0176503617_313728

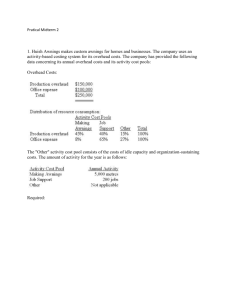

advertisement

Chapter 5 Job Order Costing COPYRIGHT © 2012 Nelson Education Ltd. Learning Objectives 1. Describe the difference between job-order costing and process costing and identify the types of firms that would use each method 2. Compute the predetermined overhead rate and use the rate to assign overhead to units or services produced 3. Identify and set up the source documents used in joborder costing 4. Describe the cost flows associated with job-order costing 5. (Appendix 5A) Prepare the journal entries associated with job-order costing 6. (Appendix 5B) Allocate support department costs to producing departments 5-2 COPYRIGHT © 2012 Nelson Education Ltd. OBJECTIVE 1 Describe the differences between job-order costing and identify the types of firms that would use each method Job-Order Production and Costing Firms operating in job-order industries produce a wide-variety of services or products that are quite distinct from each other Example industries: Printing Construction Furniture making Medical and dental services Automobile repair Beautician services The key feature is that the cost of one job differs from that of another job and must be kept track of separately 5-4 COPYRIGHT © 2012 Nelson Education Ltd. Process Production and Costing Firms in process industries mass-produce large quantities of similar or homogeneous products Example industries: Cement Food Chemicals Petroleum The key feature is that the cost of one unit of a product is identical to the cost of another 5-5 COPYRIGHT © 2012 Nelson Education Ltd. Production Costs in Job-Order Costing Direct labour Direct materials Job #1 Job #2 Job #3 Direct materials and direct labour are fairly easy to trace to individual jobs 5-6 COPYRIGHT © 2012 Nelson Education Ltd. Production Costs in Job-Order Costing Overhead Overhead is not so easy to trace to individual jobs Instead overhead is applied to production 5-7 COPYRIGHT © 2012 Nelson Education Ltd. OBJECTIVE 2 Compute the predetermined overhead rate and use the rate to assign overhead to units or services provided Actual Costing Actual costs of direct materials, direct labour, and overhead are used to determine unit cost Actual overhead can be hard to track Problems with Actual Costing: • Many overhead costs are not incurred uniformly through the year • Uneven production levels – Give rise to fluctuating unit overhead costs 5-9 COPYRIGHT © 2012 Nelson Education Ltd. Normal Costing Determine unit cost by adding actual direct materials, actual direct labour, and estimated overhead Virtually all firms use normal costing 5-10 COPYRIGHT © 2012 Nelson Education Ltd. Importance of Unit Costs to Firms For manufacturing firms, essential for: • valuing inventory • determining income • making important decisions For service firms, used to determine: • profitability • feasibility of introducing new services 5-11 COPYRIGHT © 2012 Nelson Education Ltd. Normal Costing and Estimating Overhead Three step process: 1. Calculate the predetermined overhead rate 2. Apply overhead to production 3. Reconcile applied overhead with actual overhead or allocate applied overhead to WIP and finished goods ending inventories 5-12 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 5-1 How to Calculate the Predetermined Overhead Rate and Apply Overhead to Production Information: At the beginning of the year, Argus Company estimated the following costs: Overhead $360,000 Direct labour cost $720,000 Argus uses normal costing and applies overhead on the basis of direct labour cost. For the month of February, direct labour cost was $56,000 5-13 COPYRIGHT © 2012 Nelson Education Ltd. Example Required: • Calculate the predetermined overhead rate for the year • Calculate the