The livestock sector plays an important role in the national economy

advertisement

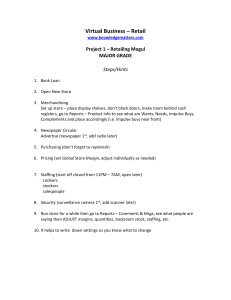

ISSN NO 2322-0147 COMMONWEALTH ASSOCATION FOR EDUCATION, ADMINISTRATION AND MANAGEMENT FEBRUARY 2014 VOLUME 2 ISSUE 2 The Development of Dairy Industry in Aligarh City: A Case Study Excellence International Journal of Education and Research (Multi- subject journal) Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 The Development of Dairy Industry in Aligarh City: A Case Study By BABU ALI Research Scholar Department of Geography Aligarh Muslim University, Aligarh-202002 Email- babua0783@gmail.com ABSTRACT The livestock sector plays an important role in the national economy and also in the socio-economic development of millions of rural households in India. It has a strategic role in ensuring food and nutritional security, income and employment generation and in balancing rural inequity. The livestock sector has been among the few growth sectors in rural India and its contribution to GDP has increased from about 4.8% in 1980-81 to 5.6% in 2003-04 and 2.3% in 2011. Among various livestock products, milk and milk products constitute a major share in the value of output from the livestock sector. Milk and milk products have emerged as the largest agricultural commodity category by value in recent years. The study of dairy industry in Aligarh city based on the study of structure and location of dairy market, to analyze the pattern of dairy industry in Aligarh City, to study the problems and prospects of dairy and to explore the effect of dairy on the socio-economic condition of the city. All the study based on primary data by selection of the different centers of the city and getting the data through personal interview. The demand of the milk towards the city is very high but supply is not proper due the transport of milk towards Delhi is very high. A lot of tons of milk is going to Delhi per day. So the rate of milk in Aligarh city is very high. Key words: Livestock, Dairy Industries, Agricultural Commodity, Socio-Economic Development, etc. INTRODUCTION Dairy farming in India is still unorganized. India has the largest number of cattle in the world .but her output is negligible. India has 196 head of cattle ,and the output of the total cattle is 1320.4 million, but her output f fresh milk in 1996 was only 67.o million metric tons according to 1996. And the total world output is 537.6 million metric tons. The central and state government are encouraging the dairying . Modern dairy have been setup in Bombay, Delhi, Poon, Kudgi ,Kurnool , Guntoor , Kadaikanal , Haringhata Dairy industries is also organised in Agra ,Aligarh ,Kolkata ,Octacumand ,Munger . There 2.38 dairy plants are found in the country in the public and co-operative center, comprising 126 liquid milk plants, 37 milk plants , 37 milk products factories and 75 pilot milk scheme rural dairies . The combined installed capacity of these dairies plants is 14091 liters per day. Despite being the largest milk producer in the world, per capita availability and consumption of milk in India is still relatively low, although it is high by developing country standards. The per capita availability of milk, which declined slightly during the 1950s and 1960s (from 124 grams per day in 1950/51 to 121 grams in 1973/74) expanded substantially during the 1980s and 1990s and reached about 232 grams per day in 2004/05. Between 1983 and 1999/20005, per capita annual milk consumption increased from 43 kg to about 74 kg. Excellence International Journal Of Education And Research (Multi-subject journal) Page 190 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 There is, however, considerable variation in consumption of milk across income classes and a strong positive association between quantity of milk consumed and income level. Milk is consumed in a variety of forms, either as liquid milk or as processed products, such as ghee, curd, butter and sweets, but the milk utilization pattern in the country has changed over the years. The share of liquid milk in total milk consumption increased from 39.3% in 1951 to 45.7% in 1995, whereas the share of ghee (clarified butter) has declined from 39.3% to about 27.5% during the same period. The share of other products showed a significant increase from barely 2% in 1951 to about 7% in 1995; this might be attributed to an increase in production of Western dairy products such as ice-cream, cheese, chocolates, milk powders and other dairy-based products. As may be observed, the market is shifting in favour of cheese, butter and other products and away from ghee. Demand for traditional dairy products like paneer, chhena, khoa and gulab jamun has increased modern formal processors, recognizing the powerful demand for traditional products, have increasingly entered these markets, competing with the small-scale traditional sector. Several factors have contributed to the increased demand for milk and dairy products in the country, including the strong cultural significance of milk in India where a large proportion of the population is lacto-vegetarian. The demand for milk and dairy products is income elastic; growth in per capita income is expected to increase demand for milk and milk products. Urbanization and changing food habits and lifestyles have also reinforced growth in demand for dairy products. Further, per capita consumption of milk is 1.5-times higher among urban households than rural households. Nevertheless, the per capita consumption of milk has been increasing faster in the rural areas. Between 1983 and 1999, consumption of milk increased by 71% in rural households and 63% in urban households. This suggests that, although urbanization would remain a key driver of demand, sustained growth in rural incomes would fuel rapid growth in rural demand for livestock products. In 1999/2000 livestock products accounted for 12.9% of the total household consumption expenditure of rural households. This is slightly higher than that of urban households (12.6%). In rural areas, the share of livestock products increased from 11.0% in 1983, to 13.1% in 1987/88 and to 13.9% in 1993/94, and then slightly declined to 12.9%. In urban areas, however, it increased slightly during 1980s, but declined during 1990s. Both the rural and urban consumers spent about 70% of the total allocation to livestock products on milk and dairy products. Given the relatively high income elasticity, the demand for milk and dairy products is expected to grow rapidly. A study conducted by Saxena (2000) using National Sample Survey (NSS) data for 1993-94 showed that the income elasticity of demand for milk and milk products is higher in rural areas (ranging from 1.24 in Punjab to 2.92 in Orissa) than in urban areas (ranging from 0.99 in Punjab to 1.78 in Bihar). Nationally, the income elasticity of demand is 1.96. Further increases in per capita income and changing consumption patterns would be expected to lead to acceleration in demand for milk and other livestock products in India and thus would give a boost to this sector. The industries are located mainly, where the cattle, which are necessary of dairy, are found because cattle are reared for a multiple purposes. However the principle purposes, for which cattle are reared, are their meat and dairy products. It is only the underdeveloped economies of Asia and Africa that cattle are used as a source of power here they serve as chief transporting and are also used for ploughing the field. In developed countries where the agriculture is highly developed, mechanized, cattle are reared either for beef and dairying. There is, in fact, a marked differentiation of functions and there is often Excellence International Journal Of Education And Research (Multi-subject journal) Page 191 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 pronounced regional specialization .this is so because the geographical and economical conditions required for the rearing of beef – cattle are somewhat different. OBJECTIVE 1. 