Here

advertisement

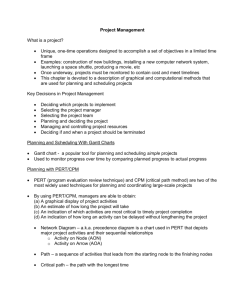

Supply Chain Management: From Vision to Implementation Chapter 7: Supply Chain Mapping Chapter 7: Learning Objectives 1. Discuss the concept of SC design and its importance. 2. Explain process mapping and describe mapping’s role in SC design. 3. Describe several popular approaches for SC design. 4. Map out a supply chain. Describe key insights a manager can gain from a SC map. 2 Supply Chain Management SCM is the design of seamless value added processes across organization boundaries to meet the real needs of the end customer. SC design and improvement is assisted by: 1. Process Mapping - creates visibility of current and improved processes. 2. Value Stream Mapping - depicts flow of information and materials 3. SC Mapping - displays the dynamics that govern how a supply chain works 3 Failure to be Proactive in Design Failure to proactively design a SC results in: Poor coordination of effort Incompatible information systems Long cycle times Communication problems Customer service issues Excessive waste and environmental degradation Relatively high inventories for the level of customer service achieved Lower the optimal profit 4 Process Mapping A process is defined as an activity that transforms or changes input into new output. A process map is a graphic representation of the system and contains a sequence of steps that are performed to produce some desired output. The primary goal behind process mapping is to make complex systems visible. 5 Process Mapping 6 Developing a Process Map Determine the purpose of the process map Establish level of detail Establish system boundaries Determine who has the required information or experience. Analyze the process through observation and interviews, document each step. Draw the map Have the people who are involved in the mapping process as well as others (including those who actually perform the process) review the map for clarity and completeness 7 Process Map – Bake a Cake 8 Process Analysis Process analysis is used to identify non-value added or redundant activities. 1. Begin process analysis by examining the time, cost, resources, and people involved in each step. Identify the steps that consume the most time or resources. Identify processes that take too long or vary greatly in time. Identify points of delay. Estimate the value added by each step and judge the value against the cost. Consider the reasons for problems and how to improve specific activities or processes. 9 Process Analysis 2. Re-examine each decision symbol. Determine if the decision is necessary and adds value? Consider combining decisions or moving them to another point in the process to create more value. 3. Check each rework loop. A rework loop involves iterative processes, like repeatedly checking a cake until it is done baking. Here, consider how rework can be reduced, eliminated, or combined with another step. 4. Finally, look at each process step again. Sometimes a process is done out of habit without verifying its value. Verify that the step adds more value than its cost. Judge if the step is redundant. Consider how steps could be recombined for greater efficiency. 10 Initial Process Map 11 Improved Process Map 12 Value Stream Mapping Specific application of process mapping based on lean Manufacturing principles. System boundaries typically defined at the macro level. Generally contains more information then typical process maps: Process time Process performance characteristics Information flows Physical flows 13 Supply Chain Design Supply chain design is just too important to leave to chance. Just as genetic engineering has begun to shortcut the process of species evolution, proactive chain design will shortcut and forever make obsolete the slow, incremental processes of industrial evolution. - Charles Fine, Professor at MIT 14 Supply Chain Design 1. Identify the chain’s end customer 2. Determine the Supply Chain’s value proposition Identify the key players at each level and the value they add Determine where your company is and value it adds 3. Analyze who possesses the power in the supply chain: manufacturer, distributor, retailer, or other party Determine who has the best linkages with the end customer Establish the key technologies that drive SC success Assess the core competencies that drive SC success 15 Supply Chain Design 4. Isolate the major processes required to support the supply chain’s value proposition Determine where there is a significant amount of time and variability 5. Establish what the ideal supply chain would look like Ascertain the as-is value-added roles of the various supply chain members Analyze how much control over supply chain activity we want or need Clarify the should-be value-added roles of the various supply chain members 16 Traditional and SC Process Focus Process Traditional Supply Chain Inventory Management Approach Only company-owned Whole chains, high turns Cost Management Approach