Operations Management: Manufacturing & Service Industries

advertisement

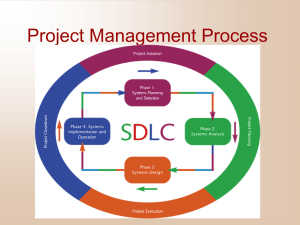

Chapter 11: Operations Management in Manufacturing and Service Industries 1. Operations Management in Manufacturing 2. Facility Layouts 3. Managing the Production Process in a Manufacturing Company 4. Graphical Tools: Pert and Gantt Charts 5. The Technology of Goods Production 6. Operations Management for Service Providers 7. Producing for Quality (cases and Problems) 1. Operations Management in Manufacturing • Define operations management and discuss the role of the operations manager in a manufacturing company • Discuss the factors to consider in a production planning process • What are the various methods of production and how do they work? • What is the difference between mass production and mass customization? • Compare Walla Walla economic development to the site selection process in te book • Explain capacity planning 2. Facility Layouts • Describe the four major types of facility layouts: process, poduct, cellular and fixed position 3. Managing the Production Process in a Manufacturing Company • What are the three components of materials management and how do they work? • Discuss purchasing and supplier selection and tools used in processing and tracking this information • What are some of the commonly used methods in maintaining inventory controls? • What is MPS and how does it work? 4. Graphical Tools: Pert and Gantt Charts • Describe the workings of Gantt and PERT charts. What are they used for? How do they work/ How are they similar? How do they differ? 5. The Technology of Goods Production • Explain how manufacturing companies use technology to produce and deliver goods in an efficient, cost-effective manner • What is CAD? CAM? CIM? and FMS? 6. Operations Management for Service Providers • Discuss the characteristics that distinguish service operations from a manufacturing operations • How does operations planning differ in a service business as opposed to manufacturing? • How does operations process differ? • Discuss service business planning functions involving facilities, site selection, size and layout and capacity planning • What unique challenges does a service provider manager have over a manufacturing manager in the areas o scheduling, inventory controls and capacity 7. Producing for Quality • What are the three tasks in total quality management and how do these principles work? • Describe tools companies use to identify areas of improvement • Discuss international quality standards that are in place to help safeguard consumers • What is outsourcing? How is it used and what are the benefits of using it in the manufacturing and service sectors? Cases and Problems The class will divide into 5 groups: Group 1 and Group 3 will address the Career Opportunity section of Chapter 11 Group 2 and group 4 will address the Global View section of chapter 11 Be prepared to discuss your answers in your groups in the next class session