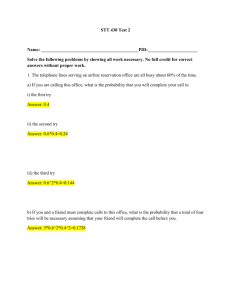

Ch_6_s01_605

advertisement

Steps in Using the X and R Chart 1. Decisions preparatory to the control charts – Objective: • Is specification met? • Does the process need any change? • Does the process need any corrective action? • Set the standard for acceptance/rejection of manufactured or purchased product 1 Steps in Using the X and R Chart – Variable • Choose the right variable – Cause and effect diagram (Figure 9.8) • measurable? • economic? – Homogeneous? – Size (minimize variation within group) – Frequency (hourly? daily?) – Forms and methods (Figures 2.7 and 2.8) 2 Steps in Using the X and R Chart 2. Starting the control chart – Recording, finding average and range, plotting – For sample size n and number of samples k n Xi j 1 X ij k Xi ,X n i 1 k Ri X i,max k Ri X i,min , R i 1 k 3 Steps in Using the X and R Chart 3. Determining trial limits – Determine a minimum number of samples UCLR D4 R,LCLR D3 R UCL X X A2 R,LCLX X A2 R 4. Preliminary conclusions – Has the mean shifted? – Is the process producing too many defective items? 5. Revision and use of the control 4 Control Chart for Attributes Topic • Control charts for attributes • The p and np charts • Variable sample size • Sensitivity of the p chart 5 Control Chart for Attributes • In a control chart for variables, quality characteristic is expressed in numbers. Many quality characteristics (e.g., clarity of glass) can be observed only as attributes, i.e., by classifying into defectives and nondefectives. • If many quality characteristics are measured, a separate control chart for variable will be needed for each quality characteristic. However, the use of one control chart for all the characteristics may be cheaper. 6 Control Chart for Attributes • The cost of collecting data for attributes is less that for the variables • There are various types of control charts for attributes: – The p chart for the fraction rejected – The np chart for the total number rejected – The c chart for the number of defectives – The u chart for the number of defectives per unit 7 Control Chart for Attributes • Poisson Approximation: – Occurrence of defectives may be approximated by Poisson distribution – Given np , the expected number of defectives in sample, Probability of c or fewer defectives is given in Table G 8 The p and np Charts • The 3-sigma limits for the p chart, for sample I p(1 p ) p(1 p ) UCLp p 3 , LCLp p 3 ni ni UCLnp n p 3 n p(1 p ), LCLnp n p 3 n p(1 p ) • Note: p is the observed mean, p is the expected mean and p0 is the target mean. 9 Variable Sample Size Problems and Solution Approaches • • • • Control limits change with the sample size. If sample size decreases, the control limits get wider. If the sample size increases, the control limits get tighter. Three solutions: – Compute new control limits for every sample – Estimate the average sample size for the immediate future. Compute control limits and use it unless the sample size is substantially different. – Draw several sets of control limits. A plan is to use 3 sets of limits - one for expected sample size, one for minimum and one for maximum. 10 Variable Sample Size Choice Between the p and np Charts • If the sample size varies, p chart, is more appropriate • If the sample size is constant, np chart, may be used 11 Sensitivity of the p Chart • Smaller samples are less sensitive • Smaller samples may not be useful at all e.g., if only 0.1% of the product is rejected • If a control chart is required for a single measurable characteristic, X chart will give useful results with a much smaller sample. 12 Problem 6.4: A manufacturer purchases small bolts in cartons that usually contain several thousand bolts. Each shipment consists of a number of cartons. As part of the acceptance procedure for these bolts, 400 bolts are selected at random from each carton and are subjected to visual inspection for certain nonconformities. In a shipment of 10 cartons, the respective percentages of rejected bolts in the samples from each carton are 0, 0, 0.5, 0.75, 0,2.0, 0.25, 0, 0.25, and 1.25. Does this shipment of bolts appear to exhibit statistical control with respect to the quality characteristics examined in this inspection? 13 Problem 6.5: An item is made in lots of 200 each. The lots are given 100% inspection. The record sheet for the first 25 lots inspected showed that a total of 75 items did not conform to specifications. a. Determine the trial limits for an np chart. b. Assume that all points fall within the control limits. What is your estimate of the process average fraction nonconforming p ? c. If this p remains unchanged, what is the probability that the 26th lot will contain exactly 7 nonconforming units? That it will contain 7 or more nonconforming units? (Hint: use Poisson approximation and Table G) 14