d10 committee on pipe and tube welding information on

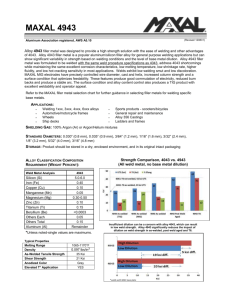

advertisement

D10 COMMITTEE ON PIPE AND TUBE WELDING INFORMATION ON-HAND, PROBLEMS SOLVED, QUESTIONS ANSWERED KNOWLEDGE IS POWER NO MATTER WHAT LEVEL OF THE INDUSTRY YOU WORK … THE D10 DOCUMENT COLLECTION HAS THE INFORMATION YOU SHOULD HAVE AT YOUR FINGERTIPS MATERIALS & METHODS COVERED •AUSTENITIC STAINLESS STEEL •TITANIUM •ALUMINUM •CHROME-MOLY •LOCAL HEAT TREATING •ROOT PASS WELDING •MILD STEEL •COPPER TUBE WELDING PROCESS •GTAW •SMAW •FCAW •GMAW •BRAZING William F. Newell, Jr. PE, IWE, Chair D10C D10.4 RECOMMENDED PRACTICES FOR WELDING AUSTENITIC CHROMIUM-NICKEL STAINLESS STEEL PIPE AND TUBING AWS D10.4 • “…to provide information which may be used to avoid, or at least minimize, difficulties in welding austenitic stainless steel piping and tubing. …” AWS D10.4 - Uses • Often overlooked…… • Excellent resource for: – Developing Corporate Procedures & Specifications – Training Engineers, Supervision and Welders – General Reference Guide AWS D10.4 - History • First published in August 1955 under the title, The Welding of Austenitic Chromium-Nickel Steel Piping and Tubing. A Committee Report and published as AWS D10.4-55T • AWS D10.4-55T was revised in 1966 AWS D10.4 - History • In 1979, a major updating of the document was completed and published as AWS D10.4-79, Recommended Practices for Welding Austenitic Chromium-Nickel Stainless Steel Piping and Tubing. This version presented a detailed discussion of the role of delta ferrite in austenitic chromium-nickel steel welds. AWS D10.4 - History • In 1986, the document was expanded and given an Annex which gives recommendations for welding highcarbon stainless steel castings. • In 1992 and 1999, the document was reaffirmed. AWS D10.4 - History • The current document, ANSI/AWS D10.4M/D10.4:199X, Guide for Welding Austenitic Chromium-Nickel Stainless Steel Piping and Tubing has extended safety and health information and provides information on super austenitic stainless steels and flux cored arc welding. • Tables listing specific chemical composition ranges for base metal and weld metal that fall under the jurisdiction of other codes or documents have been omitted from this revision. Where helpful, however, comparison data is presented. AWS D10.4 - Content • Base Metals & Weld Filler Metals • Ferrite • Welding Processes, Technique & Problems • Dissimilar Joining • Inspection • Safety AWS D10.4 – Base Metals • Austenitic – 300-series • Super Austenitic – 4% & 6% Mo • High Carbon – “HX” Grades Coming ! • D10.18 (DRAFT) • “Guide for Welding Ferritic/Austenitic Duplex Stainless Steel Piping and Tubing” Don Connell Welding Engineer Detroit Edison Company D10.6 RECOMMENDED PRACTICES FOR GAS TUNGSTEN ARC WELDING OF TITANIUM PIPING AND TUBING Applications for Ti Pipe & Tube Where Ti is selected for its corrosion resistance rather than its high strength to weight ratio • Chemical processing • Petrochemical • Desalination • Power generation plants • Navy to replace Cu-Ni in seawater piping Process-GTAW • Other processes may be used to weld Ti but are not covered in this recommended practice Base Metals • 6 grades commonly used for piping, all single phase alpha • Ref: ASTM B337 (seamless & welded pipe) & B338 (seamless & welded tubing) • Replaced by ASTM B861 and B862 Critical Factors in Welding • Cleanliness-proper means of mechanical and chemical cleaning using acids and solvents • Protection from contaminants at elevated temperatures – Trailing shields – Root shielding – Chamber welding Quality Control • Simple tests to check the process before welding & the finished weldment • Describes how weld color is an indication of weld quality Other References • AWS G2.4 to be published this year • Addresses CP and Ti alloys, such as Ti-6Al-4V • Helpful guide in base metal selection • Other welding processes included • Tables of reference documents Tony Anderson ESAB Welding & Cutting D10.7 RECOMMENDED PRACTICES FOR GAS SHIELDED ARC WELDING OF ALUMINUN AND ALUMINUM ALLOY PIPE © Copyright 2005 ESAB Welding & Cutting Presented By: Tony Anderson, ESAB North America The Number One Issue