2. 3. 4. To study the structure & location of dairy market. To analyze the pattern of dairy industry in Aligarh City. To study the problems and prospects of dairy. To explore the effect of dairy on the socio-economic condition of the city. DATA BASE The data for the study is only collected from primary sources. The study is mainly based on the primary sources of data, which has been collected through the interviews of the respondents and discussion with the owners of different shops & industries. For getting accurate information the different shops and industries were visited time of time. The maps and diagrams draw with help of different tools and techniques. METHODOLOGY The following methodologies were used in the survey………… a – Selection of different centers of the city b – Personal interview of the respondent c – Selection of mohallas & their milk shops d – Selection of main roads & sub-roads as well as street e – Taking the primary data from the Municipal Corporation of the city. STUDY AREA Aligarh, with a population of 2.99 million, is one of seventy districts in Uttar Pradesh (U.P.) and is located at 27.30 N latitude and 79.40 E longitude in the western part of U.P. Aligarh is situated at a distance of about 131 Km (81 Miles) on the plain between the Ganges river and the Yamuna. The city is the administrative headquarters of Aligarh district, Aligarh police range and Aligarh division, which is comprised of the Etah, Hathras (Mahamayanagar) and Kanshi Ram Nagar districts. It shares common boundaries with the district of Bulandshahr in the North, Etah in the East, Mathura in the west and Hathras (Mahamaya Nagar) in the south. The Aligarh city is spread over an area of 34 square kilometres. It is also an important centre of lock smithy. The town has a population of more than half a million, according to the 2001 census. The indiscriminate growth which is a hallmark of Aligarh has left its impressions on the environment. On account of its being an important centre of lock smithy, and other allied industrial functions like electroplating, casting, the town is besieged with rural migration. However, the town's infrastructure is such that it is unable to take on the extra load thereby resulting in a major breakdown of sanitary conditions. Excellence International Journal Of Education And Research (Multi-subject journal) Page 192 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 HISTORICAL DEVELOPMENT OF DAIRY INDUSTRY Milk producing animals have been domesticated for thousands of years. Initially, they were part of the subsistence farming that nomads engaged in. As the community moved about the country, their animals accompanied them. Protecting and feeding the animals were a big part of the symbiotic relationship between the animals and the herders. In the more recent past, people in agricultural societies owned dairy animals that they milked for domestic and local (village) consumption, a typical example of a cottage industry. The animals might serve multiple purposes (for example, as a draught animal for pulling a plough as a youngster, and at the end of its useful life as meat). In tis case the animals were normally milked by hand and the herd size was quite small, so that all of the animals could be milked in less than an hour—about 10 per milker. These tasks were performed by a dairymaid (dairywoman) or dairyman. The word dairy harkens back to Middle English dayerie, deyerie, from deye (female servant or dairymaid) and further back to Old English dæge (kneader of bread). With industrialisation and urbanisation, the supply of milk became a commercial industry, with specialised breeds of cattle being developed for dairy, as distinct from beef or draught animals. Initially, more people were employed as milkers, but it soon turned to mechanisation with machines designed to do the milking. Historically, the milking and the processing took place close together in space and time: on a dairy farm. People milked the animals by hand; on farms where only small numbers are kept, handmilking may still be practiced. Hand-milking is accomplished by grasping the teats (often pronounced tit or tits) in the hand and expressing milk either by squeezing the fingers progressively, from the udder end to the tip, or by squeezing the teat between thumb and index finger, then moving the hand downward from udder towards the end of the teat. The action of the hand or fingers is designed to close off the milk duct at the udder (upper) end and, by the movement of the fingers, close the duct progressively to the tip to express the trapped milk. Each half or quarter of the udder is emptied one milk-duct capacity at a time. The stripping action is repeated, using both hands for speed. Both methods result in the milk that was trapped in the milk duct being squirted out the end into a bucket that is supported between the knees (or rests on the ground) of the milker, who usually sits on a low stool. Traditionally the cow, or cows, would stand in the field or paddock while being milked. Young stock, heifers, would have to be trained to remain still to be milked. In many countries, the cows were tethered to a post and milked. The problem with this method is that it relies on quiet, tractable beasts, because the hind end of the cow is not restrained. In 1937, it was found that bovine somatotropin (bST or bovine growth hormone) would increase the yield of milk. Monsanto Company developed a synthetic (recombinant) version of this hormone (rBST). In February 1994, rBST was approved by the Food and Drug Administration (FDA) for use in the U.S. It has become common in the U.S., but not elsewhere, to inject it into milch kine (dairy cows) to increase their production by up to 15%. However, there are claims that this practice can have negative consequences for the animals themselves. A European Union scientific commission was asked to report on the incidence of mastitis and other disorders in dairy cows, and on other aspects of the welfare of dairy cows. The commission's statement, subsequently adopted by the European Union, stated that the use of BST substantially increased health problems with cows, including foot problems, mastitis and injection site reactions, impinged on the welfare of the animals and caused reproductive disorders. The report concluded that on Excellence International Journal Of Education And Research (Multi-subject journal) Page 193 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 the basis of the health and welfare of the animals, BST should not be used. Health Canada prohibited the sale of BST in 1999; the recommendations of external committees were that, despite not finding a significant health risk to humans, the drug presented a threat to animal health and, for this reason, could not be sold in Canada. STRUCTURE OF THE DAIRY INDUSTRY While most countries produce their own milk products, the structure of the dairy industry varies in different parts of the world. In major milk-producing countries most milk is distributed through wholesale markets. In Ireland and Australia, for example, farmers' co- operatives own many of the largescale processors, while in the United States many farmers and processors do business through individual contracts. In the United States, the country's 196 farmers' cooperatives sold 86% of milk in the U.S. in 2002, with five cooperatives accounting for half that. This was down from 2,300 cooperatives in the 1940s.