USE-Textile science

advertisement

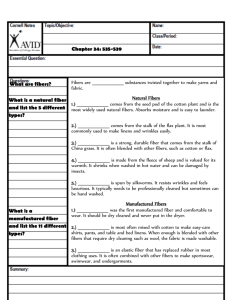

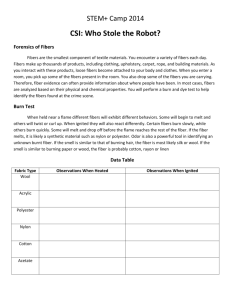

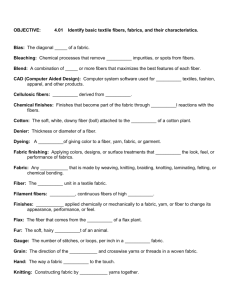

STUDENTS! •DO NOT GET YOUR MACHINES OUT TODAY Page 1 Textile Science Page 2 Fabric Weaves 1. Weaving is the process of combining threads together to form a textile. Woven fabrics are made by (2) weaving together two sets of yarn that are set at right angles to each other. Usually occurs on a loom. 3. Threads that run vertically in fabric are called the warp yarns. 4. Threads that run through the width of the fabric horizontally are called the weft or filling yarns. 5. Label 6. Cloth woven on a loom. Warp yarns Weft (filling) yarns Page 3 Traditionally there are 3 different types of weaves •Plain Weave •Twill Weave •Satin Weave Page 4 Plain Weave What is it? A plain weave is the simplest and most used weave. A plain weave is found in a wide range of fabrics. Fabrics with a plain weave are usually reversible. More fabrics are woven using a plain weave than any other type of weave. Types of fabric woven with a plain weave •Canvas •Burlap •Chiffon How it’s done Each warp yarn passes alternately over one weft yarn and then under one weft yarn for the whole length of the fabric. You alternate starting on the top of the warp yarns to starting on the bottom of the warp yarn to create the weave. Page 5 Complete the sample Start on top of warp yarn, and then on the next line alternate and start on the bottom of the warp yarn. You will be using the longer sample threads in your bag, there should be ten of them, five warp and five weft. Page 6 Twill Weave What is it? A type of weave that creates a diagonal pattern. Created by passing the weft threads over one or more warp threads and then under two of more warp threads. Twill weaves are stronger than plain weaves because twill weaves have fewer interlacings, making it more compact, durable, and heavier. Types of fabric woven with a twill weave •Denim •Fashion suiting •Dress fabrics Complete only one of the types of twill weaves shown on your guided notes, not three as noted. How it’s done There are three different types of twill weaves. A balanced twill, a warp-face twill, and a filling- face twill. Replicate the picture on the left on the right hand side in the box Page 7 Satin Weave In a true satin weave there is only one interlacing for each warp yarn. No two interlacings ever touch or are adjacent to each other. Satin weaves produce a very even surface because of the many warp floats. Types of fabrics made with a satin weave Crepe back satin Sateen How its done Refer to the picture on the right. You do not have to Complete a sample for the satin weave. Page 8 Fiber: The basic beginning structure of a textile. A fiber is an individual, fine, hair-like structure. Fibers are usually twisted together to make yarns, which are then woven to create a textile. Fiber is classified into two categories Natural or Synthetic Page 9 Natural Fiber Natural fibers come from plants or animals. •Plant fibers can come from stems, leaves, or even seeds of plants. •Animal fiber is produced from the fur of animals. •And even though silk comes from the cocoon of a silk worm it is still consdiered an animal fiber In this class we will focus on four natural fibers. Cotton, Wool, Linen, and Silk Page 10 Cotton Advantages •Low cost •Cool (Absorbs moisture) •Machine Washable •Soft Characteristics •Made from the cotton plant. •Least expensive of all natural fibers. •Absorbs moisture. (hydrophilic) •One of the most popular natural fibers because of its comfort level •Accepts dyes easily Disadvantages •Shrinkage •Little resiliency (ability of fabric to spring back into shape Lots of lint because of short fibers When creating clothing cotton is often mixed with another fiber to create a blend, why would this be? Proper Care •Press with Moisture •Wash on cooler temperatures to prevent shrinking Page 11 Cotton Fabrics •Canvas •Corduroy •Denim (Jeans) •Flannel •Knits Page 12 Proper Care •Care varies from washable to dry clean only • See the care label for specific care techniques Advantages •Keeps warm because of crimp and slow absorbing water vapor •Very high crimp •Durable •Repels outside moisture Keeps shape well Characteristics •Comes from animals (sheep, rabbits, goats) •Natural fire-retardant characteristics. •Absorbs moisture (Hydrophilic). •It is often used for coats, outer clothing, quality suits, etc. •Temperature Regulation Wool Disadvantages •Loses strength when wet •Wash with care •Expensive (Generally because of a •limited quantity) •Shrinks and mats Page 13 . Linen Proper Care • Varies from washable to dry cleanable only, dependent upon the quality • See the care label. • Press at highest temperatures. •Hydrophilic Advantages •Strong Looks Expensive Characteristics • Made from the flax plant. • Similar Characteristics of cotton Stronger than cotton. • Dyes easily. • Intricate weaving process • It is commonly used for spring/summer wear and fine suits Disadvantages •Wrinkles very easily •Expensive Sheer How can we tell that linen is a natural fiber? Page 14 How is Silk made? Page 16 Characteristics • Fiber is made by a silk worm • Luxury fabric. •Very hydrophobic Silk Proper Care • Varies from washable to dry cleanable only, dependent upon the quality. • See the care label. • Do not iron using moisture—water spots will not go away. Advantages •Natural luster! •Thinnest of all natural fibers •Dyes well •Excellent Drape Disadvantages •Degrades over time. •Extreme care in cleaning Sensitive to sunlight = fiber damage & Yellowing Page 17 A few questions about natural fibers! 