overhead applied to production in February 5-14 COPYRIGHT © 2012 Nelson Education Ltd. Calculate the Predetermined Overhead Rate Formula: Overhead Rate Best estimate of manufacturing-related costs, such as factory-related costs, indirect materials, and indirect labour = Estimated Annual Overhead Estimated Annual Activity Level Both overhead and activity level are estimated because overhead rate must be calculated at beginning of year 5-15 COPYRIGHT © 2012 Nelson Education Ltd. Example Overhead rate Overhead rate Overhead rate = Overhead Direct labour cost = $360,000 $720,000 = 50% of direct labour cost 5-16 COPYRIGHT © 2012 Nelson Education Ltd. Applying Overhead to Production Applied overhead Overhead applied to February production Overhead applied to February production = Predetermined overhead rate × Actual activity level Let’s look at an example = 50% × $56,000 Overhead = Direct labour Cost $28,000 5-17 COPYRIGHT © 2012 Nelson Education Ltd. Reconciling Applied Overhead with Actual Overhead Example: Proto Company had actual overhead of $400,000 for the year but had applied $390,000 to production 5-18 COPYRIGHT © 2012 Nelson Education Ltd. Reconciling Applied Overhead with Actual Overhead Example: Actual Overhead Applied Overhead $400,000 $390,000 Actual ≠ Applied This is called an overhead variance 5-19 COPYRIGHT © 2012 Nelson Education Ltd. Reconciling Applied Overhead with Actual Overhead Actual Overhead Applied Overhead $400,000 $390,000 Underapplied – Overhead of $10,000 Actual Overhead Actual Overhead > Applied Overhead = Underapplied Overhead < Applied Overhead = Overapplied Overhead 5-20 COPYRIGHT © 2012 Nelson Education Ltd. Disposition of Overhead Variance At year end, costs reported on the financial statements must be actual, not estimated, amounts Overhead Variance is assigned to Cost of Goods Sold 5-21 COPYRIGHT © 2012 Nelson Education Ltd. Disposition of Overapplied Overhead Actual Overhead > Applied Overhead = Underapplied Overhead Underapplied overhead would be ADDED to Cost of Goods Sold Actual Overhead < Applied Overhead = Overapplied Overhead Underapplied overhead would be SUBTRACTED from Cost of Goods Sold 5-22 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 5-2 How to Reconcile Actual Overhead with Applied Overhead Information: At the beginning of the year, Argus Company estimated the following: Overhead $360,000 Direct labour Cost $720,000 By the end of the year, actual data are: Overhead Direct labour Cost $375,400 $750,000 5-23 COPYRIGHT © 2012 Nelson Education Ltd. Example Information continued: Argus uses normal costing and applies overhead on the basis of direct labour cost At the end of the year, cost of goods sold (before adjusting for any overhead variance) is $632,000 Required: • Calculate the overhead variance for the year • Dispose of the overhead variance by adjusting cost of goods sold 5-24 COPYRIGHT © 2012 Nelson Education Ltd. Overhead Variance Calculation Actual Overhead Applied Overhead $375,400 $375,000 Overhead Rate × Actual labour Cost 0.50 × $750,000 Overhead Variance – Underapplied = $400 5-25 COPYRIGHT © 2012 Nelson Education Ltd. Disposition of Overhead Variance Unadjusted COGS $632,000 Add: Underapplied variance 400 $632,400 Adjusted COGS Underapplied variances are added since not enough overhead was applied 5-26 COPYRIGHT © 2012 Nelson Education Ltd. Linear Cost and Revenue Functions: Cornerstone 5-3 How To Calculate Predetermined Departmental Overhead Rates and Apply Overhead to Production Single overhead rate calculated using all Plantwide estimated overhead for a factory and Overhead Rate dividing by estimated activity for entire plant Departmental Estimated overhead for a department Overhead Rate divided by estimated activity level for that same department 5-27 