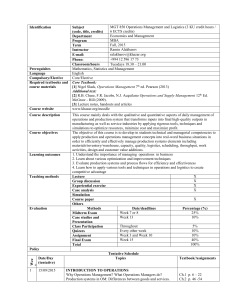

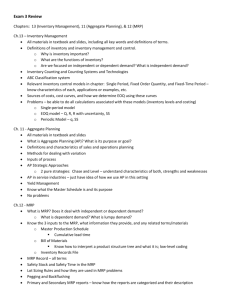

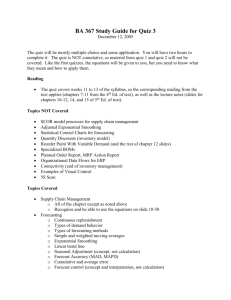

ch14

Material Requirements

Planning (MRP)

Professor Ahmadi

Slide 1

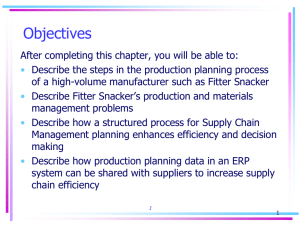

Material Requirements Planning (MRP)

MRP is a dependent demand technique that uses bill-of material, inventory, expected receipts, and a master production schedule to determine material requirement.

Slide 2

Inventory Classifications

Inventory

Process stage

Number

& Value

Raw Material

WIP

Finished Goods

A Items

B Items

C Items

Demand

Type

Other

Independent

Dependent

Maintenance

Operating

Slide 3

MRP and The Production Planning Process

Forecast &

Firm Orders

Aggregate

Production

Planning

Resource

Availability

Material

Requirements

Planning

Master

Production

Scheduling

No , modify CRP, MRP, or MPS

Capacity

Requirements

Planning

Realistic?

Yes

Shop

Floor

Schedules

Slide 4

MRP Benefits

Increased customer satisfaction due to meeting delivery schedules

Faster response to market changes

Improved labor & equipment utilization

Better inventory planning & scheduling

Reduced inventory levels without reduced customer service

Slide 6

Evaluation of MRP

Most beneficial to process-focused systems that have long processing times and complex multistage production steps

Lead times must be reliable

Difficult to implement

Slide 7

MRP and JIT

MRP - a planning and scheduling technique with fixed lead times

JIT - a way to move material expeditiously

Slide 8

MRP in Services

Can be used when demand for service or service items is directly related to or derived from demand for other services

• restaurant - rolls required for each meal

• hospitals - implements for surgery

• etc.

Slide 9

Bill-of-Material

List of components & quantities needed to make product

Provides product structure (tree)

• Parents: Items above given level

• Children: Items below given level

Shows low-level coding

• Lowest level in structure item occurs

• Top level is 0; next level is 1 etc.

Slide 10

Example: Bill-of -Material for a Moped

The following product structure diagram represents the bill of materials for a dualcarburetor Model 442 Moped.

Level 0 MOPED

Level 1

ENGINE

ASSEMBLY

Level 2

MOTOR

GAS

TANK

CARBURETOR

(2)

WHEEL

ASSEMBLY

(2)

HUB

ASSEMBLY

TIRE

FRAME

Slide 11

Requirements for Effective Use of Dependent

Demand Inventory Models

Effective use of dependent demand inventory models requires that the operations manager know the:

• master production schedule

• specifications or bills-of-material

• inventory availability

• purchase orders outstanding

• lead times

Slide 12