work-in-next-queue (WINQ) Fewest # remaining operations (NOPN) Slack per remaining operation (S/OPN) Remaining work (RWK) Study system via simulation Monitoring Gantt Chart Shows both planned and completed activities against a time scale Input / Output Control Monitors the input and output from each work center Advanced Planning and Scheduling Systems Infinite - assumes infinite capacity Loads without regard to capacity Then levels the load and sequences jobs Finite - assumes finite (limited) capacity Sequences jobs as part of the loading decision Resources are never loaded beyond capacity Advanced Planning and Scheduling Systems Advanced planning and scheduling (APS) Add-ins to ERP systems Constraint-based programming (CBP) identifies a solution space and evaluates alternatives Genetic algorithms based on natural selection properties of genetics Manufacturing execution system (MES) monitors status, usage, availability, quality Theory of Constraints Not all resources are used evenly Concentrate on the” bottleneck” resource Synchronize flow through the bottleneck Use process and transfer batch sizes to move product through facility Theory of Constraints • What to Change • What to Change to • How to cause the change