Full Depth Reclamation – Current Practice Testing Variability

advertisement

Full Depth Reclamation

Current Practice

Testing Variability

Presented To:

Canadian User Group for Asphalt

Sunday, November 15, 2009

Delta Beausejour Hotel

Moncton, New Brunswick

Tom Dziedziejko

AME Materials Engineering

FDR

Rehabilitation Technique that processes the

full depth of asphalt pavement and a

predetermined portion of the underlying base

materials

Uniformly pulverizes and blends to provide an

upgraded and homogeneous material

FDR Equipment

Including some underlying

granular helps cool cutting

tools and enhances

pulverization action

Allows simultaneous injection

of stabilizing agents.

Pulverizing drum rotates in

an up-cut direction or

opposite to the forward

direction of travel.

FDR Equipment

Pug-Mill and

Expansion

Manifold

Screen Deck

Belt Scale

Crusher

Paver Laid FDR

•Recycling Trains

•Pulverize, Wind row, Pick up

Distresses That Can Be Treated

Cracking

Ride Quality

Rutting, Shoving, Wash Boarding

General Deterioration

Bumps, Localized Depressions, Cross fall correction,

Permanent Deformation

Age, Fatigue, edge, slippage, block, longitudinal,

reflection, continuity

Raveling, Potholes, Stripping, Delamination, etc.

Inadequate Structural Capacity

Candidates for FDR

Good Candidate

Good But Approach with

Caution

Potential serious underlying problems

Enhancement likely required

Candidates for FDR

If existing pavement structure is adequate for loads

then simple pulverization and regrading may be all

that is required before applying surface.

Corrective aggregate may be required to ensure adequate

drainage and mechanical properties of the treated material.

If structural enhancement is required then

stabilizing agents can be added

Type of agent used should be selected based on the

properties of the material present.

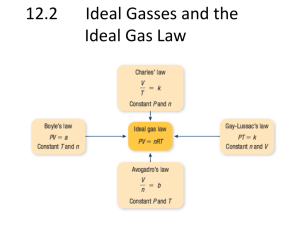

Types of Stabilizing Additives

Bituminous

Chemical

Foamed Asphalt

Asphalt Emulsions

Portland Cement

Lime

Fly Ash Types C and F

Kiln Dust (Lime/LKD or Cement/CKD), Cement, Lime Blends

Combinations of the above

Bituminous additives blended with Chemical additives

Types of Stabilizing Additives

Popularity of Recycling is spawning interest in

new stabilizers and additives

Foam Enhancing additives

Pine Tar Emulsions

Bituminous Additives

Asphalt Emulsions

Coats all aggregates with emulsion

Emulsion breaks leaving particles cemented together with

bitumen

Paving can not proceed until emulsion break is complete

Days? Weeks? Cement sometimes added to accelerate

break of emulsion

Bituminous Additives

Foamed Asphalt

Fast becoming the most popular choice for FDR

Small amount of water added to hot asphalt results in foam

Pulverized material needs fines present up to 20%

Foam mixes with fines present in material to form a mastic binder

Mastic spot welds to larger aggregate in material to form bonds that

hold mix together

Aggregates with PI as high as 15 treated successfully with no

special processes

Typical delay before paving - two days

Additive Selection for FDR

FDR is a Soil Stabilization Technique

When Bituminous Additives are used the process becomes a Hybrid

Asphalt and Soil product

Asphalt products provide a binder system

Produces a flexible material with properties that resist fatigue and

adds flexibility to the processed mat.

Additives used provide some enhancement to asphalt

interaction with soils but also impacts soil properties

similar to soil stabilization techniques.

Chemical Additives

Lime

Most often used where soil has

high PI (>10)

Benefits

Mitigates effect of reactive clays

Reduces PI of soil after application

and reduces swelling potential

Decreases susceptibility to

moisture damage (stripping)

Increases tensile and compressive

strength of mix

Typical addition 1% to 3%

No Lime

2%Hydrated

Lime

Dry Strength

445 kPa

372 kPa

Wet Strength

128 kPa

223 kPa

TSR

29%

60%

Chemical Additives

Portland Cement

Most often used where soil has low

PI (<10)

Primarily adds strength to weak

materials

Benefits

Increases compressive strength of

mix.