Filler Alloy Selection For Aluminum Welding A Need To Up Date This Information < > Many Base Alloys And Base Alloy Combinations Can Be Joined Using Several Different Filler Alloys Only one filler alloy may be optimum for a specific application When Choosing The Optimum Filler Alloy, the End Use Of The Weldment And Its Desired Performance Must Be The Prime Consideration. < > * Filler Alloy Selection Primary Characteristics W Weldability Or Freedom From Cracking S Strength Of Weld - Tensile Or Shear D Ductility Of Weld C Corrosion Resistance T Temperature Service M Match in color after anodizing * Post Weld Heat Treatment < > Hot Weld Cracking Hot Cracking On 2014 Base Alloy Plate Adjacent To A Gas Tungsten Arc (GTA) Welded 4043 Alloy Fillet < > Weld Cracking - HOT Choice Of Filler Metal Lower Melting & Solidification Point - Molten During Maximum Contraction Stresses Smaller Freezing Zone Avoid Critical Chemistry Ranges Si 0.5% To 2.0% Example: 4043 20% ( Electrode ) 1100 80% ( Base ) Avoid Welding 5xxx Esp.. ( 5086, 5083, 5456 ) With 4043 Or 4xxx. Mgsi Eutectic Problems Avoid Mg Range Up To 3.0% In Weld < > Alloy Content vs. Crack Sensitivity RELATIVE CRACK SENSITIVITY 0 Al - Cu 0 Al - Mg 0 Al - Mg2 Si 0 1 2 3 4 5 6 7 COMPOSITION OF WELD - PERCENT ALLOYING ELEMENT < > Dilution Effect On Weld Composition Base Plate 6061 Filler Metal 5356 20% Filler Metal 1.7% Mg 80% Base Metal 60% Filler Metal 3.2% Mg 40% Base Metal < > Weld Strength - Groove Welds The Heat Of Welding Softens the Aluminum Base Alloy Adjacent To The Weld In Most Groove Welds the H.A.Z. of the Base Alloy Will Control the As-welded Tensile Strength of the Joint < > Heat Affected Zone A Non Heat Treatable A - Weld Metal As Cast Structure Of Base & Filler Metal B - Fusion Zone Where Partial Melting Of Base Metal Occurs C - Anneal Zone Where Base Metal Is Fully Recrystallized - Full Soft D - Partial Anneal Zone Where Base Alloy Is Recovered And Partially Softened B A- 1200 11 0 0 B- 1000 900 800 C700 600 500 D- 400 300 E200 100 RT E - Unaffected < > -A C D E Heat Treatable A - Weld Zone -B B - Fusion Zone -C C - Solid Solution Zone Where Alloy Elements Are Solutioned & Cooled To Retain Solid Solution -D -E D - Partially Annealed Overaged Zone Where Heat Has Caused Precipitation And/or Coalescence Of Particles Of Soluable Constituents E - Unaffected Hardness Profiles of 6061-T6 Made At Three Heat Inputs 100 Hardness RE 90 580 J /cm 756 J/cm 80 70 1128 J/cm 60 AWS D1.2 MIN TENSILE -O TEMPER 50 40 Distance From Weld Interface < > Weld Strength - Fillet Welds The Shear Strength Of Fillet Welds Is The Significant Factor And Is Controlled By The Shear Strength Through The Weld Metal 5356 Produces Greater Fillet Weld Strength In The As Welded Condition Compared To 4043 < > Shear Strength 25000 5556 LBS. Per Linear Inch Shear Strength 20000 5356 4643 5554 5654 15000 4043 10000 1100 5000 0 0 1/8 1/4 3/8 1/2 TRANSVERSE Fillet Size (Inch) < > 5/8 3/4 Shear Strength Typical Shear Strengths Of Fillet Welds Filler Alloy Longitudinal Shear Strength ( Ksi ) Transverse Shear Strength ( Ksi ) 1100 7.5 7.5 2319 16.0 16.0 4043 11.5 15.0 4643 13.5 20.0 5183 18.5 28.0 5356 17.0 26.0 5554 15.0 23.0 5556 20.0 30.0 5654 12.0 18.0 < > Fracture Characteristics Heat - Treatable Alloys Ratio = Notch Tensile Strength Tensile Yield Strength Tear Resistance Unit Propagation Energy In.-lb. / In3 1.6 1600 1.2 1200 0.8 800 0.4 400 Base Metal Filler Alloy 2219 2219 6061 6061 6061 7005 7039 2319 2319 4043 4043 5356 5356 5180 Aged < > Ttear Resistance Ratio 2.0 Corrosion Facts – As Welded Alloy 7075-T6 Welded With 5356 Filler -849mv -876mv -900mv -810mv Post Weld Heat Treated and Aged -810mv -810mv -840mv -806mv Note: Fusion Zone Mechanical Properties Not Restored to PreWeld Properties < > M Color Match After Anodize Rating Scale: A - B Ratings Scale Measures Uniformity Of Color Comparing Base Alloy And Weld Metal After Anodizing. Either There Is A Good Or Reasonable Match Or There Is Not. A Blank Space Indicates No Reasonable Match. < > Color Match After Clear Anodize Base Metal: 6061 6061 6061 6061 6061 WELDED WITH 5356 < WELDED WITH 4043 > Post Weld Heat Treatment Filler Alloys Have Been Developed Which Will Respond To Postweld Heat Treatment. 