COPYRIGHT © 2012 Nelson Education Ltd. Example Information: At the beginning of the year, Sorrel Company estimated: Overhead Direct labour hours Machine hours Machining Dept. $240,000 135,000 200,000 Assembly Dept. $360,000 240,000 --- Total $600,000 375,000 200,000 Sorrel uses departmental overhead rates: • Machining dept: overhead is applied on basis of machine hours • Assembly dept: overhead is applied on basis of direct labour hours 5-28 COPYRIGHT © 2012 Nelson Education Ltd. Example Required: • Calculate the predetermined overhead rates for the machining and assembly departments • Calculate the overhead applied to production in each department for the month of June • By how much has each department’s overhead been overapplied? underapplied? 5-29 COPYRIGHT © 2012 Nelson Education Ltd. Overhead Rates Machining dept. Overhead rates = Estimated overhead Estimated machine hours Machining department’s overhead is applied on the basis of machine hours Machining dept. Overhead rates = Machining dept. Overhead rates = $240,000 200,000 $1.20 per machine hour 5-30 COPYRIGHT © 2012 Nelson Education Ltd. Overhead Rates Assembly dept. overhead rates = Assembly dept. overhead rates = Assembly dept. overhead rates = Estimated overhead Estimated direct labour hours $360,000 240,000 $1.50 per direct labour hour 5-31 COPYRIGHT © 2012 Nelson Education Ltd. Example Information continued: Sorrel Company’s actual data for June: Overhead Direct labour hours Machine hours Machining Dept. Assembly Dept. Total $22,500 $30,750 $53,250 11,000 20,000 31,000 17,000 --- 17,000 5-32 COPYRIGHT © 2012 Nelson Education Ltd. Applying Overhead to Production Machining Department Overhead applied in June Overhead = Rate × Overhead applied in June = $1.20 × Overhead applied in June = Actual Machine Hours 17,000 $20,400 5-33 COPYRIGHT © 2012 Nelson Education Ltd. Applying Overhead to Production Assembly Department Overhead applied in June = Overhead Rate × Actual Direct labour Hours Overhead applied in June = $1.50 × 20,000 Overhead applied in June = $30,000 5-34 COPYRIGHT © 2012 Nelson Education Ltd. Under of Overapplied Overhead? Machining Dept. Assembly Dept. Actual overhead $22,500 $30,750 Applied overhead 20,400 30,000 Underapplied overhead $2,100 $ 750 Actual overhead exceeded applied overhead in both departments 5-35 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 5-4 How to Convert Departmental Data to Plantwide Data to Calculate the Overhead Rate and Apply Overhead to Production Information: At the beginning of the year, Sorrel Company estimated: Machining Dept. Overhead $240,000 Direct labour hours 135,000 Machine hours 200,000 Assembly Dept. Total $360,000 $600,000 240,000 --- 375,000 200,000 Sorrel has decided to use a plant-wide overhead rate based on direct labour hours 5-36 COPYRIGHT © 2012 Nelson Education Ltd. Example Required: • Calculate the predetermined plant-wide overhead rate • Calculate the overhead applied to production for the month of June • Calculate the overhead variance for the month of June 5-37 COPYRIGHT © 2012 Nelson Education Ltd. Plantwide Overhead Rate Plantwide overhead rate Plantwide overhead rate Plantwide overhead rate = Total overhead Direct labour Hours = $600,000 375,000 = $1.60 per direct labour hour Total Estimated Overhead 5-38 COPYRIGHT © 2012 Nelson Education Ltd. Example Information continued: Sorrel Company’s actual data June: Machining Dept. Assembly Dept. Total $22,500 $30,750 $53,250 Direct labour hours 11,000 20,000 31,000 Machine hours 17,000 Overhead --- 17,000 5-39 COPYRIGHT © 2012 Nelson Education Ltd. Applying Overhead to Production Formula: Applied Overhead Plantwide × Actual activity = overhead rate level Actual direct labour hours for June: Machining 11,000 + Assembly 20,000 hours