Managing Projects

Chapter Objectives

Be able to:

Explain the difference between routine business

activities and projects.

Describe the five major phases of a project.

Construct a Gantt chart and interpret the results.

Construct a project network diagram and

calculate the earliest and latest start and finish

times for all activities.

Identify the critical activities and paths in a

network.

Crash a project.

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 2

Project Management:

Why Do It?

Building Mega Refineries in Record

Time (India, 2006):

• Demand for gasoline is increasing in

USA

• No new refineries in USA

• Need to process heavy crude

• Current capacity is not enough

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 3

Reliance Industries, Ltd:

• Mobilized initial workforce of 20,000, will

grow to 150,000 to complete project by

December 2008

• Built residential complex for 2500 families to

attract skilled workers needed and an

irrigated 2000-acre farm nearby

• Expansion will add capacity of 582,000

barrels a day

• Each welder will have six helpers to keep him

supplied with necessary materials

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 4

What Is a Project?

A series of related tasks directed toward

some major output or goal

Often driven by a completion deadline

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 5

Project Phases I

• Concept Phase

– Broad definition and feasibility analysis

– Budget estimates within 30%

• Project definition Phase

– Tentative schedules, budgets, organization

– Budget estimates refined within 5% to 10%

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 6

Project Phases II

• Planning phase

– Detailed tasks, timing, budgets and resources

– Milestones

– Project management tools

• Performance phase

– Execution and control

• Postcompletion phase

– “Wrap-up”

– Reassignment of project resources

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 7

Statement of Work (SOW)

A written description of the project objectives

to be achieved, with

• a brief statement of the work to be done

• a proposed schedule specifying the start

and completion dates

• budget and completion steps (milestones)

• written reports to be supplied.

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 8

Breaking Down the Work

•

•

•

•

Allows independent operation

Improves manageability

Decentralizes authority

Enables monitoring and

measurement

• Provides assessment of required

resources

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 9

Work Breakdown Structure

(WBS)

Level

1 Program

2

Project

3

Task (group or organization)

4

Subtask

5

Work Assignment

(organizational unit)

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 10

Work Breakdown Structure

Example

Level

1 Custom Home Builder

2

Custom Home

3

Foundation (group or organization)

4

Concrete work

5

Set-up forms

(organizational unit)

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 11

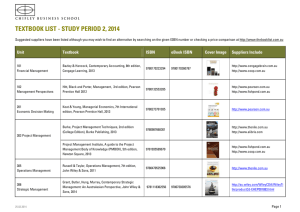

Tools for Project Control:

Gantt Charts

ID Task Name

1

2

3

4

5

Activity 1

Activity 2

Activity 3

Activity 4

Activity 5

6 Activity 6

Start

4/4/2005

4/5/2005

4/7/2005

4/8/2005

4/13/2005

Finish

Duration

Apr 2005

4 5 6 7 8 9 10 11 12 13 14 15 16 17

4/6/2005

3d

4/8/2005

3d

4/11/2005 2d

4/15/2005 5d

4/14/2005 1d 4h

4/15/2005 4/18/2005

1d

...But there is no detailed information

about interrelationships

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 12

Tools for Project Control:

Network Diagrams

•

•

•

•

Network techniques

Consider precedence relationships

Capture interdependency of activities

Determine critical path(s)

– Sequence(s) of activities that determines

overall duration of the project

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 13

Critical Path Method (CPM)

Consider the following consulting project:

Activity

Designation

Immediate

Predecessor(s)

Duration

(weeks)

Assess customer’s needs

A

None

2

Write and submit proposal

B

A

1

Obtain approval

C

B

1

Develop service vision and goals

D

C

2

Train employees

E

C

4

Quality improvement pilot groups

F

D, E

5

Write assessment report

G

F

1

Develop a network diagram and determine the duration of the

critical path(s) and slack times for all activities

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 14

This activity-on-node (AON) diagram

shows the precedence relationships ...

D, 2

START

A, 2

B, 1

C, 1

F, 5

G, 1

FINISH

E, 4

. . .as well as the length of each activity.

Do you see the two paths through the network?

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 15

Some Definitions

• Earliest Start Time (ES)

= Latest EF for all immediate predecessors

• Earliest Finish Time (EF)

= ES + activity’s duration

• Latest Start Time (LS)

= LF – activity’s duration

• Latest Finish Time (LF)

= Earliest LS for all immediate successors

• Slack = amount of allowable delay in an

activity

= Equal to LS – ES or LF – EF for an activity

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 16

Insights

• A ‘hit’ to a critical activity will make project

late

• Rational time estimates needed

• Slack activities can start later

• Difference between effort-driven and timedriven activities

• Useful to have ‘Start’ and ‘Finish’ boxes on

network diagram, particularly when there

are two or more independent activities at

the beginning and/or end of a project.