4643 Was Developed For Welding The 6xxx Base Alloys, Has Additions Of Mg And Is Less Dependant On Dilution Of The Base Alloy To Achieve Desired Composition. Filler Alloys For Welding Castings Have Been Developed With Chemistries Which Will Respond To Post Weld Heat Treatment. < > © Copyright 2005 ESAB Welding & Cutting Conclusion Filler Alloy Selection For Aluminum Can only be made after a full analysis of a welded components performance requirements Should involve the consideration of metallurgical effects (changes in crack sensitively) when combining base alloy chemistry with filler alloy chemistry Can substantially influence the strength and performance of a welded component < > William F. Newell, Jr. PE, IWE, Chair D10I D10.8 RECOMMENDED PRACTICES FOR WELDING OF CHROMIUMMOLYBDENUM STEEL PIPING AND TUBING AWS D10.8 “… provide recommendations for welding chromium-molybdenum steel pipe and tubing to itself and to various other materials. Subjects covered in detail are filler metal selection, joint design, preheating, and postheating. …” AWS D10.8 - Uses • Often overlooked…… • Excellent resource for: – Developing Corporate Procedures & Specifications – Training Engineers, Supervision and Welders – General Reference Guide AWS D10.8 - History • First presented in 1961 as a Committee Report by the AWS Committee on Piping and Tubing. • Revised in 1978 and became a “Recommended Practice” • Subsequent revisions/reaffirmations in 1986 and 1996 AWS D10.8 - Content • • • • • • Base Metals Weld Filler Metals Joint Design & Preparation (purging) Preheating Post Weld Heat Treatment Repair/Maintenance of Service Exposed Material • Safety AWS D10.8 – Base Metals • • • • • • • C-Steel C-Mo 1-1/4Cr-Mo 2-1/4Cr-Mo 5Cr-Mo 7Cr-Mo 9Cr-Mo (Standard Grade Only) AWS D10.8 – Filler Metal • Recommendations – Process – AWS Classification Options [C, CrMo & Ni-base] – Similar v. Dissimilar AWS D10.8 – Priorities ! • Preaheat w/recommendations • Interpass • Post Weld Heat Treat w/recommendations Pending ! • D10.08 (DRAFT) • Removing information on 9CrMoV (P91) • Removing References to Standard Welding Procedures Coming ! • D10.21 (DRAFT) • “Guideline for Welding Advanced Chromium-Molybdenum Steel Piping and Tubing” – P91, P911, P92, P122, T23… Dan Ciarlariello Mannings USA D10.10 RECOMMENDED PRACTICES FOR LOCAL HEATING OF WELDS IN PIPING AND TUBING Definition of Heat Treatment • Heat Treatment is generally defined as heating to a suitable temperature then cooling at a suitable rate of a solid metal or alloy in a way so as to obtain specific conditions and/or properties by changing the physical, chemical and/or mechanical properties of the steel, metal or alloy Methods Of Localized Heat Treating • Electrical Resistance • Induction • Combustion / Flame • Quartz Lamps • Exothermic Kits. Electrical Resistance Inductive Heating Combustion / Flame Quartz Lamps Reasons for Localized Heat Treating • Bake Out • Preheating and Inter-pass Temperatures • Post Heating • Post-weld Heat Treatment Comparison of Heating Processes • • • • Induction - Resistance Attribute Yes Yes Applicability to bake- • out Applicability to • Yes Yes preheat/inter-pass Applicability to postheating • Yes Yes Applicability to PWHT • Yes Yes Advantages and disadvantages of heating processes Induction Heating Advantages High heating rates Ability to heat a narrow band adjacent to a region which has temperature restrictions Disadvantages High initial equipment cost. Equipment large and less portable. Limited ability to create control zones around the circumference. Advantages and disadvantages of heating processes Electrical Resistance Advantages Ability to continuously maintain heat from welding operation to PWHT Good ability to vary heat around the circumference Disadvantages Elements may be damaged during welding Quantity of heaters required on thicker components High Frequency Induction heating • Uniform product quality • Increased surface wear-proof characteristics • Increased material fatigue strength • Minimum strain due to local surface hardening • Very localized heating Why Preheat? • • • • • • Reduce