Price focus Total cost Coordination of Sharing and Monitoring in Chain Limited Long Horizon for planning Amount of Coordination of Multiple Levels in the Chain Limited Extensive Planning in Supply Chain None Integrated with information technology Supplier Management Arms-length and/or adversarial Close relationships with key suppliers 17 Traditional and SC Process Focus Process Traditional Supply Chain Leadership in Supply Chain None Leadership roles defined among players Sharing of Risks and Rewards None Defined with key players Speed of Operations, Information/Inventory Flows Slow, limited Rapid, extensive Information Technology Not an issue; internal focus in supply chain Extensive improvements and linkages Team Process None with customers or suppliers Joint teams with key customers and suppliers 18 Approaches to Supply Chain Design Common Elements: Identification of Customer and Value Proposition Identification of Membership Structure of Member Relationships Locus of Control Design Tools 1. 2. 3. 4. SCOR Model Supply Chain Double Helix Nature of Product or Service Product Life-Cycle 19 SCOR Model Supply chains are based on a series of linked, planned-source-make-deliver-and-return processes. 20 SCOR Model Steps in the SCOR model: Analyze the basis for competition: what do you need to do well in order to succeed? How can you measure and monitor your progress in these key areas? Configure the supply chain as it is and as you would like it to be. Include geographic locations and flows. Align performance levels, practices and systems across information and work flows. Implement SC processes and systems, including people, processes, technology and organization 21 Supply Chain Double Helix Supply chains are constantly evolving and changing as the environment which they compete changes. The ability to design and redesign supply chains proactively that creates competitive advantage. As a company designs and redesigns its supply chains must take advantage of designed for initiatives. 22 Supply Chain Double Helix 23 Design for Initiatives - DFX Design for initiatives attempt to create an atmosphere where designers work with other key players internally or externally to insure critical issues are considered and integrated into design of products and processes. Design for manufacturability Design for distribution Design for disassembly Design for environment Design for supply Design for the customer 24 Nature of the Product or Service Supply chain should be structured based on whether the product or service they deliver is innovative or functional in nature. Innovative products have short life cycles Functional products fulfill basic needs Insight generated from this design strategy can complement the SCOR, Double Helix, or product life-cycle models. 25 Innovative Product Supply Chains Innovative products have relatively: high profit margins unpredictable short-lived demand high risk of obsolescence. Supply chain should: Seek to minimize inventory Focus on speed and flexibility Ideal supply chain: Responsive 26 Functional Products Supply Chains Functional products have relatively: Predictable demand Long life cycles Large number of substitutes Supply chain should: Seek to minimize cost Provide reliable and high service levels Ideal supply chain: Efficient 27 Product Life-Cycle Issues 28 Supply Chain Mapping Supply chain mapping generally begins with a high level map to identify major linkages and bottleneck areas. Supply chain maps should consider linkages with customers and key suppliers. Tools like the pipeline map may identify unnecessary complexity, thereby leading to improvements to the current competitive state of the supply chain. 29 Pipeline Map - Example 30 Pipeline Mapping Steps 1. Identify the item that you wish to map. 2. Identify all of the processes that occur on the physical pipeline for that product, including supplier processes. 3. Determine who performs each process in the chain. 4. Talk to each of the entities that performs a process, determine how long the process takes; how much inventory is present; how much inventory is in transit and transit times for materials. Inventory would include raw materials, components, and output 31 Pipeline Mapping Steps 5. Draw the SC pipeline map from raw material to end user as a series of horizontal and vertical lines. a. b. c. d. e. Begin by drawing a horizontal line from the commodity market to the end user. The length of the horizontal line represents the total process and relevant transportation time. Starting with the earliest process, write the name of the processes in order above. After the name of the process, indicate the time the process takes. Draw vertical lines at the beginning and end of each process to indicate the average amount of inventory that each party has on hand in terms of both input and output. These represent the average inventory that any party in the supply chain is holding. If the product is not physically transformed by the process, only one inventory level is shown. Adding total inventory in the pipeline identifies the amount of “non-value added” days or buffer inventory. Alternatively, use flow modeling to , identify both the time and cost associated with a process. Focus process improvement on the processes with the highest value and the longest delays. 