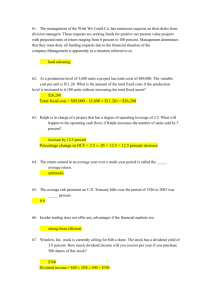

Business 3 Template

advertisement

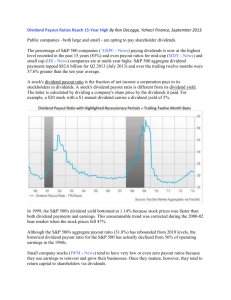

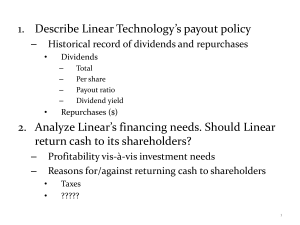

Eastboro Machine Tools Corporation Thresia Hilda Krey Nikken Nuartiana 37408023 37408037 Felix Sulistio Thio Amanda Fabiola 37408035 37408044 THE COMPANY • Founded in 1923 in Concord, New Hampshire • By two mechanical engineers: James East & David Peterboro WHAT’S THE PRODUCT? • Early years machinery parts, including metal presses, dies, and molds • 1940’s tank and armored-vehicle parts, miscellaneous equipment for the war effort • Late 1970’s computer-aided design (CAD) computer-aided manufacturing (CAM) INCOME STATEMENT 1998 1999 2000 2001 Net sales $ 858.263 $ 815.979 $ 756.638 $ 870.000 Cost of sales $ 540.747 $ 501.458 $ 498.879 $ 549.750 $ 317.516 $ 314.522 $ 257.759 $ 320.250 Research & development $ 77.678 $ 70.545 $ 75.417 $ 77.250 Selling, general, & administrative $ 229.971 $ 223.634 $ 231.008 $ 211.500 Restructuring costs $ 65.448 $ - $ 89.411 $ - $ (55.581) $ 20.343 $ (138.077) $ 31.500 $ (4.500) $ 1.065 $ (3.458) $ (4.200) $ (60.081) $ 21.408 $ (141.534) $ 27.300 $ 1.241 $ 8.415 $ (750) $ 9.282 Net income (loss) $ (61.322) $ 12.993 $ (140.784) $ 18.018 Earnings (loss) per share $ (3,25) $ 0,69 $ (7,67) $ 0,98 Dividends per share $ 0,77 $ 0,25 $ 0,25 $ 0,39 Gross profit Operating profit (loss) Other income (expense) Income (loss) before taxes Income taxes (benefit) WHAT HAPPENED? • The aggressive entry of large foreign firms into CAD/ CAM and the rise of the dollar dampened sales • Revenues declined from $ 911 million in 1994 to $ 757 million in2000 WHAT TO DO? • First, devoted a greater share of its research & development budget to CAD/ CAM to reestablish leadership • Second, the company underwent two massive restructurings in 1998 restructuring costs totaled $ 65 million in 2000 was $ 89 million The CAD/ CAM research led to the development of a system that Eastboro management believed would redefine the industry, known as Artificial Workforce. The system was an array of advanced control hardware, software, and applications that could distribute information throughout a plant TWO FACTORS THAT COULD AFFECT SALES • Two strong competitors were developing comparable products • Sales of molds, presses, machine tools, and CAD/ CAM equipment and software were highly cyclical, and the strength of the U.S. economy weren’t encouraging Eastboro management remained optimistic about the company’s prospects because of the successful of the Artificial Workforce CORPORATE GOALS • Management wanted and expected the firm to grow at an average annual compound rate of 15%. • A great deal of corporate planning had been devoted to that goal over the past 3 years and second-quarter financial data suggested that Eastboro would achieve revenues of about $870 million in 2001. (Exhibit 1) STRATEGY TO ACHIEVE GROWTH GOAL • The mix of production would shift substantially. • The company would expand aggressively internationally. • The company would expand through joint ventures and acquisitions of small software company. THE STORY • Eastboro had an aversion to debt. • Although 11 members of the East & Peterboro families owned 30% of the company’s stock & 3 were on the board of directors, management placed the interest of the public shareholders first. • At the age of 61, East was actively involved in all aspects of the company’s growth & future. THE STORY • His retirement was no more than 4 years into the future, & he wanted to leave a legacy of corporate financial strenght & technological achievement. • East took particular pride in selecting & developing young managers with promise. • Campbell, bachelor’s degree in electrical engineering. • Had been in a systems analyst for Motorola before attending graduation. • Hired in 1991, then 2000 become a CFO. Dividend Policies August 2001, Campbell has 3 possible dividend policies to recommend: • Zero-dividend payout • 40%-dividend payout • Residual-dividend-payout policy Zero-devidend payout • Firm’s strategic emphasis on advanced technologies CAD/CAM, reflected the huge cash requirement • Firm is in a class of high-growth and hightechnology firms. • Market was expecting strong capital appreciation but, perhaps, little in the way of dividends • Recent studies, company are less paying dividend market wouldn’t react unkindly with zero-dividend payout 40%-dividend payout • Dividend about $ .2 a share • $ .8/share , the highest since 1997 • Anticipation to the announcement of current stock price $ 32 per share and expected increase in order and sales – market expecting strong dividend (45%-electrical industrial equipment & 29%-machine tools industry) • Large dividend – company had conquered problems & directors were confident of future earnings • Borrowing to pay dividends was not inconsistent with the behaviour of most firms Residual-dividend-payout policy • Pay dividends only after funding all projects with positive NPVs • View of Investor paying managers to deploy their funds at return better than they could achieve (dividends) – firm would build trust with investor and higher valuation multiples (e.g. General Motors) • Dividend policy was ‘irrelevant’ in a growing firm in a perfect market – dividend payment would be unpredictable • Dividend payments tended to be ‘sticky’ upward Image Advertising and Name Change • Eastboro’s director of Investor’s Relation, Cathy Williams, had concluded that investors misperceived the firm’s prospects and that the firm’s current name was more consistent with the firm’s historical product mix and markets than with those expected in the future. • Through focus group, the consultants identified a name that appeared to suggest the firm’s promising strategy: “Eastboro Advanced Systems International, Inc.” Conclusion Jennifer Campbell was caught in a difficult position: Some managers saw the company as entering a new stage of rapid growth and thought that a large dividend would be inappropriate Some thought that it was important to make a strong gesture to the public that management believed Eastboro had turned the corner and was about to return to the levels of growth and profitability seen in the 1970s and ‘80s through a dividend