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 17

Some Assumptions

• Project activities can be identified as

entities. (There is a clear beginning and

ending point for each activity.)

• Project activity sequence relationships

can be specified and networked

• Project control should focus on the

critical path (activities with no slack)

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 18

In First Example ...

• Network-based scheduling techniques to:

Show precedence

Determine project duration

Identify critical paths and activities

• Setting EF = LF for last activity implies

that current length of project is OK

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 19

However, there are often ...

• Deadlines for finishing projects

– (Olympic stadium, dormitories, etc.)

• Penalty or overhead costs if project

is late

• Competitive pressures

– Competitors, slowing demand

(Reliance Industries, Ltd.)

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 20

Ways to Shorten (Crash) a Project

• BORROW resources from noncritical activities (ones with greatest

slack)

• Add MORE resources

• Work MORE hours

• Spend MORE $$$$

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 21

Idea behind “CRASHING”

Duration of individual effortdriven activities can be

shortened, but at a cost

Example: Following project must be

completed by Week 26

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 22

Project Data

Activity

Duration

Predecessors

Crashable Weeks

A

6

None

None

B

11

A

4

$700

C

14

A

3

$2,000

D

2

A

None

E

4

B

1

$2,000

F

5

B

1

$1,000

G

6

C

1

$1,000

H

7

C

2

$2,000

I

3

D

None

J

4

E

None

K

4

F, G

2

$1,500

L

3

H, I

1

$2,500

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Crash Cost/Week

Chapter 5, Slide 23

Network Diagram for Project

E 17 21

E

L 22 26

6 17

L 10 21

S

S

E, 4

E 21 25

F

L 26 30

F

S

E 17 22

B, 11

L 21 26

F

E

0

6

L

0

6

E

6 20

E 26 30

S

F

L

6 20

L 26 30

S

START

S

F,5

F

J, 4

A, 6

F

S

C, 14

G, 6

F

FINISH

K, 4

E 20 26

E

0

0

L 20 26

E 30 30

L

0

0

S

L 30 30

S

F

F

S

H, 7

D, 2

E

6

8

L 22 24

S

F

F

E 20 27

L 20 27

S

L, 3

F

E 27 30

L 27 30

S

I, 3

E

F

8 11

L 24 27

S

F

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 24

1. Write Down All Possible Paths

and Lengths of Time for Each

Path

ABEJ

ABFK

ACGK

ACHL

ADIL

Length

25

26

30

30

14

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 25

2. Identify All Paths to be

Shortened

Path

ABEJ

ABFK

ACGK

ACHL

ADIL

Length

25

26

30

30

14

Critical Path

Critical Path

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 26

3. Find Lowest-Cost Way to

Shorten Critical Path(s)

Path

ABEJ

ABFK

ACGK

ACHL

ADIL

Length

25

26

30

30

14

To CRASH, either:

1. Shorten C or

2. Shorten {G or K} and

{H or L}

• Shorten C by 3 weeks

Cost = 3×$2,000 =

$6,000

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 27

Update Lengths in Table

Path

ABEJ

ABFK

ACGK

ACHL

ADIL

Length

25

26

3027

3027

14

Are we done?

What are our

next cheapest

alternatives?

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 28

To Crash Further

1. Shorten C some more, or

2. Shorten {G or K} and {H or L}

• Shorten Both G and H by 1 Week:

• Cost = $1,000 + $2,000 = $3,000

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 29

Update Lengths in Table

Path

ABEJ25

ABFK

ACGK

ACHL

ADIL

Length

26

302726

302726

14

Total Cost to Crash

= $6,000 + $3,000

= $9,000

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 30

If the reduction in overhead

per week is $4000

How many more weeks should the

company try to crash the

project?

Observations

• Cost of crashing becomes more and

more expensive as cheapest options

are used up

• There is a limit to how far a project can

be crashed.

• Crashing non-critical activities is

pointless

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 32

Controlling Projects

CPM used primarily to Plan and Schedule, BUT ...

• Things rarely go as planned

• The need for additional activities arises

• Better time and resource estimates are made as

project progresses use of PERT (Program

evaluation and review technique) where

probabilistic time estimates are used

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 33

Computer-Based Package

Advantages

• Regular updates

• Change analysis, tracking, and exception

reports

• High level of detail

• Scheduling around resource constraints

• Text examples using Microsoft Project™ on

pages 139-141

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 34

Project Management Institute (PMI)

www.pmi.org

• PMI:

– Sponsors education and certification

– Sponsors conferences, research, user groups

– Publishes Guide to the Project Management Body of

Knowledge (PMBOK®)

• PMBOK®

– Part I: Various business processes for projects

– Part II: Nine project knowledge areas

© 2008 Pearson Prentice Hall --- Introduction to Operations and Supply

Chain Management, 2/e --- Bozarth and Handfield, ISBN: 0131791036

Chapter 5, Slide 35

Managing Projects Case

Study

Viva Roma!