[3] In developing countries, the past practices of farmers marketing milk in their own neighborhoods are changing rapidly. Notable developments include considerable foreign investment in the dairy industry and a growing role for dairy cooperatives. Output of milk is growing rapidly in such countries and presents a major source of income growth for many farmer. As in many other branches of the food industry, dairy processing in the major dairy producing countries has become increasingly concentrated, with fewer but larger and more efficient plants operated by fewer workers. This is notably the case in the United States, Europe, Australia and New Zealand. In 2009, charges of anti-trust violations have been made against major dairy industry players in the United States. Government intervention in milk markets was common in the 20th century. A limited anti-trust exemption was created for U.S. dairy cooperatives by the Capper-Volstead Act of 1922. In the 1930s, some U.S. states adopted price controls, and Federal Milk Marketing Orders started under the Agricultural Marketing Agreement Act of 1937 and continue in the 2000s. The Federal Milk Price Support Program began in 1949.[3] The Northeast Dairy Compact regulated wholesale milk prices in New England from 1997 to 2001 As processing plants grow fewer and larger, they tend to acquire bigger, more automated and more efficient equipment. While this technological tendency keeps manufacturing costs lower, the need for long-distance transportation often increases the environmental impact. Milk production is irregular, depending on cow biology. Producers must adjust the mix of milk which is sold in liquid form vs. processed foods (such as butter and cheese) depending on changing supply and demand farm. As herd numbers increased so did the problems of animal health. In New Zealand two approaches to this problem have been used. The first was improved veterinary medicines (and the government regulation of the medicines) that the farmer could use. The other was the creation of veterinary clubs where groups of farmers would employ a veterinarian (vet) full-time and share those services throughout the year. It was in the vet's interest to keep the animals healthy and reduce the number of calls from farmers, rather than to ensure that the farmer needed to call for service and pay regularly. Most dairy farmers milk their cows with absolute regularity at a minimum of twice a day, with some high-producing herds milking up to four times a day to lessen the weight of large volumes of milk in the udder of the cow. This daily milking routine goes on for about 300 to 320 days per year that the Excellence International Journal Of Education And Research (Multi-subject journal) Page 194 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 cow stays in milk. Some small herds are milked once a day for about the last 20 days of the production cycle but this is not usual for large herds. If a cow is left unmilked just once she is likely to reduce milkproduction almost immediately and the rest of the season may see her dried off (giving no milk) and still consuming feed for no production. However, once-a-day milking is now being practised more widely in New Zealand for profit and lifestyle reasons. This is effective because the fall in milk yield is at least partially offset by labour and cost savings from milking once per day. This compares to some intensive farm systems in the United States that milk three or more times per day due to higher milk yields per cow and lower marginal labor costs. INDUSTRIAL PROCESSING Dairy plants process the raw milk they receive from farmers so as to extend its marketable life. Two main types of processes are employed: heat treatment to ensure the safety of milk for human consumption and to lengthen its shelf-life, and dehydrating dairy products such as butter, hard cheese and milk powders so that they can be stored. The Products of dairy industries are given below….. Cream and Butter Today, milk is separated by large machines in bulk into cream and skim milk. The cream is processed to produce various consumer products, depending on its thickness, its suitability for culinary uses and consumer demand, which differs from place to place and country to country. Some cream is dried and powdered, some is condensed (by evaporation) mixed with varying amounts of sugar and canned. This butter mass is washed and, sometimes, salted to improve keeping qualities. The residual buttermilk goes on to further processing. The butter is packaged (25 to 50 kg boxes) and chilled for storage and sale. At a later stage these packages are broken down into home-consumption sized packs. Butter sells for about US$3200 a tonne on the international market in 2007 (an unusual high). Skimmed Milk The product left after the cream is removed is called skim, or skimmed, milk. Reacting skim milk with rennet or with an acid makes casein curds from the milk solids in skim milk, with whey as a residual. To make a consumable liquid a portion of cream is returned to the skim milk to make low fat milk (semiskimmed) for human consumption. By varying the amount of cream returned, producers can make a variety of low-fat milks to suit their local market. Other products, such as calcium, vitamin D, and flavouring, are also added to appeal to consumers. Casein Casein is the predominant phosphoprotein found in fresh milk. It has a very wide range of uses from being a filler for human foods, such as in ice cream, to the manufacture of products such as fabric, adhesives, and plastics. However, in the US these assorted non- food uses have led to concerns over the import of substandard (non-food-grade) powders from other countries, such as China, that are then used to artificially bolster domestic cheese yield without the casein additive undergoing FDA inspection. Excellence International Journal Of Education And Research (Multi-subject journal) Page 195 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 Cheese Cheese is another product made from milk. Whole milk is reacted to form curds that can be compressed, processed and stored to form cheese. In countries where milk is legally allowed to be processed without pasteurisation a wide range of cheeses can be made using the bacteria naturally in the milk. In most other countries, the range of cheeses is smaller and the use of artificial cheese curing is greater. Whey is also the byproduct of this process. Whey In earlier times whey was considered to be a waste product and it was, mostly, fed to pigs as a convenient means of disposal. Beginning about 1950, and mostly since about 1980, lactose and many other products, mainly food additives, are made from both casein and cheese whey. Yogurt Yoghurt (or yogurt) making is a process similar to cheese making, only the process is arrested before the curd becomes very hard. Milk Powders Milk is also processed by various drying processes into powders. Whole milk, skim milk, buttermilk, and whey products are dried into a powder form and used for human and animal consumption. The main