Product and Process Design

advertisement

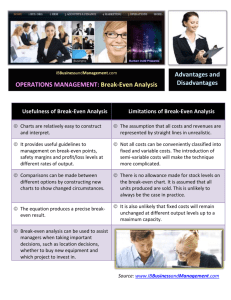

Product Design and Process Selection Based on slides for Chase Acquilano and Jacobs, Operations Management, McGraw-Hill What is a Product? A product is a package of: Goods Services Experiences Ongoing Relationships A product has: Tangible attributes Intangible attributes Examples Automobile Airplane trip Diamond Ring Restaurant Meal Dishwasher College Education Tax Preparation Basketball Game Product Design Issues Value analysis/value engineering Obtain better performance at lower cost Two Design Approaches: Over the Wall Approach vs. Concurrent Engineering Complexity of design Implications?? Reliability How can it be increased? Standardization Advantages & disadvantages? Modular design Advantages & disadvantages? Environmental Implications Exercise Pick several products and list some issues that need to be considered in its design and manufacture Include aesthetic, manufacturability, after-sales service issues among others Deliverable List and present to the class Process Selection Process Structures Continuous Processing Repetitive (assembly lines) Manufacturing cells Batch processing Job Shops Projects “continuous or semicontinuous” “intermittent” Example: Job Shop Example: Batch Processing Example: Assembly Line Processing Example: Continuous Processing Manufacturing Product Design Unique Customized Varied Standardized Very High Continuous Manufacturing Cells V High o l Moderate u m Low e One Assembly Line Batch Job Shop Project Equipment General Purpose Labor Skill Highly Skilled Scheduling Complexity Managerial Focus Homogenous (Commodity) Highly Specialized Rote Tasks Varied High Low Product Process Fixed Costs Low High Variable Costs High Low Break-Even Analysis Some managerial questions: How much should we produce to break even? For a specific volume, should we manufacture the product ourselves, or outsource? For machine alternatives A and B, at what volumes should we use machine A and at what volumes, machine B? Break-Even Analysis (example) Sale Price = $300 Option 1: Purchase = $200 * Demand Option 2: Lathe = $80,000 + $75 * Demand Option 3: Machine center = $200,000 + $15 * Demand Purchase vs. Lathe? Lathe vs. Machining Center? Calculations Purchase versus Lathe: $200 * Demand = $80,000 + $75 * Demand ($200 * Demand) - ($75 * Demand) = $80,000 $125 * Demand = $80,000 Demand = $80,000/$125 = 640 units so – less than 640 units, purchase; 640 of greater, use Lathe Lathe versus Machine Center: $80,000 + $75 *Demand = $200,000 + $15 * Demand Demand = $120,000/$60 = 2,000 units so – less that 2000 units use the Lathe; 2000 or more use the machining center Break Even Analysis Example You are starting a new business and your fixed costs are estimated to be $500,000. Your product sells for $100 and costs you $50 to manufacture. What is the breakeven point? If you sell 15,000 units, what will be your profit? Answer: Break Even Value is 10,000 and Profit is $250,000 Break Even Analysis Formulas Total Revenue = Total Cost P x = F + V x implies: BEP(x) = F/[P-V] Profit = TR-TC = (P-V) x – F Breakeven between two machines: F1 + V1 x and F2 + V2 x -- assume F2 > F1 & V2 < V1 (F2 – F1) / (V1 – V2) Note: F = Fixed Cost; P = Price; V = Variable Cost Break Even Analysis Example In your business you are considering two machines. Machine 1 costs $500,000 and has a variable per unit cost of $50 per item. Machine 2 has a fixed cost of $200,000 and has a variable per unit cost of $80 per item. What is the break-even volume for the two machines. If a friend tells you to use Machine 2 if the volume is 5,000 items, is she right or wrong? Answer: Break Even Value is 10,000 Break Even Analysis Graphical Answer Machine 2 Machine 1 1,200,000 1,100,000 D O L L A R S 1,000,000 900,000 800,000 700,000 600,000 500,000 400,000 300,000 200,000 100,000 5000 Volume 10000 15000 Summary Production Strategies Process focused >>> Product focused Other alternatives: Project, Cellular Technology Break-even Analysis