Applied Overhead = Applied Overhead = $1.60 × 31,000 direct labour hours $49,600 5-40 COPYRIGHT © 2012 Nelson Education Ltd. Over or Underapplied Overhead? Actual Overhead - $53,250 - Applied Overhead $49,600 $3,650 Underapplied Not enough overhead was applied to production 5-41 COPYRIGHT © 2012 Nelson Education Ltd. Unit Costs in the Job-Order System Unit cost of a job is the total cost of: • materials used on the job (direct materials) • labour worked on the job (direct labour) • applied overhead 5-42 COPYRIGHT © 2012 Nelson Education Ltd. OBJECTIVE 3 Identify and set up the source documents used in job-order costing Job-Order Cost Sheet • Contains: – Job description – Cost of materials, labour, and overhead • Jobs are named or numbered • Total of all unfinished job-order cost sheets should equal the ending balance of the Work In Process account 5-44 COPYRIGHT © 2012 Nelson Education Ltd. Materials Requisition Form • Provides information for assigning direct materials costs to jobs • Useful for maintaining proper control over a firm’s inventory of direct materials 5-45 COPYRIGHT © 2012 Nelson Education Ltd. Job Time Tickets • Employees fill out a time ticket that identifies: – His or her name – Wage rate – Hours worked on each job • Cost accounting department posts cost of direct labour to individual jobs 5-46 COPYRIGHT © 2012 Nelson Education Ltd. Source Documents as Sources for Account Balances Work in Process Total of all job-order cost sheets for unfinished jobs Finished Goods Total of all job-order cost sheets for finished but unsold jobs Cost of Goods Sold Total of all job-order cost sheets for sold jobs 5-47 COPYRIGHT © 2012 Nelson Education Ltd. OBJECTIVE 4 Describe the cost flows associated with job-order costing Accounting for Materials • Purchases are added to Raw Materials Inventory account • As they are used in production, direct materials are moved from Raw Materials to Work in Process ◦ Raw Materials Purchases Direct Materials used in production Materials used in production are classified by job and recorded in job-order cost sheets 5-49 COPYRIGHT © 2012 Nelson Education Ltd. Accounting for Direct Labour Cost • Time tickets indicate the amount of labour spent on each job • • Labour costs are added to job-order costs sheets Work In Process Direct materials Total of all direct labour from all jobs is recorded as a debit in the Work In Process account Direct labour 5-50 COPYRIGHT © 2012 Nelson Education Ltd. Accounting for Overhead • • • Normal costing is used Actual overhead is not assigned directly to jobs Overhead is applied to each job using a predetermined rate Work In Process Direct Materials Direct labour Applied Overhead 5-51 COPYRIGHT © 2012 Nelson Education Ltd. Accounting for Actual Overhead Costs • Never enters Work in Process account • Costs are recorded as debits in Manufacturing Overhead control account • At end of period, actual overhead is reconciled with applied overhead 5-52 COPYRIGHT © 2012 Nelson Education Ltd. Accounting for Finished Goods Costs of completed jobs are transferred from Work in Process to Finished Goods Work in Process Completed Direct jobs Materials Direct labour Finished Goods Completed jobs Applied Overhead 5-53 COPYRIGHT © 2012 Nelson Education Ltd. Accounting for Actual Overhead Costs Once job is sold, it is added to cost of goods sold which is reported on income statement Finished Goods Completed jobs Sold jobs Cost of Goods Sold Sold jobs 5-54 COPYRIGHT © 2012 Nelson Education Ltd. Cost of Goods Manufactured Statement To ensure the accuracy in computing these costs, a cost of goods manufactured statement is prepared 5-55 COPYRIGHT © 2012 Nelson Education Ltd. Accounting for Cost of Goods Sold • When jobs are sold: – finished goods inventory is decreased – costs