MECHANICAL PROPERTIES OF MATERIALS

advertisement

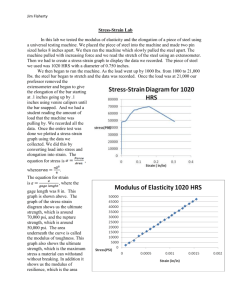

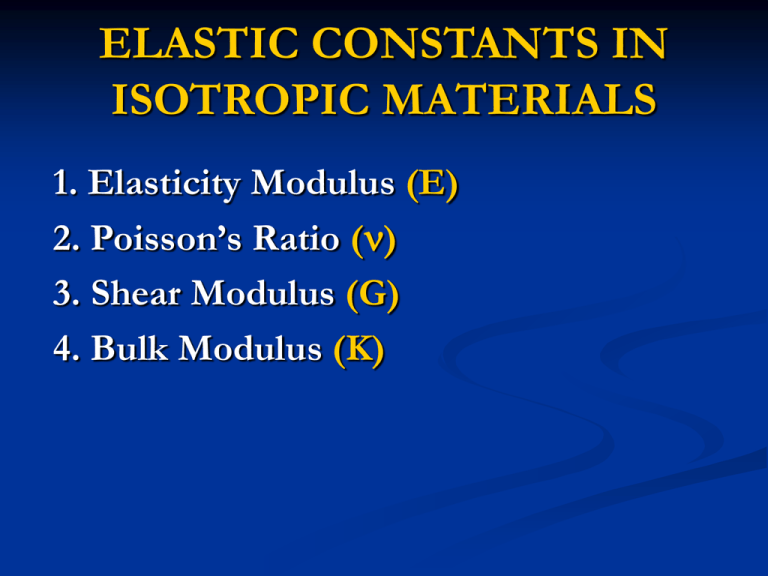

ELASTIC CONSTANTS IN ISOTROPIC MATERIALS 1. Elasticity Modulus (E) 2. Poisson’s Ratio (n) 3. Shear Modulus (G) 4. Bulk Modulus (K) 1. Modulus of Elasticity, E (Young’s Modulus) F F simple tension test s E e s=Ee Linearelastic Units: E: [GPa] Slope of stress strain plot (which is proportional to the elastic modulus) depends on bond strength of metal E= Adapted from Fig. 6.7, Callister 7e. F 2. Poisson's ratio, n eT “n” is the ratio of transverse contraction strain to longitudinal extension strain in the direction of stretching force. Either transverse strain or longitudional strain is negative, ν is positive F simple eL tension test n eT n=eL eT : Transverse Strain eL : Longitudional Strain Units: n: dimensionless Virtually all common materials undergo a transverse contraction when stretched in one direction and a transverse expansion when compressed. In an isotropic material the allowable (theoretical) range of Poisson's ratio is from -1.0 to +0.5, based on the theory of elasticity. metals: n ~ 0.33 ceramics: n ~ 0.25 polymers: n ~ 0.40 3. Shear Modulus, G t M simple torsion test G g t=Gg M Units: G: [GPa] 4. Bulk Modulus, K P Initial Volume = V0 Volume Change = DV savg = K P DV Vo σavg is the average of three stresses applied along three principal directions. P savg DV K Vo Units: K: [GPa] Elastic Constants s= E e t= G g DV savg = K Stresses Vo Strains Normal Shear Volumetric Example: Uniaxial Loading of a Prismatic Specimen P=1000 kgf 9.9 cm 10 cm Determine E and n 10.4 cm 10 cm 10 cm Before 9.9 cm After 1000 = 10kgf/cm2 P=1000kgf → σ= 10*10 P=1000 kgf Δd/2=0.05cm Δl/2=0.2cm σ E= ε 10cm εlong= 10cm 1000 kgf εlat= 10 = 250 kgf/cm2 = 0.04 Δl l0 Δd d0 ν=- = 0.4 10 =0.04 = -0.1 10 = -0.01 -0.01 0.04 = 0.25 For an isotropic material the stress-strain relations are as follows: RELATION B/W K & E Consider a cube with a unit volume σ D 1 C 1 A 1 B σ σ causes an elongation in the direction CD and contraction in the directions AB & BC. The new dimensions of the cube is : • CD direction is 1+ε • BC direction is 1-νε • AB direction is 1-νε V0 = 1 Final volume Vf of the cube is now: (1+ε) (1-νε) (1-νε) = (1+ε) (1-2νε+μ2ε2) = 1 - 2νε + μ2ε2 + ε-2νε2 + μ2ε3 = 1 + ε - 2νε - 2νε2 + μ2ε2 + μ2ε3 ε is small, ε2 & ε3 are smaller and can be neglected. Vf = 1+ ε - 2νε → ΔV = Vf - V0 = ε (1-2ν) If equal tensile stresses are applied to each of the other two pairs of faces of the cube than the total change in volume will be : ΔV = 3ε (1-2ν) σ σ σ σ σ Ξ K= + σ SΔV = 3ε (1-2ν) = K= + savg DV/V0 = ε (1-2ν) (σ+σ+σ)/3 3ε (1-2ν) E 3 (1-2ν) + = ε (1-2ν) σ 3ε (1-2ν) + = ε (1-2ν) E 3 (1-2ν) The relation between K and E is : K= E 3 (1-2ν) Moreover the relation between G and E is : The relation between G, E and K is : G= 1 E E 2 (1+ν) = 1 1 + 9K 3G Therefore, out of the four elastic constants only two of them are independent. For very soft materials such as pastes, gels, putties, K is very large Note that as K → ∞ → ν → 0.5 & E ≈ 3G If K is very large → ΔV/V0 ≈ 0 *No volume change For materials like metals, fibers & certain plastics K must be considered. Modulus of Elasticity : • High in covalent compounds such as diamond • Lower in metallic and ionic crystals • Lowest in molecular amorphous solids such as plastics and rubber. Elastic Constants of Some Materials E(psi)x106 (GPa) G(psi)x106 (GPa) ν (-) Cast Iron 16 110 7.4 50 0.17 Steel 30 205 11.8 80 0.26 Aluminum 10 70 3.6 25 0.33 4-15 0.2 0.7 0.2 ? Concrete 1.5-5.5 Wood Long 1.81 Tang 0.10 10-40 0.62-2.30 12 0.7 0.11 0.03