Partners involved in WP5

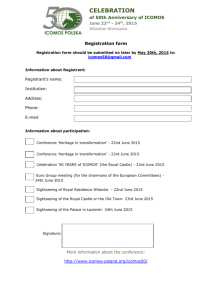

advertisement

CO2 geological storage Methodologies, capacity and options Dr Yves-Michel Le Nindre - BRGM CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Storage is the necessary complement to other mitigation efforts, but… • If technological solutions exist for capture and transport, storage is facing to the geological uncertainty • Solutions and performances vary • And industrial constraints differ CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi A number of projects have proved the feasibility of geological storage 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 EU FP3 EU FP4 JOULE SACS SACS2 CO2STORE EU FP5 EU FP6 CO2 Capture Project GESTCO NASCENT WEYBURN I II CO2NET CO2NET2 CO2NET CASTOR CO2GeoNet ULCOS InCa-CO2 EU GeoCapacity CO2ReMoVe GRASP INTAS StraCO2 SAMCARDS PICOR - A FR - RTPG PICOR B-C FR -ACI INSU/CNRS Séq. Géol. CO2 PICOREF GASIM FR - RPI THESE PICOREF INJECTIVITE INTEGRITE MONITORING FR -ANR CRISCO2 GAZ ANNEXES HETEROGENEITES FR - ADEME Example from BRGM involvement SOCECO2 METSTOR CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Conditions of storage must guarantee efficiency and safety for centuries • Understanding phenomena • Selection of proper sites • Predictive modelling • Monitoring, Measure and Verification • Risk assessment and mitigation • Regulations and standards CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi From regional exploration to industrial storage Industrial storage 1-10 Mt/y Pilot site 10,000 t – 0.5 Mt/y Site selection & characterisation Large scale sources & sinks matching The type of storage: EOR, aquifer, coal seam, must match the CO2 flux from the emission source CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi General workflow Investigation area Emission data bases Regional geology Large scale sources & sinks matching Generic studies, natural analogues Basin analysis Site selection & characterisation Economy, permitting, social acceptance Reservoir & cap rock simulations Pilot site 10,000t – 0.5Mt/y Risk assessment Monitoring and verification Industrial storage 1-10 Mt/y CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Two philosophies of sink and sources matching Academic Industrial 150 Km Sources inventory 100 Km Sinks description Classical, from regional inventories to selection Pre-screening, given a selected plant and radius, CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi First step - Mapping major CO2 emission points and storage opportunities (EU GeoCapacity project) WP 1.1 inventory of major CO2 emissions points for all countries WP 1.1 Input routes and barriers WP 1.1 Input gas storage, HC & coal fields, case studies WP 2 Geocapacity in aquifers, geothermal and other reservoirs WP 1.2 GIS mapping of new inputs and of existing data WP 3 Geocapacity in HC fields and ECBM WP 1.3 EU maps of emission and geological storage CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Storage in aquifers: Permian Rotliegend (EU GESTCO project) • • • Example of extensive aquifer in northern Europe Eolian Extent and facies of the Permian Rotliegend from UK to Polish Basin Neighbouring major CO2 emitters !( !( !( SSAB Oxelosund AB Scunthorpe Steel Works Lacustrine Port Talbot Steel Works !( !( Dunkirk Plant Hoogovens Steel !( !( CSP Plant Bruckhausen Plant Beeckerwerth Plant !( !( Fluvial Salzgitter Plant !( !( !( !( !( !( Linz Plant Kuncice !( CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Storage in HC fields and coal seams Geocapacity in hydrocarbon structures and EOR potential Scunthorpe !( Bremen !( IJmuiden !( !( Salzgitter Dunkirk Duisburg Duisburg !( !(!( !( Bruckhausen !( !( Dortmund !( !( !( Geocapacity in coal beds !( and ECBM potential Scunthorpe Steel Works !( Port Talbot Steel Works !( !( Dunkirk Plant !( Hoogovens Steel !( Beeckerwerth PlantBruckhausen Plant !( !( CSP Plant !( !( !( !( !( !( in Power Sector in India, January 22nd – 23rd, 2008 – Delhi CCS !( Capacity calculations • Raw calculation of reservoir capacity: – area * mean thickness * mean porosity * CO2 density @reservoir conditions • Use geological model: – Define reservoir geometry – Map spatial distribution of properties (K, φ) – Apply calculation to each mesh/block and integrate spatially • Capacity of HC fields: – Vol. OOIP (or gas) * FVF (Formation volume factor) * CO2 density @reservoir conditions – Field is considered as depleted CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Generic modelling exercise • • • Φmax 32% Assuming a reservoir with variable properties Example of cut off on porosity Porosity >16% CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Towards a more realistic capacity: applying coefficients • Applying cut off on porosity AND permeability focus on the most promising volume • Storage efficiency % – Used space / available space – Limitations by depth, traps, permeability, injectivity etc. • Sweep efficiency % – Sweep water to replace it by CO2: depends on K, vol, and boundary conditions, water and sediment compressibility, CO2 dissolution – Sweep HC towards production well to replace it by CO2 CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Capacity estimation - confidence in storage capacity Capacity (tm) = A.D.