difference between production of powders for human or for animal consumption is in the protection of the process and the product from contamination. Some people drink milk reconstituted from powdered milk, because milk is about 88% water and it is much cheaper to transport the dried product. Dried skim milk powder is worth about US$5300 a tonne (mid-2007 prices) on the international. Other milk products Kumis is produced commercially in Central Asia. Although it is traditionally made from mare's milk, modern industrial variants may use cow's milk instead. TRANSPORT OF MILK Historically, the milking and the processing took place in the same place: on a dairy farm. Later, cream was separated from the milk by machine, on the farm, and the cream was transported to a factory for butter making. The skim milk was fed to pigs. This allowed for the high cost of transport (taking the smallest volume high-value product), primitive trucks and the poor quality of roads. Only farms close to factories could afford to take whole milk, which was essential for cheesemaking in industrial quantities, to them. The development of refrigeration and better road transport, in the late 1950s, has meant that most farmers milk their cows and only temporarily store the milk in large refrigerated bulk tanks, whence it is later transported by truck to central processing facilities. MILKING MACHINES Milking machines are used to harvest milk from cows when manual milking becomes inefficient or labour intensive. The milking unit is the portion of a milking machine for removing milk from an Excellence International Journal Of Education And Research (Multi-subject journal) Page 196 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 udder. It is made up of a claw, four teat cups, (Shells and rubber liners) long milk tube, long pulsation tube, and a pulsator. The claw is an assembly that connects the short pulse tubes and short milk tubes from the teat cups to the long pulse tube and long milk tube. (Cluster assembly) Claws are commonly made of stainless steel or plastic or both. Teat cups are composed of a rigid outer shell (stainless steel or plastic) that holds a soft inner liner or inflation. Transparent sections in the shell may allow viewing of liner collapse and milk flow. The annular space between the shell and liner is called the pulse chamber. Milking machines work in a way that is different from hand milking or calf suckling. Continuous vacuum is applied inside the soft liner to massage milk from the teat by creating a pressure difference across the teat canal (or opening at the end of the teat). Vacuum also helps keep the machine attached to the cow. The vacuum applied to the teat causes congestion of teat tissues (accumulation of blood and other fluids). Atmospheric air is admitted into the pulsation chamber about once per second (the pulsation rate) to allow the liner to collapse around the end of teat and relieve congestion in the teat tissue. MILKING SHED LAYOUTS Bail-style sheds— this type of milking facility was the first development, after open-paddock milking, for many farmers. The building was a long, narrow, lean-to shed that was open along one long side. The cows were held in a yard at the open side and when they were about to be milked they were positioned in one of the bails (stalls). Usually the cows were restrained in the bail with a breech chain and a rope to restrain the outer back leg. The cow could not move about excessively and the milker could expect not to be kicked or trampled while sitting on a (three-legged) stool and milking into a bucket. When each cow was finished she backed out into the yard again. The UK bail, developed largely by Rex Patterson, was a six standing mobile shed with steps that the cow mounted, so the herdsman didn't have to bend so low. The milking equipment was much as today, a vacuum from a pump, pulsators, a claw-piece with pipes leading to the four shells and liners that stimulate and suck the milk from the teat. The milk went into churns, via a cooler. Herringbone Milking Parlours— In herringbone milking sheds, or parlours, cows enter, in single file, and line up almost perpendicular to the central aisle of the milking parlour on both sides of a central pit in which the milker works (you can visualise a fishbone with the ribs representing the cows and the spine being the milker's working area; the cows face outward). After washing the udder and teats the cups of the milking machine are applied to the cows, from the rear of their hind legs, on both sides of the working area. Large herringbone sheds can milk up to 600 cows efficiently with two people. Swingover Milking Parlours— Swing over parlours are the same as herringbone parlours except they have only one set of milking cups to be shared between the two rows of cows, as one side is being milked the cows on the other side are moved out and replaced with unmilked ones. The advantage of this system is that it is less costly to equip, however it operates at slightly better than half-speed and one would not normally try to milk more than about 100 cows with one person. Rotary Milking sheds— Rotary milking sheds consist of a turntable with about 12 to 100 individual stalls for cows around the outer edge. A "good" rotary will be operated with 24–32 (~48–50+) stalls by one (two) milkers. The turntable is turned by an electric-motor drive at a rate that one turn is the time for Excellence International Journal Of Education And Research (Multi-subject journal) Page 197 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 a cow to be milked completely. As an empty stall passes the entrance a cow steps on, facing the centre, and rotates with the turntable. The next cow moves into the next vacant stall and so on. The operator, or milker, cleans the teats, attaches the cups and does any other feeding or whatever husbanding operations that are necessary. Cows are milked as the platform rotates. The milker, or an automatic device, removes the milking machine cups and the cow backs out and leaves at an exit just before the entrance. The rotary system is capable of milking. Automatic Milking sheds— Automatic milking or 'robotic milking' sheds can be seen in Australia, New Zealand and many European countries. Current automatic milking sheds use the voluntary milking (VM) method. These allow the cows to voluntarily present themselves for milking at any time of the day or night, although repeat visits may be limited by the farmer through computer software. A robot arm is used to clean teats and apply milking equipment, while automated gates direct cow traffic, eliminating the need for the farmer to be present during the process. The entire process is computer controlled. CONDITION NECESSARY FOR DAIRY INDUSTRIES 1) 2) 3) 4) 5) 6) 7) Climate sufficient Supply of Skilled Labour Capital Market for Milk Developed Transport Refrigeration Facilities Public and Private Sector Government Policies Climate is one of the important things. Dairy cattle flourish in moderate coolness climate. Rainfall is sufficient for the growth of nutrious grasses and other forage. Dairy farming requires more skilled labour than crop agriculture. Tending milking and preparation of the product must be done scientifically and with great skill. Excellence International Journal Of Education And Research (Multi-subject journal) Page 198 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 A moderate dairy farm is highly mechanised and requires a large amount of capital for building