Strength increase over time

Impact on moisture susceptibility

variable (stripping)

Typical addition 1% to 2%

Excessive addition results in

potential cracking of the stabilized

soil

No Portland

Cement

With 2%

Portland

Cement

Dry Strength

276 kPa

341 kPa

Wet Strength

163 kPa

216 kPa

TSR

59%

63%

Chemical Additives

Fly ash

Fly ash is a pozzolan

typically requiring presence

of lime or hydrating cement

to gain strength

Some clays can react with

calcium oxide in Type C Fly

ash alone resulting in

strength gain.

Some fly ash has percentage

of lime present that allows

some hydration

Potential to Mitigate effect of

reactive clays - Lime

Slower strength gain than

cement but carries on longer

Excessive addition results in

potential cracking of

stabilized soil

No Fly Ash

With 1%

Fly Ash

Dry Strength

260 kPa

271 kPa

Wet Strength

168 kPa

292 kPa

TSR

65%

108%

Data Source: Job Report Cold Recycling

WR 2500: Foam recycling in Estes

National Park, Colorado /USA

Pre Engineering

Rule of Thumb Engineering is the Most Costly Form of

Design

Proper Engineering Assessment should be carried out to

identify the best choice of additive.

Must consider :

Amount of strength enhancement required.

Type and quality of base materials present

Pavement Structural Design – Traffic?

Drainage Characteristics

Presence of Clays and Silts

Plasticity Index

Pavement Drainage

Ditching

Sub drains

Pre Engineering

Thickness of existing pavement

Optimize percent of pulverized pavement in process depth

+ 60% RAP

Identify excessively thick areas

Over 200mm pavement depth could be a problem to

process due to equipment capacity

Consider Pre-milling Options to reuse excess in other

parts of project. – Shoulder stabilization

Pre Engineering

Proper Mixture Design

Pre tender laboratory design trials to confirm additive

selected will work is advisable.

Mix design before construction is compulsory

Testing Variability

Accurate Test Results Dictate Acceptance

•Stabilized Sample Temperature is Critical

60

Time (Minutes)

Room Temperature

55

Specimen Surface Temperature

Temperature ('C)

45

600

Poly. (Specimen Internal (core)

Temperature)

Poly. (Specimen Surface

Temperature)

40

35

30

500

400

Internal = 34oC

300

Surface = 28oC

Internal = 26oC

100

200

0

40

20

0

50

100

Time (Minutes)

150

200

250

30

25

20

15

Temperature (oC)

Surface = 24oC

25

35

300

Temp = 25 C: Strength = 360

Temp = 26 C: Strength = 340

Tensile Strength (kPa)

Dry Tensile Strength

Specimen Internal (core)

Temperature

Linear (Room Temperature)

50

Test Variability

Strength Change with Varying Conditioning Temperature

Wet Tensile Strength

Dry Tensile Strength

600

Tensile Strength (kPa)

500

400

300

200

100

500

400

300

200

100

0

0

15

20

25

30

35

40

15

20

25

30

Temperature (oC)

Temperature (oC)

Tensile Strength Ratio

Tensile Strenght Ratio (%)

Tensile Strength (kPa)

600

160

140

120

100

80

60

40

20

0

15

20

25

30

Temperature (oC)

35

40

35

40

Testing Variability

Tensile Strength Increase with Time

o

(Cooling Time from 60 C)

Strength Increas e

500

Tensile Strength (kPA)

450

2 Hrs Room Curing

400

350

24 Hrs Room Curing

300

4 Hrs Room Curing

250

2

4

Hours

24

Testing Variability

Optimum Moisture – Field Sample – AC 2.8%

•Strength Varies with moisture content at time of compaction

Dry Tensile Strength

2100

2080

2060

2040

2020

2000

1980

1960

1940

1920

1900

Tensile Strength (kPa)

600.0

500.0

400.0

300.0

200.0

100.0

0.0

0.0

2.0

4.0

6.0

8.0

10.0

0.0

2.0

4.0

Moisture (%)

6.0

Moisture (%)

Wet Tensile Strength

400.0

Tensile Strength (kPa)

Bulk Relative Density

Dry Bulk Relative Denstiy

350.0

300.0

250.0

200.0

150.0

100.0

50.0

0.0

0.0

2.0

4.0

6.0

Moisture (%)

8.0

10.0

8.0

10.0

Conclusions

Select FDR based on engineering design

Selected process and enhancement should be based

on existing conditions.

Chemical treatments should be established using

Material requirements

Ensure Quality Verification Testing is

completed accurately

Sample Temperature significantly influences

results

Thank You

Questions ?