Geotechnical Engineering

advertisement

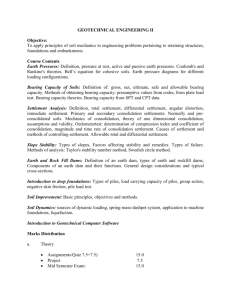

Infrastructure Civil Works Projects for Lawyers American Bar Association Forum on the Construction Industry Geotechnical Engineering Presented By: John Doe Your Engineering Group, Inc, Prepared By: Vincent Martinez VITAL Consulting Group Soil Investigation Suitability for Construction Rock Mineral based large particles strongly bonded Soil Mineral based particles strongly bonded Determine Soil Classification ▪ Sieve Analysis – Testing Course Grain soil – Sediment Analysis – Particle size distribution small grain soil ▪ Reaction to Water – Plasticity • Plastic Index – Liquid Limit • Atterberg Limit testing Soil Classification ▪ All Soils classify one of four ways 1) Clay 2) Silt 3) Sand 4) Gravel Soil Stress Compressibility Strength Function of the water in soil or capillary action of the water and the type of soil and size of soil grains Subsurface Exploration and Testing Geotechnical Engineer dictates the exploration plan based on the anticipated soil conditions and the proposed construction Sampling Split-spoon sampling Blow count in-situ relative density Shelby Tube Minimal disruption of sample Boring Advancement Solid Stem Hollow Stem Rotary Drilling Core Penetrometer Testing Ground Improvement Using Ground Improvement Techniques to build directly on improved grounds as opposed to deep foundations and or removal and replacement techniques Dynamic Compaction Lime Stabilization …Dynamic Compaction Weights from 6 to 30 tons dropped in free fall from heights from 30 to 75 feet Conventional compaction from bottom up in lifts 12 inches or less Dynamic compaction from the top down Conventional Compaction density material from 2 to 4 feet Dynamic compaction density material from 15 to 30 feet …Dynamic Compaction Soil Type Use • Highly permeable with improved drainage optimal soil. • Low permeability soil not optimal for standard compaction. • Intermediate soils (Silt, Clayey Silt, Sandy Silt) not as receptive to Dynamic Compaction, several passes required. …Dynamic Compaction Design for soil type and ultimate use Depth and degree of improvement Type of structure to be placed on the soil Design requirements Weight Area Energy to be applied Grid Passes Site constraints Vibration Lateral ground displacement Airborne particles Lime Stabilization Improving unsuitable ground using soil stabilization techniques …Lime Stabilization Various engineering properties of modified soil Plastic Index Reduction of Liquid Limit Swelling Reduce swelling potential Decreased affinity for water California Bearing Ratio Usual five fold increase in value Stability Increased modulus and shear strength Moisture Resistance Reduction in permeability of soil Foundations Spread out and transmit the structural loads into the ground at an intensity the ground can withstand without causing differential settlement Foundations Spreading out the concentrated load over a large area or extending the foundation deep into the ground until it reaches a capable soil or rock layer Foundations The Geotechnical Engineer is to determine the depth to a suitable bearing layer for a structure’s foundation, estimating bearing capacity and the likely total differential settlement on the foundation. Bearing Capacity The bearing capacity of the soil or rock is the ultimate pressure that the material can support. Estimate the likely soil bearing pressure and then apply a safety factor of 3.0 to the value to arrive at a allowable bearing pressure. Design the size or type of foundation to maintain an allowable bearing pressure. Some Footings Shallow Spread Footings Driven or Auger Cast Pile Determination of Soil Bearing Capacity ▪ Sand – allowable settlement criterion controls the allowable bearing pressure ▪ Clay – related to the unconfined strength of the clay Settlement… …not that kind The Engineer must select allowable bearing pressures that allow total and differential settlement across the structure without resulting in detrimental structural damage. Different structures for different purposes allow for different rates of settlement. Most structures are limited to at most two inches. Differential settlement within a structure is more critical than total settlement. More on Settlement ▪ Settlement on Sand – Short term often described as compression or elastic. ▪ Settlement on Clay – Usually termed consolidated, and is time dependant. Choice of Foundation The foundation type selected for a project should be the most economical available to support project loads while meeting the settlement requirements for the structure. Foundation types are either shallow or deep Shallow Foundations ▪ Isolated Column Footings ▪ Strip Footings Under Walls ▪ Combined Footings Under Multiple Columns ▪ Mat or Raft Footings Deep Foundations Heavy building loads or poor soils at normal excavation levels. Pile Foundations Driven Piles Cast in Place Piles Special Piles Driven Piles ▪ Timber – Solid wood, driven into adequate soil bearing depth. ▪ Steel – Either H Beam, considered no-displacement or Closed End Pipe, considered displacement piles, compress and densifying the soil. ▪ Concrete – Pre-stressed/Pre-cast, either square, circular or octagonal, considered displacement piles. Cast In Place Piles Placed by drilling a hole in the ground, inserting a steel casing or cage and then filling with concrete. Advantage in low noise or vibration, but can cause subsidence Auger Cast is by drilling but concrete is installed as the auger is withdrawn. Typically used in sandy soils. Excavation Support Deep excavations are used to construct underground portions of structures, often times sloped sides are utilized. If poor soil conditions are present or confined space is prohibitive steep slopes must be supported. Site Investigation A. Subsurface Exploration and Testing a. Borings at reasonable Spacing b. Borings at deepest proposed structure c. Borings at key alignments B. Investigation and Conditions Survey of Existing Site a. Location b. Existing Structures c. Existing Utilities Excavation Support Systems A. Wall Types a. b. c. d. Soldier Pile & Lagging Sheet Piling CIP Diaphragm & SPTC CIP Secant & Tangent Pile B. Soil & Groundwater Conditions a. Cohesion-less Soils b. Cohesive Soils C. Ground Movement & Adjacent Structures D. Other Considerations Design Engineering A. Earth & Water Pressures a. Water Pressure b. Earth Pressure B. General Wall & Bracing Design C. Designing to Minimize Ground Movement a. b. c. d. e. f. g. External Groundwater lowering Open Excavation for Support Wall Installation Vibration During Support Wall Installation Removal of Underground Elements Excessive Over-Excavation below Bracing Levels Poor Lagging Installation Practices Bracing Design & Installation Construction ▪ General Construction Monitoring ▪ Pre- and Post- Construction Surveys ▪ Instrumentation Roadways/Pavements ▪ Subgrade Preparation Roadways/Pavements ▪ Determination of Suitable Subgrade Analysis of Native Soils Removal of; Organic frost susceptible Soils Expansive clumps of uncontrolled fill soils Proof-Roll Determine rutting or pumping Accept or Reject Subgrade Roadways/Pavements ▪ Subgrade use of Geotextiles Roadways/Pavements ▪ Base Course Roadways/Pavements ▪ Design Criteria for Pavement Surfaces – Traffic • • • • • Type Load Frequency Distribution Speed – Facility Type to be Serviced – Economics (life cycle cost) Roadways/Pavements ▪ Asphalt Surface Course Roadways/Pavements ▪ Concrete Surfacing Questions? Thank You