cattle sheds, storing feedstuffs, purchasing dairy machinery and implements and for acquiring high quality and well-bred cows. Milk and its products are highly perishable by nature. Therefore, the development of dairy farming presupposes the existence of a big consuming market. As dairy products are not meant for local consuming but for market, well developed transport and refrigeration facilities are also necessary for the development of commercial dairy farming. The industries are located mainly, where the cattle, which are necessary of dairy, are found. Because cattle are reared for a multiple purposes. However the principle purposes, for which cattle are reared, are their meat and dairy products. It is only the underdeveloped economies of Asia and Africa that cattle are used as a source of power .here they serve as chief transporting and are also used for ploughing the field. In developed countries where the agriculture is highly developed, mechanized, cattle are reared either for beef and dairying. There is, in fact, a marked differentiation of functions and there is often pronounced regional specialization .this is so because the geographical and economical conditions required for the rearing of beef – cattle are somewhat different. IMPORTANCE OF DAIRY IN ALIGARH CITY: Dairy is a important industries among the all industries. In Aligarh its play an important role. There are a lot of small and large scale industries in Aligarh city .Due to the requirement of dairy product, its importance is much than any others. Aligarh is a big city of India. It has a lot of population and there requirement are also high .So it is necessary to develop a dairy industries in Aligarh to fulfill the needs of population. The demand of milk products is increasing continuously, due to flow of the people from the other parts of the country towards Aligarh city to complete their requirement. So it forceful to develop the dairy industries in the city. In Aligarh, there are a lot of industries but it is not enough to complete the requirement of the people. DISTRIBUTION OF DAIRY INDUSTRIES IN ALIGARH: Dairy is an important industry of the city after the Lock Industry. Lock industry play an important role in the city .Due to this dairy is not highly developed in the city. It is very comparatively distribute in the city. It is mainly divided into small and large scale industry in the city. There are many small and large scale industries in the city, are following………………… 1. Baba dairy: It is one of the famous dairy of milk .There are a lot of others products of dairy as- barfi , gulab jamun , laddu, jalebi, butter , chese , fresh milk , and so many others products of dairy are found there. It is higher supplier shop of the city .The owner of this shop collect milk towards Atroli , Dhorra,and Delhi Road,etc. 2. Neeraj dairy: This dairy is situated in Achaltal , Kanpur Road , Aligarh. This is a small dairy and provides milk in a numbers of populations of the city. The main product of this dairy is dahi , mava , saprata , etc .this s a retailer dairy . This is a retailer shop. 3. Mukesh dhudh bhandar: This also a small industry. This industry is situated in Center Point, Ramghat Road, Aligarh. In this shop there are a lot of things available. The flow of milk Excellence International Journal Of Education And Research (Multi-subject journal) Page 199 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 is towards Atroli Road. They purchase the milk at the rate of 18.50 Rs and sell at the rate of 21.00 Rs/kg/ltr. 4. Amul dhudh: This dairy is a whole seller shop and situated Bhisnupuri, Ramghat Road , Aligarh. Here amul milk, amul dhahi , amul butter, amul chese. This is also providing the products of Mother Dairy. 5. Saini sweet house: This is the dairy, which is situated in Ramghat Road, Aligarh. This is a retail shop. There are a lot of products found. As fresh milk, dhahi , butter, laddu , barfi , emerty , gulab jamun , bengali rasgulla, etc. 6. Brajwasi misthan bhandar: This is situated at Center Point Chowk , Aligarh . There are many products as brajwasi lassi , milk badam lassi , milk pakori , lachchhedar rabri, rasmalai ,etc. 7. Sindh Snacks: It is also situated at Center Point . It is a retailer shop. The main produts of this shop is special lassi, gajar halua, milk cake and other products. 8. Culcutta sweet snacks: This is situated at Railway Station. The lord of this shop is Rajiv Gupta. This is 60 years old shop. The main products of this shop is khowa, barfi, son papri , balu shahi gulab jamun , cham cham , chhenna rasgulla, bundi laddu , besan laddu , amul milk etc , 9. Garhwal sweet: This shop is situated at station road, Aligarh. It is a whole sell shop. The products of this shop are khoa ,ghee. This shop provides the servise in parties also. 10. Anmol sweet: This shop is also situated at Station Road, Aligarh. The main sweets of this shop are chocolate chhena. Barfi , black jam , laddu besan , son papri, balu shahi , mixed, etc. 11. Ghante Wale: This shop is situated at Madar Gate, Agra Road ,Aligarh. All products of this shop is made by pure ghee. The main products is dhokla , litpattu gajak,etc. this is a shop of whole sell and retail both. 12. Taj Sweets and Namkeen: it is a main shop at Dodhpur chaurah. All type of sweets are available here. The main products are jalebi and gajar ka halua all types of barfi. 13. Jalali wale sweets and gajak: This shop is situated at Madar Gate Chowki, Uppercot Road, Aligarh. This is an important shop of gajak. Gajak is the main product of this shop. 14. Sweet palace: This also an important shoo of sweet and dairy. This shop is also situated at Madar Gate, Aligrh. Here the main produts is namkeen , which is made in pure ghee. 15. Vinod kumar petha wale: This shop is situated at Achaltal, Kanpur Road ,Aligarh. This shop is famous for its pure ghee petha. It is a retailer shop. 16. Mahesh dairy: This shop of milk is situated at Dodhpur, Medical Road, Aligarh.here the main products is fresh milk. This is available at every time. This is a retailer shop. 17. Sahid sweet palace: This shop is situated at Dodhpur, Civil Lines Road; Aligarh.this shop is famous for A.M.U students. Because thereare a lot of student of this university go every time to take milk. DEVELOPMENT OF DAIRY INDUSTRY IN ALIGARH CITY The First Plan provision of Rs. 7.81 crores was almost fully utilised. The main programmes related to the supply of milk to large cities under hygienic conditions supported by schemes of procurement from rural areas. Excellence International Journal Of Education And Research (Multi-subject journal) Page 200 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 In the Second Plan, a provision of Rs. 17.44 crores was made for the dairy development programmes. Against this provision, an amount of Rs. 12.05 crores will be utilized. The Plan included 36 dairy plants for supply of milk to large consuming centres, 12 rural creameries and 7 milk product factories for the utilization of surplus milk in milk pockets, expansion of 12 dairies and salvage farms, training of technical personnel and survey of dairy areas. Due to the shortage of foreign exchange and the difficulty in obtaining plant and machinery, dairy development programmes had to be confined mostly to those schemes for which equipment was available within the country, or was provided for under foreign aid programmes. Dairies have already been set up in Delhi, Poona, Kudgi, Kurnool, Guntur, Kodaikanal and Haringhata. Pilot milk schemes have also