the level of thermal stress. Compensate for high heat losses. Minimize the rate of weld hardening. Reduce porosity. Reduce hydrogen cracking. Improve the microstructure. Typical Preheat Set-up Boiler Tube Welds Wireless Thermocouple Transmission AWS D10.11 Walter J. Sperko, P.E. Sperko Engineering Services, Inc. Guide for Root Pass Welding of Pipe Without Backing AWS D10.11 Keywords • Root pass welding, pipe, gas purging, consumable insert, gas tungsten arc welding, gas metal arc welding, shielded metal arc welding AWS D10.11 Introduction • This publication was intended to be a “how to” guide in the use of open root and consumable insert welding techniques for root pass welding of groove welds joining metal pipe. AWS D10.11 Introduction • Joint designs, fitting techniques, consumable insert configurations, filler and base metal combinations, purging, and welding processes are discussed. This publication made no provision for joints which include backing rings AWS D10.11 Introduction • This standard is a “best practices” guide to making high-quality pipe butt welds where backing cannot be used • Welders should have excellent reasons for deviating from what this standard recommends AWS D10.11 • What is “Root Pass Welding?” • Let’s look at some “root passes”. . . . AWS D10.11 • A single-vee Butt weld between two pipes AWS D10.11 • Root pass on a Socket Weld AWS D10.11 • Root pass on a Double Vee-Groove Weld AWS D10.11 • All of these “Root Passes” are on backing AWS D10.11 • Take away the Backing Strip and you have a weld without backing. . . . Welding without Backing You now have a pool of liquid metal hanging in space suspended between the ends of two pipes. . . Welding without Backing Torch Blast the arc force through the root opening and melt the edges of the metal, then fill the opening with filler metal Welding without Backing Electrode Blast the arc force through the root opening and melt the edges of the metal, then fill the opening with filler metal Effect of Included Angle LARGE included angle makes it easy to get the electrode close to the root and easy to direct the arc into the root. Effect of Included Angle included angle holds the electrode away from the root and makes it difficult to direct the arc into the root. SMALL Full Root Penetration Continuous metal surface from one member across the weld to the other member Forces on the weld pool? Longitudinal Section of a pipe joint Forces on the weld pool Gravity Longitudinal Section of a pipe joint Forces on the weld pool Surface Cohesion (wetting) between the weld pool and the solid metal Longitudinal Section of a pipe joint Forces on the weld pool weld pool must fill the gap without becoming too large The arc must melt both edges of the root face and the Longitudinal Section of a pipe joint Forces on the weld pool If the weld pool becomes too large, the surface cohesion forces are overcome. The result is root concavity or dropthrough. Longitudinal Section of a pipe joint Parts of a Groove Weld Joint Design Root Face (“Land”) Parts of a Groove Weld Joint Design Root Opening (“Root Gap”) Root Opening vs. Root Face Thick Root Face Thin Root Face Small Root opening Incomplete Penetration Proportional Root opening Complete Penetration Excessive Root opening Root concavity or burn-through Root opening - Root face thickness relationship 1/8” Root Face Thickness 3/32” 1/16” 1/16” 3/32” Root Opening 1/8” Cleaning • Cleanliness is important in all welding, but it is especially important in root pass welding. • Contamination affects wetting which affects bead shape. Purging Purging • A purge is required for stainless and nonferrous piping systems (except aluminum) if a smooth root surface is to be obtained. • Standard describes how to set up for purging • Purging time Purging • The following oxygen limits are recommended: • • • • For carbon and low alloy steels: 2%(20,000 ppm) For stainless steels: 1/2% (5000 ppm) For nickel alloys: 1/2% (5000 ppm) For titanium and zirconium alloys: 1/4% (2500 ppm) Purging • Welding technique for Open Root • Welding Technique for Consumable Insert • Maintaining purge during welding Fitting and tack welding • Size, spacing, feathering