of goods sold is increased • The selling price is recognized by: – increasing (crediting) sales revenue – increasing (debiting) accounts receivable (or cash) 5-56 COPYRIGHT © 2012 Nelson Education Ltd. Normal and Adjusted Cost of Goods Sold Normal Cost of Goods Sold Cost of Goods Sold before an adjustment for an overhead variance Adjusted Cost of Goods Sold Cost of Goods Sold after adjusting for an overhead variance 5-57 COPYRIGHT © 2012 Nelson Education Ltd. Example: Cornerstone 5-5 How to Prepare Brief Job-Order Cost Sheets Information: At the beginning of June, Galway Company had two jobs in process: Direct materials Direct labour Applied overhead Balance, June 1 Job 78 Job 79 $1,000 600 750 $2,350 $ 800 1,000 1,250 $3,050 5-58 COPYRIGHT © 2012 Nelson Education Ltd. Example Required: • Calculate the overhead rate based on direct labour cost • Prepare a job-order cost sheet for the four jobs – Show the balance as of June 1 as well as direct materials and direct labour added in June – Apply overhead to the four jobs for the month of June, and show the ending balances • Calculate the ending balances of Work in Process and Finished Goods and of June 30 • Calculate the Cost of Goods Sold for June 5-59 COPYRIGHT © 2012 Nelson Education Ltd. Calculating Overhead Rate We were not given estimated overhead or estimated direct labour cost. So we will have to work backwards to find the rate Applied Overhead Predetermined = overhead rate Actual × activity level We can compute the rate using the information from Job 78 5-60 COPYRIGHT © 2012 Nelson Education Ltd. Calculating Overhead Rate Applied Overhead $750 $750/$600 = Predetermined overhead rate × Actual activity level = Predetermined overhead rate × = Predetermined overhead rate $600 1.25 or 125% of direct labour cost 5-61 COPYRIGHT © 2012 Nelson Education Ltd. Example Information: During June, two more jobs were started The following direct materials and direct labour costs were added to the four jobs during the month of June: Direct materials Direct labour Job 78 Job 79 Job 80 Job 81 $500 $1,110 $900 $100 400 1,400 2,000 320 5-62 COPYRIGHT © 2012 Nelson Education Ltd. Job-Order Cost Sheets Job 78 Job 79 Job 80 Beg. Bal. June 1 $2,350 $3,050 Direct materials 500 1,110 900 100 Direct labour 400 1,400 2,000 320 Applied overhead 500 1,750 2,500 400 Direct labour x Overhead Rate $400 x $1.25 Direct labour x Overhead Rate $1,400 x $1.25 $ 0 Job 81 $ 0 Direct labour x Overhead Rate $2,000 x $1.25 Direct labour x Overhead Rate $320 x $1.25 5-63 COPYRIGHT © 2012 Nelson Education Ltd. Job-Order Cost Sheets Job 78 Job 79 Job 80 Beg. Bal. June 1 $2,350 $3,050 Direct Materials 500 1,110 900 100 Direct labour 400 1,400 2,000 320 Applied Overhead 500 1,750 2,500 400 $3,750 $7,310 $5,400 $820 Total, June 30 $ 0 Job 81 $ 0 5-64 COPYRIGHT © 2012 Nelson Education Ltd. Computing Ending Balances At the end of June, Jobs 78, 79 and 80 were completed Work in Process Only Job 81 was still in process at June 30 Work in Process = $820 5-65 COPYRIGHT © 2012 Nelson Education Ltd. Computing Ending Balances On June 1, the balance in Finished Goods was zero. Three jobs were finished during June (Jobs 78, 79 & 80) Job 79 was sold and transferred out of Finished Goods Finished Goods Finished goods, June 1 $ 0 Job 78 3,750 Job 80 5,400 Finished goods, June 30 $9,150 5-66 COPYRIGHT © 2012 Nelson Education Ltd. Computing Ending Balances One job, Job 79, was sold during June Cost of Goods Sold June 30 Balance = $7,310 5-67 COPYRIGHT © 2012 Nelson Education Ltd. Accounting for Nonmanufacturing Costs • Manufacturing costs are not the only costs incurred by a firm • Selling and general administrative are period costs • Period costs are shown on the Income Statement 5-68 COPYRIGHT © 2012 Nelson Education Ltd.