been started in some of the important towns. In all, 28 milk supply schemes are at various stages of implementation. Two milk product factories, one at Amritsar and the other at Rajkot and three rural creameries--one each at Barauni, Aligarh and Junagadh are being set up with foreign aid. There were 2257 co-operative milk supply societies and 77 milk supply unions in the country at the end of the year 1958- 59, With membership of 211,131 and owned funds of Rs. 183 lakhs, they sold milk and milk products worth Rs. 11.32 crores. PROGRAMMES FOR THE THIRD PLAN The policy to be pursued in regard to dairying is to develop dairy projects with greater emphasis on milk production in the rural areas linked up with plans for marketing of surplus milk in the urban centres. The supply and collection of milk will be undertaken by a network of producers' co-operatives in the villages. The processing and distribution of milk and manufacture of milk products will be organised through plants operated, as far as possible, on co-operative lines. It is expected that reliance on cooperative organisations would help in enlisting public participation and add to the pool of funds available under the Plan for this activity. In addition to development aimed at in the public sector, manufacture of milk products is proposed to be encouraged in the private sector. In the Second Plan,, two units each for the manufacture of infant milk foods and malted-milk foods and one large-scale unit for sweetened condensed milk were set up. During the Third Plan two plants with a capacity of about 900 tons will start the production of infant milk foods, three units with a total capacity of 5300 tons per annum will produce condensed milk and one unit will manufacture 670 tons per annum of milk beverages. During the Third Plan, 55 new milk supply schemes will, be taken up in cities with population exceeding one lakh and in growing industrial townships. In order to utilise economically the milk available in certain milk pockets where there are no ready markets for the disposal of fluid milk at remunerative price, rural creameries for the production of butter, ghee, cheese and other by-products such as casein, lactose, milk powder etc. will be undertaken. It is proposed to establish 8 such rural creameries, 4 milk product factories and 2 cheese factories for developing the rural milk pockets. There is also a general shortage of concentrates which raises the cost of production of milk. Production of balanced rations through the use of various agricultural wastes and by-products such as wheat and rice brans, bagasse, molasses, decorticated cake etc. can go a long way in making available cheaper feeds for the cattle. It is proposed to establish 4 cattle feed compounding factories in the close vicinity of large milk supply plants. A provision of Rs. 36 crores has been made for dairy schemes in the Third Plan. Excellence International Journal Of Education And Research (Multi-subject journal) Page 201 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 In order to give an impetus to dairy programmes, arrangements have to be made for the manufacture of dairy equipment and machinery within the country. Fabrication of dairy equipment, especially for small units, should be encouraged so as to popularize dairying as a local industry in the rural areas. Four firms have already been licensed for the manufacture of dairy equipment. These will start production during the Third Plan. Most of the milk supply schemes started during the Second Plan will be expanded to increase the intake of surplus milk offered by the producers. Since milk has to be often transported from long distances, special provision has been made for increasing facilities for refrigerated rail transport of milk to large milk processing plants. In addition to meeting the requirements of towns, the vital interests of agriculturists have been kept in view while drawing up programmes for dairy development. Emphasis will be laid on the development of smalle rdairy units and creameries in villages run on co-operative lines in order to strengthen the base of the agricultural economy through mixed farming. Salvage farms will be set up near big cities to preserve the stock of good cattle after completion of lactation. Intensive cattle development schemes will be undertaken in areas in which dairy and milk supply schemes are organised. Even in the case of large dairies in big cities, every attempt should be made to link such schemes with the countryside, so that dairy schemes could be directly helpful in enriching the rural economy through the development of cattle with the twin objectives of increasing milk production and supplying good animals for draught purposes. The existing smaller dairies in medium-size towns will also be oriented in this direction according to phased programmes. Colonies of cattle have been established at Aarey, Haringhata and Madhavaram (Madras) to improve the sanitation of the cities and organise milk supply on more economic lines. This method of colonisation has involved considerable capital outlay and it was, therefore, considered desirable to limit the responsibility of the State to the provision of land with essential services, e.g. roads, water supply and electricity. The developed areas were to be divided into plots and leased out on reasonable terms to the displaced cattle owners. Allot tees would have to construct necessary cattle sheds and other buildings according to approved plan at their own cost. Facilities for the marketing of milk would be provided. Thus, the removal of milch animals from cities and their rehabilitation in colonies would be regarded primarily as health-cum--slum clearance measure, and the main responsibility for it would devolve on city municipalities and corporations. SUPPLY AND FLOW OF MILK TOWRDS ALIGARH CITY: The dairy industry in India faced with several problems, such as, scattered and small-scale milk production, inadequate transport facilities in most parts of the country, dependence on imported plant and machinery required for milk collection, processing and manufacturing, shortage of technical and skilled personnel and the lack of properly organized systems of marketing. Efforts have therefore, to be directed towards the collection of surplus milk from rural areas on an organized basis and the development of assured supply of good quality milk and milk products at reasonable prices to the consumers. Milk is such a thing which destroys soon so its flow should not be far away from the dairy industry or consumption. In Aligarh city the consumption of milk is very high. The flow of milk towards Aligarh is not equal to all direction. The main flow of milk is found from the following direction….. 1. TOWARDS ATROLI ROAD (NH-93) Excellence International Journal Of Education And Research (Multi-subject journal) Page 202 Excellence International Journal Of Education And Research 2. 3. 4. 5. 6. VOLUME 2 ISSUE 2 ISSN 2322-0147 FROM SASNI ROAD OR AGRA ROAD (NH-93) TOWARDS IGLAS TOWARDS TAPPAL ROAD TOWARDS KANPUR ROAD (NH-91) TOWARDS DELHI ROAD(NH-93) Fig. 1. Aligarh road map. Sources: Aligarh City website. The flow of milk is not found from a long distance, but a short distance about 5-30 km. but for the big industry, milk comes for a long distance also. Because their consumption is very high. And they can take a large amount of milk The milkmen take milk only for small scale industry. But large quantity milk come by D.CM and VANS for the big industry. They can take a large quantity of milk and serve at a large scale. From Atroli Raod and Sasni Road the flow of milk is very high. Delhi and Kasganj Road are the small supplier of milk towards Aligarh, due to their position is towards Delhi and Agra respectively. Table 1: Demand of milk and its products in the city by nature of shops in kilograms. S. No. 1. 