ends • Root spacing depends on process to be used. • Inspection after fit-up. This is the most important step in pipe welding GTAW • Tungsten size, shape of end • Grinding methods GTAW Joint design and fit up GTAW • • • • • Purge containment Arc initiation Keyhole technique Wire feed techniques Orientation of torch and filler GTAW GTAW GTAW • Walking the Cup • Welding with zero root opening (autogenous welding) • Welding in different positions • Using consumable inserts Consumable Inserts 1/32” maximum mismatch Class 1 Insert, formerly the EB (Electric Boat) or “A” type insert. Consumable Inserts 1/16” maximum mismatch Class 2 Insert, formerly the “J” type insert. Consumable Inserts 1/16” maximum mismatch Class 3 Insert, formerly the “Grinnell” or flat insert. Consumable Inserts SMAW • Cellulosic Electrodes (EXX10, EXX11) • Low Hydrogen Electrodes (EXX15, EXX16, EXX18) • Rutile electrodes (E6013) GMAW • Joint design • Fit-up • Welding parameters Fill Passes • Use any suitable process • Don’t melt through the root Aluminum • • • • • Tungsten type, shape of tip Shielding gas cups, lenses Power supplies Techniques Recommended joint design Aluminum Machine and Automatic • Not much said Summary • AWS D10.11 gives very specific recommendations about techniques that have proven successful in making pipe welds without backing • Recommendations should be familiar to welder’s supervision • Recommendations should not be take lightly Alan Beckett D10.12 RECOMMENDED PRACTICES FOR WELDING MILD STEEL PIPE D10.12 Welding Mild Steel Pipe This document provides recommendations for the welding of mild steel pipe such as A106 type. This material is found in many scopes of work, and extensively in commercial building construction. A106 material is often used as a starting point for welder training. Covered Processes • • • • SMAW GTAW GMAW FCAW D10.12 A Document for All Reasons As with other D10 documents, you will find excellent attention to detail presented in a manner for all to understand. For these reasons D10.12 is a welcome addition to your library or a valuable resource for training. MICHAEL LANG AWS/CWI/CWE United Association of Plumbers & Pipefitters D10.13 RECOMMENDED PRACTICES FOR BRAZING OF COPPER PIPE AND TUBING FOR MEDICAL GAS SYSTEMS What is Medical Gas Piping? There are many perceptions of Medical Gas Piping but the facts are: • Cleanliness is entirely dependant on installation practices • Poor installation can produces conditions that harbor bacteria and diseases • These systems are not cleanable • These are life critical systems Purpose The governing document for all Medical Gas Piping is NPFA Code 99C which dictates the methods and installation practices that shall be used in system construction… However this document does not cover actual brazed joint construction or the tools and practices needed for system construction Important Notes • D10.13 is a Recommended Practice developed to work with NFPA 99C. • All recommendations have been used in actual jobsite conditions with a 100% success rate • The use of these practices have produced consistent profitable results Needed Equipment • Use and Care • Torch Selection • Tube Cutting • Purge Monitoring Consumables • • • • • Pre Braze Joint Cleaning Pre Braze Chemical Cleaning Post Braze Cleaning BCuP Brazing Alloys Bag Brazing Alloys Something you will only find in D10.13 • The only document that provides joint heating and filler metal application methods. • These methods continually produce a 99% acceptance rate in accordance with ASME Boiler & Pressure Vessel Code Section XI. And… Purging Methods • Purging is possibly the most important component to internal cleanliness. This document provides methods and parameters for the use of oxygen analyzers. • We also provide purge timing matrix charts for estimating purge times for long runs of piping. These charts should be used in conjunction with an O2 analyzer. Proven Success You Can Trust D10.13 RECOMMENDED PRACTICES FOR BRAZING OF COPPER PIPE AND TUBING FOR MEDICAL GAS SYSTEMS BECOME A COMMITTEE MEMBER FOR DETAILS CONTACT Brian McGrath at bmcgrath@aws.org THANK YOU FOR ATTENDING AND ENJOY THE AWS SHOW