φ.hst.ρCO2 • The practical storage capacity estimate decreases with the number of data and the degree of knowledge. CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Second step: site selection Site selection criteria Capacity (tm) = A.D.φ.hst.ρCO2 Injectivity (kg/s/b) = Q/ΔP No use conflict Depth (>800m, max) Capacity (min) Injectivity Lithology Onshore/offshore Trap ? Seal integrity Distance/barriers from source Sites selection CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Depth constraint Critical temperature 31 °C Critical pressure 73,83 bar Average temp. gradient : 25°C / km Average hydrostatic pressure gradient : 100 bar / km Average depth for CO2 supercritical state ~ 800 m CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Injectivity is a limiting factor Injectivity (kg/s/b) = Q/ΔP • Injectivity is the mass of supercritical CO2 injected by unit of time for a defined pressure increase • It depends on the permeability (K) and of the volume of the reservoir • Therefore the injection rate depends on the maximum pressure allowed to keep the reservoir and seal integrity (e.g. 20 bars) and of the pressure build up when injecting • Reservoir simulations enable to estimate these boundary conditions. • Lower injectivity values need additional injection wells and cost CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Injection and reaction simulation …after 1000 years …dissolution is the main process 0 SG 1 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 -25 -50 Z -75 Injection point -100 -125 Concentration of supercritical CO2 in the reservoir -150 -175 1000 2000 3000 4000 5000 X 0 XCO2L 0.05 0.045 0.04 0.035 0.03 0.025 0.02 0.015 0.01 0.005 0 -25 -50 Z -75 -100 -125 Amount of dissolved CO2 in the water (mass fraction) Note that brine with dissolved CO2 migrates downward as it is approximately 10 kg/m3 denser than brine without CO2. -150 -175 1000 2000 3000 X 4000 5000 Audigane et al., 2006 CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Sleipner case: ideal but not usual • • In Sleipner, Statoil injects CO2 since 1996 in a very high porosity, high permeability extensive sandy aquifer. It is not obvious to find a ”second Sleipner” near major steel plants CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Spatial analyse – Source sink matching • Select source(s), sink(s) – superposition of data (main emitters, capacity of storage, geology, fault, urban area, …) • Calculate the optimal transport route and distance between sources and sinks – Distance & cost – Build a network of pipeline ? – Land use : going through an urban area or a national park, crossing a big river… • Obtain a GIS-based calculation tool with an economic evaluation CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Main steps of a storage project t0 Site selection ~ t0 + 1 yr Site characterisation ~ t0 + 3 yrs Storage design & construction ~ t0 + 5 yrs Injection operations ~ t0 + 40 yrs Site closure Post-closure ~ t0 + 45 yrs … Time Knowledge of the site Confidence in the long-term evolution CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Options, concerns and economy • Options – Producing CH4 (…and store CO2) > ECBM – Producing incremental HC (and store ~1MT/y CO2) > EOR, EGR – Store large amounts / flux of CO2 (~5-10Mt/y) > aquifers • Concerns – ECBM > Stacking pattern, petrography and properties of coal seams, low capacity, needs upstream research & field experiment – EOR > Constraints of flux and volume related to HC production – Aquifers > poor geological knowledge compared to HC fields, injectivity ? – All > routes • Economy – ECBM and EOR > Direct valorisation of CO2 cost by HC – Aquifers > Avoiding CO2atm and taxes, needed by high flux plants, can be combined with HC production (various scenarios) CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Some constraints… Conflicts of use permitting Reservoir properties Costs Seal properties Geological knowledge Depth CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi Thank you for your attention ! • Keep in mind this diagram ! CCS in Power Sector in India, January 22nd – 23rd, 2008 – Delhi