32 Pipeline Mapping Steps 6. Analyze the supply chain for opportunities. 7. 8. 9. Consider means to reduce the pipeline length. Map relevant SC processes. Look for unnecessary processes and delays. Identify potential improvement opportunities. Consider means to reduce the level of buffer inventory. This represents assets that SC members have tied up increasing cost and risk while lowering the agility of the chain. Analyze where inventories are too high by focusing on areas with the highest levels and longest delays. Prioritize your ideas from step 6. Work with the team, suppliers, customers and other affected parties to implement, manage, and monitor changes. Don’t limit yourself to the first tier suppliers or customers, as the supplier’s suppliers and customer’s customers may also provide excellent ideas or opportunities for SC improvement. Analyze the new supply chain, revisiting step 6 until satisfied with the improvement results or they are no longer cost-beneficial. Repeat the procedure with other supply chains. 33 A Return to the Opening Story Based on what you have now read and discussed: 1. Does “drawing a picture” of Olympus’ core process seem like a good way to seem like a good way to identify improvement opportunities? Why or why not? 2. Does extending the idea of process mapping to the supply chain make sense? In what ways would you expect SC mapping to differ from process mapping? 3. Where would you begin in drawing the SC map? Who should be involved? 4. SC mapping answers the questions, “How do we fit?” and “How should we fit?” Why begin with a map of your current process before drawing a map of how you would like things to be? 34 Supply Chain Management: From Vision to Implementation Supplement G: Project Management Project Management Project and process management are closely related practices. Project management requires a good understanding of interdependencies among activities, time and resources necessary to complete these activities. Three best-known project management tools: critical path method (CPM), Gantt charts, and the program evaluation review technique (PERT) 36 Critical Path Method (CPM) Developed by DuPont and Remington Rand during the 1950s Projects are broken into various activities Precedence between activities determine sequence for completion Activities with no slack, amount of time an activity can slip without impacting overall completion time, are said to be along the “critical path” 37 CPM Steps Step Number Step Name 1 List required activities 2 Construct precedence diagram 3 Estimate time necessary for each activity 4 Calculate earliest start and finish times 5 Calculate latest start and finish times 6 Calculate slack of each activity 7 Identify critical path 8 Use critical path information to better manage project 9 If necessary, calculate the cost and benefits of crashing the critical path 38 CPM Example Data Activity A B C D E F G H I Time (days) 5 2 4 4 3 7 3 2 4 Preceding Activities none none A A B B D, E F C, G, H 39 Project Precedence Diagram 40 Organization of CPM Information 41 CPM with Task Times 42 CPM - Calculations Earliest Finish Time Earliest Start Time Activity Time Latest Start Time Latest Finish Time - Activity Time 43 CPM Forward Pass 44 CPM Backward Pass 45 Identification of Critical Path 46 Project Crashing In some instances a company may wish to reduce the amount of time for project completion- “Crashing the Project” Accomplished by scheduling overtime, hiring more employees, or adding an extra shift. Decisions on crashing are made by comparing the marginal cost of crashing activities along the critical path. 47 Project Crashing Normal Crash Activity Time (weeks) Cost Time (weeks) Cost A 4 $ 2,000 2 $ 4,000 B 3 $ 1,500 2 $ 1,750 C 2 $ 5,000 1 $ 6,000 Activity Normal Time (weeks) Crash Cost Time (weeks) Cost A 4 $ 2,000 2 $2,000/2 = $1,000 B 3 $ 1,500 2 $250/1 = $250 C 2 $ 5,000 1 $500/1 = $500 48 Gantt Charts A Gantt chart is a graphical trail of a project’s activities over time. Disadvantage of Gantt charts is that they do not show precedence relationships between various project activities. Gantt charts should be used with CPM to help overcome this disadvantage. 49 CPM Example Gantt Chart 50 PERT PERT was developed by the U.S. Navy and Booz Allen Hamilton for use of the Polaris missile project. Major difference between CPM and PERT is the use of multiple time estimates to allow for variation in task completion. Time estimates include: optimistic best case (A), pessimistic worst case (B), and most likely (C) activity times. 51 PERT – Time Estimate A 4C B Time Estimate (mean) 6 Variance B - A 2 2 36 52