Push Vs. Pull Systems -

advertisement

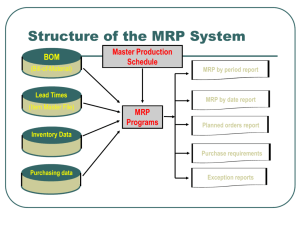

Push Vs. Pull Part Two – Focus on MRP IE 3265 POM R. R. Lindeke, Ph. D. Components of a Pull System Master Production Schedule – a breakout of the Aggregate Plan Actual MRP System Uses forecast demands/Firm Customer Orders/Safety Stock Levels/Internal Orders Structured Bill of Materials Production Times Detailed Job Shop Schedules Detailed Inventory Records Defining Explosion Calculus This is the crux of MRP MRP converts “Dependent Demands” derived from the Zero Level of an ordered product into a series of Job Orders for: Customer Orders Internal Orders Safety Stocks to meet unexpected demands The MRP explodes each order of “0’s” into the required series of Children orders needed internally to build the required products Some Other Important Terms Gross Requirements: Scheduled Receipts: Total needs of a part for ALL parents in a MPS & safety stock along with internal needs – like for maintenance parts, replacement parts, etc These are open orders placed but not yet received Planned Receipts: Planning done over time horizon to keep on hand inventories from dropping below zero (safety stock level) which are backed up into orders to arrive when the shortage would have occurred Some Other Important Terms, cont. Planned Order Releases: A release when an order for a specified quantity (EOQ, L4L, etc) is done This should happen in the correct “Time Bucket” – a time bucket is the time stage used during projection Order release considers: Setup; Processing time; Handling time; Delays, curing, waiting times These apply to each item in the product string We will consider a Seat Assembly for a Ladder Back Chair Looking at a Ladder Back Chair: Structured Bill of Materials for Ladder Back Chair Focusing on the Seat Assembly We can use several Order Schemes: EOQ or other fixed order quantity (FOQ) schemes POQ periodic order quantities which will order a computed amount needed to cover orders over an extended (specified) period of time. The orders are released at fixed time intervals corresponding to the time buckets Lot-for-Lot (L4L) – a simple plan that puts out a “time bucket” order to match lot demand – simple but not necessarily the most economical Planning for the Seat Ass’bly Used in two parent products: Ladder back and Kitchen Chairs Requirements: – – – – Wk 1: Wk 4: Wk 6: Wk 7: 150 LBC 120 KC 150 LBC 120 KC Lets try it as a L4L plan – zero on hand inventory, no safety stocks Lead time for Chair assembly is 2 weeks Assume we have 37 in inventory from previous plans and expect a delivery of 230 as we enter this period L4L Plan (manual MRP!) 1 Gross Re’ment: 150 Sch. Receipts 230 Proj. Inventory 37 + 80 = 117 2 4 5 120 117 Planned Receipts Planned O. Release 3 117 0 0 3 3 150 120 6 7 150 120 0 0 150 120 8 9 0 0 Using a (3 period) Periodic O.Q. 1 Gross Re’ment: 150 Sch. Receipts 230 Proj. Inventory 37+80 = 117 2 4 5 120 153 153 6 7 8 9 0 0 150 120 117 117 150 150 Planned Receipts Planned O. Release 3 0 0 120 120 Focusing on the “Periods” Period 1 (1-2-3): needs are 150 Receipts/onhands are 230 + 37 Xs is 117 which enters inventory Period 2 (4-5-6): needs are (120 + 150) = 270 units Less onhand (117) means we need 153 units for period to arrive at start of period Release order in period two to arrive by period 4 – start of second period Final Period: Period 3 (7-8-9): Needs are: 120 units No on-hand inventory is carried forward so must release an order in period 5 (for 120) to arrive in period 7 when needed Next, lets look at a deeper need: – The frame parts of the seat Ass’bly which has a 1 week lead time (each seat ass’bly requires 4 frame pieces) Try it with L4L 1 Gross Re’ment: 150 Sch. Receipts 230 Proj. Inventory 37 + 80 = 117 2 3 5 120 117 117 Planned Receipts 0 0 3 Planned O. Rel (SA) POR Frames 4 3 12 150 600 480 120 6 7 150 120 0 0 150 120 8 9 0 0 Effect on POQ method 1 Gross Req’men: 150 Sch. Receipts 230 Proj. Inventory 37+80 = 117 2 4 5 120 153 Planned O. Rel (SA) 153 612 7 0 0 120 120 480 6 8 9 0 0 150 120 117 117 150 150 Planned Receipts P. O. R. frames 3 Costing the plans -- Basis is Setup vs. Holding (as expected!) Given: $0.40/ass’bly holding; $120 Setup – L4L on SA: – POQ: .4*(117*3) + 3*120 = 140.4 + 360 = $500.40 .4*(3*117 + 2*150) + 2*120 = 260.4 + 120 = $500.4 Given: $0.10/ass’bly holding; same setup – L4L on SA: – 35.10 + 360 = $395.10 POQ: 65.10 + 240 = $305.10 Continuing but adding in Frame Ass’blies For Frames: K = $100; h = $0.02/piece L4L: SA Costs + (1092*.02) + 3*100 = 395.10 + 21.84 + 300 = $716.94 POQ: SA Costs + .02(612 + 480) + 2*100 = 305.10 + 21.84 + 200 = $526.94 Using EOQ (previously found to be Recognizing 230) shortfalls in P4 and P7 we release EOQ orders to fill needs 1 Gross Req’men: 150 Sch. Receipts 230 Proj. Inventory 37+80 = 117 2 4 5 120 230 230 6 7 8 9 150 120 117 117 227 227 Planned Receipts Planned O. Release 3 77 187 187 