1. What are two advantages of natural fibers? They are breathable, they feel good on your skin, they tend to be of a higher quality, and better for the environment in production than synthetic fibers. 2. What are the benefits of using blended fibers in fabrics? It helps provide beneficial qualities where natural fibers may lack them. For example when we mix cotton with polyester (cotton/poly blend) the garment will be much less likely to stretch and will have a higher resiliency. Blended fibers are also a cheaper option because synthetic fibers easier to produce. You will see mostly blends in clothing at department stores. Page 18 Synthetic Fibers Synthetic fibers are manufactured through the use of chemicals. They are Man Made Fibers. Synthetic fibers are made from chemical solutions that are forced through tiny holes, similar to water passing through a shower head. The device that allows this process to happen and allows the chemicals to become a filament strand is called a spinerette. In this class we will learn about 6 of these synthetic fibers Nylon Acetate Rayon Acrylic Polyester Spandex Page 19 Nylon Characteristics •Strongest synthetic fiber •Very light weight •Tears easily •The first chemically man-made fiber, invented to be used in parachutes during the war. •After the war it created a nylon craze Proper Care Advantages •When pressing, use very low temperature to prevent melting •Need to be kept clean for best performance •Can be machine washed in warm water •Tends to attract static, in order to prevent this add a fabric softener sheet during the drying cycle •Excellent strength •Lightweight •Excellent abrasion resistance •Washable Disadvantages •Doesn’t absorb moisture (hydro phobic) •Melts instead of burning •Static and pilling problems Poor resistance to prolonged and continuous sunlight Page 20 How nylon fiber is made: Nylon is made when molten nylon is forced through very small holes in a device called a spinneret. The streams of nylon harden once they come in contact with air. They are then wound onto bobbins, and sewn to create fabric. Page 21 Burn tests on synthetic fibers All synthetic fibers because of there chemical make up will melt when contacted with heat. Most synthetic fibers, especially polyester will also create a thick black smoke when ignited. When the fiber is still hot, you will usually be able to pull long plastic strands (filaments) out of the fabric. Which type of fabric would you rather be wearing if caught in a fire? Natural or synthetic? What will nylon do will it’s exposed to flame? Let’s make a prediction. Page 22 Acrylic How acrylic fiber is made: Acrylic fabric is made of manmade acrylic fibers. Acrylic fibers are made of synthetic polymers which essentially are a soft fibrous plastic. Acrylic fiber was invented in the 1940’s and is mainly manufactured in Asia. Acrylic fabric can be made by wet or dry spinning methods. Disadvantages •Usually dry cleaned •Never use a hot iron •Fair strength, Characteristics •weak when wet Created to be similar to wool •hydrophobic •Less expensive Advantages •static and pilling problems •Washable •Light weight, but warm •Washable Proper Care •Soft •Never Iron acrylic fabric •Machine washable Page 23 Acetate Advantages •Looks like silk •Drapes well •Inexpensive •No pilling, little static •Rarely wrinkles Disadvantages •Poor strength •May fade •May wrinkle •Poor abrasion resistance •Laundering (weak when wet) Characteristics •Man made silk alternative •Soft Great drape •Resistant to shrinking •As a chemical, acetate is found in nail polish and nail polish remover. •From cellulose of deconstructing wood or cotton •Found in formal wear and clothing lining Proper Care •Usually dry clean only •Never treat with acetone How acetate fiber is made: Acetate is made from filaments of wood shavings that are extruded as liquid and set to form a fiber. The fibers are woven together to create a fabric that is similar to silk in texture and appearance. Since acetate is derived for wood, which is a natural occurring substance it is the most ecological friendly synthetic fabric. Page 24 Polyester Characteristics Most used synthetic fiber in the US Polymer created from coal, water, and petroleum Fine to heavy weight Often mixed with other fibers to create a blended fabric Proper Care • • Disadvantages • • • Holds oily stains Static and pilling problems Hydrophobic What do you predict will happen when polyester is ignited? Why? What would happen if it was mixed with another fiber? Washes easily on any temperature The more often you wash polyester the more likely piling is to occur Advantages •Best “wash and wear” fabric •Very good strength and abrasion resistance •Will not shrink or stretch •Resists wrinkles •Washable Page 26 How polyester fiber is made: Polyester is made from petroleum byproducts creating a polymer. Fibers are derived chemical reactions involving coal, petroleum, air, and water. When making polyester fabric the polymers are extruded and heated to create long, thin fibers. They are stretched when hot until they are five times their original length making a strong fiber. What is Pilling? Why does it happen? Pilling is the