WELD 239 Pipe Welding

advertisement

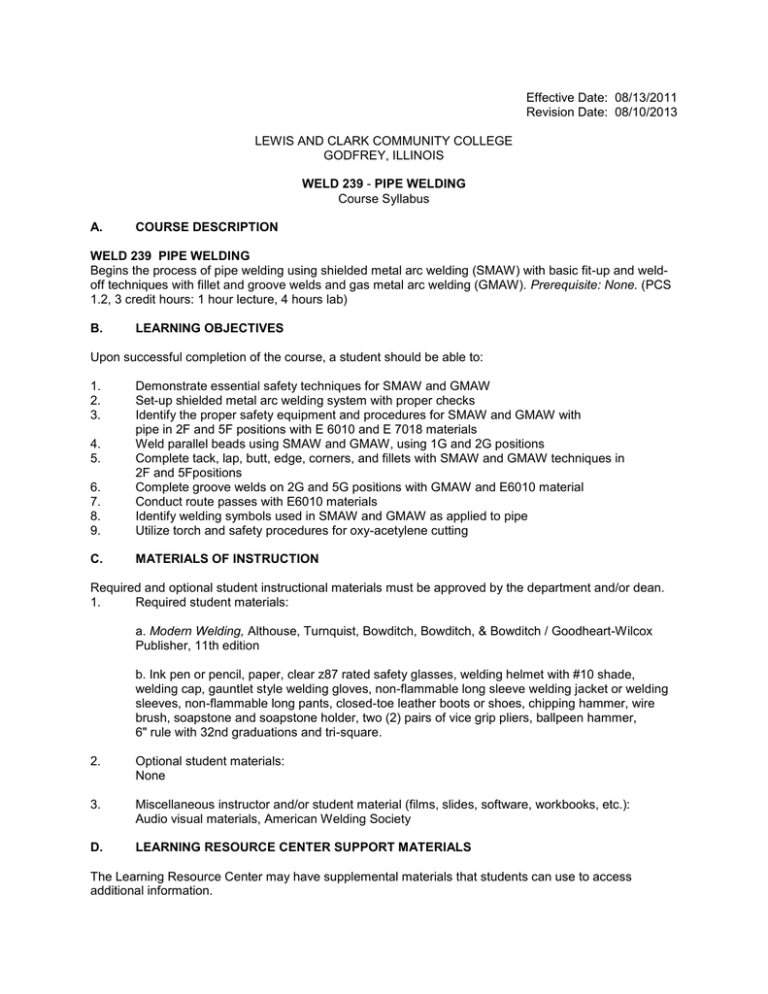

Effective Date: 08/13/2011 Revision Date: 08/10/2013 LEWIS AND CLARK COMMUNITY COLLEGE GODFREY, ILLINOIS WELD 239 - PIPE WELDING Course Syllabus A. COURSE DESCRIPTION WELD 239 PIPE WELDING Begins the process of pipe welding using shielded metal arc welding (SMAW) with basic fit-up and weldoff techniques with fillet and groove welds and gas metal arc welding (GMAW). Prerequisite: None. (PCS 1.2, 3 credit hours: 1 hour lecture, 4 hours lab) B. LEARNING OBJECTIVES Upon successful completion of the course, a student should be able to: 1. 2. 3. 6. 7. 8. 9. Demonstrate essential safety techniques for SMAW and GMAW Set-up shielded metal arc welding system with proper checks Identify the proper safety equipment and procedures for SMAW and GMAW with pipe in 2F and 5F positions with E 6010 and E 7018 materials Weld parallel beads using SMAW and GMAW, using 1G and 2G positions Complete tack, lap, butt, edge, corners, and fillets with SMAW and GMAW techniques in 2F and 5Fpositions Complete groove welds on 2G and 5G positions with GMAW and E6010 material Conduct route passes with E6010 materials Identify welding symbols used in SMAW and GMAW as applied to pipe Utilize torch and safety procedures for oxy-acetylene cutting C. MATERIALS OF INSTRUCTION 4. 5. Required and optional student instructional materials must be approved by the department and/or dean. 1. Required student materials: a. Modern Welding, Althouse, Turnquist, Bowditch, Bowditch, & Bowditch / Goodheart-Wilcox Publisher, 11th edition b. Ink pen or pencil, paper, clear z87 rated safety glasses, welding helmet with #10 shade, welding cap, gauntlet style welding gloves, non-flammable long sleeve welding jacket or welding sleeves, non-flammable long pants, closed-toe leather boots or shoes, chipping hammer, wire brush, soapstone and soapstone holder, two (2) pairs of vice grip pliers, ballpeen hammer, 6" rule with 32nd graduations and tri-square. 2. Optional student materials: None 3. Miscellaneous instructor and/or student material (films, slides, software, workbooks, etc.): Audio visual materials, American Welding Society D. LEARNING RESOURCE CENTER SUPPORT MATERIALS The Learning Resource Center may have supplemental materials that students can use to access additional information. E. METHODS OF INSTRUCTION Instructional methods in this course may include, among others, the following: 1. 2. 3. Lecture Discussion Demonstration F. EVALUATION OF STUDENT ACHIEVEMENT The instructor's policies on evaluation will be distributed to students and the division office at the outset of the course. The methods of evaluating student achievement will include, at minimum, the following: 1. 2. 3. Six homework assignments Two examinations Four presentations of pipe-welding projects Additional methods of evaluation may be used and described in the course outline. G. ATTENDANCE POLICY Regular attendance is expected. The instructor's policies on attendance will be distributed to students and the division office at the outset of the course. H. COURSE CONTENT The following topics are to be covered during the instructional process: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Rules of safety for SMAW and GMAW welding Composition of welding electrodes in SMAW and GMAW pipe welding Appropriate procedures in welding using 2F E6010 and E7010 electrodes Basic fit-up and weld-off techniques with fillet welds and groove welds Entry-level skills in GMAW pipe welding Groove welds in 2G and 5G positions with E6010 materials Route passes with E6010 materials Cutting and welding various thicknesses Vertical and horizontal welding techniques Cutting pipe materials with oxy-acetylene This work is licensed under the Creative Commons Attribution 4.0 International License. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/. This product was funded by a grant awarded by the U.S. Department of Labor’s Employment and Training Administration. The product was created by the grantee and does not necessarily reflect the official position of the U.S. Department of Labor. The Department of Labor makes no guarantees, warranties, or assurances of any kind, express or implied, with respect to such information, including any information on linked sites and including, but not limited to, accuracy of the information or its completeness, timeliness, usefulness, adequacy, continued availability or ownership. 100% of the funds for this product was provided by the US Dept. of Labor Round 3 TAACCCT grant.