187 230 230 Comparing Methods Compute Average Inventory (period) – Here: L4L is (3*117)/9 = 29 POQ is (3*117 + 2*150)/9 = 72.3 EOQ is (3*117 + 2*227 + 77 +3*187)/9 = 160.3 The choice is based on comparing setup costs vs. the average inventory costs Statement of the Lot Sizing Problem – looking for an optimal Assume there is a known set of requirements (r1, r2, . . . rn) over an n period planning horizon. Both the set up cost, K, and the holding cost, h, are given. The objective is to determine production quantities (y1, y2, . . ., yn) to meet the requirements at minimum cost. The feasibility condition to assure there are no stockouts in any period is: j j y r i 1 i i 1 i for 1 j n Methods Property of the optimal solution: every optimal solution orders exact requirements: that is, y1 r1 or y1 r1 r2 ,. . ., or y1 r1 r2 ... rn One method that utilizes this property is the Silver Meal Heuristic. The method requires computing the average cost for an order horizon of j periods for j = 1, 2, 3, etc. and stopping at the first instance when the average cost function increases. The average cost for a production quantity spanning j periods, C(j), is given by: C ( j ) ( K hr2 2hr3 ... ( j 1)hrj ) / j Methods (continued) Another method that is popular in practice is part period balancing. Here one chooses the order horizon to most closely balance the total holding cost with the set-up cost. Finally, a third heuristic is known as the least unit cost heuristic. Here one minimizes the average cost per unit of demand (as opposed to the average cost per period as is done in the Silver Meal heuristic.) The average cost per unit of demand over j periods is given by: C ( j ) ( K hr2 2hr3 ... ( j 1)hrj ) /(r1 r2 ... rj ) Methods (concluded) Experimental evidence seems to favor the Silver Meal Heuristic as the most cost efficient among the four discussed in the text. Optimal lot sizes can be found by using backwards dynamic programming. The (best?) heuristic method for lot sizing subject to capacity constraints is shown next Lets Try Silver-Meal (assumes K is $140; holding/unit/period is $0.10) Over our 9 period time horizon (looking at Seat Ass’bly Demands) R: (120, 0, 0, 120, 0, 150, 120, 0, 0) C(1) = K = 140 C(2) = (K + .1*0)/2 = 70 C(3) = (K + .1*0 + 2*.1*0)/3 = 46.67 C(4) = (K + .1*0 + 2*.1*0 + 3*.1*120)/4 = 44 C(5) = (K + .1*0 + 2*.1*0 + 3*.1*120 + 4*.1*0)/5 = 35.20 C(6) = (K + .1*0 + 2*.1*0 + 3*.1*120 + 4*.1*0 + 5*.1*150) = 41.83 Since C(6) > C(5) Stop. 1st order release is (R1 .. R5) = 240 units but due to lead time we must release it in period -2 (before the current time horizon)!!! Continuing Reset clock to Period 6 as new Start Point: C(1)6 = K = 140 C(2)7 = (K + .1*120)/2 = 76 C(3)8 = (K + .1*120 + 2*.1*0)/3 = 50.67 C(4)9 = (K + .1*120 + 2*.1*0 + 3*.1*0)/4 = 38 Done with plan – so make a lot (in period 4 due to lead time) for arrive in period 6 for 270 units. Notice: each time the cost inverts: we reset the clock and trigger an order release of the amount required by the sum of requirements identified before the cost inverted One Last Topic of Interest Capacity Constraints – Built from a comparison of: R the requirements vector C the Capacity vector Model is feasible only if: (Ci) >= (Ri) Lets examine a simple implication: R: (17, 37, 92, 55, 80): (Ri) = 281 C: (60, 60, 60, 60, 60): (Ci) = 300 This is a feasible plan – BUT – It is obvious that we could be short in period 3 and 5 without some smart planning! Lets Try to Be Smart! (Initial Thought – lets try L4L) 1 2 3 4 5 Gross Req’r 17 37 92 55 80 Planned Rec’pt 17 37 60 55 60 Xess Cap 43 23 -32 5 -20 Fixing the Shortfalls – push back needs and build inventory! Move P3’s shortfall back in time – – 23 to P2 (which fills capacity of P2) 9 additional ones back to P1 Move P5’s shortfall back too – – – 5 to P4 (filling capacity of P4) the other 15 all the way back to P1 After redistribution: P1 Production requirements are 9 + 15 + 17 = 41 Revised ‘Schedule’ 1 2 3 4 5 Gross Req’r 17 37 92 55 80 Planned Rec’pt 41 60 60 60 60 Inventory 24 47 15 20 0 Shortcomings of MRP Uncertainty. MRP ignores demand uncertainty, supply uncertainty, and internal uncertainties that arise in the manufacturing process. Capacity Planning. Basic MRP does not take capacity constraints into account. Rolling Horizons. MRP is treated as a static system with a fixed horizon of n periods. The choice of n is arbitrary and can affect the results. Lead Times Dependent on Lot Sizes. In MRP lead times are assumed fixed, but they clearly depend on the size of the lot required. Shortcomings of MRP, cont. Quality Problems. Defective items can destroy the linking of the levels in an MRP system. Data Integrity. Real MRP systems are big (perhaps more than 20 levels deep) and the integrity of the data can be a serious problem. Order Pegging. A single component may be used in multiple end items, and each lot must then be pegged to the appropriate item.