2. 3. Milk products Fresh milk Packed milk Milk powder Demand of milk in the city in kg by the nature of shops Total Retail shops Wholesale shops 6500 3900 3100 4000 2340 1660 430 430 00 Excellence International Journal Of Education And Research (Multi-subject journal) Page 203 Excellence International Journal Of Education And Research VOLUME 2 4. Whey 1059 5. Ghee 200 6. Cheese 459 7. Butter 540 8. Sweets 1500 Sources: Based on field survey by the researcher, 2009. ISSUE 2 1059 103 300 300 1500 ISSN 2322-0147 00 097 159 240 00 The demand of milk and its products (Table 1 & Fig. 2) depend on the demand of the persons and nature of shops and it’s also varying due to the choices of the persons. The demand of fresh milk is very high overall, following by the packed milk, sweets and whey. Because milk is the primary need of every person. While the lowest demanded is ghee followed by the milk powder and butter. 7000 6000 5000 4000 3000 2000 1000 0 Fig. 2. Demand of milk and its products in the city Excellence International Journal Of Education And Research (Multi-subject journal) Page 204 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 Table: 2. Employment Generations through Dairy Industry in Aligarh city. S.N. 1 2 3 4 5 6 7 Product Nature of shop Fresh milk Both Sweet Retailer Butter Both Cheese Both Milk powder Retailer Whey Retailer Ghee Both Total All Source: Based on Field Survey, 2009. Note: Both- Wholesaler and Retailer Employed Person 244 200 112 32 55 42 143 828 Percentage of Employed in Employed population 29.46 24.15 13.52 3.86 6.64 5.02 17.27 100.00 In Aligarh city the nature of shops are both retailer and wholesaler (Table 2 & Fig. 3). Fresh milk, butter, cheese and ghee have both types of shops but sweet, milk and whey have only retailer shops. The highest percentage of employed person found in fresh milk followed by sweet, ghee and butter. The lowest employed person found in cheese followed by whey and milk powder. 900 800 700 600 500 400 EMPLOYED PERSON 300 200 100 0 Percentage of Employed in Employed population Fig. 3. Employment generation through dairy products. Excellence International Journal Of Education And Research (Multi-subject journal) Page 205 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 PROBLEMS OF DAIRY INDUSTRY The dairy industry in India faced with several problems, such as, scattered and small-scale milk production, inadequate transport facilities in most parts of the country, dependence on imported plant and machinery required for milk collection, processing and manufacturing, shortage of technical and skilled personnel and the lack of properly organised systems of marketing. Efforts have therefore, to be directed towards the collection of surplus milk from rural areas on an organised basis and the development of assured supply of good quality milk and milk products at reasonable prices to the consumers. These are following problem face by dairy industry. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. Inadequate supply of quality milk Poor health of milching animals Non-availability of mother dairy Poor flow of milk due to low prices Pest and diseases of animals Long dry spell or poor climate Scattered and small scale milk production Inadequate transport facilities Dependence on imported plant and machinery required for milk collection Processing and manufacturing Shortage of technical and skilled personnel Lack of properly organized system Waste disposal PEST AND DISEASES OF ANIMALS: Leptospirosis: is one of the most common debilitating diseases of milkers, made somewhat worse since the introduction of herringbone sheds, because of unavoidable direct contact with bovine urine Cowpox: is one of the helpful diseases; it is barely harmful to humans and tends to inoculate them against other poxes such as small pox. Tuberculosis: (TB) is able to be transmitted from cattle mainly via milk products that are unpasteurized. TB has been eradicated from many countries by testing for the disease and culling suspected animals. Brucellosis: is a bacterial disease transmitted to humans by dairy products and direct animal contact. Brucellosis has been eradicated from certain countries by testing for the disease and culling suspected animals. Listeria: is a bacterial disease associated with unpasteurised milk, and can affect some cheeses made in traditional ways. Careful observance of the traditional cheesemaking methods achieves reasonable protection for the consumer. Excellence International Journal Of Education And Research (Multi-subject journal) Page 206 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 Johne's Disease (pronounced "yo-knees"): is a contagious, chronic and sometimes fatal infection in ruminants caused by a bacterium named Mycobacterium avium subspecies paratuberculosis (M. paratuberculosis). The bacteria are present in retail milk, and are believed by some researchers to be the primary cause of Crohn's disease in humans. This disease is not known to infect animals in Australia and New Zealand. PROSPECTS FOR DAIRRY INDUSTRY: For getting a lot of production, we should careful for milking animals or should careful for dairy farming. There are many prospects, which is necessary for dairy industries….. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Suitable climate Sufficient supply of skilled labour Capital or government policies Consumption or market Developed transport and refrigerating facilities Increasing rate for producer Co-operative facilities Good machinery Organised system of marketing Availability of mother dairy Storage and technological facilities Good care of milking animals If we accept all these prospects, we can success in increase the production of dairy industries. So all these facilities is necessary to us. CONCLUTION: Dairy industries in the Aligarh city is very developed. Due to the all necessary condition are found in ALIGARH CITY. Due to the shortage of foreign exchange and the difficulty in obtaining plant and machinery, dairy development programmes had to be confined mostly to those schemes for which equipment was available within the country, or was provided for under foreign aid programmes. Dairies have already been set up in Delhi, Poona, Kudgi, Kurnool, Guntur, Kodaikanal and Haringhata. Pilot milk schemes have also been started in some of the important towns like Aligarh, Agra, etc. In all, 28 milk supply schemes are at various stages of implementation. Two milk product factories, one at Amritsar and the other at Rajkot and three rural creameries--one each at Barauni, Aligarh and Junagadh are being set up with foreign aid. There were 2257 co-operative milk supply societies and 77 milk supply unions in the country at the end of the year 1958- 59, With membership of 211,131 and owned funds of Rs. 183 lakhs, they sold milk and milk products worth Rs. 11.32 crores. So the development of dairy industries in Aligarh city is in progress. It is developing continuously for the impact of industriligtion in India. Then it is proved that Aligarh is a highlighted producer of milk and its related products Excellence International Journal Of Education And Research (Multi-subject journal) Page 