formation of group of short or broken fibers on the surface of a fabric. These broken fibers then tangle together to form ball called a pill. Pills usually form after the garment has been worn several times. Pilling occurs more likely on hydrophobic fibers because they have greater electrical static attraction than hydrophilic fibers do. What natural fiber is polyester normally blended with? Page 27 Characteristics How rayon fiber is made: Rayon is the oldest manufactured fiber. It is Cotton alternative, and has similar qualities produced when the compound cellulose is Made from wood pulp converted to a soluble compound. The liquid of Many different types this compound is passed through a spinneret to form fiber filaments, Which are then spun into fabric by a wet or Proper Care •Some fabrics are machine washable but most are cry clean only Advantages •Inexpensive •Cotton-like •Absorbs moisture Disadvantages Weak when wet Should be dry cleaned Not very strong Rayon Page 28 Characteristics Spandex Can stretch at least 100%, but can snap back into shape. Often blended with rayon, wool or silk Commonly used in active wear Provides elasticity to clothing Proper Care •When cleaning avoid chlorine, drying, or a hot iron. Advantages •Excellent stretch •Great recovery •Washable How spandex fiber is made: Spandex is made of numerous polymer strands. During production the polymers are stretched to their fullest capacity. After the force is removed the fibers return to its relaxed state. By using the elastic properties of the spandex fibers we can create fabrics that can have stretching capabilities. Disadvantages Not as strong when combined with other fibers Have to avoid high heat Have to avoid chlorine bleach Page 29 Stain solutions • Mustard Stains Use a solution containing a combination of rubbing alcohol and dish soap. Mix a solution of three parts dish soap (liquid version only) and one part rubbing alcohol. Be sure that you have an absorbent material under the stain before you apply the solution. Put this solution on the stain and allow it to soak for at least 10 minutes, but not too long such that it dries. The alcohol in this solution may make the stain look dark temporarily, but not to worry, it will rinse out! Rinse the treated area thoroughly with hot water, and then launder with laundry detergent Page 31 Stain Solutions • Grass Stains This mix of bleach with hydrogen peroxide makes an incredible grass stain remover. To use this method, you should mix equal parts bleach and peroxide and then mix three parts of cold water. Place it directly on the stained area and then let it sit. After it has set for about an hour, you should then rinse it thoroughly and then wash the item as normal. Page 32 Stain Solutions • Motor Oil Method 1 • Grab a grease-cutting detergent and a scrub brush. • Apply the detergent to the stain and then scrub with the scrub brush. • Add hot water and scrub it some more. • If you are outdoors, blot it up and then flush with boiling hot water. Method 2 • Some experts swear by using a powdered laundry detergent. • They sprinkle the laundry detergent directly on the stain, • Apply enough water to make a paste, scrub it , and leave it overnight. • Add more water, scrub and then wash off. • Most likely, you will still be able to see stain on the surface. Repeat the process using the detergent and scrubbing as hard as possible with the scrub brush. Blot it up, flush with hot water. Page 33 Stain Solutions Grease • You might have heard it before that dishwashing detergent liquid is great at cutting grease. Well it doesn’t just work wonders on your dishes. It can also be a great way to get tough grease off your hands and even grease stains from clothing. • You will always have better results if you use it on a fresh stain but people have claimed it works on even older stains in some fabrics. • Place the dishwashing detergent directly on the stain. • Allow it to soak into stain for a few minutes • Wash the garment as you normally would. • Before drying, check to be sure the stain is completely removed Page 34 Stain Solutions Juice/ Kool-aid Stain • Step 1: Treat the clothing or fabric with liquid laundry detergent (use heavy-duty detergent, not mild), coating the stain with the detergent. Then, let it sit for several minutes. • Step 2: Rinse off the detergent and stained area with cool (not warm or hot) water. • Step 3: If this has not removed the stain continue on to step 4. Otherwise, launder in the hottest water the fabric will allow to get out the stain, and either chlorine bleach if the fabric will allow it, or color bleach if not. • Step 4: If the above method did not remove the stain, create a presoak solution to place the stained fabric in for at least 30 minutes, and possibly as long as overnight. This presoak solution should contain 1/4 cup of chlorine bleach (oxygen bleach if chlorine bleach is not safe on the fabric) and one gallon of water. • Step 5: After presoaking, follow step 3 above and launder as directed . Page 35 Assignments • Complete the story problems— • Notebook check beginning of class by Tuesday -- Or today . . . – Orange Section: Wordsearch, Sewing Equipment pages, Details of the Machine, Terms. – Green Section: Ironing/Pressing Notes – Yellow Section: All weaves & fiber notes (will talk about Fabric Grain Next Unit) – Worth 100 Points! • Turn in your Portfolio!!! • TIME--VIDEOS Page 36