maxal 4943

advertisement

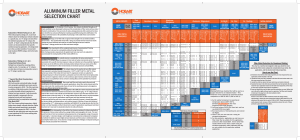

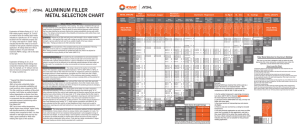

MAXAL 4943 (Revised 120831) Aluminum Association registered, AWS A5.10 Alloy 4943 filler metal was designed to provide a high strength solution with the ease of welding and other advantages of 4043. Alloy 4043 filler metal is a popular aluminum/silicon filler alloy for general purpose welding applications but can show significant variability in strength based on welding conditions and the level of base metal dilution. Alloy 4943 filler metal was formulated to be welded with the same weld procedure specifications as 4043, address 4043 shortcomings while maintaining the same excellent corrosion characteristics, low melting temperature, low shrinkage rate, higher fluidity, and low hot cracking sensitivity in most applications. Welds exhibit low welding smut and low discoloration. MAXAL MIG electrodes have precisely controlled wire diameter, cast and helix, increased column strength and a surface condition that optimizes feedability. These features produce good commutation of electricity, reduced burn backs and produce a stable arc. The surface condition and alloy content control also produces a TIG product with excellent weldability and operator appeal. Refer to the MAXAL filler metal selection chart for further guidance in selecting filler metals for welding specific base metals. APPLICATIONS: Welding 1xxx, 3xxx, 4xxx, 6xxx alloys Automotive/motorcycle frames Wheels Ship decks Sports products - scooters/bicycles General repair and maintenance Alloy 356 Castings Ladders and frames SHIELDING GAS: 100% Argon (Ar) or Argon/Helium mixtures STANDARD DIAMETERS: 0.030” (0.8 mm), 0.035” (0.9 mm), 3/64” (1.2 mm), 1/16” (1.6 mm), 3/32” (2.4 mm), 1/8” (3.2 mm), 5/32” (4.0 mm), 3/16” (4.8 mm) STORAGE: Product should be stored in a dry, enclosed environment, and in its original intact packaging ALLOY CLASSIFICATION COMPOSITION REQUIREMENT (WEIGHT PERCENT): Weld Metal Analysis Silicon (Si) Iron (Fe) Copper (Cu) Strength Comparison, 4043 vs. 4943 (All weld metal, no base metal dilution) 4943 5.0-6.0 0.40 0.10 Manganese (Mn) Magnesium (Mg) Zinc (Zn) Titanium (Ti) Beryllium (Be) Others Each Others Total Aluminum (Al) 0.05 0.30-0.50 0.10 0.15 <0.0003 0.05 0.15 Remainder *Unless noted-single values are maximums. Insufficient dilution can be a concern with alloy 4043, which can result in low weld strength. Alloy 4943 significantly reduces the impact of dilution on weld strength in as-welded, post weld aged and T6. Typical Properties Melting Range Density As-Welded Tensile Strength Shear Strength Anodized Color Elevated T° Application 1065-1170°F 0.097 lbs/in3 35 Ksi 21 Ksi Grey YES *welds with 6061 base plate Maxal • 1631 International Drive • Traverse City, MI 49686 USA • www.Maxal.com PH: (231) 933-1234(Test • FX: data(231) for post933-6110 weld artificially aged condition) Customer Service: 1-800-424-1543 MAXAL 4943 MIG EQUIPMENT SET-UP PARAMETERS: The chart below provides approximate welding parameters as a starting point only. Qualified welding procedures utilizing tested practices should be developed for actual production weldments. Diameter Inches (mm) Base Material Thickness Inches (mm) Amps 4xxx 5xxx Volts 4xxx 5xxx Wire-Feed Speed (ipm) 4xxx 5xxx 0.030 0.030 0.030 0.030 0.030 (0.8) (0.8) (0.8) (0.8) (0.8) 1/16 3/32 1/8 3/16 1/4 (1.6) (2.4) (3.2) (4.8) (6.4) 90 110 130 150 175 100 120 140 160 185 20 22 23 24 24 18 21 21 22 22 260 350 450 550 650 300 400 500 600 700 0.035 0.035 0.035 (0.9) (0.9) (0.9) 1/16 1/8 1/4 (1.6) (3.2) (6.4) 90 130 170 100 140 180 23 24 25 21 22 23 300 400 500 350 450 600 3/64 3/64 3/64 3/64 (1.2) (1.2) (1.2) (1.2) 3/32 1/8 1/4 3/8 (2.4) (3.2) (6.4) (9.5) 110 150 190 220 120 160 220 230 25 26 26 27 24 25 25 25 170 270 320 390 220 330 370 450 1/16 1/16 1/16 1/16 1/16 (1.6) (1.6) (1.6) (1.6) (1.6) 1/4 3/8 1/2 3/4 1 (6.4) (9.5) (12.7) (19.1) (25.4) 200 230 260 280 300 210 240 270 290 310 26 27 28 29 30 24 25 26 27 28 170 200 240 260 280 200 230 270 300 320 STANDARD DIAMETERS AND PACKAGES: For a complete list of diameters and packaging, please call (800) 346-2529. Diameter 1-lb. 12-lb. 16-lb. Spool Reel Reel Pats and Part numbers 16-lb. 22-lb. Plastic Plastic 100-lb. 300-lb. Mini-Drum Drum 36-In Cut Length (1 lb) 36-In Cut Length (10 lb) Inches (mm) 0.030 (0.8) 0.035 (0.9) 0.040 (1.0) 3/64 (1.2) 1/16 (1.6) 3/32 (2.4) 494309470 1/8 (3.2) 494312570 5/32 (4.0) 3/16 (4.8) 494303504 494303512 494303512P22 494303523L 494303523 494304704 494304712 494304712P22 494304723L 494304723 494306212 494306212P22 494306223L 494306223 300 lb drum dimensions: diameter = 23-1/2”; height = 36” 100 lb drum dimensions: diameter = 23-1/2”; height = 18” CONFORMANCES AND APPROVALS: AWS A5.10 CE CPD ISO 9001:2008 *The information contained or otherwise referenced herein is presented only as “typical” without guarantee or warranty, and Maxal expressly disclaims any liability incurred from any reliance thereon. Typical data are obtained when welded and tested in accordance with AWS A5.10 specification. Other tests and procedures may produce different results. No data is to be construed as a recommendation for any welding condition or technique not controlled by Maxal. Maxal • 1631 International Drive • Traverse City, MI 49686 USA • www.Maxal.com PH: (231) 933-1234 • FX: (231) 933-6110 Customer Service: 1-800-424-1543 494306270