207 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 SUGGETION FOR DAIRY DEVELOPMENT 1. Good Marketing In the interest of breeding good quality dairying, it is essential to improve the existing arrangements for the marketing of livestock and livestock products. This is an aspect of development which has hitherto received little attention. Trade practices need to be regulated and amenities such as arrangements for shelter and water for animals should be provided in market yards. Facilities for giving authentic information to breeders regarding prices and marketing prospects are at present quite unsatisfactory. There should be a programme for marketing of livestock and livestock products in each State and especially in the key-village blocks. Schemes for correct shearing, grading and marketing of wool are of considerable importance. The plans of States also include schemes for demonstrations and propaganda regarding correct methods of flaying and utilisation of carcasses. A number of States have made specific provisions for improving slaughter houses, development of meat markets and in some cases setting up of abattoirs run on hygienic lines. . 2. Cattle Insurance Sometime the farmers suffer considerable losses due to the death of their draught or milch animals when there is an out-break of epidemic. A beginning has been made by the Co- operative Mutual, Insurance Company, Bombay to insure milch animals and draught cattle in the States of Maharashtra and Gujarat. The Government of Kerala has also shown interest in such a scheme. Schemes to investigate the possibilities of cattle insurance have been proposed by Andhra Pradesh, Uttar Pradesh, Maharashtra, Rajasthan, Mysore, Madras and Punjab. 3. Goshalas Cattle development activities are proposed to be intensified through private institutions such as goshalas. In the Second Plan, 246 selected goshalas were taken up for the production of superior bulls, which will be further distributed for breeding purposes, and also for increasing the production of milk. It is proposed to provide 168 more goshalas with financial and technical assistance to convert them into cattle breeding-cum-milk production units. There are traditional nomadic cattle breeders in some parts who maintain good specimens of certain breeds of cattle. There is need for improving the economic conditions of these professional herdsmen to continue their age old profession to develop and improve the herds, so that good genetic material available with them might be used for development in nondescript areas. In the Second Plan the scheme for the rehabilitation of nomadic cattle breeders was taken up in Andhra Pradesh, the former Bombay State, U.P. and Rajasthan, Provision has also been made for the development of Rathi and Tharparkar breeds of cattle maintained by the nomadic cattle breeders of Rajasthan. 4. Central Council of Gosamvardhana: With a view to associating private institutions and organisations which are already engaged in cattle development, particularly the cow, the Central, Council of Gosamvardhana was reorganised in Excellence International Journal Of Education And Research (Multi-subject journal) Page 208 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 1960. The Council has been assigned specific functions such as to organise, implement and coordinate activities relating to the preservation and development of cattle and to administer schemes for increasing milk yield and improving draught quality. The Council will also run training centres for goshala, and charmalaya workers, organise exhibitions and issue journals, films and pamphlets for field workers. The Central Council of Gosamvardhana is also expected to bring about better coordination between various agencies interested in Gosamvardhana work. 5. The National Dairy Research Institute: It was shifted from Bangalore to Karnal with a view to increasing facilities for research and training. The Institute will be fully established during the Third Plan with its research divisions in dairy husbandry, technology, chemistry, bacteriology, nutrition, extension and economics, so as to meet the increasing requirements of the fast expanding dairy industry. The Bangalore sub-station of the Institute will also be expanded. In the field of dairy education, training facilities for the Indian dairy Diploma (I.D.D.) at Bangalore, Allahabad, Anand and Aarey and for the B.Sc. (Dairying) and post-graduate studies at Karnal are proposed to be expanded. Training courses upto the graduate level in dairying will also be started at the Agricultural Institute, Anand. In-plant training in large dairies which has already been started will be continued and expanded during the Third Plan. The F.A.0. regional training programme which has been in progress will be continued and expanded. It is also proposed to organise tutorial workshops for teachers at various dairy training centres together with other refresher courses for different categories of technical personnel needed for the various dairy projects. The requirements of dairy personnel during the Third Plan are estimated at 2830, of which 625 will be degree holders, 975 diploma holders and 1230 other categories of personnel. It is expected that these requirements of technical personnel will be adequately met. Excellence International Journal Of Education And Research (Multi-subject journal) Page 209 Excellence International Journal Of Education And Research VOLUME 2 ISSUE 2 ISSN 2322-0147 References: Committee on Agriculture (2005), ‘The Globalizing Livestock Sector: Impact of Changing Markets’, Nineteenth Session, Rome, 13-16 April, Item 6 of the Provisional Agenda, FAO. Davoy, K. et al. (2008), Survey on the Utilization of Local Foliage Species for Goats in Xaythanee District, Vientiane City, Livestock Research for Rural Development, Vol. 20 Number (supplement). Jamal, S (1994), ‘Women in Dairy Development’, Concept Publishing Company, New Delhi. Khan, N. et al. (2006), ‘Livestock Marketing and Diversification of Publishing House, Delhi, India. Agriculture’, Vista International Khan, N. et al. (2008), ‘Livestock Revolution-in Monsoon Asia during Post Economic Reform Period’, Asian Profile 36 No. 5, pp 539-542. Kulkarni, V. (2000), ‘ Rearing of Male Buffalo Calves for Quality Meat Production’, Indian Framing, ICAR, pp 31-33. Kumar, J et al. (2000), ‘An Economic Analysis of Production and Disposal Pattern of Milk in Haryana’, Indian Farming, ICAR, Vol.62, No. 2. Kumar, V. et al. (2004), ‘Regional Dimensions of Livestock Economy in Himachal Pradesh: A District Level Analysis’, Indian Journal of Agriculture Economics, Vol. 59, No. 3, p. 616. Lokollo, E. M (2005), ‘ Ongoing Food Revolution (Livestock Revolution) and Income of the Poor’, YCGPRT Flash, Vol. 3, Number 4, UNESCAP-CAPSA: Centre for Alleviation of Poverty through Secondary Crops (CGPRT Crops), Development in Asia and the Pacific. National Commission on Agriculture (1971), ‘Interim Report of National Commission on Agriculture on Milk Production through Small and Marginal Farmers and Agricultural Labourers’, Ministry of Agriculture, New Delhi. Ogle, B (1990), ‘ Suggestion for Intensive Livestock Based Small Holder Systems in Semi-Arid Areas of Tanzania’, LRRD, Vol. 2, No. 1. Banu,N. (2012), ‘Urbanization and Livelihood in Peri-Urban Interface of Aligarh City-A Case Study’, Asia-Pacific Journal of Social Sciences, Vol-IV(1), Jan-June,2012, pp-195-210. Excellence International Journal Of Education And Research (Multi-subject journal) Page 210